Professional Documents

Culture Documents

Good Practice 29 - Safe Use of Manifolds

Good Practice 29 - Safe Use of Manifolds

Uploaded by

Maxmore KarumamupiyoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Good Practice 29 - Safe Use of Manifolds

Good Practice 29 - Safe Use of Manifolds

Uploaded by

Maxmore KarumamupiyoCopyright:

Available Formats

SERVICE ENGINEERS’ SECTION GOOD PRACTICE GUIDE 29

Safe Use of Service Manifolds

Introduction

Earlier this year we carried out a survey of members of the Section on the use of service manifolds.

Most engineers are carrying more than one service manifold and many carry up to four, which are used

with different refrigerants. Some of the good practice issues you highlighted in your responses were:

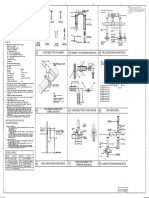

Use of specialist manifolds for carrying out leak tightness testing with OFN

Specific Nitrogen Pressure test kits are available which use braded steel hoses. These are

recommended for use during pressure testing for leaks using oxygen free nitrogen (OFN) for safety

reasons. It is essential to use a suitable regulator with the nitrogen cylinder. The regulator has an

output limiting device to prevent over pressurising of systems. The rating of this must be higher than

the test pressure to be used but not excessively so. A risk assessment must be carried out before

commencing this procedure.

Maximum likely pressures

Refrigerant Maximum Suitable regulator

Pressure

R134a 13.7bar maximum output of 26bar

R407C 23.6bar maximum output of 33bar

R404A 24.8bar maximum output of 33bar

R410A 33bar maximum output of 40bar

See Good Practice Guide 24 Leak Tightness Testing published December 2007 for recommended

procedures.

Risks of associated with sight glasses

Manifolds with sight glasses are not recommended for use with R410A, R744 (CO2) or pressure testing

systems for strength or tightness with nitrogen. These sight glasses have been known to fail and risk

causing serious injury to the engineer - the risk is greater with higher pressure fluids such as R410A,

R744 and nitrogen .Further advice about suitability of manifolds should be sought from your wholesaler.

Concerns over safety of R410A adaptors

Most R410A systems are fitted with 5/16” service connections to ensure that only the correct service

equipment is used. This is to highlight the higher pressures of R410A (see table above). However, an

adaptor is available which converts this back to ¼”. The adaptor makes it possible to connect to a

standard service manifold which does not have gauges rated for the pressures of R410A. This could

lead to a gauge being over pressurised, potentially resulting in the gauge breaking, shattering the cover

and resulting in personal injury. Service manifolds with gauges suitable for use with R410A with 5/16”

connections are readily available. It is therefore recommended that Service engineers should only use a

gauge manifold suitable for the higher pressures of R410A when working on R410A systems. See Good

Practice Guide 28 Connecting to R410A safely for further guidance.

The information contained in this Guide should be seen as a guide to interpretation of relevant industry standards, legislation and statutory information

which should be consulted by the relevant competent person responsible for servicing refrigeration equipment. The Service Engineers’ Section and the

www.ior.org.uk

Institute of Refrigeration accept no liability for any errors or omissions. page 1 of 1 Sept 2008

Service Engineers’ Section of the Institute of Refrigeration, Kelvin House, 76 Mill Lane, Carshalton SM5 2JR

You might also like

- The Mafia King - S HDocument509 pagesThe Mafia King - S Hselliswalters75% (4)

- Mark Scheme: Mechanics Year 1 (AS) Unit Test 7: Kinematics 1 (Constant Acceleration)Document6 pagesMark Scheme: Mechanics Year 1 (AS) Unit Test 7: Kinematics 1 (Constant Acceleration)Huzaifah100% (2)

- Lift Pump CalculationDocument10 pagesLift Pump CalculationMaxmore Karumamupiyo100% (1)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Annex 1C - Ice Plant and Cold Storage Inspection ChecklistDocument9 pagesAnnex 1C - Ice Plant and Cold Storage Inspection ChecklistMaxmore Karumamupiyo100% (2)

- HVAC Air Duct LeakageDocument47 pagesHVAC Air Duct LeakagePageduesca Rouel0% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Nokia Siemens Networks Flexi Multiradio 10 Datasheet Online 080512 PDFDocument2 pagesNokia Siemens Networks Flexi Multiradio 10 Datasheet Online 080512 PDFВиталий ХебибулинNo ratings yet

- Leak Tightness TestingDocument2 pagesLeak Tightness TestingSamantha HarveyNo ratings yet

