Professional Documents

Culture Documents

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Uploaded by

Israel Orta SánchezCopyright:

Available Formats

You might also like

- Asme PCC-2 - 2022 HighlightedDocument112 pagesAsme PCC-2 - 2022 HighlightedAhmed Shakir67% (3)

- F2164Document5 pagesF2164Hernando Andrés Ramírez Gil100% (1)

- Astm D3139Document3 pagesAstm D3139Hernando Andrés Ramírez GilNo ratings yet

- Astm D3212 PDFDocument3 pagesAstm D3212 PDFdamithNo ratings yet

- (Tos) Third Periodical TestDocument4 pages(Tos) Third Periodical TestMissJalene Obrador72% (32)

- File 985Document4 pagesFile 985Binay K SrivastawaNo ratings yet

- Asme Viii d1 Ma Appendix 3Document3 pagesAsme Viii d1 Ma Appendix 3Chihiya Fitria NurhayatiNo ratings yet

- Asme Viii - Div.1 - 3-2Document3 pagesAsme Viii - Div.1 - 3-2cwkimNo ratings yet

- Asme Sec Viii D1 Ma App 3Document3 pagesAsme Sec Viii D1 Ma App 3ridho arkanaNo ratings yet

- Asme Seccion Viii Division 1 Apendice 3 - 2010 (Definiciones) PDFDocument3 pagesAsme Seccion Viii Division 1 Apendice 3 - 2010 (Definiciones) PDFCristian Alejandro Huerta HernandezNo ratings yet

- Joints For Plastic Pressure Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Plastic Pressure Pipes Using Flexible Elastomeric Sealsastewayb_964354182No ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTTin Aung KyiNo ratings yet

- Process Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionDocument21 pagesProcess Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionKyle BennettNo ratings yet

- Append - A 1-3Document3 pagesAppend - A 1-3Cristian GordilloNo ratings yet

- Testing Application Standard TAS 201-94Document6 pagesTesting Application Standard TAS 201-94Shawn DeolNo ratings yet

- Compression Versus Load Properties of Gasket Materials: Standard Practice ForDocument5 pagesCompression Versus Load Properties of Gasket Materials: Standard Practice Forsalem AhmedNo ratings yet

- APPENDIXDocument2 pagesAPPENDIXLocus Jhun MichaelNo ratings yet

- Pressure Vessels Lectures 71Document1 pagePressure Vessels Lectures 71Adeel NizamiNo ratings yet

- Silver-Tungsten Electrical Contact Materials: Standard Specification ForDocument4 pagesSilver-Tungsten Electrical Contact Materials: Standard Specification ForsamehNo ratings yet

- ASME PCC 2 2022 - Article 312Document15 pagesASME PCC 2 2022 - Article 312Har Wen KitNo ratings yet

- Testing Application Standard 202 94Document6 pagesTesting Application Standard 202 94maikelc1No ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)Thomas C. Lane100% (1)

- PIP PNC00004 - Piping Flexibility AnalysisDocument10 pagesPIP PNC00004 - Piping Flexibility AnalysisAnonymous cuOIjrLI100% (2)

- EC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Document10 pagesEC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Prasad MagdumNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- Impact Test Procedures: Testing Application Standard (Tas) 201-94Document6 pagesImpact Test Procedures: Testing Application Standard (Tas) 201-94MehdiNo ratings yet

- Rubber Insulating Matting: Standard Specification ForDocument9 pagesRubber Insulating Matting: Standard Specification ForgauravNo ratings yet

- MSS SP 145 2013Document13 pagesMSS SP 145 2013alexanderNo ratings yet

- D 178 Â " 01 RDE3OADocument9 pagesD 178 Â " 01 RDE3OAFreddy CabraNo ratings yet

- ASMe Secc II D Appendix5 Guideline On The Approval of New MaDocument3 pagesASMe Secc II D Appendix5 Guideline On The Approval of New MaCARLOS MARIONo ratings yet

- Pressure Vessels Lectures 64Document1 pagePressure Vessels Lectures 64Adeel NizamiNo ratings yet

- Astm B693 17 2022Document2 pagesAstm B693 17 2022Dip MNo ratings yet

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric Sealsastewayb_964354182No ratings yet

- Astm D 5780 95 BiaozhunceshifangfaDocument14 pagesAstm D 5780 95 Biaozhunceshifangfa汤耀No ratings yet

- ASME PCC 2 2022 Article 503Document12 pagesASME PCC 2 2022 Article 503sheikbbaNo ratings yet

