Professional Documents

Culture Documents

Presentation On Chemical Management

Presentation On Chemical Management

Uploaded by

EMS 4AYDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentation On Chemical Management

Presentation On Chemical Management

Uploaded by

EMS 4AYDCopyright:

Available Formats

Presentation on

Chemical

Management

Md. Azmeri Latif Beg

M.Tech. (Textile Chemistry)

European Textile Chemical

Corporation

European Textile Chemical Corporation

The apparel sector certainly is not as chemical intensive as other

global industries, but its variety of chemical operations and

materials does present a range of potential hazards to its workers

and the surrounding communities and environment.

It can take a lot of chemicals to make clothes. However,

hazardous chemicals can harm the global environment as well as

the health of our customers, employees and workers throughout

our value chain. ETCC ensure that our products are safe and to

eliminate discharges to water, soil and air throughout the life cycle

of all our products.

European Textile Chemical Corporation

To achieve the safe use of chemicals and to control the

hazards that they present to workers, the community and the

environment, a factory must be organized in its approach to

the various aspects of chemical use.

v C hemical management dealings with costs and

environmental compliance.

v Chemical inventory management procedures advises on

how to comply with global chemical legislation, Retailer &

Brand Restricted Substance Lists (RSL’s) and Manufacturing

Restricted Substance Lists (MRSL’s), any other chemical

requirements of the textile and apparel industry.

v Chemical Management System (CMS) Guidance Manual

focuses on the approach, structure and documentation needed

to create and support a Zero Discharge of Hazardous

Chemicals (ZDHC).

European Textile Chemical Corporation

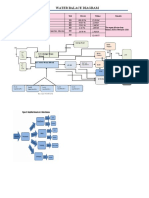

Why a Chemical Management System?

To achieve the safe use of chemicals and to control the hazards that they present to

workers, the community and the environment, a factory must be organized in its approach

to the various aspects of chemical use.

Fundamental Diagram of CMS for Apparel Industry

PLAN: Say what you should Do regarding CMS

DO: Then Do what you Say

CHECK: Prove it

(RE)ACT: Are you satisfied? Can you improve?

European Textile Chemical Corporation

KEY OBJECTIVES OF CHEMICAL MANAGEMENT

v Understand the intrinsic hazards of chemicals

stored in the facility and used in application

processes or for other functions e.g. hygiene

chemicals used in sanitary areas

v Ensure workers are given sufficient information,

training and guidance on how to safely store,

transport, use and dispose of chemicals in a safe

and consistent manner

v Maintain an up-to-date inventory of all

chemicals used in the facility

v Minimize adverse effects of chemicals on the

health and safety of the workforce

European Textile Chemical Corporation

LABELING

v A guidance on labeling routine and labeling format should be

developed and implemented in the units.

v Chemical responsible should ensure all the label information is

following the labeling routine.

v Labels on chemical containers should include the chemical

substance name, CAS/EC no. of the substance, supplier contact

information, hazard pictogram risk and safety phrase, hazardous

statement, batch info, purchase date and expiry date. All

information should be provided by chemical manufacturer.

v A clear label should be affixed to all chemical containers and

bottles for easy identification.

European Textile Chemical Corporation

STORAGE

Chemical should be stored safety and properly to provide a safe work

place.

A standard operation procedure of storage of chemicals should be

developed to ensure the chemicals are stored in proper way.

The storage guideline should provide a clear instruction in local

language on how and where chemicals should be stored.

A warning notice, e.g. ‘’chemical Storage Area’’ should be visible in

all storage areas.

Chemical storage room should be in good ventilation to keep

humidity and temperature at optimal levels. No direct sunlight on

chemicals.

All chemicals should be stored according to SDS (Safety Data Sheet)

information.

European Textile Chemical Corporation

STORAGE

Abstracted/simplified SDS in local language should be

available in storage room. Information includes:

i. Chemical product identification & company name,

ii. Hazards identification

iii. First aid measures

iv. Accidental release measures

v. Personal protective equipment

vi. Toxicological information

All chemicals stored should be recorded in chemical inventory

list (CIL) to avoid excessive storage of dangerous chemicals.

