Professional Documents

Culture Documents

Mechanical Department in Indian Railway

Mechanical Department in Indian Railway

Uploaded by

Soumen Bhatta0 ratings0% found this document useful (0 votes)

73 views5 pagesThe Mechanical Department of Indian Railways is responsible for train operations, production units, and workshops. It oversees locomotive and rolling stock maintenance, production of trains and components, technology modernization, and disaster response. The department is headed by the Member Mechanical who oversees zones led by Chief Mechanical Engineers. Workshops are managed by Chief Workshop Managers and focus on maintenance, repair, and manufacturing. The Central Organization for Modernization of Workshops modernizes production and maintenance facilities.

Original Description:

Original Title

chapter 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Mechanical Department of Indian Railways is responsible for train operations, production units, and workshops. It oversees locomotive and rolling stock maintenance, production of trains and components, technology modernization, and disaster response. The department is headed by the Member Mechanical who oversees zones led by Chief Mechanical Engineers. Workshops are managed by Chief Workshop Managers and focus on maintenance, repair, and manufacturing. The Central Organization for Modernization of Workshops modernizes production and maintenance facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

73 views5 pagesMechanical Department in Indian Railway

Mechanical Department in Indian Railway

Uploaded by

Soumen BhattaThe Mechanical Department of Indian Railways is responsible for train operations, production units, and workshops. It oversees locomotive and rolling stock maintenance, production of trains and components, technology modernization, and disaster response. The department is headed by the Member Mechanical who oversees zones led by Chief Mechanical Engineers. Workshops are managed by Chief Workshop Managers and focus on maintenance, repair, and manufacturing. The Central Organization for Modernization of Workshops modernizes production and maintenance facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

Mechanical Department in Indian Railway

Mechanical Department of Indian Railways are responsible for management of:

Train operations by ensuring Motive Power availability, Crew Management, Rolling Stock

Management and Traffic restoration in case of accidents.

Production Units engaged in production of Locomotives, Coaches, Wheel sets, etc

Workshops set up for repair, maintenance and manufacturing of rolling stock and related

components.

Function of Mechanical Department:

Maintain and supply dependable system and diesel locomotives as per predetermined power

plan

Disaster Management

Maintain coaches, keeping in view safety and amenities aspects

Maintain wagons for their safe haulage

Production of locomotives, coaches and wagons

Continuous absorption of latest technology in the fields of maintenance and production

Ensuring economic use of fuel

Linen Management

Periodic overhauling of rolling stock

To maintain Breakdown train in ready to use condition

Co-coordinating procurement of Machinery and Plant for all the departments.

Organisation of Mechanical Department

The Mechanical Department is headed by Member (Mechanical) at Railway Board. In each of the

zones the Department is headed by a Chief Mechanical Engineer who reports to the General Manager

of the Railway. The office of the Member (Mechanical) of the Railway Board guides the CME on

technical matters and policy. At the divisional level, Sr. Divisional Mechanical Engineers are

responsible for implementation of the policies framed by Railway Board and Zonal Railways. While

Production Units are managed independently by General Managers reporting to the Railway Board.

The Workshops are headed by Chief Works Managers and report to the CME.

Central Organization for Modernization of Workshops (COFMOW) under the Mechanical Department

is a centralized agency of the Indian Railways responsible for modernization of Railway Workshops

and Production Units and carries out procurement and induction of modern workshop technologies

and specialized Machines & Plant (M&P).

Chairman (Railway Board)

Member (Mechanical)

Addl. Member ( Stores) Addl. Member (Mechanical Engg.)

Addl. Member (Production Unit)

General Manager

CME

CWE CMPE(D) CRSE CME (P) CRSE (F & O)

Orga ni zatio n at

Zonal Headquarters level

DRM

Sr. DME (C&W) Sr. DME (D) Sr. DME (P)

Organization at Divisional level

Carriage & Wagon

Objective of C&W depots:-

i) To ensure maintenance and repair of carriage and wagon stock and to keep it in operational

condition by providing following attention

Examination of originating trains at maintenance depot and examination yards

Examination of terminating trains at examination yards.

