Professional Documents

Culture Documents

CMP E Type Explosive

CMP E Type Explosive

Uploaded by

Alif AnsharCopyright:

Available Formats

You might also like

- ISO 16290 - 2013 - FinalDraftDocument20 pagesISO 16290 - 2013 - FinalDraftCristiana OliveiraNo ratings yet

- Clothing Construction BookDocument172 pagesClothing Construction BookDebbie Bacalso95% (21)

- Forecasting Crude Oil Prices Using EviewsDocument5 pagesForecasting Crude Oil Prices Using EviewsNaba Kr MedhiNo ratings yet

- Developing of Nuclear Energy For Power Generation Under Malaysia's ETPDocument105 pagesDeveloping of Nuclear Energy For Power Generation Under Malaysia's ETPCheehoong YapNo ratings yet

- Ind Hub FinalDocument88 pagesInd Hub Final1mmahoney0% (1)

- North Sea DecomDocument1 pageNorth Sea DecomihsanNo ratings yet

- CareerguideDocument97 pagesCareerguidegrechenNo ratings yet

- PETRONAS Floating Liquefied Natural GasDocument9 pagesPETRONAS Floating Liquefied Natural GasDaniel Ismail100% (2)

- The Importance To Correctly Assess The Flammable Hazards During Design and OperationDocument25 pagesThe Importance To Correctly Assess The Flammable Hazards During Design and OperationMultindo Barra KaryaNo ratings yet

- RR 10-08Document30 pagesRR 10-08matinikki100% (1)

- U1146-Lost Communication With External Memory: Theory of OperationDocument7 pagesU1146-Lost Communication With External Memory: Theory of Operationkikin strong100% (1)

- IEC 60092-354 Electrical Installations in ShipsDocument7 pagesIEC 60092-354 Electrical Installations in ShipsAndrés Eduardo Ortiz CabezasNo ratings yet

- Full Report FDPDocument286 pagesFull Report FDPanip zahariNo ratings yet

- License To Supply Product/Service To Exploration and Oil/Gas Companies in MalaysiaDocument10 pagesLicense To Supply Product/Service To Exploration and Oil/Gas Companies in Malaysiaradzi amahasNo ratings yet

- Arcgis Exploration Framework Implementation A Petronas Approach FinalDocument29 pagesArcgis Exploration Framework Implementation A Petronas Approach FinalSpring DaysNo ratings yet

- Karasalihovic Sedlar Et Al EnglDocument9 pagesKarasalihovic Sedlar Et Al Englaayush007No ratings yet

- Petronas Media ResponseDocument5 pagesPetronas Media ResponseThe Vancouver SunNo ratings yet

- APPEX 2016 PetronasDocument18 pagesAPPEX 2016 PetronasDidiNo ratings yet

- Petroleum Safety Measures Act (PSMA) 1984Document38 pagesPetroleum Safety Measures Act (PSMA) 1984HnisjjNo ratings yet

- PETRONAS Activity Outlook 2018-2020Document34 pagesPETRONAS Activity Outlook 2018-2020SYED FADZIL SYED MOHAMEDNo ratings yet

- PETRONASAnnualReport2014 PDFDocument250 pagesPETRONASAnnualReport2014 PDFJessica LimNo ratings yet

- Seaharvest BrochureDocument6 pagesSeaharvest BrochurealaddinNo ratings yet

- Anchor Pattern Planning Chart TSM: 8 APPC7001Document1 pageAnchor Pattern Planning Chart TSM: 8 APPC7001sathiaselanpasskerenNo ratings yet

- FpsoDocument2 pagesFpsoankeshkatochNo ratings yet

- Training Report On Pipeline ND Dcs SystemDocument90 pagesTraining Report On Pipeline ND Dcs SystemNilesh KumarNo ratings yet

- A Project Report OnDocument73 pagesA Project Report OnskdbjfNo ratings yet

- Total Pms Scope of Work: Days Start Date End DateDocument6 pagesTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyNo ratings yet

- Kikeh Gas Pipeline System Project MalaysiaDocument4 pagesKikeh Gas Pipeline System Project MalaysiaRatih HSAINo ratings yet

- 71372-Successful Well Control in The Cantarell Field ApplyinDocument12 pages71372-Successful Well Control in The Cantarell Field ApplyinIván VelázquezNo ratings yet

- S-000-1654-012 Offshore Energy Isolation ProcedureDocument27 pagesS-000-1654-012 Offshore Energy Isolation ProcedureKharil Ashidi Abdul JabarNo ratings yet

- Azteca Milling 2-2Document12 pagesAzteca Milling 2-2api-301267735No ratings yet

- Practical Intrinsic Safety For Engineers and TechniciansDocument5 pagesPractical Intrinsic Safety For Engineers and TechniciansFathi MusaNo ratings yet

- Damar-A Jacket Lifting Study (By QP 2000)Document5 pagesDamar-A Jacket Lifting Study (By QP 2000)kiNo ratings yet

- Delloite Oil and Gas Reality Check 2015 PDFDocument32 pagesDelloite Oil and Gas Reality Check 2015 PDFAzik KunouNo ratings yet

- Slip and Cut Drilling Line. Number: 010 Date: December 5, 2002Document3 pagesSlip and Cut Drilling Line. Number: 010 Date: December 5, 2002Emre CengizNo ratings yet

- Hand OverDocument1 pageHand OvervelmuruganrahulNo ratings yet

- Technipfmc Umbilicals BrochureDocument7 pagesTechnipfmc Umbilicals Brochurerob.careyNo ratings yet

- Lecture Note 11-Production and FacilitiesDocument59 pagesLecture Note 11-Production and FacilitiesMOHAMAD IJAM SIREGAR BIN MULIA MoeNo ratings yet

- Enppi Profile SummaryDocument38 pagesEnppi Profile SummarySijo XaviarNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- OffshoreSafety After Deepwater ArticleDocument124 pagesOffshoreSafety After Deepwater ArticlemashanghNo ratings yet