The CIL should be updated and reviewed regularly.

European Textile Chemical Corporation

GLOBAL HARMONIZATION SYSTEM (GHS)

The Global Harmonization System (GHS) is the product of an effort by the

United Nations to create a uniform system for the classification and ranking of

chemical hazards and the methods by which hazard information will be

communicated.

The GHS hazard pictograms or symbols represent perhaps the most obvious

means of hazard communication, and their recognition by personnel is important

in any industry in which chemical materials are used.

Explosives and extremely reactive chemicals, such as organic

peroxides, water-reactive chemicals, and some self-reactive

chemicals (unstable in heat)

Flammable liquids, solids and gases; including pyrophorics

(ignite on contact with air), some self-reactive chemicals and

chemicals that release flammable gases (hydrogen)

European Textile Chemical Corporation

GLOBAL HARMONIZATION SYSTEM (GHS)

Gases under Pressure: compressed gases (cylinders) and

liquefied gases (such as LNG fuel)

Oxidizers: chemicals that are not necessarily combustible, but

may, generally by yielding Oxygen during a fire, cause or

contribute to the combustion of other materials

Acute Toxicity: poisons by inhalation, ingestion or skin

exposure; may be fatal or rapidly toxic

Corrosive: to the skin (severe burns), to the eye (damage), and

corrosive to metals

European Textile Chemical Corporation

GLOBAL HARMONIZATION SYSTEM (GHS)

Moderate Health Hazards: Irritation of the skin or eyes; skin

sensitizer (allergic reaction); nervous system effects such as

drowsiness or dizziness (generally: not severe and reversible)

Serious Health Hazards: Cancer, Reproductive Toxicity,

Respiratory Sensitization (Asthma), Target Organ Toxicity

(Liver, Kidneys, Nervous System, Lungs), Aspiration Hazard

Hazardous to the Aquatic Environment: to Fish, Plants and

Organisms; or Bioaccumulative

Recognition by management of the potential hazards created by the use of

chemicals in the workplace, and awareness of these hazards by workers so that

both management and workers can take appropriate steps to prevent and avoid

potential harm, are essential to a safe workplace and environment.

European Textile Chemical Corporation

R and S phrases

Hazard classification should be indicated with hazard signs and hazard symbols

and/or R phrases as well as S phrases.

v R phrase and R number: phrases indicating the risks of hazardous preparations

and substances, and their numbers respectively.

v S phrase and S number: phrases related to the safe handling of hazardous

preparations, and their numbers respectively.

Risk Phrases (R) and Safety Phrases (S) also occurs in combinations

(combined R and S phrases).

R and S Phrases are separated with dashes or slashes which mean the

following:

dash: R Phrases and S Phrases are formulated separately

slash : the possibility of formulating R Phrases or S Phrases in a single

sentence (combined R or S Phrases)

European Textile Chemical Corporation

RISK PHRASES (R) AND SAFETY PHRASES (S)

It is a general rule that in case of preparations usually a maximum of 6 phrases

are applied to inform about the risks; in this respect combined phrases are

regarded as single phrases.

The sentences that are applied should inform about all significant hazards of the

preparation, therefore in some cases more than 6 R Phrases may be necessary.

The R Phrases on the label as well as the method and aim of the preparation’s

intended use should be taken into account in the final choice of S Phrases.

As a general rule, a maximum of 6 sentences are used to inform about the most

necessary precautions; in this respect combined phrases are regarded as single

phrases.

In some cases more than 6 S Phrases may be necessary.

European Textile Chemical Corporation

STORAGE

Chemical should be stored on impervious surfaces in a systematic

way and easily identified by labels.

European Textile Chemical Corporation

STORAGE

v Incompatible chemicals should be stored separately. E.g.

potassium permanganate cannot be stored with strong

bases and acids.

i. Reactive chemicals should be stored away from possible

reaction sources, such as the water, and should be stored

in a low humidity environment.

ii. Flammable or combustible chemicals should be stored

away from sources of ignition in designated area.