Examination of through passing trains at examination yards/ station.

ROH / IOH of wagon/ coach at maintenance depot.

ii) To ensure customer satisfaction by providing:-

Clean Train station services (CTS)

on board house services (OBHS).

Auto mechanized cleaning of coaches

Carriage watering of coaches.

Amenities and safety fittings in passenger coaches.

to ensure supply of superior and cleaned quality linen to the AC coaches passenger.

iii) To ensure implementation of instruction and modification regarding rolling stock, time to time

issued by Rly Bd. and RDSO.

iv) To minimize ineffective of rolling stock by conducting :-

Periodical examination/maintenance at examination yard and maintenance siding.

By conducting rolling in and rolling out examination at intermediate C&W examination point.

To avoid nonstandard fitting/material.

To attend POH of rolling stock at nominated workshop.

Avoid to run due and overdue POH stock on train service.

Coaching Section Activities

Sick Line Activity: Repair of unfit coaches

IOH section Activity: IOH of due / overdue coaches

Maintenance section Activity: Maintenance of primary / secondary depot based rakes.

Platform Activity:

1. Examination of through passing, terminating and origination trains.

2. Carriage watering of through passing trains

3. CTS of through passing trains

4. Trouble shooting of through passing trains

Freight Section Activities

Sick Line Activity: Repair of unfit wagons

ROH section Activity: ROH of due / overdue wagons

Freight Yard Activity: Examination of freight trains (Intensive / CC / Premium)

Breakdown Section Activities

ART:

Maintenance of breakdown train including 140 T crane

Restoration work at site of accident

ARME:

Maintenance of Medical Van

Relief and Rescue operation at accident site.

Layout of C & W Depot

You might also like

- SOP-Repair of Trucks & Trailers in WorkshopDocument4 pagesSOP-Repair of Trucks & Trailers in WorkshopChiemeka Osondu100% (4)

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Handbook On Track Machine For PwayDocument99 pagesHandbook On Track Machine For PwayRajesh KumarNo ratings yet

- Course For Loco Inspector Initial (Diesel)Document239 pagesCourse For Loco Inspector Initial (Diesel)Hanuma Reddy93% (14)

- EL-60 PPT (Read-Only)Document9 pagesEL-60 PPT (Read-Only)Soumen BhattaNo ratings yet

- MechanicalDocument83 pagesMechanicaljaiNo ratings yet

- Romd - MechDocument13 pagesRomd - MechSaptarshi PalNo ratings yet

- Organization and Objectives of Mechanical Department - 0Document10 pagesOrganization and Objectives of Mechanical Department - 0Jaikanthan DasarathaNo ratings yet

- Workshop Accounts IntroductionDocument41 pagesWorkshop Accounts Introductionjeya chandranNo ratings yet

- Organization of Rolling Stock Production & Maintenance DepartmentDocument16 pagesOrganization of Rolling Stock Production & Maintenance DepartmentRajkishor GautamNo ratings yet

- Railway Intership ReportDocument19 pagesRailway Intership ReportAbdulRehmanNo ratings yet

- Chapter 4 - Rolling Stock of Report No.14 of 2017 - Compliance Audit Union Government (Railways)Document53 pagesChapter 4 - Rolling Stock of Report No.14 of 2017 - Compliance Audit Union Government (Railways)arjunsai7No ratings yet

- Executive Summary Report-K002Document22 pagesExecutive Summary Report-K002Harsh GuptaNo ratings yet

- SVKM's NMIMS University: Study of Maintenance of ICF/RCF Coaches of Indian RailwayDocument3 pagesSVKM's NMIMS University: Study of Maintenance of ICF/RCF Coaches of Indian RailwayHARDEYVEER SINGHNo ratings yet

- Inplant Training ReportDocument44 pagesInplant Training ReportPrakash DidlaNo ratings yet

- Design of Hydraulic Rail Car MoverDocument44 pagesDesign of Hydraulic Rail Car MoverAvinash BagulNo ratings yet