- 2018 Brochure Decommissioning and Abandonment SummitDocument11 pages2018 Brochure Decommissioning and Abandonment SummitluciannuNo ratings yet

- FPS HseDocument313 pagesFPS Hseavinash-mokashiNo ratings yet

- Caparo BrochureDocument32 pagesCaparo Brochurecetc qatarNo ratings yet

- ABS Guide For Enhanced Fire Protection ArrangementsDocument100 pagesABS Guide For Enhanced Fire Protection ArrangementsIsa KumNo ratings yet

- Off Shore Drilling NotesDocument15 pagesOff Shore Drilling NotesAamir LokhandwalaNo ratings yet

- BG Group PLCDocument144 pagesBG Group PLCguzman87No ratings yet

- OCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsDocument3 pagesOCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsWeR1 Consultants Pte LtdNo ratings yet

- Petronas Besar ProjectDocument12 pagesPetronas Besar ProjectMarlon MoncadaNo ratings yet

- 3500-25 Enhanced Keyphasor Module Datasheet - 141532Document10 pages3500-25 Enhanced Keyphasor Module Datasheet - 141532Ali HadiNo ratings yet

- Turbidity Meter Lutron TU-2016Document15 pagesTurbidity Meter Lutron TU-2016Ahmad Atsari SujudNo ratings yet

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Document38 pagesNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoNo ratings yet

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDocument5 pagesMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNo ratings yet

- 220295-AI R0 Commercial ProposalDocument1 page220295-AI R0 Commercial ProposalRoger GracieNo ratings yet

- Petronas - SWECs External 30092013 - SERVICESDocument41 pagesPetronas - SWECs External 30092013 - SERVICESAbdulsani3357No ratings yet

- Deep7 - Electrically Traced Pipes PDFDocument16 pagesDeep7 - Electrically Traced Pipes PDFNicolasNo ratings yet

- Chevron Annual Report SupplementDocument68 pagesChevron Annual Report SupplementLaurentiu CiobotaricaNo ratings yet

- gp860101 ComDocument38 pagesgp860101 Comfahimidrus1No ratings yet

- PETRONAS Hydraulic Series v2. 23-05-2016Document4 pagesPETRONAS Hydraulic Series v2. 23-05-2016Roter DiamNo ratings yet

- Balancing Petroleum Policy: Toward Value, Sustainability, and SecurityFrom EverandBalancing Petroleum Policy: Toward Value, Sustainability, and SecurityNo ratings yet

- CMP E Type ExplosiveDocument2 pagesCMP E Type ExplosivetungNo ratings yet

- CMP E Type ExplosiveDocument2 pagesCMP E Type ExplosiveJorge Lazo GonzalesNo ratings yet

- CMP PXSS2KDocument2 pagesCMP PXSS2Kdeckard.kim10No ratings yet

- CMP Tmc2x ResinDocument2 pagesCMP Tmc2x ResinMohamed GamalNo ratings yet

- Resume Update.23Document1 pageResume Update.23Wong Chung MengNo ratings yet

- Lead TrainerDocument1 pageLead TrainerWong Chung MengNo ratings yet

- Final TranscriptDocument1 pageFinal TranscriptWong Chung MengNo ratings yet

- DE-F-134 Public Training Request FormDocument1 pageDE-F-134 Public Training Request FormWong Chung MengNo ratings yet

- Parker 2valve ManifoldDocument3 pagesParker 2valve ManifoldWong Chung MengNo ratings yet

- Equipment PictureDocument1 pageEquipment PictureWong Chung MengNo ratings yet

- Developing Public Speaking SkillsDocument3 pagesDeveloping Public Speaking SkillsWong Chung MengNo ratings yet

- Essay-Pros and Cons of Leaving SchoolDocument1 pageEssay-Pros and Cons of Leaving SchoolWong Chung MengNo ratings yet

- Cable Cross LayoutDocument4 pagesCable Cross LayoutWong Chung MengNo ratings yet

- Detective Datasheet For WebDocument4 pagesDetective Datasheet For WebWong Chung MengNo ratings yet

- A694a694 Carbon Alloy Steel Forging For Pipe Flanges FittingDocument3 pagesA694a694 Carbon Alloy Steel Forging For Pipe Flanges FittingWong Chung MengNo ratings yet

- M07664 Detective User Manual Iss 7 GB 120618Document48 pagesM07664 Detective User Manual Iss 7 GB 120618Wong Chung MengNo ratings yet

- Comfort, Trust,: Respirators For Your WorkplaceDocument8 pagesComfort, Trust,: Respirators For Your WorkplaceWong Chung MengNo ratings yet

- Moisture Tolerant Protective Barrier Coating: Belzona® 5831Document2 pagesMoisture Tolerant Protective Barrier Coating: Belzona® 5831Wong Chung MengNo ratings yet

- Multi-Word Verbs: Learner Problems: by Vanessa SteeleDocument1 pageMulti-Word Verbs: Learner Problems: by Vanessa SteeleWong Chung MengNo ratings yet

- Smith Fibercast Green Thread Fiberglass Pipe Piping General SpecificationsDocument2 pagesSmith Fibercast Green Thread Fiberglass Pipe Piping General SpecificationsWong Chung MengNo ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- All Low VOC: Product GuideDocument16 pagesAll Low VOC: Product GuideWong Chung MengNo ratings yet

- Hi-Force Hydrostatic PDFDocument6 pagesHi-Force Hydrostatic PDFWong Chung MengNo ratings yet

- Accessories Cosasco Two Inch SystemDocument4 pagesAccessories Cosasco Two Inch SystemWong Chung MengNo ratings yet

- Chapter 1: (Network Security) : PreambleDocument21 pagesChapter 1: (Network Security) : PreambleArras DaouNo ratings yet

- 20462D ENU CompanionDocument194 pages20462D ENU CompanionjiindooNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- 45R-08 Scheduling Claims Protection MethodsDocument10 pages45R-08 Scheduling Claims Protection MethodsHatem HejaziNo ratings yet

