Professional Documents

Culture Documents

Fundamentals of Area Classification 1

Fundamentals of Area Classification 1

Uploaded by

Huan Trinh VanCopyright:

Available Formats

You might also like

- FSCR-FSCCR-FSMR Report - UAP Seminar - 02082020 PDFDocument126 pagesFSCR-FSCCR-FSMR Report - UAP Seminar - 02082020 PDFJoy Cruz88% (8)

- Air SeparationDocument53 pagesAir SeparationFran Jimenez100% (2)

- Grease Filter Equipped Kitchen Exhaust System Calculation SheetDocument2 pagesGrease Filter Equipped Kitchen Exhaust System Calculation SheetMahmoud Anwer100% (1)

- Air Seperation Technologies Used in Cement IndustryDocument53 pagesAir Seperation Technologies Used in Cement IndustryTin Nguyen100% (3)

- Anodamine HPFGDocument69 pagesAnodamine HPFGmasgrahaNo ratings yet

- Analysis and Application of Semiconductors in Air BatteriesDocument23 pagesAnalysis and Application of Semiconductors in Air Batteriessree haritha p0% (1)

- Fundamentals of Area ClassificationDocument10 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument8 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Area ClassificationDocument28 pagesArea ClassificationborrowmanaNo ratings yet

- COM ATEX Poster EN PDFDocument1 pageCOM ATEX Poster EN PDFWerner SchulzNo ratings yet

- Comliance MultistressDocument22 pagesComliance MultistressStandards IndiaNo ratings yet

- Fire ZoneDocument12 pagesFire ZoneMehman NasibovNo ratings yet

- Free Open Area Is It Relevant To Louvre PerformanceDocument5 pagesFree Open Area Is It Relevant To Louvre PerformanceZulfadzli RidzuanNo ratings yet

- Dsen 60079-10-1 & Uk PDFDocument29 pagesDsen 60079-10-1 & Uk PDFNISO9001No ratings yet

- Interpretation of IP15 in Process Plant Design: A Commonsense ApproachDocument8 pagesInterpretation of IP15 in Process Plant Design: A Commonsense ApproachAl Faruq ShinagaNo ratings yet

- RainNoiseGuidance PDFDocument7 pagesRainNoiseGuidance PDFehizojayNo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument9 pagesHazardous Area Classification and Control of Ignition SourcesKHALID HUBBAHNo ratings yet

- WEG Explosive Atmospheres 50056895 Brochure EnglishDocument20 pagesWEG Explosive Atmospheres 50056895 Brochure EnglishVaibhav PatilNo ratings yet

- b2b6606d 5af3 48d6 90e6 9116cac65645.ClassPresentationBLD122076EngineeredApproachtoLifeSafetyinaShoppingMallUsingAutodeskCFDDr - Munirajulum3Document61 pagesb2b6606d 5af3 48d6 90e6 9116cac65645.ClassPresentationBLD122076EngineeredApproachtoLifeSafetyinaShoppingMallUsingAutodeskCFDDr - Munirajulum3Arun CherianNo ratings yet

- Zone Classification: Doc. No. 50068905 Ver.1.0Document23 pagesZone Classification: Doc. No. 50068905 Ver.1.0mkpasha55mp100% (1)

- E779-10 Standard Test Method For Determining Air Leakage Rate by Fan PressurizationDocument11 pagesE779-10 Standard Test Method For Determining Air Leakage Rate by Fan PressurizationMuhammad SalmanNo ratings yet

- Heskestad 1986Document7 pagesHeskestad 1986Deives De PaulaNo ratings yet

- P.R.H.Shields: Keywords Hazard, Area, Onolysis, Zone, ClassificationDocument13 pagesP.R.H.Shields: Keywords Hazard, Area, Onolysis, Zone, ClassificationSHAILENDRANo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument10 pagesHazardous Area Classification and Control of Ignition SourcesS.KalatheeswaranNo ratings yet