- Azhar Khan: Career ObjectiveDocument5 pagesAzhar Khan: Career Objectiveأزهر يوسفNo ratings yet

- Carriage DirectorateDocument13 pagesCarriage DirectorateSunakshi SaxenaNo ratings yet

- Industrial Visit ReportDocument8 pagesIndustrial Visit ReportyerraNo ratings yet

- SVKM's NMIMS University: Study of Maintenance of ICF/RCF Coaches of Indian RailwayDocument3 pagesSVKM's NMIMS University: Study of Maintenance of ICF/RCF Coaches of Indian RailwayHARDEYVEER SINGHNo ratings yet

- Presentation On Loco OperationDocument53 pagesPresentation On Loco Operationkumar veluNo ratings yet

- TRO Train ROllinG Stock Operations PDFDocument35 pagesTRO Train ROllinG Stock Operations PDFNalin Lochan GuptaNo ratings yet

- New Microsoft Office Word 97 - 2003 DocumentDocument2 pagesNew Microsoft Office Word 97 - 2003 DocumentJayant MandalNo ratings yet

- Ais 093Document145 pagesAis 093Sreekanth Padmarajan75% (4)

- Government of India Ministry of Railways Railway BoardDocument2 pagesGovernment of India Ministry of Railways Railway BoardKaushal ShrivastavaNo ratings yet

- InternshipDocument17 pagesInternshipmuhammedaamirnaveedNo ratings yet

- North Western Railway: Brief DutiesDocument1 pageNorth Western Railway: Brief DutiesEr Rajesh BuraNo ratings yet

- TRS OperationDocument208 pagesTRS OperationIndianRailfan100% (2)

- Best Practice Guide - Construction Railways OperationsDocument21 pagesBest Practice Guide - Construction Railways OperationsAnonymous tW1zTL2ltNo ratings yet

- Rashtriya Rail Sanraksha KoshDocument4 pagesRashtriya Rail Sanraksha Koshkalpesh102386No ratings yet

- Final Report Complete Reduction in TR Exam Time 29.1.2020 PDFDocument23 pagesFinal Report Complete Reduction in TR Exam Time 29.1.2020 PDFMk SharmaNo ratings yet

- Ayush Agarwal: Study of Maintenance of ICF/RCF Coaches of Indian RailwaysDocument16 pagesAyush Agarwal: Study of Maintenance of ICF/RCF Coaches of Indian RailwaysHarsh GuptaNo ratings yet

- POH Programme 2024-25 TargetsDocument26 pagesPOH Programme 2024-25 TargetsJeetendra Singh ChauhanNo ratings yet

- Civil Engg Supr TRG Modules - 230210Document85 pagesCivil Engg Supr TRG Modules - 230210Sanjay RoutNo ratings yet

- 1613634192827-ZRTI Coaching Theory - 2020Document103 pages1613634192827-ZRTI Coaching Theory - 2020Avinash ArjunNo ratings yet

- Integrated Railway Safety ManagementDocument11 pagesIntegrated Railway Safety ManagementMuthaiya PeriyanayagamNo ratings yet

- Sas Ees LMS LasDocument30 pagesSas Ees LMS LasZishan KhanNo ratings yet

- Training Report DLWDocument30 pagesTraining Report DLWShobhit KushwahaNo ratings yet

- E2e Transportation Training ServicesDocument12 pagesE2e Transportation Training ServicesnajiruddinshaikNo ratings yet

- Harsh Gupta: Study of Maintenance of ICF/RCF Coaches of Indian RailwaysDocument16 pagesHarsh Gupta: Study of Maintenance of ICF/RCF Coaches of Indian RailwaysHarsh GuptaNo ratings yet

- Maintenance and Operational Manual For 140T Cranes PDFDocument903 pagesMaintenance and Operational Manual For 140T Cranes PDFTg Tarro83% (6)

- Formula 1 Connective Innovation PrizeDocument12 pagesFormula 1 Connective Innovation PrizeRahul BuruNo ratings yet