- Hello Kitty - The Iconic Japanese BrandDocument5 pagesHello Kitty - The Iconic Japanese BrandMaya SalmanNo ratings yet

- Kuliah Materi Budaya OrganisasiDocument19 pagesKuliah Materi Budaya OrganisasiTito YustiawanNo ratings yet

- Signal Cable Connection To Input/Output Modules (For FIO)Document15 pagesSignal Cable Connection To Input/Output Modules (For FIO)cepia sobayhakiNo ratings yet

- Computer Notes 1 Year Chapter # 1 Short Questions (According To Alp)Document4 pagesComputer Notes 1 Year Chapter # 1 Short Questions (According To Alp)Nb KashifNo ratings yet

- Product Overview: Agilent 86130A Bitalyzer Enhanced Error Analysis OptionsDocument2 pagesProduct Overview: Agilent 86130A Bitalyzer Enhanced Error Analysis OptionsRowell DizonNo ratings yet

- Topic - Child Protection Act: Submitted To Lovely Professional UniversityDocument25 pagesTopic - Child Protection Act: Submitted To Lovely Professional UniversitySahil GargNo ratings yet

- X4 7300 Sell Sheet PDFDocument2 pagesX4 7300 Sell Sheet PDFaislandesouza23No ratings yet

- Principles of Marketing Q2 Module 8 Grade 11Document27 pagesPrinciples of Marketing Q2 Module 8 Grade 11Lyn-lyn Suyom-BitosNo ratings yet

- Raspberry Pi Pico GuideDocument131 pagesRaspberry Pi Pico Guidefpralus100% (1)

- Quality Mark Guideline 0Document50 pagesQuality Mark Guideline 0Asma DahaboNo ratings yet

- Rob 01.10.2021Document10 pagesRob 01.10.2021RITESHNo ratings yet

- Referencia M PDFDocument1,008 pagesReferencia M PDFrobertocarlosricciNo ratings yet

- Products Catalogue: 9F., T2 Building Green Centre, Furong Road, Changsha, ChinaDocument6 pagesProducts Catalogue: 9F., T2 Building Green Centre, Furong Road, Changsha, ChinaSadiq TurkiNo ratings yet

- MPOWA Web3Foundation POC ProjectDocument13 pagesMPOWA Web3Foundation POC ProjectKonstantinos PappasNo ratings yet

- TMP Nedjo Jarsao For PrintDocument20 pagesTMP Nedjo Jarsao For PrintGenetNo ratings yet

- Sample Space (SS) - The Set of All Possible Outcomes in An ExperimentDocument5 pagesSample Space (SS) - The Set of All Possible Outcomes in An ExperimentDypsy Pearl A. Pantinople0% (1)

- Nebraska Medical Marijuana LawsuitDocument13 pagesNebraska Medical Marijuana LawsuitMarijuana MomentNo ratings yet

- Identifying Fake Products Through A Barcode-Based Blockchain SystemDocument8 pagesIdentifying Fake Products Through A Barcode-Based Blockchain SystemVelocity VivekNo ratings yet

- BAYE's TheormDocument27 pagesBAYE's TheormPravalika ReddyNo ratings yet

- Destination Marketing On The WebDocument75 pagesDestination Marketing On The Webmanolis_psarrosNo ratings yet

- Samier AC 2017 Islamic Public Administration Tradition Historical TheoreticalDocument19 pagesSamier AC 2017 Islamic Public Administration Tradition Historical TheoreticalJunaid AliNo ratings yet

- Chartered Institution and GOCC, DefinedDocument13 pagesChartered Institution and GOCC, DefinedZaira Gem Gonzales100% (1)

CMP E Type Explosive

CMP E Type Explosive

Uploaded by

Alif AnsharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMP E Type Explosive

CMP E Type Explosive

Uploaded by

Alif AnsharCopyright:

Available Formats

SCAN FOR INSTALLATION VIDEOS

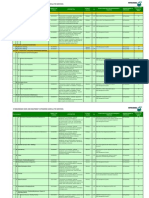

TECHNICAL DATA INSTALLATION INSTRUCTIONS

CABLE GLAND TYPE : E** Family of Glands Installation should only be performed by a competent person using

INGRESS PROTECTION : IP66, (IP67, IP68 available upon request) the correct tools. Read all instructions before beginning installation.

PROCESS CONTROL SYSTEM : ISO 9001

: ISO / IEC 80079-34:2001 INSTALLATION INSTRUCTIONS FOR E TYPE

EXPLOSIVE ATMOSPHERES CLASSIFICATION

ATEX CERTIFICATION No

ATEX CERTIFICATION CODE

: CML 18ATEX1324X, CML 18ATEX4316X

: ^ II 2G, II 1D, Ex db IIC Gb, Ex eb IIC Gb, Ex ta IIIC Da, ^ II 3G Ex nR IIC Gc,

CABLE GLANDS IN EX ATMOSPHERES

^ I M2, Ex db I Mb, Ex eb I Mb

IECEx CERTIFICATION No : IECEx CML 18.0181X

IECEx CERTIFICATION CODE : Ex db IIC Gb, Ex eb IIC Gb, Ex nR IIC Gc, Ex ta IIIC Da, Ex db I Mb, Ex eb I Mb

cCSAus CERTIFICATION No

CSA us CERTIFICATION CODE*

: 1310517X

: Class II Div 2, Groups E,F and G, Class III,

INCORPORATING EU DECLARATION OF CONFORMITY TO DIRECTIVE [2014/34/EU]

Class I Zone 1 AEx e II, Class I Zone 2 AEx nR II, Enclosure Type 4X E1FW - SWA AWA

c CSA CERTIFICATION CODE : Class I, Div 2, Groups A,B,C and D, Class II Div 2, Groups E,F and G, Class III,

Ex d IIC, Ex e II, Ex nR II, Enclosure Type 4X E2FW - SWA AWA for lead sheathed cable

*E** can be used in Class 1, Division 2 Locations for non-explosionproof applications in accordance with Article 501 of the NEC Code E1FX - Braid, Tape, etc Armour

E2FX - Braid, Tape, etc Armour for lead sheathed

CERTIFICATION CONDITIONS

ATEX & 1. The E** Type cable glands shall not be used to terminate on braided cables in group I applications.

cable

IECEx 2. The glands, when used for terminating braided cables, are only suitable for fixed installations. Cables must be effectively clamped to E1FU - Universal Gland for all Armour Types

prevent pulling or twisting.

