Professional Documents

Culture Documents

MD 010 Design Validation Sop 1 0 110905125013 Phpapp02

MD 010 Design Validation Sop 1 0 110905125013 Phpapp02

Uploaded by

Omer ZiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD 010 Design Validation Sop 1 0 110905125013 Phpapp02

MD 010 Design Validation Sop 1 0 110905125013 Phpapp02

Uploaded by

Omer ZiaCopyright:

Available Formats

Quality Management

Documents & Templates

Design Validation

Additional potential Hazards or Failure Modes may be discovered during Validation

activities. Some previously identified Hazards or Failure Modes may be observed or

estimated to have a frequency greater than previously anticipated. Risk Analysis

documentation shall be updated as necessary.

All products subject to Validation studies should be properly labelled and all equipment,

tools, and fixtures used in Validation must be documented and traceable to calibration

and maintenance records.

Validation testing should include simulation of expected environmental conditions such

as temperature, humidity, shock, vibration, etc. These environments may be

encountered during use or during shipping and storage.

Validation testing should include product labelling and packaging. These may have

human factors implications and may affect product performance.

7.2 Design Validation Deliverables

The following documents are deliverables for the Design Validation Phase:

• Design Validation Matrix

• Design Validation Equipment Log

• Validation Protocols

• Validation Reports

• Design Review documents

Each of these deliverables shall be approved by the PL /HE and Quality Assurance. The

Validation program (columns 1-6 of the Design Validation Matrix) and the Validation

Design Review documents shall also be approved by the DRC.

These documents constitute a Validation File and shall become part of the DHF.

7.3 Design Validation Matrix (Part 1)

The Design Validation Matrix serves as a plan for the Design Validation effort. The matrix

demonstrates traceability between each User Requirement and the Validation results. It

is a summary of the Validation Phase.

• 1st column: User Requirement# - list the User Requirement number.

• 2nd column: Validation Protocol# - list the number of the Validation Protocol. One

Protocol may apply to more than one User Requirement.

• 3rd column: Responsible Party - list the person or group responsible for the

Validation.

• 4th column: Validation Method, SOPs, Standards - summary of the activity to be

performed to verify the requirement is described. Activity details are entered into

the Protocol (explained below). Reference documents such as SOPs, Standards

are listed.

Document Type Document ID Version Status Page

SOP XX_WWW_ZZZ_YYYY 1.0 Approved 10/26

Copyright © by QMdocs 2010

Reproduction, photocopying, storage or transmission by magnetic or electronic means strictly prohibited by law. Neither the

document nor the information contained therein may be reproduced or disclosed without written consent of QMdocs.

You might also like

- Qa/Fm/005-Extension of Calibration Due DateDocument1 pageQa/Fm/005-Extension of Calibration Due DatePerwez21No ratings yet

- 5 Change ControlDocument20 pages5 Change ControlAnushkaManiTripathiNo ratings yet

- ISO 13485 Seminar Slide DeckDocument150 pagesISO 13485 Seminar Slide DeckOmer Zia100% (1)

- Example of EU Declaration of Conformity (DoC) Adopted by EMC ADCODocument1 pageExample of EU Declaration of Conformity (DoC) Adopted by EMC ADCOSunny PanwarNo ratings yet

- Quality Tools: Failure Mode and Effects AnalysisDocument3 pagesQuality Tools: Failure Mode and Effects AnalysisAl RammohanNo ratings yet

- OBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Document4 pagesOBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Andy RojasNo ratings yet

- MDSAP QMS P0014.003 Training Procedurev2Document7 pagesMDSAP QMS P0014.003 Training Procedurev2Mohammed YousffiNo ratings yet

- FRM-012 A D4 Change NoteDocument4 pagesFRM-012 A D4 Change NoteSvetlanaNo ratings yet

- MD 009 Design Verification Sop 1 0 110905125010 Phpapp02Document1 pageMD 009 Design Verification Sop 1 0 110905125010 Phpapp02Omer ZiaNo ratings yet

- 5 APQP 1 of 3Document3 pages5 APQP 1 of 3P G SumanNo ratings yet

- ISO 13485 - 2016-WPS OfficeDocument4 pagesISO 13485 - 2016-WPS Officerajesh.bNo ratings yet

