Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

56 viewsFinal BOQ With Qty GAIL UJJAIN

Final BOQ With Qty GAIL UJJAIN

Uploaded by

gloomyworldThis document provides a scope of work and itemized bill of quantities for an HVAC system. It includes the supply and installation of items such as chillers, cooling towers, pumps, air handling units, ducting, insulation, and other components. The total estimated cost is approximately Rs. 2,324,465 for material supply and another Rs. 2,324,465 for installation, bringing the total project cost to over Rs. 4,648,930.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Thermoset FRP Duct Construction ManualDocument216 pagesThermoset FRP Duct Construction ManualAaron AngNo ratings yet

- Hospital Case StudyDocument3 pagesHospital Case StudyShashi88% (8)

- Final BOQ With Qty GAIL UJJAIN As Per DevrajDocument8 pagesFinal BOQ With Qty GAIL UJJAIN As Per DevrajgloomyworldNo ratings yet

- Foam System PDFDocument2 pagesFoam System PDFaNo ratings yet

- HPLC Preventative Maintenance: List of Parts and Part Lifetimes Required For The 920-Series Analytical HPLCDocument9 pagesHPLC Preventative Maintenance: List of Parts and Part Lifetimes Required For The 920-Series Analytical HPLCAli RizviNo ratings yet

- Contact MR - Fahad Location Guruvayoor Scope Revision 0 Quotation Date Quotation NoDocument6 pagesContact MR - Fahad Location Guruvayoor Scope Revision 0 Quotation Date Quotation NoVMBUILDERS MANJERINo ratings yet

- MUM202001007 - 300 TR Price BOQ ChillerDocument4 pagesMUM202001007 - 300 TR Price BOQ ChillerB DASNo ratings yet

- Nozzle SummaryDocument1 pageNozzle SummaryvietsdsNo ratings yet

- Wesan WP: Bulk Water Meter - WoltmanDocument5 pagesWesan WP: Bulk Water Meter - WoltmanMohammad ZeeshanNo ratings yet

- DPWH Price QuotationDocument1 pageDPWH Price QuotationRonaldo B VillaromanNo ratings yet

- Tiloniya Fire Boq - 231228 - 142652Document5 pagesTiloniya Fire Boq - 231228 - 142652aditya chhaparwalNo ratings yet

- Foam-Novec System PDFDocument2 pagesFoam-Novec System PDFaNo ratings yet

- Revision History: Instrument Data SheetsDocument25 pagesRevision History: Instrument Data Sheetserik masongNo ratings yet

- 14-NPSHA VESSEL PR Is KnownDocument10 pages14-NPSHA VESSEL PR Is KnownAhm AnNo ratings yet

- School MoshiDocument20 pagesSchool MoshishrikantNo ratings yet

- Revised Chozhaiammal Super Mart - 02.12.2023Document6 pagesRevised Chozhaiammal Super Mart - 02.12.2023PithakarasNo ratings yet

- Data Sheet: 25 Frame Plunger PumpsDocument4 pagesData Sheet: 25 Frame Plunger PumpsGioNo ratings yet

- Thetotaltub: This Leaflet Is Made For Your InspirationDocument4 pagesThetotaltub: This Leaflet Is Made For Your InspirationmanoNo ratings yet

- Test PlanDocument4 pagesTest PlanOFFICE DANACNo ratings yet

- Fire Fighting Quotation NPI GorkhaDocument2 pagesFire Fighting Quotation NPI GorkhaDurga GandhariNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- Fire Hydrant System ACUTESUNDocument2 pagesFire Hydrant System ACUTESUNJay DholaNo ratings yet

- Labor OfferDocument3 pagesLabor Offermech95No ratings yet

- Ensival Moret PRE Pumps (French-English)Document3 pagesEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Brosur Breaker SOOSAN SB Series (New)Document8 pagesBrosur Breaker SOOSAN SB Series (New)HidayatNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- TEMPLATE Fire Hydrant RajpuraDocument5 pagesTEMPLATE Fire Hydrant RajpuraGaurav MalkotiaNo ratings yet

- Code InsruDocument7 pagesCode InsruTrisna KaranNo ratings yet

- Imtm Turbine Meters 2" - 16" For Custody Transfer: High LightsDocument6 pagesImtm Turbine Meters 2" - 16" For Custody Transfer: High LightsaliNo ratings yet

- BHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishDocument2 pagesBHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishBertin KamsipaNo ratings yet

- 30SCC160 2pdeDocument30 pages30SCC160 2pdeمحمد مرسيNo ratings yet

- Aetomate Unicut Magnetic Drill BrochureDocument8 pagesAetomate Unicut Magnetic Drill BrochureERWINNo ratings yet