3. The interface between a cable entry device and its associated enclosure / cable entry will require additional sealing to achieve ingress

E2FU - Universal Gland for all Armour Types

protection (IP) ratings higher than IP54. The minimum protection level is IP54 for explosive gas atmospheres and IP6X for explosive with lead sheathed cable

dust atmospheres. Parallel threads (and tapered threads when using a non-threaded entry) require a CMP sealing washer or integral

O-ring face seal (where available) to maintain IP66, 67 and 68 (when applicable). It is the installers responsibility to ensure the IP Outer Seal Tightening Guide

rating is maintained at the interface. GLAND SIZE

Number of turns

Note: When fitted to a threaded entry, all tapered threads will automatically provide an ingress protection rating of IP66. 20S16 20S 20 25S 25 32 40 50S 50 63S 63 75S 75

to tighten

4. Cable Glands are not intended to be repaired. If the product is damaged, the product is to be replaced. CABLE DIAMETER

5. A CMP earth tag should be used when it is necessary to provide an earth bond connection. CMP earth tags have been independently 0.5 13.2 15.9 20.9 22.0 26.2 33.9

tested to comply with Category B rating specified in IEC 62444 (no ratings stated in IEC 60079-0). Ratings are shown in the associated 1 12.5 15.3 20.0 21.2 25.4 32.9 40.4 46.7 52.8 59.2 65.9 72.1 78.5

table. CMP earth tags slip over the cable gland or accessory entry thread from inside/outside the enclosure and must be secured with a 1.5 11.9 14.7 19.0 20.4 24.6 31.9 39.0 45.4 51.4 57.7 64.6 70.6 77.2

locknut (if fitted internally). 2 11.2 14.2 18.1 19.6 23.8 30.8 37.6 44.1 50.0 56.2 63.4 69.2 75.9

6. Metric entry threads comply with ISO 965-1 and ISO 965-3 with a 6g tolerance as required by IEC 60079-1:2014. The CMP standard 2.5 10.5 13.6 17.2 18.8 23.0 29.8 36.2 42.9 48.7 54.7 62.1 67.7 74.6

metric thread pitch is 1.5mm for threads up to M75, and 2.0mm from M90 and above. Special thread pitches between 0.7 – 2.0mm are 3 9.8 13.0 16.2 18.0 22.2 28.8 34.8 41.6 47.3 53.2 60.9 66.3 73.3

available on all products on request. See certificate for details of other thread types. NPT threads are in accordance with ASME B1.20.1- 3.5 9.2 12.4 15.3 17.2 21.4 27.8 33.5 40.3 45.9 51.6 59.6 64.8 71.9

2013 gauging to Cl 8.1 for external threads. For details of other thread types refer to IECEx certificate.

4 8.5 11.8 14.4 16.4 20.6 26.8 32.1 39.0 44.5 50.1 58.4 63.4 70.6

7. The enclosure surface finish must be smooth and flat to facilitate sealing with an O-ring or Entry Thread Sealing Washer for the

4.5 7.8 11.2 13.4 15.6 19.8 25.7 30.7 37.8 43.2 48.6 57.1 61.9 69.3

required IP rating.

5 7.1 10.7 12.5 14.8 19.0 24.7 29.3 36.5 41.8 47.1 55.9 60.5 68.0

8. Enclosure will need to be sufficiently strong to support the cable and cable gland assembly. Enclosure entries shall be perpendicular.

Any draft angles from the casting/moulding process should have a perpendicular flat spot machined to facilitate sealing with an O-ring 5.5 6.5 10.1 12.0 14.0 18.2 23.7 27.9 35.2 40.4 45.6 54.6 59.0 66.7

or Entry Thread Sealing Washer. 6 5.8 9.5

9. CMP Products recommends when using the cable gland with a through-hole, the hole must be circular, free of burrs and the diameter

no larger than 0.7mm above the thread major diameter. A suitable CMP Products locknut shall be used to secure the product. See CMP Cable Gland Selection Table

Products catalogue for locknut options. Available Entry Threads Armour Range †

Cable Overall Combined Ordering

(Alternate Metric Thread Lengths Available) Across Across

CSA us 1. Cable gland connectors material may be of brass, aluminum or stainless steel. Cable

Bedding Cable Grooved Stepped Flats Corners

Reference Cable

2. Connectors with metric entry threads are only suitable for Areas Classified in ZONES unless fitted with an approved Metric to NPT Standard Option Diameter Diameter Cone (X) Cone (W) Protrusion (*Brass Metric) Gland

Gland Shroud

Length Weight

thread conversion adaptor. Size

Thread Length

Thread

Ordering (Kgs)

3. According to US (NEC) wiring method for the types of cables that can be used in Class I Zone 1 and 2 Classified Areas, should be in Metric NPT Length NPT Min Max Min Max Min Max Min Max Max Max Size Type

(Metric) Suffix

(NPT)

accordance of NFPA-70 installation wiring method restrictions.

c CSA 20S16 M20 15.0 1/2” 19.9 3/4” 3.1 8.6 6.1 13.1 0.3 1.0 0.8 1.25 24.0 26.4 72.5 20S16 E1FU 1RA PVC04 0.16

1. Cable gland connectors’ material may be of brass, aluminium or stainless steel. 20S M20 15.0 1/2” 19.9 3/4” 6.1 11.6 9.5 15.9 0.3 1.0 0.8 1.25 24.0 26.4 70.0 20S E1FU 1RA PVC04 0.15