- Lokesh PaperDocument6 pagesLokesh PaperdewasstudentNo ratings yet

- Jis A 1202Document11 pagesJis A 1202mahtrian nopeNo ratings yet

- Safety Science: Riccardo TommasiniDocument6 pagesSafety Science: Riccardo TommasiniSanaNo ratings yet

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- FirePro Leakage Compensation GuidelinesDocument11 pagesFirePro Leakage Compensation Guidelinesmohamed.rescoNo ratings yet

- Practical Diffuser Selection and Layout ProcedureDocument8 pagesPractical Diffuser Selection and Layout ProcedureHVACDESIGNNo ratings yet

- Guidance Document On BS EN 13565-2 Foam System StandardDocument8 pagesGuidance Document On BS EN 13565-2 Foam System StandardFernando KatayamaNo ratings yet

- Interpretation of IP15Document8 pagesInterpretation of IP15U Tint LwinNo ratings yet

- Hazardous Areas: Gases and VapoursDocument10 pagesHazardous Areas: Gases and VapoursShah JayNo ratings yet

- Is 4894 Standard PDFDocument21 pagesIs 4894 Standard PDFDharmendra PanchalNo ratings yet

- SPD0036ERN - 4 - Hazardous Area ClassificationDocument6 pagesSPD0036ERN - 4 - Hazardous Area ClassificationHamidNo ratings yet

- Handouts - Engineering Procedures in Hazardous Atmospheres in Power PlantsDocument15 pagesHandouts - Engineering Procedures in Hazardous Atmospheres in Power PlantsDavid Luna MolinaNo ratings yet

- HFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ADocument19 pagesHFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ATahir FadhilNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Sources and Grades of ReleaseDocument10 pagesSources and Grades of Releasebaaziz2015No ratings yet

- GGG-CAL-HAC-0007 - FMS 7 Barg FULL (28-10-2014)Document14 pagesGGG-CAL-HAC-0007 - FMS 7 Barg FULL (28-10-2014)oleg safaniukNo ratings yet

- TN 65229 05-15-12 Infiltration Modeling Guidelines For Commercial Building Energy AnalysisDocument24 pagesTN 65229 05-15-12 Infiltration Modeling Guidelines For Commercial Building Energy Analysis7.Vương Đình CủaNo ratings yet

- Air Content of Cement JIS A1128-2019Document1 pageAir Content of Cement JIS A1128-2019Rahul ReddyNo ratings yet

- 1391 2 2018 AMD4 Reff2022Document82 pages1391 2 2018 AMD4 Reff2022Abhishek SrivastvaNo ratings yet

- 0189PF N DG DG03 SR SCH 1001 B02Document4 pages0189PF N DG DG03 SR SCH 1001 B02Jalal AlbadriNo ratings yet

- Manufacturer and DesignationDocument3 pagesManufacturer and DesignationEmma DNo ratings yet

- Guidelines On Hazardous Area ClassificationDocument8 pagesGuidelines On Hazardous Area ClassificationKalam Nagappan100% (1)

- HAC An Ignition Source ControlDocument48 pagesHAC An Ignition Source ControlMoh Fahmi NajahiNo ratings yet

- Selection of Explosion Protected Equipment For Hazardous LoctionsDocument32 pagesSelection of Explosion Protected Equipment For Hazardous Loctionsasex4uNo ratings yet

- Fire ZoneDocument8 pagesFire ZoneKannan NNo ratings yet

- ASTM Pump Test MethodDocument3 pagesASTM Pump Test MethodAlberto GranadosNo ratings yet

- Guidelines On Hazardous Area Classification 1Document8 pagesGuidelines On Hazardous Area Classification 1cherif yahyaoui100% (1)

- XXXXX: Important Instructions To ExaminersDocument24 pagesXXXXX: Important Instructions To Examinersketanpawar322No ratings yet