- Syllabus LDCEDocument6 pagesSyllabus LDCEAnurag KumarNo ratings yet

- Railway Monitoring System PDFDocument12 pagesRailway Monitoring System PDFSanjana Singh100% (1)

- Our Visit To Rail Coach FactoryDocument42 pagesOur Visit To Rail Coach FactoryRadha KrishnanNo ratings yet

- Vocational Training Report: National Institute of Technology, PatnaDocument28 pagesVocational Training Report: National Institute of Technology, Patnaarvind raiNo ratings yet

- Auto Manual PDFDocument40 pagesAuto Manual PDFFiroz AminNo ratings yet

- Crown Training Flyer Aug 2009Document1 pageCrown Training Flyer Aug 2009Bill BurnsNo ratings yet

- O-Train Confederation Line & Bus Service UpdateDocument81 pagesO-Train Confederation Line & Bus Service UpdateCTV OttawaNo ratings yet

- Prashant Mishra ReportDocument27 pagesPrashant Mishra ReportPrashant MishraNo ratings yet

- 90 Degree Turning Motorized Steering MechanismDocument62 pages90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- Mechanical Scissor Gearbox Lowering and Lifting MachineDocument22 pagesMechanical Scissor Gearbox Lowering and Lifting Machinemaes fakeNo ratings yet

- Operating Department ReportDocument9 pagesOperating Department ReportAnish AnandNo ratings yet

- Summer Training Report, DLW VaranasiDocument29 pagesSummer Training Report, DLW VaranasiShailesh ShuklaNo ratings yet

- FinalDocument52 pagesFinalYesuf DawudNo ratings yet

- Industrial Training ReportDocument82 pagesIndustrial Training ReportAshish Bansal100% (2)

- Extending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12From EverandExtending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12No ratings yet

- TFC On Single LineDocument17 pagesTFC On Single LineSoumen BhattaNo ratings yet

- TFC On Double LineDocument9 pagesTFC On Double LineSoumen BhattaNo ratings yet

- Precaution Required During Maintenance Work of Rolling Stock in YardDocument6 pagesPrecaution Required During Maintenance Work of Rolling Stock in YardSoumen BhattaNo ratings yet

- Accident: Dhananjay Kumar Singh Instructor ZRTI BhuliDocument17 pagesAccident: Dhananjay Kumar Singh Instructor ZRTI BhuliSoumen BhattaNo ratings yet

- North Western Railway Rajbhasha DepartmentDocument10 pagesNorth Western Railway Rajbhasha DepartmentSoumen BhattaNo ratings yet

- Accident Relief TrainDocument6 pagesAccident Relief TrainSoumen BhattaNo ratings yet

- Long Haul Train OperationDocument4 pagesLong Haul Train OperationSoumen BhattaNo ratings yet

- Coach Shell (Autosaved)Document24 pagesCoach Shell (Autosaved)Soumen BhattaNo ratings yet

- Mechanized Cleaning of CoachesDocument15 pagesMechanized Cleaning of CoachesSoumen BhattaNo ratings yet

- Diesel Engine - FundamentalDocument20 pagesDiesel Engine - FundamentalSoumen BhattaNo ratings yet

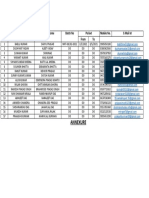

- Annexure: SL - No Trainee Name Fathers Name Batch No Period Mobile No. E-Mail Id From ToDocument1 pageAnnexure: SL - No Trainee Name Fathers Name Batch No Period Mobile No. E-Mail Id From ToSoumen BhattaNo ratings yet

- BMBS For Freight Stock-SKDocument25 pagesBMBS For Freight Stock-SKSoumen BhattaNo ratings yet

- Application Form For SS & HLT ExaminationDocument2 pagesApplication Form For SS & HLT ExaminationSoumen BhattaNo ratings yet

- Diesel Locomotive: Prepared By: - Soumen Bhatta Tr. JE, HWH Division, ERDocument69 pagesDiesel Locomotive: Prepared By: - Soumen Bhatta Tr. JE, HWH Division, ERSoumen Bhatta100% (1)