2. These glands are not suitable for use with flameproof enclosures installed in Group IIC atmospheres, which have a volume greater than 20 M20 15.0 1/2” 19.9 3/4” 6.5 13.9 12.5 20.9 0.4 1.0 0.8 1.25 30.5 33.6 73.0 20 E1FU 1RA PVC06 0.21

2000 cc (2 Litre). 25S M25 15.0 3/4” 20.2 1” 11.1 19.9 14.0 22.0 0.4 1.2 1.25 1.6 37.5 41.3 89.0 25S E1FU 1RA PVC09 0.33

3. These Glands are for use with Certified Marine Shipboard metal braided cables constructed according to CSA Std. 245 and IEEE45/ 25 M25 15.0 3/4” 20.2 1” 11.1 19.9 18.2 26.2 0.4 1.2 1.25 1.6 37.5 41.3 89.0 25 E1FU 1RA PVC09 0.33

IEC600092-353 Standards, or Certified equivalent), for use on Shipboards and Offshore Rigs/platforms only. 32 M32 15.0 1” 25.0 1 1/4” 17.0 26.2 23.7 33.9 0.4 1.2 1.6 2.0 46.0 50.6 86.0 32 E1FU 1RA PVC11 0.43

4. “E**” cable gland connectors when installed into Class I, Division 2 Classified Areas, are not suitable to be interfaced with an 40 M40 15.0 1 1/4” 25.6 1 1/2” 22.0 32.1 27.9 40.4 0.4 1.6 1.6 2.0 55.0 60.5 90.0 40 E1FU 1RA PVC15 0.62

explosion proof enclosure containing arcing and sparking devices, unless installed in conjunction with an approved explosion proof 50S M50 15.0 1 1/2” 26.1 2” 29.5 38.1 35.2 46.7 0.4 1.6 2.0 2.5 60.0 66.0 91.0 50S E1FU 1RA PVC18 0.75

sealing fitting. 50 M50 15.0 2” 26.9 2 1/2” 35.6 44.0 40.4 53.0 0.6 1.6 2.0 2.5 70.1 77.1 95.0 50 E1FU 1RA PVC21 0.95

63S M63 15.0 2” 26.9 2 1/2” 40.1 49.9 45.6 59.4 0.6 1.6 2.0 2.5 75.0 82.5 102.0 63S E1FU 1RA PVC23 1.34

63 M63 15.0 2 1/2” 39.9 3” 47.2 55.9 54.6 65.8 0.6 1.6 2.0 2.5 80.0 88.0 104.0 63 E1FU 1RA PVC25 1.34

ACCESSORIES Short Circuit Ratings Symmetrical Fault Current 75S M75 15.0 2 1/2” 39.9 3” 52.8 61.9 59.0 72.0 0.6 1.6 2.0 2.5 90.0 99.0 115.0 75S E1FU 1RA PVC28 2.11

CMP Earth Tag Size

The following accessories are available from CMP Products, as optional extras, (kA) for 1 second 75 M75 15.0 3” 41.5 3 1/2” 59.1 67.9 66.7 78.4 0.6 1.6 2.5 3.0 100.0 110.0 117.0 75 E1FU 1RA PVC30 2.42

to assist with fixing, sealing and earthing: Locknut, Earth Tag, Serrated Washer, 20 3.06 90 M90 24.0 3 1/2” 42.8 4” 66.6 78.6 76.2 90.3 0.8 1.6 3.15 4.0 114.3 125.4 147.0 90 E1FU 1RA PVC32 4.21

Entry Thread (I.P.) Sealing Washer, Shroud 25 4.06 100 M100 24.0 3 1/2” 42.8 4” 76.0 90.9 86.1 101.4 0.8 1.6 3.15 4.0 123.0 135.3 140.0 100 E1FU 1RA LSF33 4.45

32 5.40 115 M115 24.0 4” 44.0 5” 86.0 97.9 101.5 110.2 0.8 1.6 3.15 4.0 133.4 146.7 162.0 115 E1FU 1RA LSF34 6.19

40 7.20 130 M130 24.0 5” 46.8 - 97.0 114.9 110.2 123.2 0.8 1.6 3.15 4.0 152.4 167.6 174.0 130 E1FU 1RA LSF35 8.34

50 10.40 Dimensions are displayed in millimetres unless otherwise stated

63 10.40 Order codes shown are for E1FU glands - For e.g. E1FWD glands substitute E1FWD for E1FU - e.g. 20E1FWD1RA

75 10.40 Stepped cone is for single wire armour and grooved cone is for all other armours

CMP Products Limited on its sole responsibility declares that the equipment referred to herein conforms to the requirements of the ATEX Directive 2014/34/EU and the FI407

following standards: - EN60079-0:2018, EN60079-1:2014, EN60079-7:2015, EN60079-15:2017, EN60079-31:2013, BS6121:1989, EN62444:2013 Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS Certification Revision Date

David Willcock – Certification Engineer (Authorised Person) Tel: +44 191 265 7411 • Fax: +44 1670 715 646

CMP Products Limited. Cramlington, NE23 1WH, UK E-Mail: customerservices@cmp-products.co.uk • Web: www.cmp-products.com IFS 23 05/19

15 April 2019

ATEX / IECEx 12 04/19

2776 www.cmp-products.com CSA 11 -

INSTALLATION INSTRUCTIONS FOR E TYPE CABLE GLANDS IN EX ATMOSPHERES 4. Locate the Armour Cone (3) into its recess in the Main Item (2). (For E1FU and E2FU variants, make sure the correct side of

the cone is outermost - grooved for braid/tape armour and stepped for SWA). Pass the cable through sub-assembly “A” until the

CABLE GLAND COMPONENTS - It is not necessary to dismantle the cable gland any further than illustrated below armour engaged with the cone. Spread the armour evenly around the cone.