- 234 D7091 344Document7 pages234 D7091 344Ivan AlanizNo ratings yet

- Primer On The Asme Section ViiiDocument7 pagesPrimer On The Asme Section ViiiCITRIXNo ratings yet

- A Primer On Asme Section ViiiDocument9 pagesA Primer On Asme Section ViiiCITRIXNo ratings yet

- Definitions and Acronyms: Engineering Standards Manual STD-342-100Document9 pagesDefinitions and Acronyms: Engineering Standards Manual STD-342-100Abdul Gafoor ShaikhNo ratings yet

- AC20-107A Composite Aircraft StructuresDocument11 pagesAC20-107A Composite Aircraft StructuresSanteBrucoliNo ratings yet

- Asme Viii - Div.1Document2 pagesAsme Viii - Div.1cwkimNo ratings yet

- WNS00 SP SG 0460 (Pressure Vessel)Document26 pagesWNS00 SP SG 0460 (Pressure Vessel)zachleong891No ratings yet

- ASTM D 412 (Physical)Document13 pagesASTM D 412 (Physical)Keyzer SozeNo ratings yet

- Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeDocument3 pagesNickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeNav TalukdarNo ratings yet

- C1583 1751769-1Document5 pagesC1583 1751769-1وديع البصريNo ratings yet

- Section Welding: 4 Procedure Tests, Production TestsDocument7 pagesSection Welding: 4 Procedure Tests, Production TestsMahtemeselasie Tesfamariam HailuNo ratings yet

- ASTM D 5882-07 STD Test Method For Low Strain Impact Integrity Testing of Deep FoundationsDocument7 pagesASTM D 5882-07 STD Test Method For Low Strain Impact Integrity Testing of Deep FoundationsILSEN N. DAET0% (1)

- Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed To Cyclic Pressure DifferentialsDocument8 pagesPerformance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed To Cyclic Pressure DifferentialsAhmad Zubair Rasuly100% (1)

- Astm C 1850 - 17Document5 pagesAstm C 1850 - 17HaniAminNo ratings yet

- Rubber Insulating Matting: Standard Specification ForDocument9 pagesRubber Insulating Matting: Standard Specification ForEliecer Emilio Carvajal SantosNo ratings yet

- Printed in GermanyDocument109 pagesPrinted in GermanyGilberto GonzalezNo ratings yet

- National Board Pressure Relief Device Certification Administrative RequirementsDocument3 pagesNational Board Pressure Relief Device Certification Administrative RequirementsHaroltAlexisLeonTripulNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1Document36 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1iplaruffNo ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)anish_am2005No ratings yet

- Astm d621 Deformacion PlasticaDocument6 pagesAstm d621 Deformacion PlasticamsalinasaguilarNo ratings yet

- ASTM D3212.wdge8775Document3 pagesASTM D3212.wdge8775Mariana AvilaNo ratings yet

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocument17 pagesAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNo ratings yet

- Astm E3121 E3121m 17Document3 pagesAstm E3121 E3121m 17aref akel100% (1)

- Annex D Excerpt From The Rules For Welding: I - Part 3 GL 2003 Page D-1Document8 pagesAnnex D Excerpt From The Rules For Welding: I - Part 3 GL 2003 Page D-1J T Mendonça SantosNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- D 5582 - 00 Rdu1odiDocument7 pagesD 5582 - 00 Rdu1odiIsrael Orta SánchezNo ratings yet

- D 5516 - 03 Rdu1mtyDocument7 pagesD 5516 - 03 Rdu1mtyIsrael Orta SánchezNo ratings yet

- D 5536 - 94 R99 Rdu1mzytotrsotkDocument9 pagesD 5536 - 94 R99 Rdu1mzytotrsotkIsrael Orta SánchezNo ratings yet

- D 3737 - 03 RDM3MZCDocument28 pagesD 3737 - 03 RDM3MZCIsrael Orta SánchezNo ratings yet

- D 5457 - 93 R98 Rdu0ntcDocument7 pagesD 5457 - 93 R98 Rdu0ntcIsrael Orta SánchezNo ratings yet

- Evaluating Wood Preservatives by Field Tests With Stakes: Standard Test Method ofDocument7 pagesEvaluating Wood Preservatives by Field Tests With Stakes: Standard Test Method ofIsrael Orta SánchezNo ratings yet

- Iso 9226 2012-02 PDFDocument12 pagesIso 9226 2012-02 PDFIsrael Orta Sánchez100% (1)

- Masonry Cement: Standard Specification ForDocument6 pagesMasonry Cement: Standard Specification ForIsrael Orta SánchezNo ratings yet

