Professional Documents

Culture Documents

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Uploaded by

KumbamCopyright:

Available Formats

You might also like

- IB Chemistry AnswersDocument20 pagesIB Chemistry Answerssh50% (2)

- A Beginner's Guide To Mass Spectral InterpretationDocument240 pagesA Beginner's Guide To Mass Spectral Interpretationastroguille80% (5)

- Amity Institute of Pharmacy: B Pharm Ist Semester Pharmaceutical Analysis Pawan Kumar GuptaDocument35 pagesAmity Institute of Pharmacy: B Pharm Ist Semester Pharmaceutical Analysis Pawan Kumar Guptapawan kumar guptaNo ratings yet

- Purification of Crude Glycerol Using Acidification PDFDocument7 pagesPurification of Crude Glycerol Using Acidification PDFNestor Armando Marin Solano100% (1)

- Whole Pattern Fitting and Rietveld Refinement: Sr0.33Mnla0.67O2.91 (Xs (?) 876 (151), LC - 0.936)Document1 pageWhole Pattern Fitting and Rietveld Refinement: Sr0.33Mnla0.67O2.91 (Xs (?) 876 (151), LC - 0.936)baokeliNo ratings yet

- A Methodology For Afterburner EvaluationDocument12 pagesA Methodology For Afterburner EvaluationAbdul QaderNo ratings yet

- Numerical Modeling of Steady Burning Characteristics of Spherical Ethanol Particles in A Spray EnvironmentDocument6 pagesNumerical Modeling of Steady Burning Characteristics of Spherical Ethanol Particles in A Spray EnvironmentRISHA RAJUNo ratings yet

- Ramped Temperature Oxidation Testing and in Situ Combustion ProjectsDocument17 pagesRamped Temperature Oxidation Testing and in Situ Combustion ProjectsNeetish Kumar MauryaNo ratings yet

- Broman 1961Document13 pagesBroman 1961Muhammed Cm SönmezNo ratings yet

- May 2020 Experimental Investigation of The Influence of Ignition System ParametersDocument14 pagesMay 2020 Experimental Investigation of The Influence of Ignition System ParameterscahyaniwindartoNo ratings yet

- Study On Plasma Combustion Process in Aero Engine Combustor: Journal of Physics: Conference SeriesDocument13 pagesStudy On Plasma Combustion Process in Aero Engine Combustor: Journal of Physics: Conference SeriesSwarniv ChandraNo ratings yet

- Combustion Modes Periodical Transition in A Hydrogen-Fueled Scramjet Combustor With Rearwall-Expansion Cavity FlameholderDocument7 pagesCombustion Modes Periodical Transition in A Hydrogen-Fueled Scramjet Combustor With Rearwall-Expansion Cavity FlameholderSouhardya BanerjeeNo ratings yet

- CFD Modeling of The Hydrodynamics and Reaction Kinetics of Fkuidized Bed ReactorDocument10 pagesCFD Modeling of The Hydrodynamics and Reaction Kinetics of Fkuidized Bed ReactorfaheemNo ratings yet

- Acsomega 8b03405Document11 pagesAcsomega 8b03405sachinNo ratings yet

- EbulliscopicDocument3 pagesEbulliscopicAlexandra Rondán LizanaNo ratings yet

- An Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetsDocument9 pagesAn Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetskangsungjinNo ratings yet

- Combustion LES of A Multi-Burner Annular Aero-Engine Combustor Using A Skeletal Reaction Mechanism For Jet-A Air MixturesDocument19 pagesCombustion LES of A Multi-Burner Annular Aero-Engine Combustor Using A Skeletal Reaction Mechanism For Jet-A Air MixturesstepanovatvNo ratings yet

- Experimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketDocument8 pagesExperimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketAzeem KhanNo ratings yet

- Aerospace 10 00410 1Document15 pagesAerospace 10 00410 1animeshdonikar11No ratings yet

- 2 1 1621237268 4ijaerdjun20214Document22 pages2 1 1621237268 4ijaerdjun20214TJPRC PublicationsNo ratings yet

- Thermodynamic Behavior of Hydrogen NaturDocument6 pagesThermodynamic Behavior of Hydrogen NaturisvpNo ratings yet

- Research On Copper Erosion in Hydrogen Peroxide - Kerosene Bipropellant Thrust ChamberDocument13 pagesResearch On Copper Erosion in Hydrogen Peroxide - Kerosene Bipropellant Thrust ChamberDarius MaximusNo ratings yet

- Strategy To Synthesize Integrated Solar Energy Coproduction Processes With Optimal Process IntensificationDocument1 pageStrategy To Synthesize Integrated Solar Energy Coproduction Processes With Optimal Process IntensificationGiovanna JimenezNo ratings yet