- SQMP ManualDocument81 pagesSQMP ManualAnkita DwivediNo ratings yet

- Change Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-XxxDocument7 pagesChange Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-Xxxrouss1906No ratings yet

- Risk Assessment Tools For IVD AssaysDocument52 pagesRisk Assessment Tools For IVD AssaysOiinkieNo ratings yet

- Isr 13485 Delta ChecklistDocument11 pagesIsr 13485 Delta ChecklistMs. ThuNo ratings yet

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowrajarajanNo ratings yet

- Sop Feedback ManagementDocument4 pagesSop Feedback Managementalaa.saadi711No ratings yet

- Iso13485 QM06 MngResponsibilityDocument9 pagesIso13485 QM06 MngResponsibilityQuality and Safety Consultants Co.No ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- KOGS-BMS-PRO-002 (Document Change Control) (Rev 1.0)Document8 pagesKOGS-BMS-PRO-002 (Document Change Control) (Rev 1.0)KOGSNo ratings yet

- Sop PurchasingDocument5 pagesSop PurchasingSteven TanNo ratings yet

- Device Master RecordsDocument15 pagesDevice Master Recordstrungthanhnguyen_83No ratings yet

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDocument2 pages85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007No ratings yet

- Plastic Injection Molding Tool Transfer Checklist: Disclosure of Existing DocumentationDocument2 pagesPlastic Injection Molding Tool Transfer Checklist: Disclosure of Existing DocumentationHector NinoNo ratings yet

- 789 G5500 Rev. 9.2 Quality Manual Final1.UnlockedDocument23 pages789 G5500 Rev. 9.2 Quality Manual Final1.Unlockeddrmohamed120No ratings yet

- Turtle Diagrams - Stores + ShippingDocument1 pageTurtle Diagrams - Stores + Shippingcem electromechNo ratings yet

- Apqp Time Plan: Risk AnalysisDocument4 pagesApqp Time Plan: Risk AnalysisRakesh PandeyNo ratings yet

- IA Audit Observation ReportDocument12 pagesIA Audit Observation ReportKeval ShethNo ratings yet

- CSL P5-007229 AuditReportDocument5 pagesCSL P5-007229 AuditReportIdrus IsmailNo ratings yet

- Statistical Quality ControlDocument56 pagesStatistical Quality ControlcmukherjeeNo ratings yet

- Seventh Schedule, Medical Device RulesDocument20 pagesSeventh Schedule, Medical Device RulesGurneet Kaur KhalsaNo ratings yet

- Stanzen Links: Procedure For Control of DocumentsDocument5 pagesStanzen Links: Procedure For Control of DocumentsasderbvaNo ratings yet

- SOP-RD-7.1-001 Advanced Product Quality PlanningDocument13 pagesSOP-RD-7.1-001 Advanced Product Quality PlanningXionNo ratings yet

- Process Change NoteDocument1 pageProcess Change NoteSUBODHHNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- What's Changed in ISO 13485:2016?: BrandwoodDocument22 pagesWhat's Changed in ISO 13485:2016?: BrandwoodHilario AlinabonNo ratings yet

- 002 Standards TableDocument14 pages002 Standards TableNurul Fatia JannahNo ratings yet

- Design Validation TipsDocument2 pagesDesign Validation Tipsanilsamuel0077418No ratings yet

- ISO 13485 2012 Anexes EDocument22 pagesISO 13485 2012 Anexes Ercjpedroyahoocom0% (1)

- Device Master Record Index: Sl. No. Document No. Device Specifications (DS)Document6 pagesDevice Master Record Index: Sl. No. Document No. Device Specifications (DS)normalNo ratings yet

- Main Process Complaint ManagementDocument12 pagesMain Process Complaint Managementsafit_rhyNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- Rca SopDocument4 pagesRca SopShiva Prakasam PernetiNo ratings yet

- Keerthi Engineering: Initial Production Part TagDocument2 pagesKeerthi Engineering: Initial Production Part Tagkeerthi EngineeringNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- 10 Questions On 21 CFR Part 820Document2 pages10 Questions On 21 CFR Part 820Ali Imamudeen100% (1)