- Cyano Inters ReceiverDocument1 pageCyano Inters Receiversushant_jhawerNo ratings yet

- Qty Variation For WCPMDocument5 pagesQty Variation For WCPMapi-25885200No ratings yet

- Bill of Quantity: Name of Work:-Fire Hydrant SystemDocument2 pagesBill of Quantity: Name of Work:-Fire Hydrant Systempramod tiwariNo ratings yet

- CAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesCAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- TCX TTDSeriesDocument2 pagesTCX TTDSeriespaachangaNo ratings yet

- Control Valves: Slaney Direct LTDDocument15 pagesControl Valves: Slaney Direct LTDParis AnabelNo ratings yet

- SUPERTYFON AT 150-200 With Valve Unit TV 784Document6 pagesSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshNo ratings yet

- Mpdi K3000Document2 pagesMpdi K3000Juan JuanNo ratings yet

- Yuva Packaging - Fire HydrantDocument2 pagesYuva Packaging - Fire HydrantRagukumarNo ratings yet

- BOQ - Centrifugal Water CooledDocument10 pagesBOQ - Centrifugal Water CooleddesignairNo ratings yet

- Catalogo Denison Serie PVDocument4 pagesCatalogo Denison Serie PVEdison YesidNo ratings yet

- Ghazipur VRV VoltasDocument8 pagesGhazipur VRV VoltasFluidus EngineeringNo ratings yet

- Fire ProtectionDocument4 pagesFire ProtectionAgung ChrisnayantoNo ratings yet

- 1 - Flowline CatalogueDocument16 pages1 - Flowline CatalogueRamesh MarimuthuNo ratings yet

- American Block FlowlineDocument16 pagesAmerican Block Flowlineclaudio godinezNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Orbital Welding & Induction Machine ConsumablesDocument1 pageOrbital Welding & Induction Machine ConsumablesSheikh ShoaibNo ratings yet

- Central HeatingDocument4 pagesCentral HeatingDanish NowshariNo ratings yet

- PIBCV CatalogueDocument1 pagePIBCV Cataloguesidparikh254No ratings yet

- Materials Price ListDocument6 pagesMaterials Price ListSatish SharmaNo ratings yet

- Annexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3Document3 pagesAnnexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3kallappa naikNo ratings yet

- Hot BoltingDocument6 pagesHot BoltingNickath Banu100% (1)

- Nat SpecsDocument10 pagesNat SpecsAndre CabralNo ratings yet

- Argapura, PT - Rvs.05ENG - 044 - 1509Document4 pagesArgapura, PT - Rvs.05ENG - 044 - 1509TristanNo ratings yet

- 01 - Revised Summary of HVAC MaterialsDocument1 page01 - Revised Summary of HVAC MaterialsfebousNo ratings yet

- Regulator With Filter: Model KZ03Document4 pagesRegulator With Filter: Model KZ03Asthy FaridaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Drying Costs of Woody Biomass in A Semi-Industrial Experimental Rotary Dryer - 2008Document5 pagesDrying Costs of Woody Biomass in A Semi-Industrial Experimental Rotary Dryer - 2008Peter Kimbel100% (1)

- MEP Modeler User Guide For ARCHICAD 20Document52 pagesMEP Modeler User Guide For ARCHICAD 20Rodrigo MasacheNo ratings yet

- 23-ES.2.14.0015 REV A - LV Switchgear & Controlgear For Use QatarDocument71 pages23-ES.2.14.0015 REV A - LV Switchgear & Controlgear For Use QatarAmmar Lateef Gakhar100% (1)

- Heating CoolingDocument40 pagesHeating Coolingamirthalingam_b671No ratings yet

- Basic Concepts of Stairwell PressurizationDocument4 pagesBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNo ratings yet

- Check ListDocument19 pagesCheck ListrihanNo ratings yet

- Price - What Is Inlet Effect - Diffuser SelectionsDocument27 pagesPrice - What Is Inlet Effect - Diffuser SelectionssabotaaageNo ratings yet

- Heaters PDFDocument624 pagesHeaters PDFReza JabbarzadehNo ratings yet

- Liebert CW - User ManualDocument136 pagesLiebert CW - User ManualluisNo ratings yet

- Bwy IomDocument17 pagesBwy IomReginald D. De GuzmanNo ratings yet

- Standard System of Measuring Bulding Work RSADocument71 pagesStandard System of Measuring Bulding Work RSAmutyoka100% (1)

- SOP For Refrigeration PlantDocument37 pagesSOP For Refrigeration PlantGaurav Swarup67% (3)