- D 2512 - 95 R02 Rdi1mtiDocument13 pagesD 2512 - 95 R02 Rdi1mtiIsrael Orta SánchezNo ratings yet

- Gray Iron Castings: Standard Specification ForDocument5 pagesGray Iron Castings: Standard Specification ForIsrael Orta SánchezNo ratings yet

- Para Estudiar Asme Secc IXDocument40 pagesPara Estudiar Asme Secc IXIsrael Orta SánchezNo ratings yet

- Interpreting Sntc-1a (2018)Document45 pagesInterpreting Sntc-1a (2018)Israel Orta Sánchez100% (3)

- Ecg Machine Contec Type 1200gDocument3 pagesEcg Machine Contec Type 1200gFeliciaSetiawanNo ratings yet

- Soal Bahasa Inggris 10Document12 pagesSoal Bahasa Inggris 10kikiptikc16No ratings yet

- Eon 2019 Sustainability ReportDocument122 pagesEon 2019 Sustainability ReportDarryl Farhan WidyawanNo ratings yet

- 1976 - Susan Leigh Star - LeighDocument3 pages1976 - Susan Leigh Star - LeighEmailton Fonseca Dias100% (1)

- Tech Bulletin 718 PDFDocument28 pagesTech Bulletin 718 PDFJ. BangjakNo ratings yet

- For Checking Reso 101Document3 pagesFor Checking Reso 101Cath VillarinNo ratings yet

- Ba SyllabusDocument5 pagesBa SyllabusKamlesh Kumar MandalNo ratings yet

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Epidemiology and Public Health: Burton's Microbiology For The Health SciencesDocument33 pagesEpidemiology and Public Health: Burton's Microbiology For The Health SciencesMarlop Casicas100% (1)

- This Study Resource Was: Practice Set 6 Demand Management and ForecastingDocument8 pagesThis Study Resource Was: Practice Set 6 Demand Management and ForecastingAbinashMahapatraNo ratings yet

- MDRDocument3 pagesMDRjeffreymacasero100% (1)

- Lasers in Oral MedicineDocument35 pagesLasers in Oral MedicineShreya singh0% (1)

- 4.1 Basic Physics and Band Diagrams For MOS CapacitorsDocument5 pages4.1 Basic Physics and Band Diagrams For MOS CapacitorsvinodNo ratings yet

- Astm A184Document3 pagesAstm A184racingspirit800% (1)

- Electronic Filter Simulation and DesignDocument9 pagesElectronic Filter Simulation and DesignMartinaReyes0% (1)

- Terms ICT 1Document27 pagesTerms ICT 1Quỳnh Trang NguyễnNo ratings yet

- Dextrose Prolotherapy For Muscle, Tendon and Ligament Injury or Pathology: A Systematic ReviewDocument21 pagesDextrose Prolotherapy For Muscle, Tendon and Ligament Injury or Pathology: A Systematic ReviewJP ChenNo ratings yet

- Sds File-16179386Document7 pagesSds File-16179386omar silimNo ratings yet

- MB Manual Ga-C807n eDocument40 pagesMB Manual Ga-C807n eJairo maldonadoNo ratings yet

- DIGITAL CONTROL SYSTEMS April 2018Document8 pagesDIGITAL CONTROL SYSTEMS April 2018KOTHYADA JOSHNANo ratings yet

- Programmes For School, Strengthening Environmental Education in School SystemDocument10 pagesProgrammes For School, Strengthening Environmental Education in School SystemRuhi waliaNo ratings yet

- Man As A Geologic Agent - Sherlock - 1922Document404 pagesMan As A Geologic Agent - Sherlock - 1922geoecologistNo ratings yet

- Machine Design Final Coaching ProblemsDocument63 pagesMachine Design Final Coaching ProblemsasapamoreNo ratings yet

- UNHCR WASH Standards and IndicatorsDocument1 pageUNHCR WASH Standards and IndicatorsMohammad Bahram MonibNo ratings yet

- Equipment Maintenance Log Template 03Document2 pagesEquipment Maintenance Log Template 03Thoni LacknerNo ratings yet

- Model Based Control Design: Alf IsakssonDocument17 pagesModel Based Control Design: Alf IsakssonSertug BaşarNo ratings yet

- What Is Biodecoding?: Only After Using Biodecoding AsDocument3 pagesWhat Is Biodecoding?: Only After Using Biodecoding AsAna DominguezNo ratings yet