Universal Cone

1. Entry Component (E1FU, E2FU) use

stepped side for SWA

SUB ASSEMBLY A and grooved side for SUB ASSEMBLY B

2. Main Item all other armours

3. Detachable Armour Cone

4. AnyWay Clamping Ring

5. Body

6. Outer Seal Nut 1. 2. 3. 4. 5. 6.

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION 5. While continuing to push the cable forward to maintain contact between the armour and the cone, tighten the Main Item (2)

until the inner seal makes contact with the cable inner sheath (heavier resistance is felt at this point). Tighten a further full turn.

1. If required fit shroud over the cable outer sheath; NOTE: The earthing device on E2* type glands will automatically engage the lead sheath.

Prepare the cable by stripping back the cable outer sheath and armour to suit the equipment geometry.

Expose the armour by stripping back the outer sheath further using the table below as a guide.

If applicable remove any tapes or wrappings to expose cable inner sheath.

Cable Strip Tape armour should be further

Length “L”

prepared by cutting the tape into

strips as shown below:

6. Hold the Main Item (2) with a spanner and tighten sub-assembly “B” onto sub-assembly “A” using a spanner until all available

threads are used.

CABLE GLAND SIZE 20S/16, 20S, 20 25S, 25, 32, 40 50S, 50, 63S, 63 75S, 75, 90, 100, 115, 130

CABLE STRIP LENGTH “L” 12mm 15mm 18mm 20mm

2. Separate the gland into two sub-assemblies “A & B”. Ensuring that the Outer Seal Nut (6) is relaxed, pass sub-assembly “B” over

the cable outer sheath and armour followed by the “AnyWay” clamping ring (4).

Note: On maximum size cables the clamping ring may 7. Only using finger pressure, tighten the outer seal nut assembly (6) until light resist-

only pass over the armour. ance to tightening is met.

Then either use the outer seal tightening guide tape or table on the rear of the page to

determine how much further to tighten the seal using a spanner (using the outer seal

tightening guide is recomended).

3. Ensure that the inner seal is relaxed by slackening the Main Item (2). Secure sub-assembly “A” into the equipment either by

screwing the Entry Item (1) into a threaded hole or by securing it in a clearance hole using a locknut as applicable. Wrap the outer seal tightening guide tape around the cable to show the amount of

spanner turns needed (as shown here). Make sure the correct side of the outer seal

tightening guide tape is used depending on the cable gland size.

www.cmp-products.com www.cmp-products.com

You might also like

- ISO 16290 - 2013 - FinalDraftDocument20 pagesISO 16290 - 2013 - FinalDraftCristiana OliveiraNo ratings yet

- Clothing Construction BookDocument172 pagesClothing Construction BookDebbie Bacalso95% (21)

- Forecasting Crude Oil Prices Using EviewsDocument5 pagesForecasting Crude Oil Prices Using EviewsNaba Kr MedhiNo ratings yet

- Developing of Nuclear Energy For Power Generation Under Malaysia's ETPDocument105 pagesDeveloping of Nuclear Energy For Power Generation Under Malaysia's ETPCheehoong YapNo ratings yet

- Ind Hub FinalDocument88 pagesInd Hub Final1mmahoney0% (1)

- North Sea DecomDocument1 pageNorth Sea DecomihsanNo ratings yet

- CareerguideDocument97 pagesCareerguidegrechenNo ratings yet

- PETRONAS Floating Liquefied Natural GasDocument9 pagesPETRONAS Floating Liquefied Natural GasDaniel Ismail100% (2)

- The Importance To Correctly Assess The Flammable Hazards During Design and OperationDocument25 pagesThe Importance To Correctly Assess The Flammable Hazards During Design and OperationMultindo Barra KaryaNo ratings yet

- RR 10-08Document30 pagesRR 10-08matinikki100% (1)

- U1146-Lost Communication With External Memory: Theory of OperationDocument7 pagesU1146-Lost Communication With External Memory: Theory of Operationkikin strong100% (1)

- IEC 60092-354 Electrical Installations in ShipsDocument7 pagesIEC 60092-354 Electrical Installations in ShipsAndrés Eduardo Ortiz CabezasNo ratings yet

- Full Report FDPDocument286 pagesFull Report FDPanip zahariNo ratings yet

- License To Supply Product/Service To Exploration and Oil/Gas Companies in MalaysiaDocument10 pagesLicense To Supply Product/Service To Exploration and Oil/Gas Companies in Malaysiaradzi amahasNo ratings yet

- Arcgis Exploration Framework Implementation A Petronas Approach FinalDocument29 pagesArcgis Exploration Framework Implementation A Petronas Approach FinalSpring DaysNo ratings yet

- Karasalihovic Sedlar Et Al EnglDocument9 pagesKarasalihovic Sedlar Et Al Englaayush007No ratings yet

- Petronas Media ResponseDocument5 pagesPetronas Media ResponseThe Vancouver SunNo ratings yet

- APPEX 2016 PetronasDocument18 pagesAPPEX 2016 PetronasDidiNo ratings yet

- Petroleum Safety Measures Act (PSMA) 1984Document38 pagesPetroleum Safety Measures Act (PSMA) 1984HnisjjNo ratings yet

- PETRONAS Activity Outlook 2018-2020Document34 pagesPETRONAS Activity Outlook 2018-2020SYED FADZIL SYED MOHAMEDNo ratings yet

- PETRONASAnnualReport2014 PDFDocument250 pagesPETRONASAnnualReport2014 PDFJessica LimNo ratings yet

- Seaharvest BrochureDocument6 pagesSeaharvest BrochurealaddinNo ratings yet

- Anchor Pattern Planning Chart TSM: 8 APPC7001Document1 pageAnchor Pattern Planning Chart TSM: 8 APPC7001sathiaselanpasskerenNo ratings yet

- FpsoDocument2 pagesFpsoankeshkatochNo ratings yet

- Training Report On Pipeline ND Dcs SystemDocument90 pagesTraining Report On Pipeline ND Dcs SystemNilesh KumarNo ratings yet