European Textile Chemical Corporation

STORAGE

iii. The amount of flammable or combustible chemicals stored

should fulfill fire safety requirements.

iv. Acids and bases should be segregated from each other.

v. Oxidizers should be kept away from chemicals, especially

flammables or combustibles.

vi. Corrosives should be kept away from substances that they may

react with and release corrosive.

v Chemicals must be sealed when not In use.

v Containers should not be corroded, broken, rusted or leaking.

Secondary containment is required for the storage of all

regulated hazardous chemicals.

v Chemical drums should be placed on elevated racks and far away

from drains.

v First in first out system should be implemented in the storage

room to avoid chemical degradation.

European Textile Chemical Corporation

STORAGE

v Expired chemicals should be removed from chemical storage room

and recollected by chemical suppliers or qualified third party.

v Food, beverage and tobacco should not be allowed in chemical

storage area.

v Chemical storage room is not allowed to enter without permission.

European Textile Chemical Corporation

STORAGE

v Chemicals should be stored higher than 1,5m.

v Chemicals are stored too high, posing risk for

work accident.

European Textile Chemical Corporation

STORAGE

v First aid box, personal protective equipment (PPE) box, proper

extinguisher, emergency shower/eye wash station spill kits,

secondary containment should be placed in chemical storage area.

European Textile Chemical Corporation

HANDLING

v Clear instruction and safety precaution (in local languages) on

chemical handing should be clearly stated in the working area.

v Chemical handling staffs should check the expiry date of

chemicals before use.

v Chemical handling staff should review SDS and understand the

hazard before using a chemical.

v Chemically hazard assessment should be done periodically.

European Textile Chemical Corporation

HANDLING

v Chemical handing staff should wear proper PPE, such as gloves, masks

and safety glasses, when handling chemicals. The section of PPE should

be based on potential hazard of chemicals handled by workers.

v Appropriate personal protective equipment (PPE) should be provided to

the workers.

European Textile Chemical Corporation

WEIGHTING AND TRANSFERRING

v Chemical should be kept in clean and ventilated area which keeps

away from sunlight.

v Chemical should be used according to first in first out basis

v Chemical handling staff should wash their hands after handling

chemicals

v Chemicals should be transferred in a correct way to avoid

contamination and ensure worker safety.

v Appropriate and clean tools should be used when measuring and

weighting the chemicals to avoid the cross contamination of

chemicals.

European Textile Chemical Corporation

WEIGHTING AND TRANSFERRING

v Reactive and volatile chemicals should be transferred in a closed

and well ventilated system to avoid spreading of chemical vapors

and spillage.

v Equipment and apparatus used for dispensing chemicals must be

clean, dried and working properly.

European Textile Chemical Corporation

WEIGHTING AND TRANSFERRING

v Materials of containers used for dispensing must be

compatible with the chemicals.

v Dispensed chemicals should not be returned to stock to

reduce the risk of contamination.

v Transporting apparatus should be available to move chemical

materials to ensure safety.

v The usage of chemical must be recorded in a chemical usage

log book. The chemical usage log book should record the

person using the chemicals, time of use of chemicals, used

which product/process and the quantity of chemicals used.

European Textile Chemical Corporation

APPLICATION OF CHEMICALS

v Production responsible and chemical handling staff should be

well trained on how to handle and use of chemicals.

v Chemical handling staff should ensure best use of chemicals.

The amount of chemicals used should be with reference to

suggestions from chemical suppliers. Excessive use of

chemicals should be avoided.

v The total amount of chemicals used in production should be

calculated.

v The amount of chemicals that are contaminated, lost or

wasted should be evaluated.

v Chemicals should not be pre mixed before use.

European Textile Chemical Corporation

CHEMICAL WASTE

v Factories should set up a procedure to minimize the amount of

chemical waste produced.

v Factories should develop a guideline on chemical waste disposal.

v Factories should appoint a responsible person for chemical waste

disposal.

v Containers for chemical waste should be chemical compatible.

v All waste containers must be covered.

v Appropriate transporting apparatus, e.g. spring loaded funnels

should be used for adding waste to waste containers.

v Containers should not be fully filled. Each container must have at

least one inch of headspace above the waste.

v The waste container should be labeled with hazardous waste label.

v The waste should be stored in a safe area, and should be away

from emergency equipment such as safety showers and emergency

access panels.

v The waste container should not block exits of workplace.