- Electrical Safety Explained SimplyDocument175 pagesElectrical Safety Explained SimplyAndi TakwaNo ratings yet

- HINO US Chap02Document10 pagesHINO US Chap02Andres GomezNo ratings yet

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Uploaded by

Israel Orta SánchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling Services

Uploaded by

Israel Orta SánchezCopyright:

Available Formats

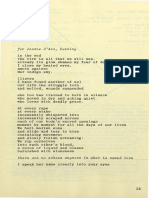

APPENDIX 3

DEFINITIONS

3-1 INTRODUCTION certificate of compliance — a document by which

the material manufacturer or supplier certifies that the

This Appendix contains definitions of terms generally

material represented has been produced and tested in

used in this Division. Definitions relating to specific

accordance with the requirements of the basic material

applications, such as for layered vessels, may be found

specification shown on the certificate. Signatures are

in related parts of this Division.

not required to appear on certificates of compliance.

Objective evidence of compliance with the requirements

of the material specification shall be maintained in the

3-2 DEFINITION OF TERMS records of the material manufacturer or supplier.

clad vessel — a vessel made from a base material

acceptance by the Inspector — where words such as

having a corrosion resistant material either integrally

“acceptance by the Inspector” and /or “accepted by the

bonded or weld metal overlaid to the base of less

Inspector” are used in this Division, they shall be

resistant material

understood to mean that the Inspector has reviewed a

subject in accordance with his duties as required by design pressure — the pressure used in the design of

the rules of this Division and after such review is able a vessel component together with the coincident design

to sign the Certificate of Inspection for the applicable metal temperature, for the purpose of determining the

Manufacturer’s Data Report Form. Such words do minimum permissible thickness or physical characteris-

not imply assumption by the Inspector of any of the tics of the different zones of the vessel. When applicable,

responsibilities of the Manufacturer. static head shall be added to the design pressure to

determine the thickness of any specific zone of the

angle joint — a joint between two members located

vessel (see UG-21).

in intersecting planes between 0 deg. (a butt joint) and

90 deg. (a corner joint) design temperature — see UG-20

basic material specification — a description of the efficiency of a welded joint — the efficiency of a

identifying characteristics of a material (product form, welded joint is expressed as a numerical (decimal)

ranges of composition, mechanical properties, methods quantity and is used in the design of a joint as a

of production, etc.) together with the sampling, testing, multiplier of the appropriate allowable stress value

and examination procedures to be applied to production taken from the applicable table in Subpart 1 of Section

lots of such material to verify acceptable conformance II, Part D (see UW-12)

to the intended characteristics layered vessel — a vessel having a shell and /or heads

bolt — a threaded fastener with a head on one end made up of two or more separate layers

calculated test pressure — the requirements for de- lined vessel — a vessel having a corrosion resistant

termining the test pressure based on calculations are lining attached intermittently to the vessel wall

outlined in UG-99(c) for the hydrostatic test and in liquid penetrant examination (PT) — a method of

UG-100(b) for the pneumatic test. The basis for calcu- nondestructive examination which provides for the de-

lated test pressure in either of these paragraphs is the tection of imperfections open to the surface in ferrous

highest permissible internal pressure as determined by and nonferrous materials which are nonporous. Typical

the design formulas, for each element of the vessel imperfections detectable by this method are cracks,

using nominal thicknesses with corrosion allowances seams, laps, cold shuts, and laminations.

included and using the allowable stress values given magnetic particle examination (MT) — a method of

in Subpart 1 of Section II, Part D for the temperature detecting cracks and similar imperfections at or near

of the test. the surface in iron and the magnetic alloys of steel.

350

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

3-2 APPENDIX 3 — MANDATORY 3-2

It consists of properly magnetizing the material and maximum allowable working pressure — the maximum

applying finely divided magnetic particles which form gage pressure permissible at the top of a completed

patterns indicating the imperfections. vessel in its normal operating position at the designated

material — any substance or product form which is coincident temperature for that pressure. This pressure

covered by an SA, SB, or SFA material specification is the least of the values for the internal or external

in Section II or any other material permitted by the Code pressure to be determined by the rules of this Division

material manufacturer — the organization which per- for any of the pressure boundary parts, including the

forms or supervises and directly controls one or more static head thereon, using nominal thicknesses exclusive

of the operations which affect the material properties of allowances for corrosion and considering the effects

required by the basic material specification. The material of any combination of loadings listed in UG-22 which

manufacturer certifies the results of one or more of are likely to occur (see UG-98) at the designated

the tests, examinations, repairs, or treatments required by coincident temperature [see UG-20(a)]. It is the basis

the basic material specification. When the specification for the pressure setting of the pressure relieving devices

permits certain specific requirements to be completed protecting the vessel. The design pressure may be used

later, those incomplete items must be noted. in all cases in which calculations are not made to

determine the value of the maximum allowable working

material supplier — the organization which supplies pressure.

