Professional Documents

Culture Documents

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

Uploaded by

irinaCopyright:

Available Formats

You might also like

- Flextral Crimp Chart - 2018Document15 pagesFlextral Crimp Chart - 2018cristhiahnoNo ratings yet

- CRS Marketing & Services: Price List For Floating Ball ValvesDocument1 pageCRS Marketing & Services: Price List For Floating Ball ValvesAniket AngreNo ratings yet

- SLBSLTSLTESpecSheet4 18 12Document1 pageSLBSLTSLTESpecSheet4 18 12KM KarthikNo ratings yet

- Motors Connecting Loads Update On 04.03.2016Document4 pagesMotors Connecting Loads Update On 04.03.2016Durgesh MauryaNo ratings yet

- Air Filter SilencerDocument2 pagesAir Filter SilencerDavid OteroNo ratings yet

- NO Pupm Name Pupm No Model RPM Flow Rate Head D.EDocument6 pagesNO Pupm Name Pupm No Model RPM Flow Rate Head D.ELay PatelNo ratings yet

- Filter - Inline - HFR: (Threads To Depth 20mm)Document2 pagesFilter - Inline - HFR: (Threads To Depth 20mm)nvkjayanthNo ratings yet

- Pilot Operated Relief Valve RF Series: SymbolDocument4 pagesPilot Operated Relief Valve RF Series: SymbolEvandro Amaral RodriguesNo ratings yet

- Indoor Electrical DataDocument1 pageIndoor Electrical DataSkill IndiaNo ratings yet

- Copper Straight Lengths (Eur. Standard)Document1 pageCopper Straight Lengths (Eur. Standard)Carlos SolerNo ratings yet

- Air Motors PDFDocument6 pagesAir Motors PDFBe HappyNo ratings yet

- Panel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8TDocument1 pagePanel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8THieu Nguyen ThaiNo ratings yet

- FE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPDocument28 pagesFE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPZaen SalimNo ratings yet

- Brocure Pump FPS 4400 4 Inch Franklin ElectricDocument28 pagesBrocure Pump FPS 4400 4 Inch Franklin ElectricErich ThomasNo ratings yet

- Compressor Tabela de Aplicacao PDFDocument3 pagesCompressor Tabela de Aplicacao PDFjhon padronNo ratings yet

- Hvac Pipe SizingDocument1 pageHvac Pipe SizingRaja Antony100% (1)

- BS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01Document4 pagesBS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01skodgeNo ratings yet

- Mangueras de Tanque de RefrigeranteDocument3 pagesMangueras de Tanque de RefrigeranteAlvaro Escalona GtzNo ratings yet

- Sin Rot Jul13 Jun14Document8 pagesSin Rot Jul13 Jun14Dennis Leandro Muñoz MuñozNo ratings yet

- 04 - Stock Out CardDocument11 pages04 - Stock Out CardShirley AngNo ratings yet

- Titan Slide GateDocument1 pageTitan Slide GateJavier CharrezNo ratings yet

- 8 21 Meter AsmDocument4 pages8 21 Meter AsmLuis MirandaNo ratings yet

- Catalog 4400 US: Transportation - Air Brake HoseDocument1 pageCatalog 4400 US: Transportation - Air Brake Hoseanoop9079No ratings yet

- RE5R01A (BMW A5S 300J), (JF503E) : 5 Speed RWD (Electronic Control)Document4 pagesRE5R01A (BMW A5S 300J), (JF503E) : 5 Speed RWD (Electronic Control)Denis KonovalovNo ratings yet

- 5GP100-23 15 Quintuplex Plunger Pump Fluid EndDocument1 page5GP100-23 15 Quintuplex Plunger Pump Fluid EndCARLITOS 25No ratings yet

- CT 138167Document46 pagesCT 138167Srand DanNo ratings yet

- Hydraulic Quotation OrientflexDocument1 pageHydraulic Quotation OrientflexiglesiasljNo ratings yet

- Craftsman CompressorDocument8 pagesCraftsman Compressorhorseriderintexas100% (1)

- Edoc - Pub ManualDocument4 pagesEdoc - Pub ManualVictoria CoronaNo ratings yet

- Fluden - Suction StrainerDocument1 pageFluden - Suction StrainermcrajpuraNo ratings yet

- Bertolini-Pumps-APL0540-SPEC-015 IMPAC 600Document3 pagesBertolini-Pumps-APL0540-SPEC-015 IMPAC 600Pablo Ernesto Veloso ContrerasNo ratings yet