European Textile Chemical Corporation

CHEMICAL WASTE

v Empty chemical containers should be kept separate and store in

designated area which not directly affected by direct sunlight, rain,

fire.

European Textile Chemical Corporation

CHEMICAL WASTE

v Empty chemical containers should be kept separate and store in

designated area which not directly affected by direct sunlight, rain,

fire.

European Textile Chemical Corporation

CHEMICAL WASTE

v Factories should develop a guideline on controlling the chemicals

discharged through waste water.

v Factories should appoint a responsible person for controlling and

monitoring waste water discharge.

v Factories should develop and implement environment impact evaluation on

chemical discharge.

v Waste water should be treated by effluent treatment plant before discharge

to open bodies.

v Quality and quantity of waste water discharged should be monitored and

recorded periodically.

v Waste water should be tested and recorded must be kept future analyses.

v Containers for chemical waste should be chemical compatible.

v All waste containers must be covered.

v The amount of waste water discharged and goals on controlling of chemical

discharge should be disclosed and transparent to public.

v Corrective action should be implemented when non conformities are found.

European Textile Chemical Corporation

European Textile Chemical Corporation

You might also like

- Textbook Environmental Organic Chemistry 3Rd Edition Rene P Schwarzenbach Ebook All Chapter PDFDocument53 pagesTextbook Environmental Organic Chemistry 3Rd Edition Rene P Schwarzenbach Ebook All Chapter PDFfrancisco.brown366100% (14)

- Fission and Fusion POGIL Answer KeyDocument3 pagesFission and Fusion POGIL Answer KeyFadhilah ArifNo ratings yet

- Presenting by Praveen Kumar ChoudharyDocument60 pagesPresenting by Praveen Kumar ChoudharyPraveen Kumar ChoudharyNo ratings yet

- Chemical Handling Presentation by HenryDocument30 pagesChemical Handling Presentation by HenryHenry chukwumaNo ratings yet

- What Are Chemical SubstancesDocument25 pagesWhat Are Chemical SubstancesKuenieBondocoyNo ratings yet

- Hazardous Substances RJC Guidance Draftv1Document6 pagesHazardous Substances RJC Guidance Draftv1Chaitanya NarreddyNo ratings yet

- 3.2. Procedures For Proper Labeling, Storage, and Management of ChemicalsDocument5 pages3.2. Procedures For Proper Labeling, Storage, and Management of ChemicalsRhieza Perez UmandalNo ratings yet

- The Globally Harmonized System (GHS) For Hazard Classification and LabellingDocument36 pagesThe Globally Harmonized System (GHS) For Hazard Classification and Labellingrazy896100% (2)

- Asdf Asdfa Sdfas DDocument3 pagesAsdf Asdfa Sdfas DKeaton EisenmengerNo ratings yet

- Unit 3 - ISEDocument60 pagesUnit 3 - ISEavenesh231No ratings yet

- Substante Periculoase - Reparatii AutoDocument8 pagesSubstante Periculoase - Reparatii AutoI.i.PascuC.GheorgheNo ratings yet

- CHEMICALnHAZARDSnn1n 12627b00e1e8638Document13 pagesCHEMICALnHAZARDSnn1n 12627b00e1e8638Cristian RomeroNo ratings yet

- Ismail's Presentaion ForThe 7th International CBRN Safety and Security ConferenceDocument36 pagesIsmail's Presentaion ForThe 7th International CBRN Safety and Security ConferenceIsmail Abdi AliNo ratings yet

- Linde Gases & Applications PDFDocument201 pagesLinde Gases & Applications PDFsohelazamNo ratings yet

- Coshh, Risk Assessment and Chemical SafetyDocument8 pagesCoshh, Risk Assessment and Chemical SafetyMD AZHER ULLAH BAIGNo ratings yet