- Beerer 2008Document8 pagesBeerer 2008Ally EnemmyNo ratings yet

- Analysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorDocument10 pagesAnalysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorSangHao NgNo ratings yet

- Combustion Science and TechnologyDocument12 pagesCombustion Science and TechnologySyafiqahNo ratings yet

- CFD MissileCombustion Scramjet DRDL 001 PDFDocument9 pagesCFD MissileCombustion Scramjet DRDL 001 PDFSai Santhosh ManepallyNo ratings yet

- Occurrence of Mists in A Chemical Engineering Process PlantDocument3 pagesOccurrence of Mists in A Chemical Engineering Process PlantRashaM.AtwiNo ratings yet

- Acetic Acid ZgasDocument4 pagesAcetic Acid ZgasPatrice PariNo ratings yet

- FT9908600567Document4 pagesFT9908600567baizidiNo ratings yet

- A Comparison of Numerical Predictions of Supersonic Combustion of Hydrogen Using Different Chemistry Models in A Model CombustorDocument9 pagesA Comparison of Numerical Predictions of Supersonic Combustion of Hydrogen Using Different Chemistry Models in A Model CombustoraruntnjNo ratings yet

- Design and Simulation of Gas Burner Ejectors - Pichler (2021)Document8 pagesDesign and Simulation of Gas Burner Ejectors - Pichler (2021)John SMithNo ratings yet

- On-Board Inert Gas Generating System (OBIGGS) P/N: 3261151-0101Document2 pagesOn-Board Inert Gas Generating System (OBIGGS) P/N: 3261151-0101DANIEL ENRIQUE ALDANA LOPERANo ratings yet

- Published ShcherbanevDocument11 pagesPublished ShcherbanevsoroushNo ratings yet

- Processes: PEM Fuel Cell Voltage Neural Control Based On Hydrogen Pressure RegulationDocument15 pagesProcesses: PEM Fuel Cell Voltage Neural Control Based On Hydrogen Pressure RegulationShashi KumarNo ratings yet

- Mathematical Modeling of Ethane Cracking PDFDocument14 pagesMathematical Modeling of Ethane Cracking PDFAlfonso BlancoNo ratings yet

- Joint 27-29,: June INDocument8 pagesJoint 27-29,: June INAIEIMANo ratings yet

- Gamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsDocument13 pagesGamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsBOURECHAK TayebNo ratings yet

- 1-S2.0-S1359431121011376-MainDocument13 pages1-S2.0-S1359431121011376-MainFurqanNo ratings yet

- Reactor Physics Experiment For Advanced Nuclear Reactor System at Kyoto University Critical Assembly (KUCA)Document8 pagesReactor Physics Experiment For Advanced Nuclear Reactor System at Kyoto University Critical Assembly (KUCA)amyounisNo ratings yet

- SPE 70053 Evaluation of Displacement Efficiency in Volatile Oil Reservoirs Under Nitrogen InjectionDocument9 pagesSPE 70053 Evaluation of Displacement Efficiency in Volatile Oil Reservoirs Under Nitrogen InjectionMIGUEL ANGEL MARCOS CERVANTESNo ratings yet

- Ford 1964Document8 pagesFord 1964Luiggi Silvestre MuchaNo ratings yet

- Combustion and Flame: K. Kumaran, V. BabuDocument8 pagesCombustion and Flame: K. Kumaran, V. BabuaruntnjNo ratings yet

- C3h8flame Counter Flow PitzDocument6 pagesC3h8flame Counter Flow Pitzsudar4No ratings yet

- Dept. of Mechanical Engineering Krishna Engineering CollegeDocument16 pagesDept. of Mechanical Engineering Krishna Engineering CollegebharatNo ratings yet

- A Jet Fuel Surrogate Formulated by RealDocument7 pagesA Jet Fuel Surrogate Formulated by Realdarelho mouraNo ratings yet

- Effect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorDocument17 pagesEffect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorCristianNo ratings yet

- Combustion in SituDocument9 pagesCombustion in SitujcNo ratings yet

- Spe 24336 MSDocument8 pagesSpe 24336 MSAwaiizNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument5 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityKumbamNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument10 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityaruntnjNo ratings yet

- Orca Share Media1666854183242 6991293168192527483Document6 pagesOrca Share Media1666854183242 6991293168192527483阿尔坎塔拉约翰·肯尼斯No ratings yet

- Experimental Investigation of Solid Rocket ScramjeDocument12 pagesExperimental Investigation of Solid Rocket Scramjeravideo2007No ratings yet

