Professional Documents

Culture Documents

Asme B30.16, BS 3243, BS 4898

Asme B30.16, BS 3243, BS 4898

Uploaded by

engmuhmudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme B30.16, BS 3243, BS 4898

Asme B30.16, BS 3243, BS 4898

Uploaded by

engmuhmudCopyright:

Available Formats

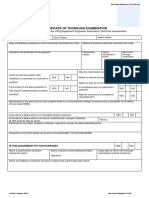

Equipment Owner Type / Model

Manufacturer Serial

Manufacture Date Capacity / SWL

Reference Specification ASME B30.16, BS 3243, Standard Lifting Procedure

BS 4898

A R

Final Result

(A: Accept / R: Reject)

RESULTS

Item Inspection Criteria

Pass Fail N/A Comments

1 General Requirements

1.1 Equipment documents are available

1.2 Previous inspection reports are checked

Serial number and Rated Load are clearly marked or

1.3

tagged

1.4 Chain Block manufacturer’s data available

The examination is to be carried out in adequate

1.5

lighting

2 BODY & HOISTING COMPONENT

Check for general damage to the block body,

2.1 including the gear covers, breaking of torque limiting

devices (if fitted) chain stripper and chain guides.

Operate the block under load and listen for any

2.2 excessive noise (The pawl should make an audible

clicking noise during lifting)

When operated, the block should not require

2.3 excessive effort nor should it jump or the brakes are

seen to slip

The chain sprocket and idler sprocket is to be cleared

2.4

of debris

2.5 Check that the hand chain is not worn or damaged

Check the chain for cracks, nicks, gouges, bent or

2.6

distorted links and any wear, stretch or corrosion

Measure chain diameter and compare to

2.7

manufacturer wear tolerance

Check all chain anchors (if fitted) and chain end stop

2.8

(if fitted) for signs of damage

Check the hooks for cracks, nicks, gouges, corrosion,

opening out of the throat and safety latches fitted or

2.9

some suitable means of preventing the accidental

displacement of the load from the hook

2.10 Check for loose or insecure locking nuts and bolts

2.11 Hoisting unit brakes is working

2.12 All moving parts are lubricated

REMARKS

You might also like

- BS en 280-2-2022Document26 pagesBS en 280-2-2022gokhanekinci92100% (1)

- BS en 00500Document66 pagesBS en 00500bugseNo ratings yet

- LEEA Report of Thorough ExaminationDocument1 pageLEEA Report of Thorough ExaminationengmuhmudNo ratings yet

- Ford Ranger 2011 Workshop ManualDocument20 pagesFord Ranger 2011 Workshop ManualRaymond100% (68)

- Rigging Guide 2008Document222 pagesRigging Guide 2008Alex1No ratings yet

- LEEA Certificate of Thorough ExaminationDocument1 pageLEEA Certificate of Thorough Examinationengmuhmud100% (1)

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNo ratings yet

- LEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Document9 pagesLEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Deepak RMNo ratings yet

- Owen Falls MovementsDocument12 pagesOwen Falls Movementssemuwemba100% (2)

- Mobile CraneDocument84 pagesMobile CraneFar Away100% (1)

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFHadiwinata DjakariaNo ratings yet

- Hyundai HFC6 Gen Mar Gen Man1Document56 pagesHyundai HFC6 Gen Mar Gen Man1Miguel-WilfredSusanLim89% (9)

- Catalog Detectie Incendiu InimDocument76 pagesCatalog Detectie Incendiu InimMavio ViorelNo ratings yet

- LEEA 3 - MLM Manual Lifting Machines 2022Document221 pagesLEEA 3 - MLM Manual Lifting Machines 2022Osama MoghulNo ratings yet

- Chain Block Inspection Checklist FormDocument1 pageChain Block Inspection Checklist FormIhsan yaqoobNo ratings yet

- LEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFDocument14 pagesLEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFopreamihNo ratings yet

- BSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFDocument54 pagesBSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFVenkatesh MohanNo ratings yet