- I Ec StandardsDocument4 pagesI Ec StandardsAhmad Adel El TantawyNo ratings yet

- Specification For Trolly Mounted DCPDocument12 pagesSpecification For Trolly Mounted DCPAshok KumarNo ratings yet

- Technical Specification - Orifice Plate Sizing - DDocument8 pagesTechnical Specification - Orifice Plate Sizing - DAlexis VélezNo ratings yet

- 1391 1Document26 pages1391 1Aaron AngNo ratings yet

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- Journal of Loss Prevention in The Process Industries: Renato BenintendiDocument6 pagesJournal of Loss Prevention in The Process Industries: Renato BenintendiEfari BahcevanNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Thực hiện Fire and Gas MappingDocument4 pagesThực hiện Fire and Gas MappingHuan Trinh VanNo ratings yet

- Tính toán & Lựa chọn SILDocument4 pagesTính toán & Lựa chọn SILHuan Trinh VanNo ratings yet

- Phân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPDocument5 pagesPhân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPHuan Trinh VanNo ratings yet

- User Manual Hazcalc: Version: Final 1.0Document10 pagesUser Manual Hazcalc: Version: Final 1.0Huan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument8 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Content: 2 User Manual Hazcalc 1.0Document38 pagesContent: 2 User Manual Hazcalc 1.0Huan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument10 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Appendix 9D: SPU Electrical Design ChecklistDocument9 pagesAppendix 9D: SPU Electrical Design ChecklistHuan Trinh VanNo ratings yet

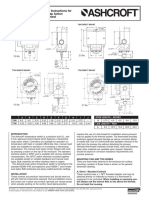

- Ashcomstd DialDocument23 pagesAshcomstd DialHuan Trinh VanNo ratings yet

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- ASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportDocument57 pagesASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportHuan Trinh VanNo ratings yet

- Vessel Design (External Loads) 2 PDFDocument50 pagesVessel Design (External Loads) 2 PDFEzekielNo ratings yet

- Chemical Equilibrium McqsDocument3 pagesChemical Equilibrium Mcqssadaf yousafzaiNo ratings yet

- Support Roller - AKSDocument31 pagesSupport Roller - AKSAnanth Iyer91% (11)

- Experiment No. 7: The Conical PendulumDocument6 pagesExperiment No. 7: The Conical PendulumTrina Rose AutidaNo ratings yet

- Protein Structure PredictionDocument41 pagesProtein Structure PredictionpatelNo ratings yet

- Machanical System DesignDocument4 pagesMachanical System DesignGreyphen GreyNo ratings yet

- Assignment 1 WeldingDocument11 pagesAssignment 1 WeldingLee Eyyh DeeNo ratings yet

- Bronze: LG2 - Leaded GunmetalDocument3 pagesBronze: LG2 - Leaded GunmetalDodi SuhendraNo ratings yet

- Compaction Properties: Hygroscopicity, Powder RheologyDocument12 pagesCompaction Properties: Hygroscopicity, Powder RheologyjoshNo ratings yet

- Lecture 2Document30 pagesLecture 2Thiet AnhNo ratings yet

- Chemical Kinetics Act. No. 3Document2 pagesChemical Kinetics Act. No. 3bae joohyunNo ratings yet

- Tpro - CIP Data QuestionnaireDocument4 pagesTpro - CIP Data QuestionnaireUgur TucNo ratings yet

- Design& Manufacturing of Explosion ChambersDocument25 pagesDesign& Manufacturing of Explosion Chambersshakirhamid6687No ratings yet

- Fly Wheel Weight ReductionDocument15 pagesFly Wheel Weight ReductionHari KrishNo ratings yet

- Conceptual and Functional Chemistry-Book SummaryDocument8 pagesConceptual and Functional Chemistry-Book SummaryJehan CodanteNo ratings yet

- Lateral-Torsional Buckling of Beams and The Southwell PlotDocument15 pagesLateral-Torsional Buckling of Beams and The Southwell PlotPablo Augusto Krahl0% (1)