- York Ducted Split Ac Yefe 18-48Document6 pagesYork Ducted Split Ac Yefe 18-48DANISH0% (1)

- Columbia Care Medical Marijuana Dispensary in Marco Island, Florida 1Document22 pagesColumbia Care Medical Marijuana Dispensary in Marco Island, Florida 1Omar Rodriguez Ortiz100% (1)

- 10 GS-08 - Air Conditioning - Ventilation SystemDocument111 pages10 GS-08 - Air Conditioning - Ventilation SystemshivvaramNo ratings yet

- Carrier Handbook Part 1Document162 pagesCarrier Handbook Part 1Tanveer100% (3)

- CSP-A510 - SubmittalDocument3 pagesCSP-A510 - SubmittalElmer Ramón Murillo MejiaNo ratings yet

- The Fire Code of The Philippines 2008Document12 pagesThe Fire Code of The Philippines 2008Pete PinonNo ratings yet

- ACHR News June 2 PDFDocument46 pagesACHR News June 2 PDFSantiago J. ramos jrNo ratings yet

- FE-1500-FX Tech Data SheetDocument8 pagesFE-1500-FX Tech Data SheetIeong L KanNo ratings yet

- Hotchkiss Group 2010 BrochureDocument6 pagesHotchkiss Group 2010 BrochureGiải Pháp Cơ ĐiệnNo ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument11 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionNoushad P HamsaNo ratings yet

- Topic 5 Duct SizingDocument24 pagesTopic 5 Duct SizingDominador M. Mejia IIINo ratings yet

- Gravity ShuttersDocument8 pagesGravity ShuttersKUMAARRRNo ratings yet

- MJ Smoke Spill CF May21Document11 pagesMJ Smoke Spill CF May21BN YADAVNo ratings yet

- CETA Application Guide For The Exhaust System Requirements of Class II, Type B Biosafety Cabinets CAG-007-2010 March 24, 2010Document12 pagesCETA Application Guide For The Exhaust System Requirements of Class II, Type B Biosafety Cabinets CAG-007-2010 March 24, 2010natrajangNo ratings yet

- Transformer Inspection Monthly ReportDocument11 pagesTransformer Inspection Monthly ReportIbnu RozaqNo ratings yet

- MechanicalDocument56 pagesMechanicalntt_121987No ratings yet

Final BOQ With Qty GAIL UJJAIN

Final BOQ With Qty GAIL UJJAIN

Uploaded by

gloomyworld0 ratings0% found this document useful (0 votes)

56 views8 pagesThis document provides a scope of work and itemized bill of quantities for an HVAC system. It includes the supply and installation of items such as chillers, cooling towers, pumps, air handling units, ducting, insulation, and other components. The total estimated cost is approximately Rs. 2,324,465 for material supply and another Rs. 2,324,465 for installation, bringing the total project cost to over Rs. 4,648,930.

Original Description:

Original Title

Final BOQ with Qty GAIL UJJAIN

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a scope of work and itemized bill of quantities for an HVAC system. It includes the supply and installation of items such as chillers, cooling towers, pumps, air handling units, ducting, insulation, and other components. The total estimated cost is approximately Rs. 2,324,465 for material supply and another Rs. 2,324,465 for installation, bringing the total project cost to over Rs. 4,648,930.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

56 views8 pagesFinal BOQ With Qty GAIL UJJAIN

Final BOQ With Qty GAIL UJJAIN

Uploaded by

gloomyworldThis document provides a scope of work and itemized bill of quantities for an HVAC system. It includes the supply and installation of items such as chillers, cooling towers, pumps, air handling units, ducting, insulation, and other components. The total estimated cost is approximately Rs. 2,324,465 for material supply and another Rs. 2,324,465 for installation, bringing the total project cost to over Rs. 4,648,930.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 8

GAIL UJJAIN BOQ

Scope of Work

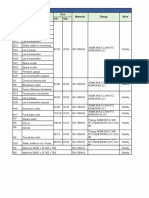

Sr.N Description of Work Unit Qty. Supply Installation Total AMT

o

Rate Amount Rate Amount

1 Chiller 120 TR %

Supply of 120 TR (nominal) capacity Confrigure water cooled

series. Nos 2 blue star scope 32000 64000 64000

5"Butterfly valve for cooler & condenser Inlet & outlet Nos 8 0 1350 10800 10800

6mm Vibration pad Nos 16 125 2000 30 480 2480

RCC foundation for chiller Nos 2 15000 30000 5000 10000 40000

2 Condenser Water Pumps 25 mtr head

Supply, Installation, Testing and Commissioning of Split Casing

Chiller Water Pump (end suction type pump) set capable of

delivering required flow of water against 25 mtr head, - Flow

Rate - 386.1 usgpm, Pressure Drop- 11.7 ft H2O,Max Operating Nos 2 blue star scope 3200 6400 6400