- Environmental Management Exam 2Document101 pagesEnvironmental Management Exam 2Muhammad UzairNo ratings yet

- Safe Storage HC PDFDocument65 pagesSafe Storage HC PDFSahanara shaikhNo ratings yet

- Module-5 Chemical Safety and Other Safety Checks: Some Most Common Features of High Cost AccidentsDocument17 pagesModule-5 Chemical Safety and Other Safety Checks: Some Most Common Features of High Cost AccidentsBuddies Da Neeghe PuroNo ratings yet

- TITLE: SOP For The Safe Use of Diaminobenzidine (DAB) : High Hazard Chemical PolicyDocument3 pagesTITLE: SOP For The Safe Use of Diaminobenzidine (DAB) : High Hazard Chemical PolicyABHINABA GUPTANo ratings yet

- CDT Cutting Oil (Aerosol) - CRC IndDocument4 pagesCDT Cutting Oil (Aerosol) - CRC IndBiju_PottayilNo ratings yet

- Primark Chemical Commitment Meeting - Dhaka - Sep - 2016Document31 pagesPrimark Chemical Commitment Meeting - Dhaka - Sep - 2016Dyeing DyeingNo ratings yet

- Chemical and Hazardous Materials SafetyDocument38 pagesChemical and Hazardous Materials SafetyardodotNo ratings yet

- Chemicals and Other Hazards in Painting: NdlonDocument29 pagesChemicals and Other Hazards in Painting: NdlonSijo RajanNo ratings yet

- 7 Fasey GHS QuickoverviewDocument28 pages7 Fasey GHS QuickoverviewvengielNo ratings yet

- Chemical Safety in Catering IndustryDocument41 pagesChemical Safety in Catering Industrypoornima1268100% (1)

- What Is Hazard CommunicationDocument3 pagesWhat Is Hazard CommunicationdanerdrrellNo ratings yet

- NPCA GHS OverviewDocument40 pagesNPCA GHS OverviewJatin TakkarNo ratings yet

- Chemical SafetyDocument14 pagesChemical SafetyARULSELVAN MURUGESANNo ratings yet

- Final REACHPractical GuideDocument53 pagesFinal REACHPractical Guideamrit.itbhuNo ratings yet

- Lecture #2 Chemical Engineering Plant Design: Prof - Dr.A.K SALARIYADocument49 pagesLecture #2 Chemical Engineering Plant Design: Prof - Dr.A.K SALARIYAAdil AslamNo ratings yet

- Chemical Handling1Document44 pagesChemical Handling1yelsa otreblaNo ratings yet

- Industrial Safety Module-5Document25 pagesIndustrial Safety Module-5Chinthan HBNo ratings yet

- COSHH: Control of Substances Hazardous To HealthDocument4 pagesCOSHH: Control of Substances Hazardous To HealthmahyarbNo ratings yet

- Tom Tailor - Chemical Management Handbook V1.0 - May2018Document49 pagesTom Tailor - Chemical Management Handbook V1.0 - May2018Rezoanul HaqueNo ratings yet

- Basic Principles of PreventionDocument37 pagesBasic Principles of Preventionerryrahman72No ratings yet

- Chemical Safety Management PDFDocument39 pagesChemical Safety Management PDFArun ByakodNo ratings yet

- Industrial HygieneDocument30 pagesIndustrial HygieneJes AsiNo ratings yet

- 06 Hazardous Chemical ManagementDocument18 pages06 Hazardous Chemical ManagementImranNo ratings yet

- Chemical Hazard MGNT - ProgramDocument23 pagesChemical Hazard MGNT - Programgshdavid100% (3)

- Safety Data Sheet: According To EC Directive 91/155/EECDocument6 pagesSafety Data Sheet: According To EC Directive 91/155/EECSiti HannaNo ratings yet

- Chemicals Safety PresentationDocument39 pagesChemicals Safety Presentatione cube100% (3)

- The American University in Cairo Environmental Health & Safety DepartmentDocument91 pagesThe American University in Cairo Environmental Health & Safety DepartmentBabbooNo ratings yet