- Chemistry Syllabus IitDocument3 pagesChemistry Syllabus IitanantNo ratings yet

- Design Analysis & Optimization of Hub Used in FSAE CarsDocument10 pagesDesign Analysis & Optimization of Hub Used in FSAE CarsMukul ChandraNo ratings yet

- 159 - 09 - E Reciprocating Pumps Pump InstallationsDocument14 pages159 - 09 - E Reciprocating Pumps Pump InstallationsbrewerlyNo ratings yet

- High Temperature SuperconductorsDocument5 pagesHigh Temperature SuperconductorsROJA MACHERLANo ratings yet

- Recent Technology of Powder Metallurgy and ApplicationsDocument32 pagesRecent Technology of Powder Metallurgy and ApplicationsMuralli Jayaganesan100% (2)

- Chen 2013Document8 pagesChen 2013najiha_tahirNo ratings yet

- Erodible ChannelsDocument5 pagesErodible ChannelsAriza100% (1)

- Portals and Trussed Frame StructuresDocument5 pagesPortals and Trussed Frame StructuresMichael SandersNo ratings yet

- R-Rods and Subs EpirocDocument5 pagesR-Rods and Subs EpirocElgi Alam PangestuNo ratings yet

- Mount Zion College of Engineering and Technology, PudukkottaiDocument162 pagesMount Zion College of Engineering and Technology, PudukkottaisolomonrajarNo ratings yet

- Solved Problem 04Document8 pagesSolved Problem 04Abdullah SimpsonNo ratings yet

- Physics ExamDocument19 pagesPhysics ExamAji Nikka AngelesNo ratings yet

Fundamentals of Area Classification 1

Fundamentals of Area Classification 1

Uploaded by

Huan Trinh VanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fundamentals of Area Classification 1

Fundamentals of Area Classification 1

Uploaded by

Huan Trinh VanCopyright:

Available Formats

HAZARDOUS AREA CLASSIFICATION

An accurate area classification study is of the most importance for selecting suitable

explosion protected equipment by providing enough information and to ensure that the

correct level of protection is afforded to render the plant safe without making everyday

operations impractical.

MEC have ability to classify hazardous area according to IEC-60079-10, the outline

procedure as following 8 steps:

1. List the flammable materials.

We will study process of the plant and and list all flamable materials with the

MSDSs (Material Safety Data Sheets).

2. Select those present in significant quantities.

Enough information on flammable materials is provided in the example above to

enable the reader of the final assessment report to select the equipment according

to the gas group and temperature class of these materials as well as additional

information to allow traceability of the material data and even guidance on the

explosive concentrations to help with using gas sensors.

3. Determine sources of release.

The sources of release will typically be liquid surfaces, vents, sample points,

pump shaft seals, spillage containment areas, flange, material transfer points, etc.

The accurate identification of these will enable us to determine an accurate and

specific zone around each release point.

4. Determine grades of release.

This section is calculated purely on how frequent explosive atmospheres are

likely to be present. The grade of the release will have the greatest influence on

determining the Zone around the source of release.

As a guide the following relationship can be used:

Frequency of formation of

Total duration of explosive atmosphere

explosive atmosphere

Continuous >1 000 hours per year

Normal conditions (Primary) >10 ≤1 000 hours per year

Abnormal conditions (Secondary) >1 ≤10 hours per year (or from >0.1, in some

literature)

5. Determine zones.

There is, in most cases, under unrestricted ‘open air’ conditions a direct

relationship between the grade of release and the zone classification to which it

gives rise;

• Continuous grade normally leads to Zone 0.

• Primary grade normally leads to Zone 1.

• Secondary grade normally leads to Zone 2.