Pressure- 150 psig (Water Side), Fouling Factor-0.000250 Sq ft

Hr °F/Btu, Total Heat Rejection -149.6 TR

Gate valve -125mm Nos 4 0 1350 5400 5400

NRV valve -125 mm Nos 2 0 1350 2700 2700

Y-stainer -125mm Nos 2 0 1350 2700 2700

Pressuse guage -Pressure gauge of appropriate range and 150

mm. dial size Nos 4 0 150 600 600

6mm Vibration pad Nos 8 125 1000 30 240 1240

RCC foundation for pump Nos 2 7000 14000 3000 6000 20000

3 Chilled Water Pumps 25 mtr head

Supply, Installation, Testing and Commissioning of Split Casing

Chiller Water Pump (end suction type pump) set capable of

delivering required flow of water against 25 mtr head, - Flow

Rate -300.0 usgpm, Pressure Drop- 9 ft H2O,Max Operating Nos 2 blue star scope 3200 6400 6400

Pressure- 150 psig (Water Side), Fouling Factor-0.000100 Sq ft

Hr °F/Btu

Gate valve -125mm Nos 4 0 1350 5400 5400

NRV valve -125 mm Nos 2 0 1350 2700 2700

Y-stainer -125mm Nos 2 0 1350 2700 2700

Pressuse guage -Pressure gauge of appropriate range and 150

mm. dial size Nos 4 0 150 600 600

6mm Vibration pad Nos 8 125 1000 30 240 1240

RCC foundation for pump Nos 2 7000 14000 3000 6000 20000

4 Cooling tower 150 TR

Cooling tower 150 TR Nos 2 blue star scope 20000 40000 40000

Butter fly valves -6" Nos 4 0 1450 5800 5800

Pressuse guage -Pressure gauge of appropriate range and 150

mm. dial size Nos 4 0 150 600 600

6mm Vibration pad Nos 16 125 2000 30 480 2480

RCC foundation for Cooling tower Nos 2 21000 42000 5000 10000 52000

Air Handing Unit 28000 CFM

Supply of double skin modular construction, Floor Mounted

(FM) Air Handling Units,28000 CFM , FM, Coil-6 +2, SP- Nos 2 blue star scope ###

65,Phase/HP- 3 /25

Gate valves 4" Nos 8 0 1300 10400 10400

Y-stainer -5" Nos 3 0 0 0 0

Pressuse guage -Pressure gauge of appropriate range and 150

mm. dial size Nos 10 0 150 1500 1500

6mm Vibration pad Nos 36 125 4500 30 1080 5580

RCC foundation for AHU Nos 2 10000 20000 5000 10000 30000

CONDENSER and CHILLED WATER PIPING- Pipes shall be

6 Mild Steel confirming with IS 1239 and IS 3589. ###

150mm M 127 1495 189865 1090 138430 328295

125 mm M 66 1299 85734 925 61050 146784

100 MM M 16 1104 17664 760 12160 29824

80 mm M 9 840 7560 595 5355 12915

50 mm M 9 627 5643 430 3870 9513

25 mm M 40 545 21800 290 11600 33400

232465

7 CHILLED WATER PIPE INSULATION ###

19 mm thick nitrile pipe 125 mm dia chilled water piping SQMT 145 450 65250 215 31175 96425

Balancing Valve shall be of cast iron flanged construction

with EPDM/SG iron with epoxy coated disc with built in

8 pressure drop measuring facility (pressure test cocks) to ###

compute flow rate across the valve. The test cocks shall be

long enough to protrude out of pipe insulation.

125 MM Balancing valve at the outlet of coil. Nos 0 0 0

9 Expansion tank ###

PVC expansion tank of 1000 Ltr. Nos 1 12000 12000 1500 1500 13500

10 G. I. DUCTING & GRILLES AND DIFFUSERS ###

Supply, fabrication, installation and testing of G. I.

sheet 24 guage as per IS-655, GI sheets having SQMT 182.5 765 139612.5 369 67342.5 206955

minimum 120 g/m2 of zinc coating.