- School Report Chemical HazardsDocument22 pagesSchool Report Chemical HazardsoatcookiesNo ratings yet

- Ghshazcom 3 RDQTRDocument60 pagesGhshazcom 3 RDQTRmirzasaeed314No ratings yet

- Sterilisation Research:: Safety SignsDocument5 pagesSterilisation Research:: Safety SignsMichael LangleyNo ratings yet

- 1cleaner Production Trabajo FinalDocument12 pages1cleaner Production Trabajo FinalSammy CadenaNo ratings yet

- PBL 2 LawDocument19 pagesPBL 2 LawAMMARNo ratings yet

- Environmental Health & Safety Program For Chemical Waste ManagementDocument19 pagesEnvironmental Health & Safety Program For Chemical Waste ManagementAlbie KawaiiNo ratings yet

- Safety Methods in Pharmaceutical Industry: What Is Industrial Safety?Document21 pagesSafety Methods in Pharmaceutical Industry: What Is Industrial Safety?Md. Zd HasanNo ratings yet

- LABORATORY-SAFETY-and-REGULATIONSDocument7 pagesLABORATORY-SAFETY-and-REGULATIONSAira Jane GamboaNo ratings yet

- Report WritingDocument15 pagesReport WritingYashwanth NethaNo ratings yet

- 12-Chemical Hazard CommunicationDocument9 pages12-Chemical Hazard CommunicationHalime HalimeNo ratings yet

- Pharmaceutical SafetyDocument77 pagesPharmaceutical Safetydankshavali shaikNo ratings yet

- Safety Data Sheet: According To EC Directive 91/155/EECDocument6 pagesSafety Data Sheet: According To EC Directive 91/155/EECSiti HannaNo ratings yet

- Hazard Communication: Division of Administration Office of Risk ManagementDocument29 pagesHazard Communication: Division of Administration Office of Risk ManagementkenshinkimuraNo ratings yet

- Lab Safety With NotesDocument42 pagesLab Safety With NotesDavidson BravoNo ratings yet

- SanitasiDocument3 pagesSanitasiSeprtiSang FajardisorehariNo ratings yet

- A Good Chemical Storage Area Should HaveDocument6 pagesA Good Chemical Storage Area Should HavekaiNo ratings yet

- Material Safety Data Sheets (MSDS)Document27 pagesMaterial Safety Data Sheets (MSDS)ahmet yasin karlıkNo ratings yet

- MSDS HDLDocument5 pagesMSDS HDLFendyLon TacisNo ratings yet

- Chemical Safety: Barrameda, John Marvel Cadiente, Jerome Tamayo, Karina Beatriz Vargas, KorinaDocument16 pagesChemical Safety: Barrameda, John Marvel Cadiente, Jerome Tamayo, Karina Beatriz Vargas, KorinaKim SantosNo ratings yet

- BSCI Audit Checklist For Apparel IndustryDocument7 pagesBSCI Audit Checklist For Apparel IndustryEMS 4AYD100% (2)

- Higg FSLM Questions 2020Document1 pageHigg FSLM Questions 2020EMS 4AYD100% (1)

- Authorization Letter - EMSDocument1 pageAuthorization Letter - EMSEMS 4AYDNo ratings yet

- FEE CAP - Sam Ree Dyeing LTDDocument11 pagesFEE CAP - Sam Ree Dyeing LTDEMS 4AYDNo ratings yet

- Water Consumption Tracking Inventory 2018Document8 pagesWater Consumption Tracking Inventory 2018EMS 4AYDNo ratings yet

- Sam Ree Dyeing (BD) LTD.: 1.select All Water Sources Used by Your FacilityDocument2 pagesSam Ree Dyeing (BD) LTD.: 1.select All Water Sources Used by Your FacilityEMS 4AYDNo ratings yet

- Implementation Plan To Improve Water UseDocument1 pageImplementation Plan To Improve Water UseEMS 4AYDNo ratings yet

- Job Responsibility EMS + OthersDocument2 pagesJob Responsibility EMS + OthersEMS 4AYDNo ratings yet