This relationship is also described as:

Zone Frequency of formation Total duration of explosive

of explosive atmosphere atmosphere

Zone 0 Continuous >1 000 hours per year

Zone 1 Normal conditions

>10 ≤1 000 hours per year

(Primary)

Zone 2 Abnormal conditions

>1 & ≤10 hours per year

(Secondary)

The level of ventilation and its ability to dilute the flammable mixture is then

considered to determine if the Zoning should be amended to a lower or higher

Zone.

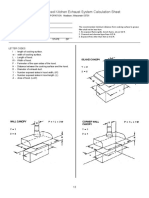

6. Size and Shape Zones.

This can be determined by using the direct examples such as the examples in IP-

15 or by calculating the volumes from suitable Standard documents. Equivalent

release hole size diameters can for example be successfully used to calculate the

extent of a zone around a pump shaft seal or vent diameter.

It is also advisable to recommend at this stage what measures can be taken to

reduce the zones. Like to render areas zone 2 instead of zone 1 by employing

additional ventilation or using deflection walls. This can significantly reduce the

burden on maintenance and allow additional explosion protection techniques to

be used in the area.

7. Rationalize, i.e. merge overlapping areas with the same zones and

simplification of the zones.

In an aim to provide enough information to select the appropriate equipment but

also to capture enough information to make the assessment traceable the data is

presented in a table form as shown below example.

Equipment SOR Grade of Flammable Material Ventilation Hazardous Area Reference

ID Item release Material P T State Type Degree Availa= Zone Horiz (m) Vert (m)

(C/P/S) No. (Gas (kPag) (°C) (S/A/B (N/A) (Open- bility

Group; /C/G(i air/ (G/F/P)

Temp. Class) )/G(ii)) Adq/

Inadq)

Booth A and B

1 Spray gun Spray gun P 1 (IIA; T3) 5 000 Amb C N A G 1 5 5 IP 15 Table C9

nozzle. (assumed with nozzle

maximum release hole

for spray Extend to include size equivalent

gun) the interior of the

of 2mm.

booth.

Use figure 6.2

below to extend

beyond openings

in the walls.

2 Spray gun Spray gun S 1 (IIA; T3) 5 000 Amb C N A G 2 Interior of the IP 15 Table C9

nozzle. (assumed extraction with nozzle

maximum ventilation system. release hole

for spray size equivalent

gun) of 2mm,

(dilution from

ventilation

expected).

You might also like

- FSCR-FSCCR-FSMR Report - UAP Seminar - 02082020 PDFDocument126 pagesFSCR-FSCCR-FSMR Report - UAP Seminar - 02082020 PDFJoy Cruz88% (8)

- Air SeparationDocument53 pagesAir SeparationFran Jimenez100% (2)

- Grease Filter Equipped Kitchen Exhaust System Calculation SheetDocument2 pagesGrease Filter Equipped Kitchen Exhaust System Calculation SheetMahmoud Anwer100% (1)

- Air Seperation Technologies Used in Cement IndustryDocument53 pagesAir Seperation Technologies Used in Cement IndustryTin Nguyen100% (3)

- Anodamine HPFGDocument69 pagesAnodamine HPFGmasgrahaNo ratings yet

- Analysis and Application of Semiconductors in Air BatteriesDocument23 pagesAnalysis and Application of Semiconductors in Air Batteriessree haritha p0% (1)

- Fundamentals of Area ClassificationDocument10 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument8 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Area ClassificationDocument28 pagesArea ClassificationborrowmanaNo ratings yet

- COM ATEX Poster EN PDFDocument1 pageCOM ATEX Poster EN PDFWerner SchulzNo ratings yet

- Comliance MultistressDocument22 pagesComliance MultistressStandards IndiaNo ratings yet

- Fire ZoneDocument12 pagesFire ZoneMehman NasibovNo ratings yet

- Free Open Area Is It Relevant To Louvre PerformanceDocument5 pagesFree Open Area Is It Relevant To Louvre PerformanceZulfadzli RidzuanNo ratings yet