- Thesis Title Defence (Ali Anjum)Document17 pagesThesis Title Defence (Ali Anjum)HusnainNo ratings yet

- Pasini 2008Document9 pagesPasini 2008Aybüke BekmezciNo ratings yet

- Flow Induced Paper-4Document9 pagesFlow Induced Paper-4Suresh KumarNo ratings yet

- 1002550-becht-1Document3 pages1002550-becht-1Eslam MetwalyNo ratings yet

- Applied Energy: Antonio Mariani, Fabrice FoucherDocument11 pagesApplied Energy: Antonio Mariani, Fabrice Fouchermanu binodNo ratings yet

- Jiang 2021Document16 pagesJiang 2021Badis GueloulNo ratings yet

- Kinetics of Liquid Phase Oxidation of Cumene in Bubble Column"Document7 pagesKinetics of Liquid Phase Oxidation of Cumene in Bubble Column"Sergio Alejandro Leon AngaritaNo ratings yet

- Me 1023Document6 pagesMe 1023Shahfin Ahmed IftiNo ratings yet

- Fuel and Energy Abstracts Volume 38 Issue 5 1997 Utilization of Coal-Water Fuels in Fire-Tube BoilersDocument1 pageFuel and Energy Abstracts Volume 38 Issue 5 1997 Utilization of Coal-Water Fuels in Fire-Tube BoilerssergioteroNo ratings yet

- Mixing and Cooling Modelling of Cryogenic Fuel in Liquid Fuel Rocket Engine TanksDocument5 pagesMixing and Cooling Modelling of Cryogenic Fuel in Liquid Fuel Rocket Engine Tanksait oubella marouaneNo ratings yet

- Affect of Recombiner Location On Its Performance in Closed Containment Under Dry and Steam ConditionsDocument17 pagesAffect of Recombiner Location On Its Performance in Closed Containment Under Dry and Steam ConditionsArun MurthyNo ratings yet

- Atomization Liquid in Supersonic: FuelsDocument1 pageAtomization Liquid in Supersonic: FuelsKumbamNo ratings yet

- A Acc Cap: C'iloDocument1 pageA Acc Cap: C'iloKumbamNo ratings yet

- AB AA-92-8338: As AsDocument1 pageAB AA-92-8338: As AsKumbamNo ratings yet

- Numerical Study of Hydrogen Jet Flames in Supersonic Flows: Effect of Shock WavesDocument1 pageNumerical Study of Hydrogen Jet Flames in Supersonic Flows: Effect of Shock WavesKumbamNo ratings yet

- On The Numerical Simulation of Supersonic Combustion: AIAA-97-1914Document1 pageOn The Numerical Simulation of Supersonic Combustion: AIAA-97-1914KumbamNo ratings yet

- Numerical Investigation of Hydrogen Strut Injections: Into Supersonic Air FlowsDocument1 pageNumerical Investigation of Hydrogen Strut Injections: Into Supersonic Air FlowsKumbamNo ratings yet

- AA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerDocument1 pageAA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerKumbamNo ratings yet

- Numerical Investigation of Radiation and Turbulence Interactions in Supersonically Expanded Hydrogen Diffusion FlamesDocument1 pageNumerical Investigation of Radiation and Turbulence Interactions in Supersonically Expanded Hydrogen Diffusion FlamesKumbamNo ratings yet

- Numerical Investigation of Shock/Vortex Interaction in Hypersonic Thermochemical Nonequilibrium FlowDocument1 pageNumerical Investigation of Shock/Vortex Interaction in Hypersonic Thermochemical Nonequilibrium FlowKumbamNo ratings yet

- Numerical Study Mixing in Supersonic Combustors With Hypermixing InjectorsDocument1 pageNumerical Study Mixing in Supersonic Combustors With Hypermixing InjectorsKumbamNo ratings yet

- Scramjets and Surfboards: Some Forgotten HistoryDocument1 pageScramjets and Surfboards: Some Forgotten HistoryKumbamNo ratings yet

- Structure and Penetration of A Transverse Fluid Jet Injected at Supercritical Pressure in Supersonic HowDocument1 pageStructure and Penetration of A Transverse Fluid Jet Injected at Supercritical Pressure in Supersonic HowKumbamNo ratings yet

- Gasdyna-C In: Kef?Osee E Cctl3L'S1I@4 Chamj3EeDocument1 pageGasdyna-C In: Kef?Osee E Cctl3L'S1I@4 Chamj3EeKumbamNo ratings yet

- Spray Characteristics of Fischer-Tropsch Alternate Jet FuelsDocument6 pagesSpray Characteristics of Fischer-Tropsch Alternate Jet FuelsKumbamNo ratings yet