- M&S Buyer: Checklist (Compliance)Document2 pagesM&S Buyer: Checklist (Compliance)EMS 4AYD67% (3)

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- SDDDMMMMJJJJJJJDocument1 pageSDDDMMMMJJJJJJJEMS 4AYDNo ratings yet

- Cad U1Document1 pageCad U1EMS 4AYDNo ratings yet

- WashingDocument1 pageWashingEMS 4AYDNo ratings yet

- 6th Floor, Prod, U1Document1 page6th Floor, Prod, U1EMS 4AYDNo ratings yet

- Micoco c40 Technical Data SheetDocument2 pagesMicoco c40 Technical Data SheetNilesh GuptaNo ratings yet

- Suncid Red N-2RLDocument7 pagesSuncid Red N-2RLWaqas Ahmed KhanNo ratings yet

- Methods of Estimating Steam ConsumptionDocument8 pagesMethods of Estimating Steam ConsumptionHimanshu1712No ratings yet

- Benzoyl ChlorideDocument3 pagesBenzoyl Chloridesamy599No ratings yet

- Book - Metabolism NotesDocument408 pagesBook - Metabolism NotesSarah JuárezNo ratings yet

- Atomic Absorption Spectroscopy MeasurementDocument3 pagesAtomic Absorption Spectroscopy MeasurementDozdiNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- Cathodic Protection Pipeline SuppliesDocument2 pagesCathodic Protection Pipeline SuppliesVijay GaikwadNo ratings yet

- Gen Chem Module 16Document21 pagesGen Chem Module 16Henry LanguisanNo ratings yet

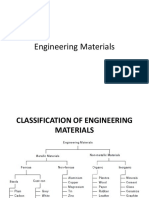

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- Lectures On CFD Multiphase Flow PDFDocument62 pagesLectures On CFD Multiphase Flow PDFPhilippe LAVOISIERNo ratings yet

- 01Document4 pages01Robert StormNo ratings yet

- CENG0009 CW2.pdf 643537 498427274Document26 pagesCENG0009 CW2.pdf 643537 498427274gshontongNo ratings yet

- Earth Science: Quarter 1-ModuleDocument51 pagesEarth Science: Quarter 1-ModuleBoison Prince ChristianNo ratings yet

- CHAPTER 2 (Partial) : - Notation and TerminologyDocument16 pagesCHAPTER 2 (Partial) : - Notation and TerminologyxavierlthNo ratings yet

- 200 Wog Globe ValveDocument1 page200 Wog Globe ValveSandi AslanNo ratings yet

- Product Catalogue Hefe FertilizerDocument48 pagesProduct Catalogue Hefe FertilizerSamir alQurashiNo ratings yet

- FLUOR-lesson04 VesselOrientationDocument146 pagesFLUOR-lesson04 VesselOrientationHernâni CruzNo ratings yet

- Formation of The Heavy ElementsDocument17 pagesFormation of The Heavy ElementsSheiloiNo ratings yet

- Lecture PFD & P &idDocument46 pagesLecture PFD & P &idsanjaykumarkadam2289100% (2)

- 1.6 Atp QPDocument5 pages1.6 Atp QPshahbazhu006No ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- Appendix 3 Application Checklist ACTDDocument17 pagesAppendix 3 Application Checklist ACTDWilliam ChandraNo ratings yet

- Contavac Pumps - PIII1 PDFDocument18 pagesContavac Pumps - PIII1 PDFrakacyuNo ratings yet

- 1-Polystyrene-Graphene Oxide Modified Glassy Carbon Electrode As ADocument4 pages1-Polystyrene-Graphene Oxide Modified Glassy Carbon Electrode As AwardaninurindahNo ratings yet

- Ukqa 2032Document9 pagesUkqa 2032Mohamad IkhwanNo ratings yet

- (1.3) Reference MaterialDocument7 pages(1.3) Reference MaterialMuhammad SaquibNo ratings yet

- Estabilidad Termica ASTM D6468Document6 pagesEstabilidad Termica ASTM D6468Coordinador LaboratorioNo ratings yet