- Dsen 60079-10-1 & Uk PDFDocument29 pagesDsen 60079-10-1 & Uk PDFNISO9001No ratings yet

- Interpretation of IP15 in Process Plant Design: A Commonsense ApproachDocument8 pagesInterpretation of IP15 in Process Plant Design: A Commonsense ApproachAl Faruq ShinagaNo ratings yet

- RainNoiseGuidance PDFDocument7 pagesRainNoiseGuidance PDFehizojayNo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument9 pagesHazardous Area Classification and Control of Ignition SourcesKHALID HUBBAHNo ratings yet

- WEG Explosive Atmospheres 50056895 Brochure EnglishDocument20 pagesWEG Explosive Atmospheres 50056895 Brochure EnglishVaibhav PatilNo ratings yet

- b2b6606d 5af3 48d6 90e6 9116cac65645.ClassPresentationBLD122076EngineeredApproachtoLifeSafetyinaShoppingMallUsingAutodeskCFDDr - Munirajulum3Document61 pagesb2b6606d 5af3 48d6 90e6 9116cac65645.ClassPresentationBLD122076EngineeredApproachtoLifeSafetyinaShoppingMallUsingAutodeskCFDDr - Munirajulum3Arun CherianNo ratings yet

- Zone Classification: Doc. No. 50068905 Ver.1.0Document23 pagesZone Classification: Doc. No. 50068905 Ver.1.0mkpasha55mp100% (1)

- E779-10 Standard Test Method For Determining Air Leakage Rate by Fan PressurizationDocument11 pagesE779-10 Standard Test Method For Determining Air Leakage Rate by Fan PressurizationMuhammad SalmanNo ratings yet

- Heskestad 1986Document7 pagesHeskestad 1986Deives De PaulaNo ratings yet

- P.R.H.Shields: Keywords Hazard, Area, Onolysis, Zone, ClassificationDocument13 pagesP.R.H.Shields: Keywords Hazard, Area, Onolysis, Zone, ClassificationSHAILENDRANo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument10 pagesHazardous Area Classification and Control of Ignition SourcesS.KalatheeswaranNo ratings yet

- Lokesh PaperDocument6 pagesLokesh PaperdewasstudentNo ratings yet

- Jis A 1202Document11 pagesJis A 1202mahtrian nopeNo ratings yet

- Safety Science: Riccardo TommasiniDocument6 pagesSafety Science: Riccardo TommasiniSanaNo ratings yet

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- FirePro Leakage Compensation GuidelinesDocument11 pagesFirePro Leakage Compensation Guidelinesmohamed.rescoNo ratings yet

- Practical Diffuser Selection and Layout ProcedureDocument8 pagesPractical Diffuser Selection and Layout ProcedureHVACDESIGNNo ratings yet

- Guidance Document On BS EN 13565-2 Foam System StandardDocument8 pagesGuidance Document On BS EN 13565-2 Foam System StandardFernando KatayamaNo ratings yet

- Interpretation of IP15Document8 pagesInterpretation of IP15U Tint LwinNo ratings yet

- Hazardous Areas: Gases and VapoursDocument10 pagesHazardous Areas: Gases and VapoursShah JayNo ratings yet

- Is 4894 Standard PDFDocument21 pagesIs 4894 Standard PDFDharmendra PanchalNo ratings yet

- SPD0036ERN - 4 - Hazardous Area ClassificationDocument6 pagesSPD0036ERN - 4 - Hazardous Area ClassificationHamidNo ratings yet

- Handouts - Engineering Procedures in Hazardous Atmospheres in Power PlantsDocument15 pagesHandouts - Engineering Procedures in Hazardous Atmospheres in Power PlantsDavid Luna MolinaNo ratings yet

- HFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ADocument19 pagesHFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ATahir FadhilNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Sources and Grades of ReleaseDocument10 pagesSources and Grades of Releasebaaziz2015No ratings yet