- Sabs GuideDocument3 pagesSabs Guidealextentwenty0% (1)

- Short Link Chain For Lifting Purposes - SafetyDocument26 pagesShort Link Chain For Lifting Purposes - SafetyAHMED LUOSHNo ratings yet

- ASME B30.8 2020 Floating Cranes and Floating DerricksDocument45 pagesASME B30.8 2020 Floating Cranes and Floating DerricksVijay KumarNo ratings yet

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocument2 pagesLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979No ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

- Asli Bs7262Document26 pagesAsli Bs7262umar_hazrad8219100% (1)

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Document6 pagesGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- 4478 BS 7121 Part 3 2017Document76 pages4478 BS 7121 Part 3 2017Ahmed AliNo ratings yet

- As 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationDocument7 pagesAs 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationSAI Global - APAC0% (1)

- International Standard: Cranes - Inspections - GeneralDocument6 pagesInternational Standard: Cranes - Inspections - GeneralNational MarineNo ratings yet

- Final Revision On Mechanics For Final Exam 2017 21-05-43Document97 pagesFinal Revision On Mechanics For Final Exam 2017 21-05-43mohamed sabryNo ratings yet

- Crane Safety On Construction Sites: Standards, Regulations, CertificationsDocument22 pagesCrane Safety On Construction Sites: Standards, Regulations, Certificationsedcamil100% (1)

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- BS Iso 13105-1-2014Document18 pagesBS Iso 13105-1-2014Salafi MhmdNo ratings yet

- Window CradleDocument10 pagesWindow CradleHarris ShehzadNo ratings yet

- BS 7121 Part 3 2017Document76 pagesBS 7121 Part 3 2017Arsénio MatolaNo ratings yet

- Iso 10325 2018Document9 pagesIso 10325 2018Julio Andrés Casal Ramos0% (1)

- Thorough Examination of Lifting Tables: GuidelineDocument11 pagesThorough Examination of Lifting Tables: Guidelineairdrop makrotestNo ratings yet

- Iso 2307 2019Document12 pagesIso 2307 2019adonaies19No ratings yet

- LEEA 059 5 Guidance To Documentation & Marking Part5Document23 pagesLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuNo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- A Simple Guide To LolerDocument3 pagesA Simple Guide To LolerbalasubramaniamNo ratings yet

- Asme b30.30 Slide Deck Awrf 2018Document57 pagesAsme b30.30 Slide Deck Awrf 2018Conrad v/d westhuizenNo ratings yet

- Mobile Crane Operator Candidate Handbook - 120122aDocument33 pagesMobile Crane Operator Candidate Handbook - 120122a전우영No ratings yet

- DOE Standard - Hoisting and Rigging - 2020 UpdateDocument39 pagesDOE Standard - Hoisting and Rigging - 2020 UpdateLogic TurnipNo ratings yet

- BS en 474-4 (Latest)Document26 pagesBS en 474-4 (Latest)AkhilNo ratings yet

- 22 - B56.11 4 2013 Rev 07 01 14 PDFDocument16 pages22 - B56.11 4 2013 Rev 07 01 14 PDFalexdaniel26No ratings yet

- As 3585-2008 End Fittings For Synthetic Flat-Webbing and Round SlingsDocument7 pagesAs 3585-2008 End Fittings For Synthetic Flat-Webbing and Round SlingsSAI Global - APAC0% (1)

- Articulating Boom Cranes: ASME B30.22-2016Document5 pagesArticulating Boom Cranes: ASME B30.22-2016Sugi AriyantoNo ratings yet

- BS en 474-13-2022 - (2022-05-04 - 08-01-57 Am)Document58 pagesBS en 474-13-2022 - (2022-05-04 - 08-01-57 Am)yamen sayedNo ratings yet

- SS-22 Forklift Safety Management Training - Materi PDFDocument54 pagesSS-22 Forklift Safety Management Training - Materi PDFAgung PramonoNo ratings yet