- AlemiteDocument10 pagesAlemiteGer DclNo ratings yet

- Alp Prof Price BRK DWN Per MTR at 122Document1 pageAlp Prof Price BRK DWN Per MTR at 122nagesh raoNo ratings yet

- Air Systems May June FlyerDocument16 pagesAir Systems May June FlyerairsystemsoffersNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- MeasurementDocument3 pagesMeasurementstormyhsNo ratings yet

- Importacion Anillos TP - Marzo 23 de 2.023Document2 pagesImportacion Anillos TP - Marzo 23 de 2.023alexisnioNo ratings yet

- Carefusion FlowmetersDocument4 pagesCarefusion Flowmetersrubenr25No ratings yet

- TowerPro Motor SpecDocument2 pagesTowerPro Motor SpecmdoyokNo ratings yet

- GPM DatasheetDocument1 pageGPM DatasheetMohamed MosaedNo ratings yet

- OMEGA AIR-OMD - Dryers - EN - 950094 PDFDocument2 pagesOMEGA AIR-OMD - Dryers - EN - 950094 PDFJunaid AhmedNo ratings yet

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDocument2 pagesSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNo ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- Fire Retardant Cable Tie 1576222614 1Document1 pageFire Retardant Cable Tie 1576222614 1pratik jainNo ratings yet

- 13-5/8" 10M 3 Step-Wellhead ComponentsDocument7 pages13-5/8" 10M 3 Step-Wellhead ComponentsYasmin NabilahNo ratings yet

- C2263pe DM Solid BaseDocument4 pagesC2263pe DM Solid Baseapi-295828551No ratings yet

- Ebara CDXDocument5 pagesEbara CDXCrystal Novel Ligar Lestari100% (1)

- Offset Analysis - BR-016 Well, Run SummaryDocument3 pagesOffset Analysis - BR-016 Well, Run SummaryChinyere NkereNo ratings yet

- Part Catalog ScoopyDocument54 pagesPart Catalog Scoopymasbianto100% (1)

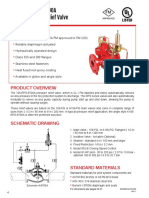

- Model 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesDocument3 pagesModel 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesCandela BarbisanNo ratings yet

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pages100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalNo ratings yet

- StaticDocument4 pagesStaticsimonNo ratings yet

- Type 1227: High Flow Gas Pressure RegulatorDocument4 pagesType 1227: High Flow Gas Pressure RegulatorgffNo ratings yet

- Bha 79-Pozo-Sal-18 BV9M 20150917Document11 pagesBha 79-Pozo-Sal-18 BV9M 20150917Cristhian Escobar MendezNo ratings yet

- S14 023Document4 pagesS14 023Julie LafranceNo ratings yet

- SMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2Document14 pagesSMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2DanielNo ratings yet

- Precision Clamping FixturesDocument2 pagesPrecision Clamping FixturesirinaNo ratings yet

- SUPERFLEX Coupling: Instruction ManualDocument20 pagesSUPERFLEX Coupling: Instruction ManualirinaNo ratings yet

- KAT0815-0001-E Single Pole Insulated Conductor RailDocument36 pagesKAT0815-0001-E Single Pole Insulated Conductor RailirinaNo ratings yet

- JKF Filters and Separators Product ProgrammeDocument3 pagesJKF Filters and Separators Product ProgrammeirinaNo ratings yet

- The Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringDocument10 pagesThe Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringirinaNo ratings yet

- Series 40 Cylinders: Double Acting, Cushioned, Magnetic Ø 160 - 200 - 250 - 320 MMDocument9 pagesSeries 40 Cylinders: Double Acting, Cushioned, Magnetic Ø 160 - 200 - 250 - 320 MMirinaNo ratings yet

- ROTHDocument93 pagesROTHirinaNo ratings yet

- Multivariate Statistical Methods and Six-SigmaDocument2 pagesMultivariate Statistical Methods and Six-SigmaANo ratings yet

- 7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasDocument1 page7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasyacasiestaNo ratings yet

- Design and Evaluation of High Gain Microstrip Patch Antenna Using Double Layer With Air GapDocument4 pagesDesign and Evaluation of High Gain Microstrip Patch Antenna Using Double Layer With Air GapEditor IJRITCCNo ratings yet