- FR3 Change From Mineral Oil in Transformer Na3072835Document4 pagesFR3 Change From Mineral Oil in Transformer Na3072835classicalgasNo ratings yet

- Analizadores de Presion de Vapor Analizador RVPDocument6 pagesAnalizadores de Presion de Vapor Analizador RVPLuis OsorioNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Hose Usage Guide PDFDocument10 pagesHose Usage Guide PDFKaustav SahaNo ratings yet

- Service Manual PUHZ P100 140VHADocument110 pagesService Manual PUHZ P100 140VHASoyyo JopetasNo ratings yet

- Parr Hydrogenator 3900 SeriesDocument31 pagesParr Hydrogenator 3900 SeriesPedro MendoncaNo ratings yet

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

- Puz Ha30 36nha4 - (Och504)Document100 pagesPuz Ha30 36nha4 - (Och504)RusmansyahNo ratings yet

- BR CAT Mechanical Pressure en Us 17802Document68 pagesBR CAT Mechanical Pressure en Us 17802Praise Sam AbrahamNo ratings yet

- Method Statement - Refrigerant Pipeline Pressure - Test - ProcedureDocument10 pagesMethod Statement - Refrigerant Pipeline Pressure - Test - ProcedureBibin VijayakumarNo ratings yet

- ARP5996C-Evaluation of Coking Propensity of Aviation Lubricants Using The Single Phase Flow TechniqueDocument23 pagesARP5996C-Evaluation of Coking Propensity of Aviation Lubricants Using The Single Phase Flow TechniqueJicheng PiaoNo ratings yet

- Safe Handling of GasesDocument50 pagesSafe Handling of GasesDarby Morgan100% (1)

- Safe Handling of GasesDocument48 pagesSafe Handling of GasesDarby MorganNo ratings yet

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanNo ratings yet

- Well Testing Systems: Norsok StandardDocument40 pagesWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- Well Testing Recommended PracticesDocument40 pagesWell Testing Recommended Practicessajithv78100% (1)

- Selecting Control ValveDocument1 pageSelecting Control ValveA. Pradipta Triestanto W.No ratings yet

- z9673BR - Hydrogen Refuelling StationsDocument12 pagesz9673BR - Hydrogen Refuelling StationsShigueo EnamotoNo ratings yet

- Type 1227: Installation, Operation and Maintenance InstructionsDocument11 pagesType 1227: Installation, Operation and Maintenance InstructionsgffNo ratings yet

- Standard Pressure Testing ProcedureDocument10 pagesStandard Pressure Testing ProcedureAbdulbasit JunaidNo ratings yet

- Series PEAD R407C/R410A: Split-Type, Heat Pump Air ConditionersDocument34 pagesSeries PEAD R407C/R410A: Split-Type, Heat Pump Air ConditionersGiovani RodriguesNo ratings yet

- Service Manual PUHZ-RP250YKADocument85 pagesService Manual PUHZ-RP250YKAAntonio FerriNo ratings yet

- Trainee Name: Trainee Engineer Mechanical Maintenance DeptDocument50 pagesTrainee Name: Trainee Engineer Mechanical Maintenance DeptAdnan119No ratings yet

- Purge Points Are Pipe Nipples InstalledDocument2 pagesPurge Points Are Pipe Nipples Installedengg_mech77No ratings yet

- Mitsubishi Service - ManualDocument142 pagesMitsubishi Service - ManualMohammed Jahir Husain100% (1)

- Control Valve OpeningDocument3 pagesControl Valve OpeningConnor SailorNo ratings yet

- Pressure Gauge SelectionDocument2 pagesPressure Gauge SelectiondjendraHeniNo ratings yet

- Davis Butler API StandardsDocument27 pagesDavis Butler API StandardsAnkit GandhiNo ratings yet

- Carrier Transicold TECHLINE July2012Document4 pagesCarrier Transicold TECHLINE July2012Carlitos Enrique Corpus PonceNo ratings yet

- RB 4000Document24 pagesRB 4000Công PhạmNo ratings yet

- Procedure 4000: General Hydrostatic Testing Information: Caution!Document2 pagesProcedure 4000: General Hydrostatic Testing Information: Caution!Shaite Shaite AylaneNo ratings yet

- Training Program On: Pressure Relief ValveDocument71 pagesTraining Program On: Pressure Relief ValveShoaib JadoonNo ratings yet

- Mitsubishi Puhz W85vhaDocument44 pagesMitsubishi Puhz W85vhaPataki RóbertNo ratings yet

- Safety Relief Valves Information SheetDocument3 pagesSafety Relief Valves Information Sheetiyan7681No ratings yet