- Assessment For - RiggersDocument3 pagesAssessment For - RiggersShakeb RahmanNo ratings yet

- Side Boom TrainingDocument40 pagesSide Boom TrainingMauricio Bulla ValenciaNo ratings yet

- Chain&AccessoriesDocument57 pagesChain&AccessoriesAnonymous YggO6T6GzNo ratings yet

- BS en 13414-1 2003 PresentationDocument6 pagesBS en 13414-1 2003 PresentationAlbadeel Inspection & Conformity Co. ltd100% (1)

- ToolboxTalks D-D Ratio 041315 PDFDocument1 pageToolboxTalks D-D Ratio 041315 PDFkaniniuserNo ratings yet

- LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad Eyes Version 2 July 2015Document10 pagesLEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad Eyes Version 2 July 2015Ather AliNo ratings yet

- LEEA 032 Guide To Written Schemes Free VersionDocument7 pagesLEEA 032 Guide To Written Schemes Free VersionGaniyu100% (1)

- OSHA Man Basket User ManualDocument9 pagesOSHA Man Basket User Manualwalid EttihNo ratings yet

- REPORT Model of Wire RopesDocument32 pagesREPORT Model of Wire RopesalexremNo ratings yet

- Mobile Crane Operator Exam OutlineDocument1 pageMobile Crane Operator Exam OutlineHermon PakpahanNo ratings yet

- Shackle - Rejection CriteriaDocument1 pageShackle - Rejection CriteriaSaad GhouriNo ratings yet

- ASME B30.2 Gantry CranesDocument12 pagesASME B30.2 Gantry Cranesحسين عبدالله0% (1)

- Loler AcopDocument71 pagesLoler AcopMoheb BotrosNo ratings yet

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedNo ratings yet

- Iso 22915-1-2016Document16 pagesIso 22915-1-2016Mohamed KANENo ratings yet

- Osha 1910.180 Crawler, Locomotive and Truck Cranes PDFDocument79 pagesOsha 1910.180 Crawler, Locomotive and Truck Cranes PDFM. Henrry Guerreros SNo ratings yet

- Man Rider HoistsDocument2 pagesMan Rider Hoistsengmuhmud100% (1)

- Cold Stress - Toolbox TalksDocument2 pagesCold Stress - Toolbox TalksengmuhmudNo ratings yet

- Risks Associated With Building Maintenance UnitsDocument2 pagesRisks Associated With Building Maintenance UnitsengmuhmudNo ratings yet

- Man Rider HoistsDocument2 pagesMan Rider Hoistsengmuhmud100% (1)

- Yoke Test Weight BlockDocument1 pageYoke Test Weight BlockengmuhmudNo ratings yet

- Swim Sec.03 ISO 7000-1368: Inspection PointsDocument2 pagesSwim Sec.03 ISO 7000-1368: Inspection PointsengmuhmudNo ratings yet

- Api RP 8B / Astm E709Document1 pageApi RP 8B / Astm E709engmuhmudNo ratings yet

- Api 7K & ASTME 165E/E709Document1 pageApi 7K & ASTME 165E/E709engmuhmudNo ratings yet

- SWIM Sec.6 / SWIM Sec.3 Api RP 8B / Astm E709Document2 pagesSWIM Sec.6 / SWIM Sec.3 Api RP 8B / Astm E709engmuhmudNo ratings yet

- SWIM SEC.03, BS EN 12097, BS 7072: Inspection PointsDocument2 pagesSWIM SEC.03, BS EN 12097, BS 7072: Inspection PointsengmuhmudNo ratings yet

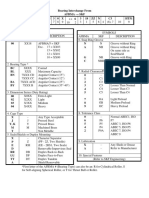

- Gi 7.030 Asme B30.16, Asme B30.7 BS 3243, BS 4898Document3 pagesGi 7.030 Asme B30.16, Asme B30.7 BS 3243, BS 4898engmuhmudNo ratings yet

- Vacon 100 HVAC Product BrochureDocument4 pagesVacon 100 HVAC Product Brochureknightfelix12No ratings yet