- PROCEDURE For Color Coding R01 (28.06.2014)Document9 pagesPROCEDURE For Color Coding R01 (28.06.2014)punitg_2No ratings yet

- Soal UTS Bahasa Inggris SD Semester Genap Kelas 5Document5 pagesSoal UTS Bahasa Inggris SD Semester Genap Kelas 5Yusuf HamdaniNo ratings yet

- USR-GPRS232-730 Guide LineDocument18 pagesUSR-GPRS232-730 Guide LineKutu BukuNo ratings yet

- SM 64348Document24 pagesSM 64348HENKO7659No ratings yet

- Compact DC Power SteeringDocument18 pagesCompact DC Power SteeringTihomir MarkovicNo ratings yet

- MGT LearningDocument18 pagesMGT Learningmoraiskp321No ratings yet

- Ihueze MgbemenaSDIDocument16 pagesIhueze MgbemenaSDImosanidNo ratings yet

- 04.pure Maths 4Document53 pages04.pure Maths 4Gracious SakaNo ratings yet

- 4.negative and Zero SequenceDocument6 pages4.negative and Zero Sequencebalaer0550% (2)

- Multi Product Brochure 2023 HiResDocument51 pagesMulti Product Brochure 2023 HiResikhwan.138986No ratings yet

- 1.3 Analytical Chemistry 1Document17 pages1.3 Analytical Chemistry 1zedrickNo ratings yet

- How To Trade Pullbacks With 5 Key Technical Tools.: Fxtechstrategy TeamDocument10 pagesHow To Trade Pullbacks With 5 Key Technical Tools.: Fxtechstrategy TeamkanapunditNo ratings yet

- Midterm Report: in Electrical EngineeringDocument11 pagesMidterm Report: in Electrical Engineeringdr.Sabita shresthaNo ratings yet

- Customer Inquiry Sheet BlankDocument3 pagesCustomer Inquiry Sheet BlankAbunawas_MJNo ratings yet

- Hybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueDocument2 pagesHybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueJuan NarvaezNo ratings yet

- X21101 - ENGINEERING MATHEMATICS I Model QP 12.04.22Document3 pagesX21101 - ENGINEERING MATHEMATICS I Model QP 12.04.22Krishna PrasadNo ratings yet

- Motores de Combustion Interna A DieselDocument2 pagesMotores de Combustion Interna A DieselAlex Francisco Santillán QuinteroNo ratings yet

- GE8152 Engineering Graphics - Course Materials PDFDocument110 pagesGE8152 Engineering Graphics - Course Materials PDFkabilanNo ratings yet

- 3V FM Transmitter CircuitDocument6 pages3V FM Transmitter CircuitMahmood AhmedNo ratings yet

- 2004 Presentation 549Document42 pages2004 Presentation 549Vani BalanNo ratings yet

- Hydraulic Components and SystemsDocument157 pagesHydraulic Components and SystemsFernando TezzaNo ratings yet

- A Novel Hybrid Data Balancing and Fraud Detection Approach For Automobile Insurance ClaimsDocument30 pagesA Novel Hybrid Data Balancing and Fraud Detection Approach For Automobile Insurance ClaimsAtul Kumar AgrawalNo ratings yet

- Technical Specs PDFDocument12 pagesTechnical Specs PDFcsolanki6586100% (1)

- Ag-Mechanical Monitoring Systems PDFDocument2 pagesAg-Mechanical Monitoring Systems PDFqdod_waffiNo ratings yet

- Automation in Material Handling System at Site: By: Varun Babbar Abhishek Arora Sombudhha DuttaDocument13 pagesAutomation in Material Handling System at Site: By: Varun Babbar Abhishek Arora Sombudhha Duttaशर्मा अविनाशNo ratings yet

- Last Area Day 8 - Basic Electronics-1Document7 pagesLast Area Day 8 - Basic Electronics-1ellajanepoNo ratings yet

- CHEDocument2 pagesCHEpsjeeveshNo ratings yet

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

Uploaded by

irinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

LTM Series: Designed For Ease of Servicing. Access To Tank Interior Is Not Necessary

Uploaded by

irinaCopyright:

Available Formats

FILTERS & STRAINERS

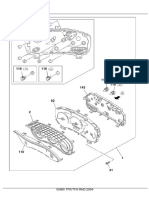

LTM Series

Designed for ease of servicing.