- QCI - AIMED Voluntary Initiative On Medical DevicesDocument24 pagesQCI - AIMED Voluntary Initiative On Medical DevicesSureshNo ratings yet

- SOP - Complaint & SurveyDocument5 pagesSOP - Complaint & SurveySheila BonusNo ratings yet

- GG SOP QA004 Change Control System OkDocument9 pagesGG SOP QA004 Change Control System OkMishra DiveshNo ratings yet

- 4.4.1 Product SafetyDocument5 pages4.4.1 Product SafetyVijayendran VijayNo ratings yet

- D&D RequirementsDocument2 pagesD&D RequirementsJanak DoshiNo ratings yet

- ISO 13485: 2016 Planner and Delta Checklist: InstructionsDocument10 pagesISO 13485: 2016 Planner and Delta Checklist: InstructionsYogesh H NarkhedeNo ratings yet

- Process Flow Diagram DetailedDocument1 pageProcess Flow Diagram Detailedhugo toledoNo ratings yet

- Point 1 - B) Procedure For Managemet of ChangeDocument3 pagesPoint 1 - B) Procedure For Managemet of Changemahesh KhatalNo ratings yet

- Vda Fmea TemplateDocument54 pagesVda Fmea Templatehmp90No ratings yet

- Capa and Change ManagementDocument2 pagesCapa and Change ManagementEldaniz HasanovNo ratings yet

- QUAMA000Document41 pagesQUAMA000Abd ZouhierNo ratings yet

- Safety: A) Machine Safety SystemDocument5 pagesSafety: A) Machine Safety SystemSagar DaundNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Content Weightages For Project Funded Positions PPS 7 To 10 HECDocument4 pagesContent Weightages For Project Funded Positions PPS 7 To 10 HECOmer ZiaNo ratings yet

- Deviations Corrective and Preventative Actions April 2015Document33 pagesDeviations Corrective and Preventative Actions April 2015Omer Zia100% (1)

- Implementing An Effective CAPA SystemDocument60 pagesImplementing An Effective CAPA SystemOmer ZiaNo ratings yet

- Conducting CAPA Investigations: September 21, 2016Document47 pagesConducting CAPA Investigations: September 21, 2016Omer ZiaNo ratings yet

- AdvaMed CAPA GuideDocument26 pagesAdvaMed CAPA GuideOmer ZiaNo ratings yet

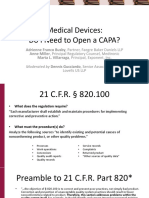

- Medical Devices: Do I Need To Open A CAPA?Document5 pagesMedical Devices: Do I Need To Open A CAPA?Omer ZiaNo ratings yet

- HR Management PolicyDocument1 pageHR Management PolicyOmer ZiaNo ratings yet

- MD 009 Design Verification Sop 1 0 110905125010 Phpapp02Document1 pageMD 009 Design Verification Sop 1 0 110905125010 Phpapp02Omer ZiaNo ratings yet

- Medical Device Product Development Process: David Farrar Head of New Technologies Xiros LTD, Leeds, UKDocument29 pagesMedical Device Product Development Process: David Farrar Head of New Technologies Xiros LTD, Leeds, UKOmer ZiaNo ratings yet

- US FDA 21 CFR 820.30 Design Control RequirementsDocument1 pageUS FDA 21 CFR 820.30 Design Control RequirementsOmer ZiaNo ratings yet

- A Brief History of Jazz DrummingDocument8 pagesA Brief History of Jazz DrummingManoloPantalonNo ratings yet

- Start-Up Report Warranty Registration - EDITABLEDocument1 pageStart-Up Report Warranty Registration - EDITABLESAED ALAWNEHNo ratings yet

- Gs This That Those - ExercisesDocument2 pagesGs This That Those - ExercisesWilvertein C ChambiNo ratings yet

- A Seminar Report On: An International Study On A Risk of Cyber TerrorismDocument7 pagesA Seminar Report On: An International Study On A Risk of Cyber TerrorismManish SakalkarNo ratings yet