- GGG-CAL-HAC-0007 - FMS 7 Barg FULL (28-10-2014)Document14 pagesGGG-CAL-HAC-0007 - FMS 7 Barg FULL (28-10-2014)oleg safaniukNo ratings yet

- TN 65229 05-15-12 Infiltration Modeling Guidelines For Commercial Building Energy AnalysisDocument24 pagesTN 65229 05-15-12 Infiltration Modeling Guidelines For Commercial Building Energy Analysis7.Vương Đình CủaNo ratings yet

- Air Content of Cement JIS A1128-2019Document1 pageAir Content of Cement JIS A1128-2019Rahul ReddyNo ratings yet

- 1391 2 2018 AMD4 Reff2022Document82 pages1391 2 2018 AMD4 Reff2022Abhishek SrivastvaNo ratings yet

- 0189PF N DG DG03 SR SCH 1001 B02Document4 pages0189PF N DG DG03 SR SCH 1001 B02Jalal AlbadriNo ratings yet

- Manufacturer and DesignationDocument3 pagesManufacturer and DesignationEmma DNo ratings yet

- Guidelines On Hazardous Area ClassificationDocument8 pagesGuidelines On Hazardous Area ClassificationKalam Nagappan100% (1)

- HAC An Ignition Source ControlDocument48 pagesHAC An Ignition Source ControlMoh Fahmi NajahiNo ratings yet

- Selection of Explosion Protected Equipment For Hazardous LoctionsDocument32 pagesSelection of Explosion Protected Equipment For Hazardous Loctionsasex4uNo ratings yet

- Fire ZoneDocument8 pagesFire ZoneKannan NNo ratings yet

- ASTM Pump Test MethodDocument3 pagesASTM Pump Test MethodAlberto GranadosNo ratings yet

- Guidelines On Hazardous Area Classification 1Document8 pagesGuidelines On Hazardous Area Classification 1cherif yahyaoui100% (1)

- XXXXX: Important Instructions To ExaminersDocument24 pagesXXXXX: Important Instructions To Examinersketanpawar322No ratings yet

- I Ec StandardsDocument4 pagesI Ec StandardsAhmad Adel El TantawyNo ratings yet

- Specification For Trolly Mounted DCPDocument12 pagesSpecification For Trolly Mounted DCPAshok KumarNo ratings yet

- Technical Specification - Orifice Plate Sizing - DDocument8 pagesTechnical Specification - Orifice Plate Sizing - DAlexis VélezNo ratings yet

- 1391 1Document26 pages1391 1Aaron AngNo ratings yet

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- Journal of Loss Prevention in The Process Industries: Renato BenintendiDocument6 pagesJournal of Loss Prevention in The Process Industries: Renato BenintendiEfari BahcevanNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Thực hiện Fire and Gas MappingDocument4 pagesThực hiện Fire and Gas MappingHuan Trinh VanNo ratings yet

- Tính toán & Lựa chọn SILDocument4 pagesTính toán & Lựa chọn SILHuan Trinh VanNo ratings yet

- Phân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPDocument5 pagesPhân Tích Mối Nguy Và Khả Năng Vận Hành HAZOPHuan Trinh VanNo ratings yet

- User Manual Hazcalc: Version: Final 1.0Document10 pagesUser Manual Hazcalc: Version: Final 1.0Huan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument8 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Content: 2 User Manual Hazcalc 1.0Document38 pagesContent: 2 User Manual Hazcalc 1.0Huan Trinh VanNo ratings yet

- Fundamentals of Area ClassificationDocument10 pagesFundamentals of Area ClassificationHuan Trinh VanNo ratings yet

- Appendix 9D: SPU Electrical Design ChecklistDocument9 pagesAppendix 9D: SPU Electrical Design ChecklistHuan Trinh VanNo ratings yet

- Ashcomstd DialDocument23 pagesAshcomstd DialHuan Trinh VanNo ratings yet

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- ASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportDocument57 pagesASC Q14!5!075 R001 V1R3 Redundant Solenoid SIL Verificaiton ReportHuan Trinh VanNo ratings yet

