Professional Documents

Culture Documents

Bonds Law Application

Bonds Law Application

Uploaded by

Danny joaquinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bonds Law Application

Bonds Law Application

Uploaded by

Danny joaquinCopyright:

Available Formats

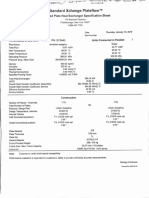

Moly-Cop Tools TM (Version 2.

0)

BOND'S LAW APPLICATION

Conventional Ball Mill Sizing

Remarks Base Case Example

GRINDING TASK :

Ore Work Index, kWh(net) /metric ton 13.00 Specific Energy, kWh/ton 9.30

Feed Size, F80, microns 9795 Net Power Requirement, kW 7441

Product Size, P80, microns 150.0 Number of Mills for the Task 2

Design Throughput, ton/hr 800.00 Net kW / Mill 3720

MILL DESIGN PARAMETERS AND OPERATING CONDITIONS : Power, kW

3348 Balls

Eff. Diameter Eff. Length Mill Speed Charge Balls Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% Slurry Filling,% Angle, (°) 536 Slurry

18.50 22.00 72.00 38.00 38.00 100.00 35.00 3885 Net Total

L/D rpm 10.0 % Losses

1.189 12.82 4316 Gross Total

% Solids in the Mill 72.00 Charge Mill Charge Weight, tons Apparent

Ore Density, ton/m3 2.80 Volume, Ball Slurry Density

Slurry Density, ton/m3 1.86 m3 Charge Interstitial above Balls ton/m3

Balls Density, ton/m3 7.75 63.76 296.48 47.48 0.00 5.395

Power Oversize, % 4.4

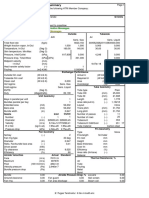

HYDROCYCLONES CLUSTER : (Preliminary Sizing)

# Cyclones Cyclone Feed Circulating ton/hr m3/hr Pressure

per Mill Diameter, in % Solids Load, % per Cyclone per Cyclone Loss, psi

6 26.00 62.00 350.0 300.0 291.0 8.10

ARBITER'S FLOW NUMBER:

Mill Feed (incl. Recycle) Flow

ton/hr m3/hr Number

Direct Circuit: 1800.0 966.9 1.97

Reverse Circuit: 1400.0 752.0 1.54

You might also like

- Multistage Flowsheets SampleDocument1 pageMultistage Flowsheets SampleDanny joaquinNo ratings yet

- Bond Mill ThroughputDocument5 pagesBond Mill ThroughputAnonymous TsKN7XZBNo ratings yet

- Bond Mill Throughput10X10Document5 pagesBond Mill Throughput10X10Flia Diaz Zuniga100% (1)

- Bond - Op. Work Index (HGE SRL)Document3 pagesBond - Op. Work Index (HGE SRL)Pedro RodriguezNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Media Charge - Wear - Ball MillsDocument4 pagesMedia Charge - Wear - Ball MillsPedro RodriguezNo ratings yet

- GR/KWH, KG/HR or Tons/Month.: ScopeDocument5 pagesGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementNo ratings yet

- Especialización en Molienda de Minerales: Por: Moly-Cop Adesur S.ADocument100 pagesEspecialización en Molienda de Minerales: Por: Moly-Cop Adesur S.AHector Bolaños100% (1)

- Mediacharge OptimalballsizeDocument4 pagesMediacharge OptimalballsizeHoàng HùngNo ratings yet

- Media Charge - Optimal Ball SizeDocument6 pagesMedia Charge - Optimal Ball SizeMetalurgia ProcesosNo ratings yet

- Media Charge - Wear - Non-LinearDocument85 pagesMedia Charge - Wear - Non-LinearPedro Rodriguez100% (1)

- Heat Balance Line 2 - Birla White CementDocument16 pagesHeat Balance Line 2 - Birla White Cementanurag soniNo ratings yet

- Scope:: About The Mill Power - SAG Mills Spreadsheet ..Document4 pagesScope:: About The Mill Power - SAG Mills Spreadsheet ..percyNo ratings yet

- Heat Balance Line 1 - Birla White CementDocument18 pagesHeat Balance Line 1 - Birla White Cementanurag soniNo ratings yet

- Mill Power Ball MillsDocument5 pagesMill Power Ball MillsCarlos de la TorreNo ratings yet

- 12 (B 100) Metre KonveyörDocument30 pages12 (B 100) Metre KonveyörHasan arif KısaalioğluNo ratings yet

- Raw Mill - Birla White CementDocument9 pagesRaw Mill - Birla White Cementanurag soniNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- F:/anni/contoh Htri/latihan 1.htriDocument1 pageF:/anni/contoh Htri/latihan 1.htriAnni RahmatNo ratings yet