material furnished and certified by a material manufac-

turer, but which does not perform any operation intended membrane stress — the component of normal stress

to affect the material properties required by the basic which is uniformly distributed and equal to the average

material specification. The material supplier may per- value of stress across the thickness of the section under

form and certify the results of tests, examinations, consideration

repairs, and treatments not performed by the material normal operation — operation within the design limits

manufacturer. for which the vessel has been stamped. [See UG-

Material Test Report — a document, or documents, on 116(a).] Any coincident pressure and temperature during

which are recorded the results of tests, examinations, a specific operation are permissible, provided they do

repairs, or treatments required by the basic material not constitute a more severe condition than that assumed

specification to be reported. Supplementary or special in the design of the vessel.

requirements in addition to the requirements of the operating or working temperature — the temperature

basic material specification may also be included on that will be maintained in the metal of the part of the

the Material Test Report. All such documents shall vessel being considered for the specified operation of

identify the applicable material specification and shall the vessel (see UG-20 and UG-23)

be identified to the material represented. When preparing

operating pressure — the pressure at the top of a

a Material Test Report, a material manufacturer may

vessel at which it normally operates. It shall not exceed

transcribe data produced by other organizations provided

the maximum allowable working pressure, and it is

he accepts responsibility for the accuracy and authentic-

usually kept at a suitable level below the setting of

ity of the data and maintains a file containing the test

the pressure relieving devices to prevent their frequent

report from the originator of the data. In such instances,

opening (see M-9).

the material manufacturer shall identify on the Material

Test Report the source of the data and the location of porosity — gas pockets or voids in metal

the file containing the test report from the originator primary stress — a stress developed by the imposed

of the data. Signatures are not required to appear on loading which is necessary to satisfy the simple laws

Material Test Reports. A material supplier shall not of equilibrium of external and internal forces and

transcribe data certified by a material manufacturer but moments. Primary stress can be either membrane or

shall furnish a copy of that certification, supplemented bending stress.

as necessary by additional documents which certify the Primary membrane stress may be of two types:

results of tests, examinations, repairs, or treatments general and local. A general primary membrane stress

required by the basic material specification and per- is one which is so distributed in the structure that

formed by the material supplier. no redistribution of load occurs as a result of yielding.

maximum allowable stress value — the maximum unit A local primary membrane stress is one which is

stress permissible for any specified material that may produced by pressure or other mechanical loading and

be used in the design formulas given in this Division which is associated with a primary and /or discontinuity

(see UG-23) effect.

351

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

3-2 2001 SECTION VIII — DIVISION 1 3-2

Examples of primary stress are: (a) design thickness — the sum of the required

(a) general membrane stress in a circular cylinder thickness and the corrosion allowance (see UG-25)

or a spherical shell due to internal pressure or to (b) required thickness — that computed by the formu-

distributed loads; las in this Division before corrosion allowance is added

(b) bending stress in the central portion of a flat (see UG-22)

head due to pressure. (c) nominal thickness — except as defined in UW-

40(f) and modified in UW-11(g), the nominal thickness

is the thickness selected as commercially available, and

radiographic examination (RT) — a method of detecting supplied to the Manufacturer. For plate material, the

imperfections in materials by passing X-ray or nuclear nominal thickness shall be, at the Manufacturer’s option,

radiation through the material and presenting their image either the thickness shown on the Material Test Report

on a recording medium {or material Certificate of Compliance [UG-93(a)(1)]}

before forming, or the measured thickness of the plate

at the joint or location under consideration.

safety valve set pressure — See ASME PTC 25

ultrasonic examination (UT) — a method for detecting

imperfections in materials by passing ultrasonic vibra-

stationary pressure vessel — a pressure vessel to be tions (frequencies normally 1 MHz to 5 MHz) through

installed and operated as a fixed geographical location the material

vessel Manufacturer — any Manufacturer who con-

structs an item such as a pressure vessel, vessel compo-

stud — a threaded fastener without a head, with threads nent, or part in accordance with rules of this Division

on one end or both ends, or threaded full length and who holds an ASME Certificate of Authorization

thickness of vessel wall to apply the Code Symbol Stamp to such an item

352

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Asme PCC-2 - 2022 HighlightedDocument112 pagesAsme PCC-2 - 2022 HighlightedAhmed Shakir67% (3)