Access to tank interior is not necessary

Specifications:

• Steel Zinc Plate Bushing 3, 5, 10, 11, 12 GPM

• Cast iron bushings 15 thru 200 GPM

• Perforated steel support tubes

• 100 mesh stainless steel pleated screen (standard) LTM-15

thru 200

Options:

• No bypass or 3 & 5 P.S.I. bypass LTM-3, 5, 10,

• Custom screens available on request

11 and 12

• Stainless nuts 100 pc. minimum

Dimensional Details

Optional Relief

Valve Shown

A/F AREA

MODEL A B

C D E HEX IN2

NUMBER FLOW NPT NPT

DIA. (CM)2

LTM-3

3 GPM 3/4" 3/8" IN 4.00 0.98 0.79 1.18 30 B

12 LPM MM 101.6 25 20 30 (194)

5 GPM 1" 1/2" IN 5.39 1.13 1.10 1.50 55

LTM-5 A/F

20 LPM MM 137 28 28 38 (355)

10 GPM 1-1/4" 3/4" IN 7.48 1.22 1.42 1.81 90

LTM-10

40 LPM MM 190 31 36 46 (581)

15 GPM 1-1/4" 3/4" IN 5.75 1.30 1.65 1.97 75

LTM-11

60 LPM MM 146 33 42 50 (484)

12 GPM 1-1/2" 3/4" IN 4.00 1.30 1.66 1.97 48

LTM-12

45 LPM MM 101.5 33 42 50 (311) D

18 GPM 1-1/2" 1" IN 8.27 1.30 1.65 1.97 110

LTM-15

72 LPM MM 210 33 42 50 (710) A

25 GPM 2" 1 1/4" IN 10.00 1.30 2.13 2.60 175

LTM-25

100 LPM MM 254 33 54 66 (1129)

30 GPM 3" 1 1/4" IN 10.24 1.69 3.07 2.60 265

LTM-30

120 LPM MM 260 43 78 66 (1709)

30 GPM 3" 1 1/2" IN 10.24 1.69 3.07 2.60 265

LTM-40

120 LPM MM 260 43 78 66 (1709)

40 GPM 3" 2" IN 10.24 1.69 3.07 3.23 265 C

LTM-50

160 LPM MM 260 43 78 82 (1709)

60 GPM 3" 2 1/2" IN 10.24 2.01 3.07 3.54 265

LTM-60

100 LPM MM 260 51 78 90 (1709)

75 GPM 4" 2 1/2" IN 9.69 1.81 3.78 4.65 300

LTM-75

300 LPM MM 246 46 96 118 (1935)

100 GPM 4" 3" IN 11.30 1.81 3.78 4.65 355

LTM-100

380 LPM MM 287 46 96 118 (2290)

200 GPM 6" 4" IN 12.44 2.28 5.71 0.06 860

LTM-200

750 LPM MM 316 58 145 1.44 (5547)

See Page 49a for WFN Series Weld Flanges E

Mounting Details:

Mount through sidewall or through tank top and

into standpipe. See page 48a for details.

44a Phone: 937/277-9364 FAX: 937/277-6516 www.lenzinc.com

FILTERS & STRAINERS

0.40 .028 0.40 .028

.024 .024

-5

0.35 0.35

LTM

.021 0.30 .021

0.30

11

2

M- .017

-1

-3

.017 0.25 -40

M

LT -10

LTM

0.25

30 LTM

LT

LTM M-

PSID

LT .014

BAR

5

PSID

.014

BAR

0.20 0.20 -2

M

LT

-1 5

.010 0.15 .010

LTM

0.15

0.10 .007 0.10 .007

0.05 .003 0.05 .003

0.00 0 0.00 0

GPM 0 1.7 3.4 5.1 6.8 8.5 10.2 11.9 GPM 0 6 12 18 24 32 36 42

LPM 0 6 13 19 26 32 39 45 LPM 0 23 45 68 91 114 136 159

0.40 .028

.024

-60

0.35

LTM

0.30 .021

-50

5

-7

LTM

.017

M

0.25 00

LT

M -1

LT .014

PSID

BAR

0.20

- 200

LTM .010

0.15

0.10 .007

0.05 .003

0.00 0

GPM 0 25 50 75 100 125 150 175

LPM 0 95 189 284 379 473 568 662

Temperature 100° F Viscosity 150 SUS

Average pressure drop through clean assembly

Strainer Ordering Code

LTM — 15 — R3 — 100 —

SERIES FLOW BYPASS MESH OPTIONS

LTM 3 OMIT NO BYPASS 100 100 MESH *SS ALL

5 R3 3 PSI BYPASS (STANDARD) STAINLESS

10 R5 5 PSI BYPASS 30 30 MESH *100 pc. minimum

11 60 60 MESH Special Order

12 200 200 MESH

15

25

30

40

50

60

75

100

200

See Technical Bulletin TB.FIL17.708, TB.FIL19.708, or further information at

(Technical Data – www.lenzinc.com)