- 10 - Simple Mud Engineerv1.22Document22 pages10 - Simple Mud Engineerv1.22Abdul Hameed OmarNo ratings yet

- Series B3: 3M175 Roots Meter: Units Imperial Units MetricDocument2 pagesSeries B3: 3M175 Roots Meter: Units Imperial Units Metricmiki_tazNo ratings yet

- Surface Area of GMDocument6 pagesSurface Area of GMAnoop TiwariNo ratings yet

- SMS#1 SMS#2: PERFROMANCE DATA (Refractory & Operation)Document14 pagesSMS#1 SMS#2: PERFROMANCE DATA (Refractory & Operation)Binod Kumar PadhiNo ratings yet

- UntitledDocument235 pagesUntitledUsman HayderNo ratings yet

- Demister CalcDocument3 pagesDemister Calcahmad santosoNo ratings yet

- WORKSHOP 9 - SAG SABC Circuit Model Fit: FlowsheetDocument4 pagesWORKSHOP 9 - SAG SABC Circuit Model Fit: FlowsheetFer MabNo ratings yet

- Mill Power - Rod MillsDocument4 pagesMill Power - Rod MillsFredy PeñaNo ratings yet

- Roghur - VT 5 StagesDocument7 pagesRoghur - VT 5 StagesRoberto Cabrera MillerNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- Presentasi Coal MILL Pulverizer Modeling AwalDocument26 pagesPresentasi Coal MILL Pulverizer Modeling Awalbhisma aktaNo ratings yet

- Mill Power - Ball MillsDocument6 pagesMill Power - Ball MillsPedro RodriguezNo ratings yet

- Tugas Take Home UTSDocument18 pagesTugas Take Home UTSdodikNo ratings yet

- Heat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriDocument1 pageHeat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriEduardoNo ratings yet

- Belt Den Design Calculations NeWDocument42 pagesBelt Den Design Calculations NeWIbz AjagbeNo ratings yet

- 2.2 Métodos Alternativos de ConminuciónDocument16 pages2.2 Métodos Alternativos de ConminuciónFranco Alexander SuniNo ratings yet

- Simulation Flow Sheet Model-1Document4 pagesSimulation Flow Sheet Model-1Sheraz AliNo ratings yet

- HE Rating Data Sheet v6Document1 pageHE Rating Data Sheet v6dhaNo ratings yet

- SDM Cyclone SizingDocument17 pagesSDM Cyclone Sizingsadegh firouzshahiNo ratings yet

- PDS Ga-401Document1 pagePDS Ga-401wahyuNo ratings yet

- Inter Cambiado RDocument2 pagesInter Cambiado RmilenarixNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Chamber Mill Volume Loads and Power Drawn Calculation Existing Chamber Configuration Modify Mill ConfigurationDocument4 pagesChamber Mill Volume Loads and Power Drawn Calculation Existing Chamber Configuration Modify Mill ConfigurationDilnesa EjiguNo ratings yet

- Steam Liquid Ex With Steam Flow of 0.224 KgpersecDocument5 pagesSteam Liquid Ex With Steam Flow of 0.224 Kgpersecchemical509No ratings yet

- ERSELDocument105 pagesERSELMed MohamedNo ratings yet

- Clariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MDocument6 pagesClariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MAnonymous EKxXjqyVHNo ratings yet

- Design (Metric) 5 (1) .37Document7 pagesDesign (Metric) 5 (1) .37Huy NguyenmbvNo ratings yet

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingsnamprogNo ratings yet

- PT Synergy Engineering: WarningsDocument1 pagePT Synergy Engineering: Warningsokky wddNo ratings yet

- System Information Idler Set DataDocument98 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Ricis 2Document1 pageRicis 2Hariyono Rudi NovantoNo ratings yet

- Media Charge - Dynamics - SAG MillsDocument31 pagesMedia Charge - Dynamics - SAG Millsedwin javier valdivia guillenNo ratings yet

- Media Charge Wear Rod MillsDocument3 pagesMedia Charge Wear Rod MillspolsiemprealdoNo ratings yet

- RodParam OpenDocument39 pagesRodParam OpenJunior Romero ChavezNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidinfonetsmgNo ratings yet

- Heat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriDocument1 pageHeat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriEslam ShiblNo ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- Ficha Tecnica G40Document2 pagesFicha Tecnica G40JoseLuisAramayoNo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- Intersection 2 2019 AM Stage 2Document4 pagesIntersection 2 2019 AM Stage 2Krzysztof SarnaNo ratings yet

- SAG Mill Flowsheet SampleDocument1 pageSAG Mill Flowsheet SampleDanny joaquinNo ratings yet

- Ball Mills Flowsheet SampleDocument1 pageBall Mills Flowsheet SampleDanny joaquinNo ratings yet