- F2164Document5 pagesF2164Hernando Andrés Ramírez Gil100% (1)

- Astm D3139Document3 pagesAstm D3139Hernando Andrés Ramírez GilNo ratings yet

- Astm D3212 PDFDocument3 pagesAstm D3212 PDFdamithNo ratings yet

- (Tos) Third Periodical TestDocument4 pages(Tos) Third Periodical TestMissJalene Obrador72% (32)

- File 985Document4 pagesFile 985Binay K SrivastawaNo ratings yet

- Asme Viii d1 Ma Appendix 3Document3 pagesAsme Viii d1 Ma Appendix 3Chihiya Fitria NurhayatiNo ratings yet

- Asme Viii - Div.1 - 3-2Document3 pagesAsme Viii - Div.1 - 3-2cwkimNo ratings yet

- Asme Sec Viii D1 Ma App 3Document3 pagesAsme Sec Viii D1 Ma App 3ridho arkanaNo ratings yet

- Asme Seccion Viii Division 1 Apendice 3 - 2010 (Definiciones) PDFDocument3 pagesAsme Seccion Viii Division 1 Apendice 3 - 2010 (Definiciones) PDFCristian Alejandro Huerta HernandezNo ratings yet

- Joints For Plastic Pressure Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Plastic Pressure Pipes Using Flexible Elastomeric Sealsastewayb_964354182No ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTTin Aung KyiNo ratings yet

- Process Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionDocument21 pagesProcess Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionKyle BennettNo ratings yet

- Append - A 1-3Document3 pagesAppend - A 1-3Cristian GordilloNo ratings yet

- Testing Application Standard TAS 201-94Document6 pagesTesting Application Standard TAS 201-94Shawn DeolNo ratings yet

- Compression Versus Load Properties of Gasket Materials: Standard Practice ForDocument5 pagesCompression Versus Load Properties of Gasket Materials: Standard Practice Forsalem AhmedNo ratings yet

- APPENDIXDocument2 pagesAPPENDIXLocus Jhun MichaelNo ratings yet

- Pressure Vessels Lectures 71Document1 pagePressure Vessels Lectures 71Adeel NizamiNo ratings yet

- Silver-Tungsten Electrical Contact Materials: Standard Specification ForDocument4 pagesSilver-Tungsten Electrical Contact Materials: Standard Specification ForsamehNo ratings yet

- ASME PCC 2 2022 - Article 312Document15 pagesASME PCC 2 2022 - Article 312Har Wen KitNo ratings yet

- Testing Application Standard 202 94Document6 pagesTesting Application Standard 202 94maikelc1No ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)Thomas C. Lane100% (1)

- PIP PNC00004 - Piping Flexibility AnalysisDocument10 pagesPIP PNC00004 - Piping Flexibility AnalysisAnonymous cuOIjrLI100% (2)

- EC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Document10 pagesEC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Prasad MagdumNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- Impact Test Procedures: Testing Application Standard (Tas) 201-94Document6 pagesImpact Test Procedures: Testing Application Standard (Tas) 201-94MehdiNo ratings yet

- Rubber Insulating Matting: Standard Specification ForDocument9 pagesRubber Insulating Matting: Standard Specification ForgauravNo ratings yet

- MSS SP 145 2013Document13 pagesMSS SP 145 2013alexanderNo ratings yet

- D 178 Â " 01 RDE3OADocument9 pagesD 178 Â " 01 RDE3OAFreddy CabraNo ratings yet

- ASMe Secc II D Appendix5 Guideline On The Approval of New MaDocument3 pagesASMe Secc II D Appendix5 Guideline On The Approval of New MaCARLOS MARIONo ratings yet

- Pressure Vessels Lectures 64Document1 pagePressure Vessels Lectures 64Adeel NizamiNo ratings yet

- Astm B693 17 2022Document2 pagesAstm B693 17 2022Dip MNo ratings yet

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric Sealsastewayb_964354182No ratings yet

- Astm D 5780 95 BiaozhunceshifangfaDocument14 pagesAstm D 5780 95 Biaozhunceshifangfa汤耀No ratings yet

- ASME PCC 2 2022 Article 503Document12 pagesASME PCC 2 2022 Article 503sheikbbaNo ratings yet

- 234 D7091 344Document7 pages234 D7091 344Ivan AlanizNo ratings yet

- Primer On The Asme Section ViiiDocument7 pagesPrimer On The Asme Section ViiiCITRIXNo ratings yet