22 Gauge SQMT 224.08 925 207276.775 369 82686.627 289963.402

20 Gauge SQMT 102.24 1025 104796 369 37726.56 142522.56

Canvas Connection Nos 2 2500 5000 1500 3000 8000

Supply and fixing of 25 mm thick Acoustic lining inside the

ducts SQMT 111.60 0 215 23994 23994

Supply and fixing of 19 mmcomplete

thick aluminum foil thermal

insulation ducts SQMT 508.38 0 215 109301.7 109301.7

supply air grill with VCD SQMT 3.96 0 968 3833.28 3833.28

Return air grill with VCD SQMT 3.74 0 968 3620.32 3620.32

Supply air diffuser with VCD SQMT 5 0 0 0

SITC. volume control damper SQMT 3.99 5300 21147 968 3862.32 25009.32

Fire Dampers SQMT 2.80 0 968 2710.4 2710.4

11 MAIN AC AUXILLARY PANEL, EARTING PITS blue star scope ###

SITC of free standing floor mounted dust and vermin proof

compartmentalised cubical Electrical Main panel. SET 1 45000 45000 45000

Earthing strip of 25 X 4 mm minimum aluminum RMT 150 142 21300 35 5250 26550

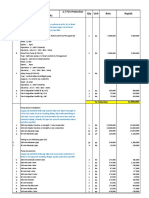

12 POWER & CONTROL CABLE, BMS PLANT MANAGER ###

ARMOURED CABLES Aluminium 3.5C X 120 sqmm RMT 64 0 95 6080 6080

ARMOURED CABLES Aluminium 3.5C X 50 sqmm RMT 77 0 75 5775 5775

ARMOURED CABLES Aluminium 4C X 25 sqmm RMT 100 0 60 6000 6000

ARMOURED CABLES Aluminium 4C X 10 sqmm RMT 100 0 50 5000 5000

PVC copper cable 2C X 1.5 sqmm RMT 100 0 35 3500 3500

13 Cable try ###

150X 50 mm X 1.6 mm thickness RMT 80 265 21200 125 10000 31200

300 X 150 mm X 1.6 mm tbick ness RMT 20 445 8900 125 2500 11400

14 PLC microprocess ###

PLC Panel Set 1 blue star scope 15000 15000 15000

16 Temporery cooling proviation JOB 1 135000 135000 40000 40000 175000

17 Transportation & other expanses Lot 1 0 0 0 0 100000

1 Three way valve Nos 2 6000 12000 12000

2 Make up water line of Cooling tower & Expansion tank Rmt 36 32000

3 Civil Work Lot 1 85000

4 Diffrance amount of Flanges change Lot 1 21600

5 Old system Dismantaling charges Lot 1 100000

6 fire panel Nos 1 14000

7 Angle frames for duct, Duct supports & piping supports, Kg 1820 150 273000 273000

8 Gate Valve 3" Nos 1 4750 4750

9 Flanges for 3" Gate Valve Nos 2 1200

10 Flanges for 3 way Valve Nos 6 3600

margin

11 on insulation, valves, cable, three way valve, grill dampers, fire dampers 100000

12 Unloading Charges of Chillers, Cooling Towers, AHUs. Lot 1 25000

SUB TOTAL 1200248.28 1193007.71 2932940.982

GST @ 18% 527929

GRAND TOTAL 3460870

GRAND TOTAL(in words)

Condenser pump - Qty - 2 No.s Evaporator Pump - Qty - 2 no.s

Leaving Temperature 94.30 °F Leaving Temperature

Entering Temperature 85.00 °F Entering Temperature

Delta T 9.30 °F Delta T

Flow Rate 386.1 usgpm Flow Rate

Pressure Drop 11.7 ft H2O Pressure Drop

Max Operating Pressure 150 psig (Water Side) Max Operating Pressure

Fouling Factor 0.000250 Sq ft Hr °F/Btu Fouling Factor

Total Heat Rejection 149.6 TR Head

Head 25 Mtr.

porator Pump - Qty - 2 no.s

44.00 °F

54.00 °F

10.00 °F

300.0 usgpm

9.00 ft H2O

150 psig (Water Side)

0.000100 Sq ft Hr °F/Btu

25 Mtr.

Valves:

8.5.1. The gates valves shall be cast iron body confirming with IS standards.

8.5.2. Balancing valve shall be of cast iron flanged construction with EPDM/SG iron with epoxy

coated disc with built in pressure drop measuring facility (pressure test cocks) to

compute flow rate across the valve. The test cocks shall be long enough to protrude out

of pipe insulation.

8.5.3. Non return valves shall be of gun metal construction upto 65 mm, the metal conforming

to class 2 of IS: 778. For 75 mm and above, the valve shall be of bronze or gun metal,

body being of cast iron. While screwed or flanged ends may be provided upto 65 mm,

flanged ends shall be provided for larger sizes.