- 0 - Symbols and UnitsDocument12 pages0 - Symbols and UnitsDanny joaquinNo ratings yet

- Optimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFDocument19 pagesOptimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFEnrique Javier González HenríquezNo ratings yet

- Types & Prices of Marble Flooring in Pakistan Zameen Blog 5Document1 pageTypes & Prices of Marble Flooring in Pakistan Zameen Blog 5M Wasim IshaqNo ratings yet

- PAG11.3 Determining Strength of Bfield 1Document4 pagesPAG11.3 Determining Strength of Bfield 1rithun.ashmiyaNo ratings yet

- Math10 Q1 Mod2-3 Week3Document54 pagesMath10 Q1 Mod2-3 Week3Grace Joy CansecoNo ratings yet

- LLC Water Contentas For MGS Ver7Document2 pagesLLC Water Contentas For MGS Ver7saiful islam100% (1)

- Articulo GeofisicaDocument12 pagesArticulo GeofisicaAndrés Felipe CastroNo ratings yet

- Free Space Management System in Operating SystemDocument8 pagesFree Space Management System in Operating SystemShreyashNo ratings yet

- Whitepaper: Trade Race ManagerDocument36 pagesWhitepaper: Trade Race ManagerGaëtan DEGUIGNENo ratings yet

- ADS1115 ComparatorDifferentialDocument5 pagesADS1115 ComparatorDifferentialLeandro De VegaNo ratings yet

- Guidlines - ProductionDocument6 pagesGuidlines - ProductionRizwanAliNo ratings yet

- BCF Type Local WF 400 (Full Weld)Document4 pagesBCF Type Local WF 400 (Full Weld)Puji KurniawanNo ratings yet

- Zero Base BudgetingDocument13 pagesZero Base BudgetingRey Bahillo RojoNo ratings yet

- Honeywell 4100sm Installion ManualDocument4 pagesHoneywell 4100sm Installion ManualVictor AamNo ratings yet

- ByronKatie Judge Your Neighbor WorksheetDocument1 pageByronKatie Judge Your Neighbor Worksheetgetsmartpaul625No ratings yet

- 41 2os02Document12 pages41 2os02Miguel Angel RodriguezNo ratings yet

- Spesifikasi HINO 130 HDL Cargo NewDocument6 pagesSpesifikasi HINO 130 HDL Cargo NewsetianusNo ratings yet

- Functions of The Parts of The MicroscopeDocument2 pagesFunctions of The Parts of The MicroscopeNdawula IsaacNo ratings yet

- How To Avoid Hand Bounce at The Top of Your Back SwingDocument3 pagesHow To Avoid Hand Bounce at The Top of Your Back SwingLes RossNo ratings yet

- Lesson 10 Graphic OrganizersDocument22 pagesLesson 10 Graphic Organizersisabelcadagtan10No ratings yet

- 2.3.02 AOAC of Fi Cial Method 958.01 Phos Pho Rus (To Tal) in Fer Til IzersDocument1 page2.3.02 AOAC of Fi Cial Method 958.01 Phos Pho Rus (To Tal) in Fer Til Izersestefania100% (1)

- Start - Smart - 1 (Teacher's Guide)Document44 pagesStart - Smart - 1 (Teacher's Guide)kame_rainNo ratings yet

- Short Term Plan Template LitDocument2 pagesShort Term Plan Template Litapi-3829502No ratings yet

- Dokumen - Tips Net Zero Energy Buildings 56871a1fa910aDocument33 pagesDokumen - Tips Net Zero Energy Buildings 56871a1fa910aHussain J. AlSadahNo ratings yet

- Hydroline Breather FSB TB 130417Document3 pagesHydroline Breather FSB TB 130417Arun GeorgeNo ratings yet

- The Engineering Handbook: ManufacturingDocument7 pagesThe Engineering Handbook: ManufacturingChertong WangNo ratings yet

- Comparative Efficacy and Safety of New Surgical Treatments For Benign Prostatic Hyperplasia Systematic Review and NetwoDocument11 pagesComparative Efficacy and Safety of New Surgical Treatments For Benign Prostatic Hyperplasia Systematic Review and NetwoMahesa Kurnianti PutriNo ratings yet

- Brosnan y Sun PDFDocument14 pagesBrosnan y Sun PDFSandra KristellNo ratings yet

- When We Communicate With OthersDocument4 pagesWhen We Communicate With OthersSmaranda BerenghiaNo ratings yet

- Consolidated Quotes - Ian Gardner 2016 + TOCDocument228 pagesConsolidated Quotes - Ian Gardner 2016 + TOCIan GardnerNo ratings yet

- Costbenefit Analysis 2015Document459 pagesCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHNo ratings yet