- A Project Report OnDocument73 pagesA Project Report OnskdbjfNo ratings yet

- Total Pms Scope of Work: Days Start Date End DateDocument6 pagesTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyNo ratings yet

- Kikeh Gas Pipeline System Project MalaysiaDocument4 pagesKikeh Gas Pipeline System Project MalaysiaRatih HSAINo ratings yet

- 71372-Successful Well Control in The Cantarell Field ApplyinDocument12 pages71372-Successful Well Control in The Cantarell Field ApplyinIván VelázquezNo ratings yet

- S-000-1654-012 Offshore Energy Isolation ProcedureDocument27 pagesS-000-1654-012 Offshore Energy Isolation ProcedureKharil Ashidi Abdul JabarNo ratings yet

- Azteca Milling 2-2Document12 pagesAzteca Milling 2-2api-301267735No ratings yet

- Practical Intrinsic Safety For Engineers and TechniciansDocument5 pagesPractical Intrinsic Safety For Engineers and TechniciansFathi MusaNo ratings yet

- Damar-A Jacket Lifting Study (By QP 2000)Document5 pagesDamar-A Jacket Lifting Study (By QP 2000)kiNo ratings yet

- Delloite Oil and Gas Reality Check 2015 PDFDocument32 pagesDelloite Oil and Gas Reality Check 2015 PDFAzik KunouNo ratings yet

- Slip and Cut Drilling Line. Number: 010 Date: December 5, 2002Document3 pagesSlip and Cut Drilling Line. Number: 010 Date: December 5, 2002Emre CengizNo ratings yet

- Hand OverDocument1 pageHand OvervelmuruganrahulNo ratings yet

- Technipfmc Umbilicals BrochureDocument7 pagesTechnipfmc Umbilicals Brochurerob.careyNo ratings yet

- Lecture Note 11-Production and FacilitiesDocument59 pagesLecture Note 11-Production and FacilitiesMOHAMAD IJAM SIREGAR BIN MULIA MoeNo ratings yet

- Enppi Profile SummaryDocument38 pagesEnppi Profile SummarySijo XaviarNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- OffshoreSafety After Deepwater ArticleDocument124 pagesOffshoreSafety After Deepwater ArticlemashanghNo ratings yet

- 2018 Brochure Decommissioning and Abandonment SummitDocument11 pages2018 Brochure Decommissioning and Abandonment SummitluciannuNo ratings yet

- FPS HseDocument313 pagesFPS Hseavinash-mokashiNo ratings yet

- Caparo BrochureDocument32 pagesCaparo Brochurecetc qatarNo ratings yet

- ABS Guide For Enhanced Fire Protection ArrangementsDocument100 pagesABS Guide For Enhanced Fire Protection ArrangementsIsa KumNo ratings yet

- Off Shore Drilling NotesDocument15 pagesOff Shore Drilling NotesAamir LokhandwalaNo ratings yet

- BG Group PLCDocument144 pagesBG Group PLCguzman87No ratings yet

- OCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsDocument3 pagesOCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsWeR1 Consultants Pte LtdNo ratings yet

- Petronas Besar ProjectDocument12 pagesPetronas Besar ProjectMarlon MoncadaNo ratings yet

- 3500-25 Enhanced Keyphasor Module Datasheet - 141532Document10 pages3500-25 Enhanced Keyphasor Module Datasheet - 141532Ali HadiNo ratings yet

- Turbidity Meter Lutron TU-2016Document15 pagesTurbidity Meter Lutron TU-2016Ahmad Atsari SujudNo ratings yet

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Document38 pagesNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoNo ratings yet

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDocument5 pagesMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNo ratings yet

- 220295-AI R0 Commercial ProposalDocument1 page220295-AI R0 Commercial ProposalRoger GracieNo ratings yet

- Petronas - SWECs External 30092013 - SERVICESDocument41 pagesPetronas - SWECs External 30092013 - SERVICESAbdulsani3357No ratings yet

- Deep7 - Electrically Traced Pipes PDFDocument16 pagesDeep7 - Electrically Traced Pipes PDFNicolasNo ratings yet

- Chevron Annual Report SupplementDocument68 pagesChevron Annual Report SupplementLaurentiu CiobotaricaNo ratings yet

- gp860101 ComDocument38 pagesgp860101 Comfahimidrus1No ratings yet

- PETRONAS Hydraulic Series v2. 23-05-2016Document4 pagesPETRONAS Hydraulic Series v2. 23-05-2016Roter DiamNo ratings yet

- Balancing Petroleum Policy: Toward Value, Sustainability, and SecurityFrom EverandBalancing Petroleum Policy: Toward Value, Sustainability, and SecurityNo ratings yet

- CMP E Type ExplosiveDocument2 pagesCMP E Type ExplosivetungNo ratings yet

- CMP E Type ExplosiveDocument2 pagesCMP E Type ExplosiveJorge Lazo GonzalesNo ratings yet

- CMP PXSS2KDocument2 pagesCMP PXSS2Kdeckard.kim10No ratings yet

- CMP Tmc2x ResinDocument2 pagesCMP Tmc2x ResinMohamed GamalNo ratings yet

- Resume Update.23Document1 pageResume Update.23Wong Chung MengNo ratings yet

- Lead TrainerDocument1 pageLead TrainerWong Chung MengNo ratings yet

- Final TranscriptDocument1 pageFinal TranscriptWong Chung MengNo ratings yet

- DE-F-134 Public Training Request FormDocument1 pageDE-F-134 Public Training Request FormWong Chung MengNo ratings yet

- Parker 2valve ManifoldDocument3 pagesParker 2valve ManifoldWong Chung MengNo ratings yet

- Equipment PictureDocument1 pageEquipment PictureWong Chung MengNo ratings yet

- Developing Public Speaking SkillsDocument3 pagesDeveloping Public Speaking SkillsWong Chung MengNo ratings yet