- Catalogo de Industria Minera PoberajDocument48 pagesCatalogo de Industria Minera PoberajWillintonPoloNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Washpipe Packing AssembliesDocument10 pagesWashpipe Packing AssembliesJohn Holding100% (1)

- Ruvac Ws/Wsu 251/501/1001/2001: Leybold VacuumDocument26 pagesRuvac Ws/Wsu 251/501/1001/2001: Leybold VacuumacamipNo ratings yet

- Introduction To API 6A SpecificationDocument21 pagesIntroduction To API 6A SpecificationYovaraj KarunakaranNo ratings yet

- Algunos Estandares de La Valvula de Control Entre OtrasDocument9 pagesAlgunos Estandares de La Valvula de Control Entre OtrasDoris Alfaro TorrezNo ratings yet

- Electrical System - PPT 2014Document86 pagesElectrical System - PPT 2014Kenneth100% (1)

- Harris Regulator ManualDocument12 pagesHarris Regulator ManualButton DavidsonNo ratings yet

- Ref Compressor HASEEGAVA PDFDocument65 pagesRef Compressor HASEEGAVA PDFigorNo ratings yet

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCDocument6 pagesTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1No ratings yet

- Best Practices For Rupture Disc (RD) / Pressure Relief Valve (PRV) CombinationsDocument4 pagesBest Practices For Rupture Disc (RD) / Pressure Relief Valve (PRV) Combinationskamy001No ratings yet

- Instrumentation8 Contious Gas AnalizerDocument58 pagesInstrumentation8 Contious Gas Analizersairam2234100% (1)

- Guidance On UseDocument7 pagesGuidance On UseLoveNo ratings yet

- Challenges Crude ProcessingDocument17 pagesChallenges Crude ProcessingAnonymous msVFzaNo ratings yet

- Regulators: Certifi Ed ISO 9001Document16 pagesRegulators: Certifi Ed ISO 9001HUBERT GERMAN BRIOSO BARRENECHEANo ratings yet

- 390 InstructionsDocument48 pages390 InstructionsemaanazeemNo ratings yet

- Station Test Device SpecificationDocument7 pagesStation Test Device SpecificationJEY KEYNo ratings yet

- Bourdon Tube InstallationDocument1 pageBourdon Tube InstallationKrushik DhadukNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Vol 6 Nwamitwa Dam Preliminary Design ReportDocument80 pagesVol 6 Nwamitwa Dam Preliminary Design ReportMaxmore KarumamupiyoNo ratings yet

- Reserve Report - Main - KomatiDocument121 pagesReserve Report - Main - KomatiMaxmore KarumamupiyoNo ratings yet

- Chapter 2: MethodologyDocument33 pagesChapter 2: MethodologyMaxmore KarumamupiyoNo ratings yet

- A4 Pollution Control DamsDocument81 pagesA4 Pollution Control DamsMaxmore KarumamupiyoNo ratings yet

- Komati River Report 2014 FinalDocument307 pagesKomati River Report 2014 FinalMaxmore KarumamupiyoNo ratings yet

- En Product Info Smartzoom 5 Rel 1.0Document16 pagesEn Product Info Smartzoom 5 Rel 1.0Maxmore KarumamupiyoNo ratings yet

- Basson Considerations 2005Document113 pagesBasson Considerations 2005Maxmore KarumamupiyoNo ratings yet

- Mvoti - Water Resource Analysis Report For PSC Comments Due by 11december2014Document135 pagesMvoti - Water Resource Analysis Report For PSC Comments Due by 11december2014Maxmore KarumamupiyoNo ratings yet

- Foxwood Dam - Inception Report - FINAL - Incl AppendicesDocument91 pagesFoxwood Dam - Inception Report - FINAL - Incl AppendicesMaxmore KarumamupiyoNo ratings yet

- Tensegrity Planter: InstructablesDocument8 pagesTensegrity Planter: InstructablesMaxmore KarumamupiyoNo ratings yet

- Dam Safety Guidelines: July 1992 (Revised February 2008) 92-55BDocument40 pagesDam Safety Guidelines: July 1992 (Revised February 2008) 92-55BMaxmore KarumamupiyoNo ratings yet

- Your House 3D Printed For The BirdsDocument7 pagesYour House 3D Printed For The BirdsMaxmore KarumamupiyoNo ratings yet

- Chess Salt and Pepper MillsDocument23 pagesChess Salt and Pepper MillsMaxmore KarumamupiyoNo ratings yet

- Rotary CNC Laser Engraver: InstructablesDocument11 pagesRotary CNC Laser Engraver: InstructablesMaxmore Karumamupiyo100% (1)