- A Primer On Asme Section ViiiDocument9 pagesA Primer On Asme Section ViiiCITRIXNo ratings yet

- Definitions and Acronyms: Engineering Standards Manual STD-342-100Document9 pagesDefinitions and Acronyms: Engineering Standards Manual STD-342-100Abdul Gafoor ShaikhNo ratings yet

- AC20-107A Composite Aircraft StructuresDocument11 pagesAC20-107A Composite Aircraft StructuresSanteBrucoliNo ratings yet

- Asme Viii - Div.1Document2 pagesAsme Viii - Div.1cwkimNo ratings yet

- WNS00 SP SG 0460 (Pressure Vessel)Document26 pagesWNS00 SP SG 0460 (Pressure Vessel)zachleong891No ratings yet

- ASTM D 412 (Physical)Document13 pagesASTM D 412 (Physical)Keyzer SozeNo ratings yet

- Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeDocument3 pagesNickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Pipe and TubeNav TalukdarNo ratings yet

- C1583 1751769-1Document5 pagesC1583 1751769-1وديع البصريNo ratings yet

- Section Welding: 4 Procedure Tests, Production TestsDocument7 pagesSection Welding: 4 Procedure Tests, Production TestsMahtemeselasie Tesfamariam HailuNo ratings yet

- ASTM D 5882-07 STD Test Method For Low Strain Impact Integrity Testing of Deep FoundationsDocument7 pagesASTM D 5882-07 STD Test Method For Low Strain Impact Integrity Testing of Deep FoundationsILSEN N. DAET0% (1)

- Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed To Cyclic Pressure DifferentialsDocument8 pagesPerformance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed To Cyclic Pressure DifferentialsAhmad Zubair Rasuly100% (1)

- Astm C 1850 - 17Document5 pagesAstm C 1850 - 17HaniAminNo ratings yet

- Rubber Insulating Matting: Standard Specification ForDocument9 pagesRubber Insulating Matting: Standard Specification ForEliecer Emilio Carvajal SantosNo ratings yet

- Printed in GermanyDocument109 pagesPrinted in GermanyGilberto GonzalezNo ratings yet

- National Board Pressure Relief Device Certification Administrative RequirementsDocument3 pagesNational Board Pressure Relief Device Certification Administrative RequirementsHaroltAlexisLeonTripulNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1Document36 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1iplaruffNo ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)anish_am2005No ratings yet

- Astm d621 Deformacion PlasticaDocument6 pagesAstm d621 Deformacion PlasticamsalinasaguilarNo ratings yet

- ASTM D3212.wdge8775Document3 pagesASTM D3212.wdge8775Mariana AvilaNo ratings yet

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocument17 pagesAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNo ratings yet

- Astm E3121 E3121m 17Document3 pagesAstm E3121 E3121m 17aref akel100% (1)

- Annex D Excerpt From The Rules For Welding: I - Part 3 GL 2003 Page D-1Document8 pagesAnnex D Excerpt From The Rules For Welding: I - Part 3 GL 2003 Page D-1J T Mendonça SantosNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- D 5582 - 00 Rdu1odiDocument7 pagesD 5582 - 00 Rdu1odiIsrael Orta SánchezNo ratings yet

- D 5516 - 03 Rdu1mtyDocument7 pagesD 5516 - 03 Rdu1mtyIsrael Orta SánchezNo ratings yet

- D 5536 - 94 R99 Rdu1mzytotrsotkDocument9 pagesD 5536 - 94 R99 Rdu1mzytotrsotkIsrael Orta SánchezNo ratings yet

- D 3737 - 03 RDM3MZCDocument28 pagesD 3737 - 03 RDM3MZCIsrael Orta SánchezNo ratings yet

- D 5457 - 93 R98 Rdu0ntcDocument7 pagesD 5457 - 93 R98 Rdu0ntcIsrael Orta SánchezNo ratings yet

- Evaluating Wood Preservatives by Field Tests With Stakes: Standard Test Method ofDocument7 pagesEvaluating Wood Preservatives by Field Tests With Stakes: Standard Test Method ofIsrael Orta SánchezNo ratings yet

- Iso 9226 2012-02 PDFDocument12 pagesIso 9226 2012-02 PDFIsrael Orta Sánchez100% (1)

- Masonry Cement: Standard Specification ForDocument6 pagesMasonry Cement: Standard Specification ForIsrael Orta SánchezNo ratings yet

- D 2512 - 95 R02 Rdi1mtiDocument13 pagesD 2512 - 95 R02 Rdi1mtiIsrael Orta SánchezNo ratings yet