- WL WL: Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesWL WL: Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Soumen BhattaNo ratings yet

- Objective Mechanical EngineeringDocument163 pagesObjective Mechanical EngineeringSoumen BhattaNo ratings yet

- Weekly Journal 1 - MahbubaDocument3 pagesWeekly Journal 1 - MahbubaasfaqoveeNo ratings yet

- Walkathon Brochure - 2021 Trifold 2Document2 pagesWalkathon Brochure - 2021 Trifold 2api-208159640No ratings yet

- Level 2 Unit 7Document10 pagesLevel 2 Unit 7Yigal AlonNo ratings yet

- Derivative SecuritiesDocument3 pagesDerivative SecuritiesWataru TeradaNo ratings yet

- Bank Reconciliation StatementDocument6 pagesBank Reconciliation StatementHarshitaNo ratings yet

- World Health OrganizationDocument13 pagesWorld Health OrganizationVincent Ranara Sabornido100% (1)

- HLS PON FR12 TheNewConflictMgmt 102021 EdsDocument10 pagesHLS PON FR12 TheNewConflictMgmt 102021 Edskarishma PradhanNo ratings yet

- Catálogo ErdemirDocument334 pagesCatálogo ErdemirveraNo ratings yet

- Assignment 1Document6 pagesAssignment 1Meron SolomonNo ratings yet

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet

- Ethics in Engineering Profession - IES General StudiesDocument16 pagesEthics in Engineering Profession - IES General StudiesSandeep PrajapatiNo ratings yet

- Special Continuous Probability DistributionsDocument11 pagesSpecial Continuous Probability DistributionsnofacejackNo ratings yet

- Rating Pocket Size LEXE2576-08Document21 pagesRating Pocket Size LEXE2576-08Octavio Morales0% (1)

- A Study On Environmental Variables Affecting MarketingDocument23 pagesA Study On Environmental Variables Affecting MarketingShankarPrasaiNo ratings yet

- Stage 2 ChecklistDocument4 pagesStage 2 ChecklistNapoleón ChurioNo ratings yet

- LotusDocument91 pagesLotusJayant SinghalNo ratings yet

- UT Dallas Syllabus For Soc4396.501.11s Taught by Malinda Hicks (Meh033000)Document11 pagesUT Dallas Syllabus For Soc4396.501.11s Taught by Malinda Hicks (Meh033000)UT Dallas Provost's Technology GroupNo ratings yet

- Uni Line Top 4921240130 UkDocument6 pagesUni Line Top 4921240130 UkLUATNo ratings yet

- Xe145m PDFDocument61 pagesXe145m PDFMohamed ZianiNo ratings yet

- Spar Design of A Fokker D-VII - Aerospace Engineering BlogDocument8 pagesSpar Design of A Fokker D-VII - Aerospace Engineering Blogjohn mtz100% (1)

- Design of Iot Blockchain Based Smart Agriculture For Enlightening Safety and SecurityDocument14 pagesDesign of Iot Blockchain Based Smart Agriculture For Enlightening Safety and Securitysumit kaushikNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Exercise Chapters 1-5 No SolutionDocument7 pagesExercise Chapters 1-5 No SolutionTrâm Lê Ngọc BảoNo ratings yet

- BDA PresentationsDocument26 pagesBDA PresentationsTejaswiniNo ratings yet

- FULL TEXT - President Duterte's 2018 State of The Nation Address PDFDocument37 pagesFULL TEXT - President Duterte's 2018 State of The Nation Address PDFDarlene VenturaNo ratings yet

- FORM 11 - Test 4 - Var 2 (D)Document2 pagesFORM 11 - Test 4 - Var 2 (D)Nikita AtrahimovicsNo ratings yet

- Alyssa Locken Resume Jan 2021Document3 pagesAlyssa Locken Resume Jan 2021api-544203584No ratings yet

- 3.methodology of Pressure Settings On Storage Tanks.Document10 pages3.methodology of Pressure Settings On Storage Tanks.heyheyNo ratings yet

- Cox OstromDocument20 pagesCox OstromPeterNo ratings yet