8.6. Strainers

8.6.1. 'Y' strainers shall be provided on the inlet side of each air-handling unit and pump in

chilled water and condenser water circuit.

8.6.2. Strainers shall be provided with equal size isolating gate valves on either side so that the

strainers may be cleaned without draining the system.

Capacity 28000CFM, Static Pressure 65 mm Wg.

The air handling unit shall be of double skin construction, draw through type in

sectionalized construction consisting of blower section, coil section, filter section and

insulated drain pan. The unit may be vertical or horizontal type.

The coil shall be designed for a face velocity of air not exceeding 155m/min.

The air outlet velocity from the blower fan shall not exceed 610 m/min.

Noise level at a distance of 2M from AHU shall not exceed 75 dBA.

Double skin panels shall be 25mm+1 thick, made of 0.6mm (minimum) preplasticized

and pre-painted with PVC guard, galvanized steel sheet on outside and

0.8mm galvanized sheet inside with Polyurethane foam insulation of density not

less than 38 kg/cu. m injected in between by injection molding machine.

The entire housing shall be mounted on galvanized steel channel frame

work made out of G.I. sheet of thickness not less than 2mm. For higher capacity

AHUs hot dip galvanized steel channel framework made of minimum 3 mm thick

G.S. sheet shall be used.

The coil shall be made from seamless solid drawn copper tubes. The minimum

thickness of tube shall be 0.5 mm for the cooling coils.

The depth of the coil shall be such as to suit the requirements as per the

application. The coil shall be minimum 4 rows deep. In case of 8 rows deep coils,

it shall be made of 2x4 rows deep coils with a spacing of 200mm between the two

coils, access door and independent drain pan.

The headers shall be of copper and shall be complete

with water in/out connections, vent plug on top and drain at the bottom. The coil

shall be designed to provide water velocity between 0.6 to 1.8 m/s in the tubes.

The fins shall be of aluminum. The minimum thickness of the fins shall be 0.15

mm nominal. The no. of fins shall not be less than 4.7 per cm length (12-13 per

inch) of coil. Fins may be of either spiral or plate type.

Water coils shall be designed for a minimum working pressure of 10 kg./sq.cm.

The supply air fan shall be AMCA certified centrifugal type with

forward/backward curved blades double inlet double width type.

Fan outlet velocity shall be restricted within 9.2 m/s.

The fan motor shall be totally enclosed fan cooled squirrel cage induction motor with IP-54 protection & selected

running. The motor shall be suitable for operation on 415 + 10%V, 3 phase, 50 Hz, A.C. supply. The fan motor s

premium efficiency IE3 class, as per IS 12615. The motor rating (exclusive of service factor) shall be minimum 1

limit load power required (including the transmission losses) at operating condition. The motor shall be suitably d

for use with variable frequency drive.

Pre filter section with MERV-7 filters

You might also like

- Thermoset FRP Duct Construction ManualDocument216 pagesThermoset FRP Duct Construction ManualAaron AngNo ratings yet

- Hospital Case StudyDocument3 pagesHospital Case StudyShashi88% (8)

- Final BOQ With Qty GAIL UJJAIN As Per DevrajDocument8 pagesFinal BOQ With Qty GAIL UJJAIN As Per DevrajgloomyworldNo ratings yet

- Foam System PDFDocument2 pagesFoam System PDFaNo ratings yet

- HPLC Preventative Maintenance: List of Parts and Part Lifetimes Required For The 920-Series Analytical HPLCDocument9 pagesHPLC Preventative Maintenance: List of Parts and Part Lifetimes Required For The 920-Series Analytical HPLCAli RizviNo ratings yet

- Contact MR - Fahad Location Guruvayoor Scope Revision 0 Quotation Date Quotation NoDocument6 pagesContact MR - Fahad Location Guruvayoor Scope Revision 0 Quotation Date Quotation NoVMBUILDERS MANJERINo ratings yet

- MUM202001007 - 300 TR Price BOQ ChillerDocument4 pagesMUM202001007 - 300 TR Price BOQ ChillerB DASNo ratings yet

- Nozzle SummaryDocument1 pageNozzle SummaryvietsdsNo ratings yet

- Wesan WP: Bulk Water Meter - WoltmanDocument5 pagesWesan WP: Bulk Water Meter - WoltmanMohammad ZeeshanNo ratings yet

- DPWH Price QuotationDocument1 pageDPWH Price QuotationRonaldo B VillaromanNo ratings yet

- Tiloniya Fire Boq - 231228 - 142652Document5 pagesTiloniya Fire Boq - 231228 - 142652aditya chhaparwalNo ratings yet