- Gray Iron Castings: Standard Specification ForDocument5 pagesGray Iron Castings: Standard Specification ForIsrael Orta SánchezNo ratings yet

- Para Estudiar Asme Secc IXDocument40 pagesPara Estudiar Asme Secc IXIsrael Orta SánchezNo ratings yet

- Interpreting Sntc-1a (2018)Document45 pagesInterpreting Sntc-1a (2018)Israel Orta Sánchez100% (3)

- Ecg Machine Contec Type 1200gDocument3 pagesEcg Machine Contec Type 1200gFeliciaSetiawanNo ratings yet

- Soal Bahasa Inggris 10Document12 pagesSoal Bahasa Inggris 10kikiptikc16No ratings yet

- Eon 2019 Sustainability ReportDocument122 pagesEon 2019 Sustainability ReportDarryl Farhan WidyawanNo ratings yet

- 1976 - Susan Leigh Star - LeighDocument3 pages1976 - Susan Leigh Star - LeighEmailton Fonseca Dias100% (1)

- Tech Bulletin 718 PDFDocument28 pagesTech Bulletin 718 PDFJ. BangjakNo ratings yet

- For Checking Reso 101Document3 pagesFor Checking Reso 101Cath VillarinNo ratings yet

- Ba SyllabusDocument5 pagesBa SyllabusKamlesh Kumar MandalNo ratings yet

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Epidemiology and Public Health: Burton's Microbiology For The Health SciencesDocument33 pagesEpidemiology and Public Health: Burton's Microbiology For The Health SciencesMarlop Casicas100% (1)

- This Study Resource Was: Practice Set 6 Demand Management and ForecastingDocument8 pagesThis Study Resource Was: Practice Set 6 Demand Management and ForecastingAbinashMahapatraNo ratings yet

- MDRDocument3 pagesMDRjeffreymacasero100% (1)

- Lasers in Oral MedicineDocument35 pagesLasers in Oral MedicineShreya singh0% (1)

- 4.1 Basic Physics and Band Diagrams For MOS CapacitorsDocument5 pages4.1 Basic Physics and Band Diagrams For MOS CapacitorsvinodNo ratings yet

- Astm A184Document3 pagesAstm A184racingspirit800% (1)

- Electronic Filter Simulation and DesignDocument9 pagesElectronic Filter Simulation and DesignMartinaReyes0% (1)

- Terms ICT 1Document27 pagesTerms ICT 1Quỳnh Trang NguyễnNo ratings yet

- Dextrose Prolotherapy For Muscle, Tendon and Ligament Injury or Pathology: A Systematic ReviewDocument21 pagesDextrose Prolotherapy For Muscle, Tendon and Ligament Injury or Pathology: A Systematic ReviewJP ChenNo ratings yet

- Sds File-16179386Document7 pagesSds File-16179386omar silimNo ratings yet

- MB Manual Ga-C807n eDocument40 pagesMB Manual Ga-C807n eJairo maldonadoNo ratings yet

- DIGITAL CONTROL SYSTEMS April 2018Document8 pagesDIGITAL CONTROL SYSTEMS April 2018KOTHYADA JOSHNANo ratings yet

- Programmes For School, Strengthening Environmental Education in School SystemDocument10 pagesProgrammes For School, Strengthening Environmental Education in School SystemRuhi waliaNo ratings yet

- Man As A Geologic Agent - Sherlock - 1922Document404 pagesMan As A Geologic Agent - Sherlock - 1922geoecologistNo ratings yet

- Machine Design Final Coaching ProblemsDocument63 pagesMachine Design Final Coaching ProblemsasapamoreNo ratings yet

- UNHCR WASH Standards and IndicatorsDocument1 pageUNHCR WASH Standards and IndicatorsMohammad Bahram MonibNo ratings yet

- Equipment Maintenance Log Template 03Document2 pagesEquipment Maintenance Log Template 03Thoni LacknerNo ratings yet

- Model Based Control Design: Alf IsakssonDocument17 pagesModel Based Control Design: Alf IsakssonSertug BaşarNo ratings yet

- What Is Biodecoding?: Only After Using Biodecoding AsDocument3 pagesWhat Is Biodecoding?: Only After Using Biodecoding AsAna DominguezNo ratings yet

- Electrical Safety Explained SimplyDocument175 pagesElectrical Safety Explained SimplyAndi TakwaNo ratings yet

- HINO US Chap02Document10 pagesHINO US Chap02Andres GomezNo ratings yet