Professional Documents

Culture Documents

Qdoc - Tips Iso 13373 Part 1

Qdoc - Tips Iso 13373 Part 1

Uploaded by

José Cuenca0 ratings0% found this document useful (0 votes)

16 views57 pagesOriginal Title

Qdoc.tips Iso 13373 Part 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

16 views57 pagesQdoc - Tips Iso 13373 Part 1

Qdoc - Tips Iso 13373 Part 1

Uploaded by

José CuencaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 57

ome

INTERNATIONAL iso |

STANDARD 13373-1 | :

(nex tores cae

| 80 hn, aninee Sin

Condition monitoring and diagnostics of

machines — Vibration condition

monitoring —

Part 1:

General procedures

‘Surveillance des conditions et sclomnosth ‘des machines — Surveillance

‘relative aux conditions des vibrations

Partie 1. Procedures généreles

TIS! Library

downqauiann

‘30078806

Reference number

180 13373-4:2002€)

19 MAR 2002

+ e1s0 2002

180 13373-1:2002(E)

PDF disclaimer

‘This POF fle may contain embedded typetaces. In accordance with Adobe's icensing policy. thas fe may be prised or viewed but shall not

be edtod unless the typetaoss which are embedded are oensed o and inctaled on the computer performing the edtrg. In cewnloang thi

‘le, parties accept therein the resporsibity of not ininging Adobe's lensing poly. The ISO Cerwal Secretarial accepis i Uablty i his

‘Adobe ic a radomark of Adobe Systems Incorporated.

Dotaie of the sotware product used to create this POF fle can De found inthe Genel info relative to the fle; he POF-

180 13373-1:2002(E)

Introduction

‘The principal purpose of vibration condition monitoring of machinery is to Provide information on the operating

‘congition of the machine for protection and predictive maintenance. An integral part of this process is the evaluation

of the vibratory condition of the machine over operating time. The purpose of this part of ISO 13373 is to promate

the use of well-accepted guidelines for acquiring and evaluating vibration measurements for condition monitoring

In contrast to vibration testing used strictly for diagnostic or acceptance purposes, condition monitaring invoWves the

‘acquisition of data which can te compared over a span of time, and emphasizes the changes in vibration

behaviour rather than any particular behaviour by itset.

Changes in vibration behaviour may typically be caused by

— changes in balance,

— changes in alignment,

— wear of or damage to journals or anti friction bearings, t

— gear of coupling defects,

—~_ctacks in the entical components,

— operational transients,

— fluid-tlow disturbances in hydraulic machinery,

— transient excitations in electric machinery,

— rubbing, and

— mechanical looseness.

Vibration condition monitoring can provide information for the following purposes:

— to increase equipment protection

— to improve safety for personne!

— toimprove maintenance procedures;

— to detect problems early;

— to avoid catastrophic failures;

— toextend equipment lite;

— . to enhance operations.

Vibration measurements for condition monitoring may ta

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Contrato Entre La CGE y La PostaDocument13 pagesContrato Entre La CGE y La PostaJosé CuencaNo ratings yet

- Soldadura Arco Electrico y Electrodo Revestido IDocument174 pagesSoldadura Arco Electrico y Electrodo Revestido Ined123100% (3)

- 34 26 PB PDFDocument126 pages34 26 PB PDFJosé CuencaNo ratings yet

- Uso Del Calibrador y Tornillo MicrométricoDocument21 pagesUso Del Calibrador y Tornillo MicrométricoJosé Cuenca100% (1)

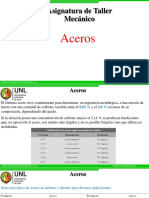

- ACEROSDocument12 pagesACEROSJosé CuencaNo ratings yet

- Contratos TrampososDocument5 pagesContratos TrampososJosé CuencaNo ratings yet

- Maquinas Herramientas EspecialesDocument158 pagesMaquinas Herramientas EspecialesJosé CuencaNo ratings yet