Phone: 937/277-9364 FAX: 937/277-6516 www.lenzinc.com 45a

You might also like

- Flextral Crimp Chart - 2018Document15 pagesFlextral Crimp Chart - 2018cristhiahnoNo ratings yet

- CRS Marketing & Services: Price List For Floating Ball ValvesDocument1 pageCRS Marketing & Services: Price List For Floating Ball ValvesAniket AngreNo ratings yet

- SLBSLTSLTESpecSheet4 18 12Document1 pageSLBSLTSLTESpecSheet4 18 12KM KarthikNo ratings yet

- Motors Connecting Loads Update On 04.03.2016Document4 pagesMotors Connecting Loads Update On 04.03.2016Durgesh MauryaNo ratings yet

- Air Filter SilencerDocument2 pagesAir Filter SilencerDavid OteroNo ratings yet

- NO Pupm Name Pupm No Model RPM Flow Rate Head D.EDocument6 pagesNO Pupm Name Pupm No Model RPM Flow Rate Head D.ELay PatelNo ratings yet

- Filter - Inline - HFR: (Threads To Depth 20mm)Document2 pagesFilter - Inline - HFR: (Threads To Depth 20mm)nvkjayanthNo ratings yet

- Pilot Operated Relief Valve RF Series: SymbolDocument4 pagesPilot Operated Relief Valve RF Series: SymbolEvandro Amaral RodriguesNo ratings yet

- Indoor Electrical DataDocument1 pageIndoor Electrical DataSkill IndiaNo ratings yet

- Copper Straight Lengths (Eur. Standard)Document1 pageCopper Straight Lengths (Eur. Standard)Carlos SolerNo ratings yet

- Air Motors PDFDocument6 pagesAir Motors PDFBe HappyNo ratings yet

- Panel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8TDocument1 pagePanel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8THieu Nguyen ThaiNo ratings yet

- FE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPDocument28 pagesFE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPZaen SalimNo ratings yet

- Brocure Pump FPS 4400 4 Inch Franklin ElectricDocument28 pagesBrocure Pump FPS 4400 4 Inch Franklin ElectricErich ThomasNo ratings yet

- Compressor Tabela de Aplicacao PDFDocument3 pagesCompressor Tabela de Aplicacao PDFjhon padronNo ratings yet

- Hvac Pipe SizingDocument1 pageHvac Pipe SizingRaja Antony100% (1)

- BS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01Document4 pagesBS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01skodgeNo ratings yet

- Mangueras de Tanque de RefrigeranteDocument3 pagesMangueras de Tanque de RefrigeranteAlvaro Escalona GtzNo ratings yet

- Sin Rot Jul13 Jun14Document8 pagesSin Rot Jul13 Jun14Dennis Leandro Muñoz MuñozNo ratings yet

- 04 - Stock Out CardDocument11 pages04 - Stock Out CardShirley AngNo ratings yet

- Titan Slide GateDocument1 pageTitan Slide GateJavier CharrezNo ratings yet

- 8 21 Meter AsmDocument4 pages8 21 Meter AsmLuis MirandaNo ratings yet

- Catalog 4400 US: Transportation - Air Brake HoseDocument1 pageCatalog 4400 US: Transportation - Air Brake Hoseanoop9079No ratings yet

- RE5R01A (BMW A5S 300J), (JF503E) : 5 Speed RWD (Electronic Control)Document4 pagesRE5R01A (BMW A5S 300J), (JF503E) : 5 Speed RWD (Electronic Control)Denis KonovalovNo ratings yet

- 5GP100-23 15 Quintuplex Plunger Pump Fluid EndDocument1 page5GP100-23 15 Quintuplex Plunger Pump Fluid EndCARLITOS 25No ratings yet

- CT 138167Document46 pagesCT 138167Srand DanNo ratings yet

- Hydraulic Quotation OrientflexDocument1 pageHydraulic Quotation OrientflexiglesiasljNo ratings yet

