Professional Documents

Culture Documents

Chemical & Mechanical Properties IS2062

Chemical & Mechanical Properties IS2062

Uploaded by

VijayGowthaman0 ratings0% found this document useful (0 votes)

23 views2 pagesCHEMICAL MECHANICAL PROPERTIES OF IS 2062

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCHEMICAL MECHANICAL PROPERTIES OF IS 2062

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

23 views2 pagesChemical & Mechanical Properties IS2062

Chemical & Mechanical Properties IS2062

Uploaded by

VijayGowthamanCHEMICAL MECHANICAL PROPERTIES OF IS 2062

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

IS 2062 : 2011

Table 1 Chemical Composition

(Clauses 5, 8.1 and 8.2)

Grade | Quality Ladle Analysis, Percent, Max Carbon Mode of

Designation Equivalent| _Deoxidation

c Mn $ P S| (CB, Mar

@ @) @ C} © © o ® ®

a 023 | 150 | 0.045 | 004s | 040 | 0.42 ‘Semi Killed/klled

E250 Bo | 022 | 130 | 0.04 | 0.045 | 0.40 | 0.41 Semi-killedkilled

c 020 | 150 | 0.040 | 0.040 | 040 | 0.39 Killed

A 023 | 150 | 0.045 | 0.045 | 040 | 0.43 ‘Semi killed/aled

E275 BR | 022 | 150 | 004s | 0.045 | 040 | 0.42 ‘Semi-killedkilled

c 020 | 130 | 0040 | 0040 | 040 | 041 Killed

A

BR | 020 | 1.50 | 0.04 | 0.045 | 045 | 0.44 ‘Semi killed/klled

E 300 re

Cc 020 | 150 | 0.040 | 0.040 | 045 | 0.44 Killed

E350 a

: = |

Br | 020 | 1.60 | 0.04 | 0.045 | 045 | 0.50 ‘Semi killed/killed

E410 BO

c 020 | 1.60 | 0.040 | 0040 | 045 | 0.50 Killed

E 450 Ae 022 | 165] ooas | 004s | 04s | 032 ‘Semi Killed/alled

E550 A] 022 | 165 | 002 | 025 | 050 | ose ‘Semi killed/kalled

E 600 =. 0.22 1.70 0.020 | 0.025 | 0.50 0.54 ‘Semi-killedkilled

E650 A 022 | 170 | oos | 0025 | 050 | 055 ‘Semi killed/killed

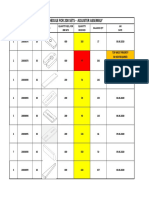

Is 2062 : 2011

‘Table 2 Mechanical Properties

(Clauses 5,103, 10-3.1,11.3.1,12.2and12.4)

Grade [Quality] Tensile “Yield Stress Percentage] Internal Charpy

Designation Strength Elongation Bend Impact Test

Ra. Min ‘4, Min Diameter

R,, Min Spa at Gauge Min (See Note 3)

Ma? Length,

mash (See Note 2) Temp | Min

(See Note 1) 290] 20-40] sa0_| 7 <5 [| =5 | I

@ Q @) @) @ (6) mM @) @) oy an

A —

E250 [SR 410 250 | 240 | 230 23 2t 3 Arta

c © 20) 27

A _— [_

BR Rr | 27

e275 [SR 430 275 | 265 | 255 2 2 3 Rt __27

C ©2) 27

A Si

BR Rr [37

E300 [BR 440 300 | 290 | 280 2 at = SE

Cc © 2) 27

A = tase

BR ET_| 25

Ea [BR 540 10 | 390 | 380 20 2 = aI_{ 23

c OW] 25

x — [=

E40 Gk 570 450 | 430 | 420 20 ast | = ss

A _ eile

E530 [oA 650 350] 530 | 520 1 at ace

A _ — | —

E600 [A 730 oo | 580 | 370 2 3.5¢ ee

A _ ails

E60 [GA 780 650 | 630 | 620 12 4 ate

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Sist Iso 7072 1995Document7 pagesSist Iso 7072 1995VijayGowthaman100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Athena Engineers: Session InformationDocument3 pagesAthena Engineers: Session InformationVijayGowthamanNo ratings yet

- 341-5752 July 22Document3 pages341-5752 July 22VijayGowthamanNo ratings yet

- Din 6796Document2 pagesDin 6796VijayGowthaman0% (1)

- Temperature Monitoring SheetDocument3 pagesTemperature Monitoring SheetVijayGowthamanNo ratings yet

- SL. No. Description Serial No. JAK Identifica Tion No.: Range Least Count Frequenc Yof Calibratio NDocument2 pagesSL. No. Description Serial No. JAK Identifica Tion No.: Range Least Count Frequenc Yof Calibratio NVijayGowthamanNo ratings yet

- 8.8 ISO 4762 / DIN 912: Socket Head Cap Screws, SteelDocument9 pages8.8 ISO 4762 / DIN 912: Socket Head Cap Screws, SteelVijayGowthamanNo ratings yet

- Ajuster Assembly Drawing CorrectionsDocument1 pageAjuster Assembly Drawing CorrectionsVijayGowthamanNo ratings yet

- .List of TPSDocument3 pages.List of TPSVijayGowthamanNo ratings yet

- Silent BlockDocument21 pagesSilent BlockVijayGowthamanNo ratings yet