- Marantz 2245Document28 pagesMarantz 2245Jeff EdlundNo ratings yet

- MTO Rigging Equipment (Sling & Shackles) - BP Tangguh ProjectDocument4 pagesMTO Rigging Equipment (Sling & Shackles) - BP Tangguh ProjectokahertaberNo ratings yet

- Proforma Invoice: Seller/Exporter Invoice No. and DateDocument1 pageProforma Invoice: Seller/Exporter Invoice No. and DateESTEBAN CASTILLONo ratings yet

- Competency Based Curriculum NC3 AutomotiveDocument10 pagesCompetency Based Curriculum NC3 AutomotiveGilbert MendozaNo ratings yet

- SUN2000-330KTL-H1 Datasheet-LATAM-1102Document2 pagesSUN2000-330KTL-H1 Datasheet-LATAM-1102JOGmzNo ratings yet

- DTD154RFEDocument3 pagesDTD154RFEsivachariNo ratings yet

- Ic 7404Document4 pagesIc 7404Putri Rose Amanda PuriNo ratings yet

- Installation & Operation Manual: Series 340 BN/MB Btu TransmitterDocument28 pagesInstallation & Operation Manual: Series 340 BN/MB Btu TransmitterPhilippe RibeiroNo ratings yet

- Presentation For RiggingDocument18 pagesPresentation For RiggingRameese MuhammedNo ratings yet

- AFBMA Bearing Interchange PDFDocument1 pageAFBMA Bearing Interchange PDFaazznovskyNo ratings yet

- Heat-Shrink Terminations (HVT-Z-J/SJ) : For JCN Cables (15 - 35 KV)Document2 pagesHeat-Shrink Terminations (HVT-Z-J/SJ) : For JCN Cables (15 - 35 KV)Taacsa MatrizNo ratings yet

- VRV X & A (Catalogue)Document6 pagesVRV X & A (Catalogue)Stephanie GregasNo ratings yet

- GA55+-90 (2022) AC Pack Metric Dimension Drawing EN Antwerp 9820980032 Ed00Document1 pageGA55+-90 (2022) AC Pack Metric Dimension Drawing EN Antwerp 9820980032 Ed00Luis LabradorNo ratings yet

- Electric Car Drive Motor TrainerDocument2 pagesElectric Car Drive Motor Trainermanual imbNo ratings yet

- Design String Inverters ShcneiderDocument104 pagesDesign String Inverters ShcneiderDavid GarciaNo ratings yet

- l3n71b l4n71b E4n71b PDFDocument10 pagesl3n71b l4n71b E4n71b PDFHectorNo ratings yet

- TIER3 4.3L Generic Service Manual RADocument421 pagesTIER3 4.3L Generic Service Manual RASgly Zemog100% (1)

- HDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightDocument1 pageHDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightVallerynNo ratings yet

- E2 Plunger Pumps Revised 2015Document6 pagesE2 Plunger Pumps Revised 2015Muzammil Iqbal100% (1)

- 408-8906 Instruction Sheet RevBDocument3 pages408-8906 Instruction Sheet RevBBuild SolutionsNo ratings yet

- TMW 2600/21200 Medium Wave Transmitter S7HP: Diagnosis HelpDocument13 pagesTMW 2600/21200 Medium Wave Transmitter S7HP: Diagnosis HelpadiNo ratings yet

- Experiment 5Document3 pagesExperiment 5Farhana LisaNo ratings yet

- Drilling MachineDocument30 pagesDrilling MachineMSME Technology CentreNo ratings yet

- ARO-Expert Series-PD10P-1-Inch-Non-Metallic-Diaphragm-Pump-ManualDocument8 pagesARO-Expert Series-PD10P-1-Inch-Non-Metallic-Diaphragm-Pump-ManualArif Fatkhur RahmanNo ratings yet

- FIR-Engine of Volvo LoaderDocument1 pageFIR-Engine of Volvo LoaderCwsNo ratings yet