- Foam-Novec System PDFDocument2 pagesFoam-Novec System PDFaNo ratings yet

- Revision History: Instrument Data SheetsDocument25 pagesRevision History: Instrument Data Sheetserik masongNo ratings yet

- 14-NPSHA VESSEL PR Is KnownDocument10 pages14-NPSHA VESSEL PR Is KnownAhm AnNo ratings yet

- School MoshiDocument20 pagesSchool MoshishrikantNo ratings yet

- Revised Chozhaiammal Super Mart - 02.12.2023Document6 pagesRevised Chozhaiammal Super Mart - 02.12.2023PithakarasNo ratings yet

- Data Sheet: 25 Frame Plunger PumpsDocument4 pagesData Sheet: 25 Frame Plunger PumpsGioNo ratings yet

- Thetotaltub: This Leaflet Is Made For Your InspirationDocument4 pagesThetotaltub: This Leaflet Is Made For Your InspirationmanoNo ratings yet

- Test PlanDocument4 pagesTest PlanOFFICE DANACNo ratings yet

- Fire Fighting Quotation NPI GorkhaDocument2 pagesFire Fighting Quotation NPI GorkhaDurga GandhariNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- Fire Hydrant System ACUTESUNDocument2 pagesFire Hydrant System ACUTESUNJay DholaNo ratings yet

- Labor OfferDocument3 pagesLabor Offermech95No ratings yet

- Ensival Moret PRE Pumps (French-English)Document3 pagesEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Brosur Breaker SOOSAN SB Series (New)Document8 pagesBrosur Breaker SOOSAN SB Series (New)HidayatNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- TEMPLATE Fire Hydrant RajpuraDocument5 pagesTEMPLATE Fire Hydrant RajpuraGaurav MalkotiaNo ratings yet

- Code InsruDocument7 pagesCode InsruTrisna KaranNo ratings yet

- Imtm Turbine Meters 2" - 16" For Custody Transfer: High LightsDocument6 pagesImtm Turbine Meters 2" - 16" For Custody Transfer: High LightsaliNo ratings yet

- BHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishDocument2 pagesBHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishBertin KamsipaNo ratings yet

- 30SCC160 2pdeDocument30 pages30SCC160 2pdeمحمد مرسيNo ratings yet

- Aetomate Unicut Magnetic Drill BrochureDocument8 pagesAetomate Unicut Magnetic Drill BrochureERWINNo ratings yet

- Cyano Inters ReceiverDocument1 pageCyano Inters Receiversushant_jhawerNo ratings yet

- Qty Variation For WCPMDocument5 pagesQty Variation For WCPMapi-25885200No ratings yet

- Bill of Quantity: Name of Work:-Fire Hydrant SystemDocument2 pagesBill of Quantity: Name of Work:-Fire Hydrant Systempramod tiwariNo ratings yet

- CAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesCAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- TCX TTDSeriesDocument2 pagesTCX TTDSeriespaachangaNo ratings yet

- Control Valves: Slaney Direct LTDDocument15 pagesControl Valves: Slaney Direct LTDParis AnabelNo ratings yet

- SUPERTYFON AT 150-200 With Valve Unit TV 784Document6 pagesSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshNo ratings yet

- Mpdi K3000Document2 pagesMpdi K3000Juan JuanNo ratings yet

- Yuva Packaging - Fire HydrantDocument2 pagesYuva Packaging - Fire HydrantRagukumarNo ratings yet

- BOQ - Centrifugal Water CooledDocument10 pagesBOQ - Centrifugal Water CooleddesignairNo ratings yet

- Catalogo Denison Serie PVDocument4 pagesCatalogo Denison Serie PVEdison YesidNo ratings yet

- Ghazipur VRV VoltasDocument8 pagesGhazipur VRV VoltasFluidus EngineeringNo ratings yet

- Fire ProtectionDocument4 pagesFire ProtectionAgung ChrisnayantoNo ratings yet

- 1 - Flowline CatalogueDocument16 pages1 - Flowline CatalogueRamesh MarimuthuNo ratings yet

- American Block FlowlineDocument16 pagesAmerican Block Flowlineclaudio godinezNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Orbital Welding & Induction Machine ConsumablesDocument1 pageOrbital Welding & Induction Machine ConsumablesSheikh ShoaibNo ratings yet

- Central HeatingDocument4 pagesCentral HeatingDanish NowshariNo ratings yet

- PIBCV CatalogueDocument1 pagePIBCV Cataloguesidparikh254No ratings yet

- Materials Price ListDocument6 pagesMaterials Price ListSatish SharmaNo ratings yet

- Annexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3Document3 pagesAnnexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3kallappa naikNo ratings yet