- Vessel Design (External Loads) 2 PDFDocument50 pagesVessel Design (External Loads) 2 PDFEzekielNo ratings yet

- Chemical Equilibrium McqsDocument3 pagesChemical Equilibrium Mcqssadaf yousafzaiNo ratings yet

- Support Roller - AKSDocument31 pagesSupport Roller - AKSAnanth Iyer91% (11)

- Experiment No. 7: The Conical PendulumDocument6 pagesExperiment No. 7: The Conical PendulumTrina Rose AutidaNo ratings yet

- Protein Structure PredictionDocument41 pagesProtein Structure PredictionpatelNo ratings yet

- Machanical System DesignDocument4 pagesMachanical System DesignGreyphen GreyNo ratings yet

- Assignment 1 WeldingDocument11 pagesAssignment 1 WeldingLee Eyyh DeeNo ratings yet

- Bronze: LG2 - Leaded GunmetalDocument3 pagesBronze: LG2 - Leaded GunmetalDodi SuhendraNo ratings yet

- Compaction Properties: Hygroscopicity, Powder RheologyDocument12 pagesCompaction Properties: Hygroscopicity, Powder RheologyjoshNo ratings yet

- Lecture 2Document30 pagesLecture 2Thiet AnhNo ratings yet

- Chemical Kinetics Act. No. 3Document2 pagesChemical Kinetics Act. No. 3bae joohyunNo ratings yet

- Tpro - CIP Data QuestionnaireDocument4 pagesTpro - CIP Data QuestionnaireUgur TucNo ratings yet

- Design& Manufacturing of Explosion ChambersDocument25 pagesDesign& Manufacturing of Explosion Chambersshakirhamid6687No ratings yet

- Fly Wheel Weight ReductionDocument15 pagesFly Wheel Weight ReductionHari KrishNo ratings yet

- Conceptual and Functional Chemistry-Book SummaryDocument8 pagesConceptual and Functional Chemistry-Book SummaryJehan CodanteNo ratings yet

- Lateral-Torsional Buckling of Beams and The Southwell PlotDocument15 pagesLateral-Torsional Buckling of Beams and The Southwell PlotPablo Augusto Krahl0% (1)

- Chemistry Syllabus IitDocument3 pagesChemistry Syllabus IitanantNo ratings yet

- Design Analysis & Optimization of Hub Used in FSAE CarsDocument10 pagesDesign Analysis & Optimization of Hub Used in FSAE CarsMukul ChandraNo ratings yet

- 159 - 09 - E Reciprocating Pumps Pump InstallationsDocument14 pages159 - 09 - E Reciprocating Pumps Pump InstallationsbrewerlyNo ratings yet

- High Temperature SuperconductorsDocument5 pagesHigh Temperature SuperconductorsROJA MACHERLANo ratings yet

- Recent Technology of Powder Metallurgy and ApplicationsDocument32 pagesRecent Technology of Powder Metallurgy and ApplicationsMuralli Jayaganesan100% (2)

- Chen 2013Document8 pagesChen 2013najiha_tahirNo ratings yet

- Erodible ChannelsDocument5 pagesErodible ChannelsAriza100% (1)

- Portals and Trussed Frame StructuresDocument5 pagesPortals and Trussed Frame StructuresMichael SandersNo ratings yet

- R-Rods and Subs EpirocDocument5 pagesR-Rods and Subs EpirocElgi Alam PangestuNo ratings yet

- Mount Zion College of Engineering and Technology, PudukkottaiDocument162 pagesMount Zion College of Engineering and Technology, PudukkottaisolomonrajarNo ratings yet

- Solved Problem 04Document8 pagesSolved Problem 04Abdullah SimpsonNo ratings yet

- Physics ExamDocument19 pagesPhysics ExamAji Nikka AngelesNo ratings yet