- Typical HVAC Report - 2Document34 pagesTypical HVAC Report - 2Maxmore KarumamupiyoNo ratings yet

- Mini CNC Milling Machine: InstructablesDocument26 pagesMini CNC Milling Machine: InstructablesMaxmore KarumamupiyoNo ratings yet

- Cold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentDocument2 pagesCold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentMaxmore KarumamupiyoNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document16 pagesPump System Total Head Calculation Example Complete (Imperial Units)Maxmore KarumamupiyoNo ratings yet

- 7me5930 5fa00 0aa0Document2 pages7me5930 5fa00 0aa0Maxmore KarumamupiyoNo ratings yet

- Pc30Mr Pc35Mr: Compact Hydraulic ExcavatorDocument20 pagesPc30Mr Pc35Mr: Compact Hydraulic ExcavatorWarunaNo ratings yet

- Csweapon ManualDocument39 pagesCsweapon ManualMehedi HasanNo ratings yet

- ch11 PDFDocument4 pagesch11 PDFLarasati FitriaNo ratings yet

- Lecture-04 Maintenance of Rotatory and Stationary EquipmentDocument38 pagesLecture-04 Maintenance of Rotatory and Stationary EquipmentMohammad ShafiNo ratings yet

- Section 10 Radiographic Inspection and Other NDTDocument18 pagesSection 10 Radiographic Inspection and Other NDTAnirbanNo ratings yet

- To Adjust Air SuspensionDocument2 pagesTo Adjust Air SuspensionThar KyiNo ratings yet

- Workbench Fe ModelerDocument118 pagesWorkbench Fe Modelermorralla123No ratings yet

- Aviation ReportDocument22 pagesAviation ReportNguyen LinhNo ratings yet

- Future of Autonomous Vehicles - FINAL Report PPT - MAY 2020Document47 pagesFuture of Autonomous Vehicles - FINAL Report PPT - MAY 2020igrazerpubgNo ratings yet

- Nigh OmniscienceDocument11 pagesNigh OmniscienceFlosie Otanez100% (1)

- For Tender: NotesDocument5 pagesFor Tender: NotesTeam RelentlessNo ratings yet

- Assessment of Ground Water Quality of The First Industrial-Residential Confluence Area of VisakhapatnamDocument31 pagesAssessment of Ground Water Quality of The First Industrial-Residential Confluence Area of VisakhapatnammirmohallNo ratings yet

- Chemistry Investigatory Project On Analysis of ColddrinksDocument22 pagesChemistry Investigatory Project On Analysis of ColddrinksVigneshwar ReddyNo ratings yet

- Sap Hana Iot IntegrationDocument12 pagesSap Hana Iot IntegrationR.P. PorwalNo ratings yet

- Aluminium & Steel Book Mai SeDocument3 pagesAluminium & Steel Book Mai SeJatin TilwaniNo ratings yet

- The Aptitude Test FormatDocument4 pagesThe Aptitude Test FormatIzhamKhairi100% (1)

- PropheticDocument20 pagesPropheticJeremy MonroeNo ratings yet

- Dilr 10Document102 pagesDilr 10gargi pimplaskarNo ratings yet

- CTS-V Conversion PDFDocument7 pagesCTS-V Conversion PDFAnonymous XbqU3gYDmNo ratings yet

- Cover LetterDocument2 pagesCover Letterphanis9No ratings yet

- Return Condensate To The Boiler: Condensate Recovery Produces SavingsDocument2 pagesReturn Condensate To The Boiler: Condensate Recovery Produces SavingsRodrigo SerapiaoNo ratings yet

- Course Handout-TURBO MACHINESDocument12 pagesCourse Handout-TURBO MACHINESkaran sharmaNo ratings yet

- CE RefDocument3 pagesCE Refcat buenafeNo ratings yet

- The Realisation of The 6.2km Long Padma Multipurpose Road and Rail Bridge in BangladeshDocument9 pagesThe Realisation of The 6.2km Long Padma Multipurpose Road and Rail Bridge in BangladeshTanvirH.ChowdhuryNo ratings yet

- Rajiv Gandhi University of Knowledge Technologies, BasarDocument3 pagesRajiv Gandhi University of Knowledge Technologies, BasarAMRUTHWAR SWAROOPANo ratings yet

- Cancers 02 02001Document10 pagesCancers 02 02001Madalina CordonasuNo ratings yet

- ADAPTER Class E Rev 1 - 5.2.2018Document16 pagesADAPTER Class E Rev 1 - 5.2.2018Rajbir SinghNo ratings yet