- Craftsman CompressorDocument8 pagesCraftsman Compressorhorseriderintexas100% (1)

- Edoc - Pub ManualDocument4 pagesEdoc - Pub ManualVictoria CoronaNo ratings yet

- Fluden - Suction StrainerDocument1 pageFluden - Suction StrainermcrajpuraNo ratings yet

- Bertolini-Pumps-APL0540-SPEC-015 IMPAC 600Document3 pagesBertolini-Pumps-APL0540-SPEC-015 IMPAC 600Pablo Ernesto Veloso ContrerasNo ratings yet

- AlemiteDocument10 pagesAlemiteGer DclNo ratings yet

- Alp Prof Price BRK DWN Per MTR at 122Document1 pageAlp Prof Price BRK DWN Per MTR at 122nagesh raoNo ratings yet

- Air Systems May June FlyerDocument16 pagesAir Systems May June FlyerairsystemsoffersNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- MeasurementDocument3 pagesMeasurementstormyhsNo ratings yet

- Importacion Anillos TP - Marzo 23 de 2.023Document2 pagesImportacion Anillos TP - Marzo 23 de 2.023alexisnioNo ratings yet

- Carefusion FlowmetersDocument4 pagesCarefusion Flowmetersrubenr25No ratings yet

- TowerPro Motor SpecDocument2 pagesTowerPro Motor SpecmdoyokNo ratings yet

- GPM DatasheetDocument1 pageGPM DatasheetMohamed MosaedNo ratings yet

- OMEGA AIR-OMD - Dryers - EN - 950094 PDFDocument2 pagesOMEGA AIR-OMD - Dryers - EN - 950094 PDFJunaid AhmedNo ratings yet

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDocument2 pagesSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNo ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- Fire Retardant Cable Tie 1576222614 1Document1 pageFire Retardant Cable Tie 1576222614 1pratik jainNo ratings yet

- 13-5/8" 10M 3 Step-Wellhead ComponentsDocument7 pages13-5/8" 10M 3 Step-Wellhead ComponentsYasmin NabilahNo ratings yet

- C2263pe DM Solid BaseDocument4 pagesC2263pe DM Solid Baseapi-295828551No ratings yet

- Ebara CDXDocument5 pagesEbara CDXCrystal Novel Ligar Lestari100% (1)

- Offset Analysis - BR-016 Well, Run SummaryDocument3 pagesOffset Analysis - BR-016 Well, Run SummaryChinyere NkereNo ratings yet

- Part Catalog ScoopyDocument54 pagesPart Catalog Scoopymasbianto100% (1)

- Model 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesDocument3 pagesModel 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesCandela BarbisanNo ratings yet

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pages100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalNo ratings yet

- StaticDocument4 pagesStaticsimonNo ratings yet

- Type 1227: High Flow Gas Pressure RegulatorDocument4 pagesType 1227: High Flow Gas Pressure RegulatorgffNo ratings yet

- Bha 79-Pozo-Sal-18 BV9M 20150917Document11 pagesBha 79-Pozo-Sal-18 BV9M 20150917Cristhian Escobar MendezNo ratings yet

- S14 023Document4 pagesS14 023Julie LafranceNo ratings yet

- SMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2Document14 pagesSMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2DanielNo ratings yet

- Precision Clamping FixturesDocument2 pagesPrecision Clamping FixturesirinaNo ratings yet

- SUPERFLEX Coupling: Instruction ManualDocument20 pagesSUPERFLEX Coupling: Instruction ManualirinaNo ratings yet

- KAT0815-0001-E Single Pole Insulated Conductor RailDocument36 pagesKAT0815-0001-E Single Pole Insulated Conductor RailirinaNo ratings yet

- JKF Filters and Separators Product ProgrammeDocument3 pagesJKF Filters and Separators Product ProgrammeirinaNo ratings yet

- The Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringDocument10 pagesThe Book 5.0: Lifting Load Securing Light Material Handling Application EngineeringirinaNo ratings yet

- Series 40 Cylinders: Double Acting, Cushioned, Magnetic Ø 160 - 200 - 250 - 320 MMDocument9 pagesSeries 40 Cylinders: Double Acting, Cushioned, Magnetic Ø 160 - 200 - 250 - 320 MMirinaNo ratings yet