- PreliminariesDocument11 pagesPreliminariesGhabbFloresPalNo ratings yet

- Catalogo Biomédico 2016 PDFDocument36 pagesCatalogo Biomédico 2016 PDFMartinNo ratings yet

- SACH Tooth Brush - Launch Docket PDFDocument13 pagesSACH Tooth Brush - Launch Docket PDFSami ShaikhNo ratings yet

- Roll No. 31 - SportsDocument8 pagesRoll No. 31 - SportsAdnan NawabNo ratings yet

- SMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Document6 pagesSMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Sri KanthNo ratings yet

- SCS Method PDFDocument55 pagesSCS Method PDFWesley BridgemohansinghNo ratings yet

- The Role of Customer Trust in Mediating Influence of Brand Image and Brand Awareness of The Purchase Intention in Airline Tickets OnlineDocument10 pagesThe Role of Customer Trust in Mediating Influence of Brand Image and Brand Awareness of The Purchase Intention in Airline Tickets OnlineSuriya SamNo ratings yet

- Iygb Gce: Core Mathematics C2 Advanced SubsidiaryDocument6 pagesIygb Gce: Core Mathematics C2 Advanced SubsidiaryssmithNo ratings yet

- SUMMATIVE TEST 1 (Quarter 3 Science 7) A4 SIZEDocument6 pagesSUMMATIVE TEST 1 (Quarter 3 Science 7) A4 SIZEZayn Daniel World of GamesNo ratings yet

- Sma 6512H 2017Document9 pagesSma 6512H 2017jieNo ratings yet

- Introduction To Micromine PDFDocument220 pagesIntroduction To Micromine PDFDamos TinambunanNo ratings yet

- CALR - SUPPL X Sequenze PrimersDocument53 pagesCALR - SUPPL X Sequenze PrimersNicoletta ColomboNo ratings yet

- LEFORT, Claude. Thinking With and Against Hannah ArendtDocument14 pagesLEFORT, Claude. Thinking With and Against Hannah ArendtGabriel VecchiettiNo ratings yet

- Piping Engineer: Resume CV: Sponsored LinksDocument7 pagesPiping Engineer: Resume CV: Sponsored Linksravi gurungNo ratings yet

- Application of Negative Stiffness Devices For Seismic Protection of Bridge StructuresDocument10 pagesApplication of Negative Stiffness Devices For Seismic Protection of Bridge StructuresganeshNo ratings yet

- Record Keeping MisconceptionsDocument9 pagesRecord Keeping MisconceptionsPeaceNo ratings yet

- ManSci ReviewDocument7 pagesManSci ReviewCathleen TenaNo ratings yet

- Triangular Sum Labeling NEWDocument33 pagesTriangular Sum Labeling NEWMurugananthamParamasivamNo ratings yet

- WKB ApproxDocument21 pagesWKB ApproxdevendrakphyNo ratings yet

- Product Catalogue-IoT PT. MSIDocument30 pagesProduct Catalogue-IoT PT. MSIMaz ZildaneNo ratings yet

- Textiles Mills Waste: Cotton Textile Mill Waste Woolen Textile Mills Waste Synthetic Textile Mill WasteDocument3 pagesTextiles Mills Waste: Cotton Textile Mill Waste Woolen Textile Mills Waste Synthetic Textile Mill WasteAbhishek AryaNo ratings yet

- Fresh AHU ComparisonDocument8 pagesFresh AHU Comparisonevo2oo2No ratings yet

- The Sinister Genius of Qassem Soleimani - WSJ PDFDocument5 pagesThe Sinister Genius of Qassem Soleimani - WSJ PDFMuhammad Anique RawnNo ratings yet

- Catalog 2010 - 2011 Optical Warning SystemsDocument56 pagesCatalog 2010 - 2011 Optical Warning SystemsSamir FerreiraNo ratings yet

- Production Planning - 095252Document13 pagesProduction Planning - 095252Jocidelle LubricoNo ratings yet

- Accura 2500 - 2550 - AC - Communication User Guide - Rev1 - 00 - English - 220712Document165 pagesAccura 2500 - 2550 - AC - Communication User Guide - Rev1 - 00 - English - 220712Phạm BìnhNo ratings yet