- Essay-Pros and Cons of Leaving SchoolDocument1 pageEssay-Pros and Cons of Leaving SchoolWong Chung MengNo ratings yet

- Cable Cross LayoutDocument4 pagesCable Cross LayoutWong Chung MengNo ratings yet

- Detective Datasheet For WebDocument4 pagesDetective Datasheet For WebWong Chung MengNo ratings yet

- A694a694 Carbon Alloy Steel Forging For Pipe Flanges FittingDocument3 pagesA694a694 Carbon Alloy Steel Forging For Pipe Flanges FittingWong Chung MengNo ratings yet

- M07664 Detective User Manual Iss 7 GB 120618Document48 pagesM07664 Detective User Manual Iss 7 GB 120618Wong Chung MengNo ratings yet

- Comfort, Trust,: Respirators For Your WorkplaceDocument8 pagesComfort, Trust,: Respirators For Your WorkplaceWong Chung MengNo ratings yet

- Moisture Tolerant Protective Barrier Coating: Belzona® 5831Document2 pagesMoisture Tolerant Protective Barrier Coating: Belzona® 5831Wong Chung MengNo ratings yet

- Multi-Word Verbs: Learner Problems: by Vanessa SteeleDocument1 pageMulti-Word Verbs: Learner Problems: by Vanessa SteeleWong Chung MengNo ratings yet

- Smith Fibercast Green Thread Fiberglass Pipe Piping General SpecificationsDocument2 pagesSmith Fibercast Green Thread Fiberglass Pipe Piping General SpecificationsWong Chung MengNo ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- All Low VOC: Product GuideDocument16 pagesAll Low VOC: Product GuideWong Chung MengNo ratings yet

- Hi-Force Hydrostatic PDFDocument6 pagesHi-Force Hydrostatic PDFWong Chung MengNo ratings yet

- Accessories Cosasco Two Inch SystemDocument4 pagesAccessories Cosasco Two Inch SystemWong Chung MengNo ratings yet

- Chapter 1: (Network Security) : PreambleDocument21 pagesChapter 1: (Network Security) : PreambleArras DaouNo ratings yet

- 20462D ENU CompanionDocument194 pages20462D ENU CompanionjiindooNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- 45R-08 Scheduling Claims Protection MethodsDocument10 pages45R-08 Scheduling Claims Protection MethodsHatem HejaziNo ratings yet

- Hello Kitty - The Iconic Japanese BrandDocument5 pagesHello Kitty - The Iconic Japanese BrandMaya SalmanNo ratings yet

- Kuliah Materi Budaya OrganisasiDocument19 pagesKuliah Materi Budaya OrganisasiTito YustiawanNo ratings yet

- Signal Cable Connection To Input/Output Modules (For FIO)Document15 pagesSignal Cable Connection To Input/Output Modules (For FIO)cepia sobayhakiNo ratings yet

- Computer Notes 1 Year Chapter # 1 Short Questions (According To Alp)Document4 pagesComputer Notes 1 Year Chapter # 1 Short Questions (According To Alp)Nb KashifNo ratings yet

- Product Overview: Agilent 86130A Bitalyzer Enhanced Error Analysis OptionsDocument2 pagesProduct Overview: Agilent 86130A Bitalyzer Enhanced Error Analysis OptionsRowell DizonNo ratings yet

- Topic - Child Protection Act: Submitted To Lovely Professional UniversityDocument25 pagesTopic - Child Protection Act: Submitted To Lovely Professional UniversitySahil GargNo ratings yet

- X4 7300 Sell Sheet PDFDocument2 pagesX4 7300 Sell Sheet PDFaislandesouza23No ratings yet

- Principles of Marketing Q2 Module 8 Grade 11Document27 pagesPrinciples of Marketing Q2 Module 8 Grade 11Lyn-lyn Suyom-BitosNo ratings yet

- Raspberry Pi Pico GuideDocument131 pagesRaspberry Pi Pico Guidefpralus100% (1)

- Quality Mark Guideline 0Document50 pagesQuality Mark Guideline 0Asma DahaboNo ratings yet

- Rob 01.10.2021Document10 pagesRob 01.10.2021RITESHNo ratings yet

- Referencia M PDFDocument1,008 pagesReferencia M PDFrobertocarlosricciNo ratings yet

- Products Catalogue: 9F., T2 Building Green Centre, Furong Road, Changsha, ChinaDocument6 pagesProducts Catalogue: 9F., T2 Building Green Centre, Furong Road, Changsha, ChinaSadiq TurkiNo ratings yet

- MPOWA Web3Foundation POC ProjectDocument13 pagesMPOWA Web3Foundation POC ProjectKonstantinos PappasNo ratings yet

- TMP Nedjo Jarsao For PrintDocument20 pagesTMP Nedjo Jarsao For PrintGenetNo ratings yet

- Sample Space (SS) - The Set of All Possible Outcomes in An ExperimentDocument5 pagesSample Space (SS) - The Set of All Possible Outcomes in An ExperimentDypsy Pearl A. Pantinople0% (1)

- Nebraska Medical Marijuana LawsuitDocument13 pagesNebraska Medical Marijuana LawsuitMarijuana MomentNo ratings yet

- Identifying Fake Products Through A Barcode-Based Blockchain SystemDocument8 pagesIdentifying Fake Products Through A Barcode-Based Blockchain SystemVelocity VivekNo ratings yet

- BAYE's TheormDocument27 pagesBAYE's TheormPravalika ReddyNo ratings yet

- Destination Marketing On The WebDocument75 pagesDestination Marketing On The Webmanolis_psarrosNo ratings yet

- Samier AC 2017 Islamic Public Administration Tradition Historical TheoreticalDocument19 pagesSamier AC 2017 Islamic Public Administration Tradition Historical TheoreticalJunaid AliNo ratings yet

- Chartered Institution and GOCC, DefinedDocument13 pagesChartered Institution and GOCC, DefinedZaira Gem Gonzales100% (1)