- Hot BoltingDocument6 pagesHot BoltingNickath Banu100% (1)

- Nat SpecsDocument10 pagesNat SpecsAndre CabralNo ratings yet

- Argapura, PT - Rvs.05ENG - 044 - 1509Document4 pagesArgapura, PT - Rvs.05ENG - 044 - 1509TristanNo ratings yet

- 01 - Revised Summary of HVAC MaterialsDocument1 page01 - Revised Summary of HVAC MaterialsfebousNo ratings yet

- Regulator With Filter: Model KZ03Document4 pagesRegulator With Filter: Model KZ03Asthy FaridaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Drying Costs of Woody Biomass in A Semi-Industrial Experimental Rotary Dryer - 2008Document5 pagesDrying Costs of Woody Biomass in A Semi-Industrial Experimental Rotary Dryer - 2008Peter Kimbel100% (1)

- MEP Modeler User Guide For ARCHICAD 20Document52 pagesMEP Modeler User Guide For ARCHICAD 20Rodrigo MasacheNo ratings yet

- 23-ES.2.14.0015 REV A - LV Switchgear & Controlgear For Use QatarDocument71 pages23-ES.2.14.0015 REV A - LV Switchgear & Controlgear For Use QatarAmmar Lateef Gakhar100% (1)

- Heating CoolingDocument40 pagesHeating Coolingamirthalingam_b671No ratings yet

- Basic Concepts of Stairwell PressurizationDocument4 pagesBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNo ratings yet

- Check ListDocument19 pagesCheck ListrihanNo ratings yet

- Price - What Is Inlet Effect - Diffuser SelectionsDocument27 pagesPrice - What Is Inlet Effect - Diffuser SelectionssabotaaageNo ratings yet

- Heaters PDFDocument624 pagesHeaters PDFReza JabbarzadehNo ratings yet

- Liebert CW - User ManualDocument136 pagesLiebert CW - User ManualluisNo ratings yet

- Bwy IomDocument17 pagesBwy IomReginald D. De GuzmanNo ratings yet

- Standard System of Measuring Bulding Work RSADocument71 pagesStandard System of Measuring Bulding Work RSAmutyoka100% (1)

- SOP For Refrigeration PlantDocument37 pagesSOP For Refrigeration PlantGaurav Swarup67% (3)

- York Ducted Split Ac Yefe 18-48Document6 pagesYork Ducted Split Ac Yefe 18-48DANISH0% (1)

- Columbia Care Medical Marijuana Dispensary in Marco Island, Florida 1Document22 pagesColumbia Care Medical Marijuana Dispensary in Marco Island, Florida 1Omar Rodriguez Ortiz100% (1)

- 10 GS-08 - Air Conditioning - Ventilation SystemDocument111 pages10 GS-08 - Air Conditioning - Ventilation SystemshivvaramNo ratings yet

- Carrier Handbook Part 1Document162 pagesCarrier Handbook Part 1Tanveer100% (3)

- CSP-A510 - SubmittalDocument3 pagesCSP-A510 - SubmittalElmer Ramón Murillo MejiaNo ratings yet

- The Fire Code of The Philippines 2008Document12 pagesThe Fire Code of The Philippines 2008Pete PinonNo ratings yet

- ACHR News June 2 PDFDocument46 pagesACHR News June 2 PDFSantiago J. ramos jrNo ratings yet

- FE-1500-FX Tech Data SheetDocument8 pagesFE-1500-FX Tech Data SheetIeong L KanNo ratings yet

- Hotchkiss Group 2010 BrochureDocument6 pagesHotchkiss Group 2010 BrochureGiải Pháp Cơ ĐiệnNo ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument11 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionNoushad P HamsaNo ratings yet

- Topic 5 Duct SizingDocument24 pagesTopic 5 Duct SizingDominador M. Mejia IIINo ratings yet

- Gravity ShuttersDocument8 pagesGravity ShuttersKUMAARRRNo ratings yet

- MJ Smoke Spill CF May21Document11 pagesMJ Smoke Spill CF May21BN YADAVNo ratings yet

- CETA Application Guide For The Exhaust System Requirements of Class II, Type B Biosafety Cabinets CAG-007-2010 March 24, 2010Document12 pagesCETA Application Guide For The Exhaust System Requirements of Class II, Type B Biosafety Cabinets CAG-007-2010 March 24, 2010natrajangNo ratings yet

- Transformer Inspection Monthly ReportDocument11 pagesTransformer Inspection Monthly ReportIbnu RozaqNo ratings yet

- MechanicalDocument56 pagesMechanicalntt_121987No ratings yet