- ROTHDocument93 pagesROTHirinaNo ratings yet

- Multivariate Statistical Methods and Six-SigmaDocument2 pagesMultivariate Statistical Methods and Six-SigmaANo ratings yet

- 7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasDocument1 page7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasyacasiestaNo ratings yet

- Design and Evaluation of High Gain Microstrip Patch Antenna Using Double Layer With Air GapDocument4 pagesDesign and Evaluation of High Gain Microstrip Patch Antenna Using Double Layer With Air GapEditor IJRITCCNo ratings yet

- PROCEDURE For Color Coding R01 (28.06.2014)Document9 pagesPROCEDURE For Color Coding R01 (28.06.2014)punitg_2No ratings yet

- Soal UTS Bahasa Inggris SD Semester Genap Kelas 5Document5 pagesSoal UTS Bahasa Inggris SD Semester Genap Kelas 5Yusuf HamdaniNo ratings yet

- USR-GPRS232-730 Guide LineDocument18 pagesUSR-GPRS232-730 Guide LineKutu BukuNo ratings yet

- SM 64348Document24 pagesSM 64348HENKO7659No ratings yet

- Compact DC Power SteeringDocument18 pagesCompact DC Power SteeringTihomir MarkovicNo ratings yet

- MGT LearningDocument18 pagesMGT Learningmoraiskp321No ratings yet

- Ihueze MgbemenaSDIDocument16 pagesIhueze MgbemenaSDImosanidNo ratings yet

- 04.pure Maths 4Document53 pages04.pure Maths 4Gracious SakaNo ratings yet

- 4.negative and Zero SequenceDocument6 pages4.negative and Zero Sequencebalaer0550% (2)

- Multi Product Brochure 2023 HiResDocument51 pagesMulti Product Brochure 2023 HiResikhwan.138986No ratings yet

- 1.3 Analytical Chemistry 1Document17 pages1.3 Analytical Chemistry 1zedrickNo ratings yet

- How To Trade Pullbacks With 5 Key Technical Tools.: Fxtechstrategy TeamDocument10 pagesHow To Trade Pullbacks With 5 Key Technical Tools.: Fxtechstrategy TeamkanapunditNo ratings yet

- Midterm Report: in Electrical EngineeringDocument11 pagesMidterm Report: in Electrical Engineeringdr.Sabita shresthaNo ratings yet

- Customer Inquiry Sheet BlankDocument3 pagesCustomer Inquiry Sheet BlankAbunawas_MJNo ratings yet

- Hybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueDocument2 pagesHybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueJuan NarvaezNo ratings yet

- X21101 - ENGINEERING MATHEMATICS I Model QP 12.04.22Document3 pagesX21101 - ENGINEERING MATHEMATICS I Model QP 12.04.22Krishna PrasadNo ratings yet

- Motores de Combustion Interna A DieselDocument2 pagesMotores de Combustion Interna A DieselAlex Francisco Santillán QuinteroNo ratings yet

- GE8152 Engineering Graphics - Course Materials PDFDocument110 pagesGE8152 Engineering Graphics - Course Materials PDFkabilanNo ratings yet

- 3V FM Transmitter CircuitDocument6 pages3V FM Transmitter CircuitMahmood AhmedNo ratings yet

- 2004 Presentation 549Document42 pages2004 Presentation 549Vani BalanNo ratings yet

- Hydraulic Components and SystemsDocument157 pagesHydraulic Components and SystemsFernando TezzaNo ratings yet

- A Novel Hybrid Data Balancing and Fraud Detection Approach For Automobile Insurance ClaimsDocument30 pagesA Novel Hybrid Data Balancing and Fraud Detection Approach For Automobile Insurance ClaimsAtul Kumar AgrawalNo ratings yet

- Technical Specs PDFDocument12 pagesTechnical Specs PDFcsolanki6586100% (1)

- Ag-Mechanical Monitoring Systems PDFDocument2 pagesAg-Mechanical Monitoring Systems PDFqdod_waffiNo ratings yet

- Automation in Material Handling System at Site: By: Varun Babbar Abhishek Arora Sombudhha DuttaDocument13 pagesAutomation in Material Handling System at Site: By: Varun Babbar Abhishek Arora Sombudhha Duttaशर्मा अविनाशNo ratings yet

- Last Area Day 8 - Basic Electronics-1Document7 pagesLast Area Day 8 - Basic Electronics-1ellajanepoNo ratings yet

- CHEDocument2 pagesCHEpsjeeveshNo ratings yet