- Experimental Study of Near-Field Flow Structure in Hollow Cone Pressure Swirl SpraysDocument1 pageExperimental Study of Near-Field Flow Structure in Hollow Cone Pressure Swirl SpraysKumbamNo ratings yet

- A Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsDocument1 pageA Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsKumbamNo ratings yet

- Simulation of Transverse Gaseous Injection Through Diamond Ports Into Supersonic FreestreamDocument1 pageSimulation of Transverse Gaseous Injection Through Diamond Ports Into Supersonic FreestreamKumbamNo ratings yet

- Applied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangDocument6 pagesApplied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangKumbamNo ratings yet

- Jet Fuel Oxidation Involves A Very Large Number Reaction Species, Thus A Large Number of DifferentialDocument1 pageJet Fuel Oxidation Involves A Very Large Number Reaction Species, Thus A Large Number of DifferentialKumbamNo ratings yet

- Elementary Kinetic Steps. Current Computational: O) F - O4 IJJDocument1 pageElementary Kinetic Steps. Current Computational: O) F - O4 IJJKumbamNo ratings yet

- Paper 4Document4 pagesPaper 4KumbamNo ratings yet

- Energy and Buildings: Madhavi Indraganti, Djamel BoussaaDocument5 pagesEnergy and Buildings: Madhavi Indraganti, Djamel BoussaaKumbamNo ratings yet

- Case Studies in Thermal Engineering: Thoranis Deethayat, Tanongkiat Kiatsiriroat, Chakkraphan ThawonngamyingsakulDocument5 pagesCase Studies in Thermal Engineering: Thoranis Deethayat, Tanongkiat Kiatsiriroat, Chakkraphan ThawonngamyingsakulKumbamNo ratings yet

- A Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsDocument1 pageA Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsKumbamNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument5 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityKumbamNo ratings yet

- Applied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaDocument10 pagesApplied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaKumbamNo ratings yet

- Applied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaDocument5 pagesApplied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaKumbamNo ratings yet

- Synthesis and Characterization of NanocompositesDocument6 pagesSynthesis and Characterization of NanocompositesN.R. ShirishaNo ratings yet

- 1454924281CHE P8 M21 E-TextDocument8 pages1454924281CHE P8 M21 E-TextAdam AlhusseniNo ratings yet

- 08 WS7 LowRes WavemeterDocument2 pages08 WS7 LowRes Wavemeterdan_fitz_3No ratings yet

- 2D-NMR SpectrosDocument25 pages2D-NMR Spectrosابراهيم الاسطىNo ratings yet

- 1.1 - 1.2 Engineering Chemistry (CSE, ECE, EEE and IT)Document5 pages1.1 - 1.2 Engineering Chemistry (CSE, ECE, EEE and IT)hgiri2007No ratings yet

- MSC Genetics SyllabusDocument36 pagesMSC Genetics SyllabusMohak SahuNo ratings yet

- Bharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSDocument27 pagesBharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSSarjithNo ratings yet

- Chapter 1-Fall-2022-2023-C411Document25 pagesChapter 1-Fall-2022-2023-C411hesham khaledNo ratings yet

- Set C: CouplingDocument7 pagesSet C: CouplingLuke Matthew MondaresNo ratings yet

- Biological Approach To Synthesize TiO2 Nanoparticles Using Staphylococcus Aureus For Antibacterial and Anti-Biofilm ApplicationsDocument8 pagesBiological Approach To Synthesize TiO2 Nanoparticles Using Staphylococcus Aureus For Antibacterial and Anti-Biofilm ApplicationsMainak GhosalNo ratings yet

- PhosphorescenceDocument14 pagesPhosphorescencejaanabhenchodNo ratings yet

- Gerald Pollack - WaterDocument44 pagesGerald Pollack - Watercrisolaris100% (6)

- 19p NMR Part 7 2Document26 pages19p NMR Part 7 2Go RikanNo ratings yet

- Quinine FluorescenceDocument4 pagesQuinine FluorescenceDrGajanan VaishnavNo ratings yet

- 2425finalreview PahlavanDocument4 pages2425finalreview PahlavanRicardo PascualNo ratings yet

- It GR18 RegulationsDocument82 pagesIt GR18 RegulationsSrinivas KanakalaNo ratings yet

- Ch6 - Diatomic Vibration SpectraDocument15 pagesCh6 - Diatomic Vibration SpectraKamsNo ratings yet

- Experiment 4-1Document7 pagesExperiment 4-1SajinNo ratings yet

- Unit 5-Lecture 2 - IR SpectrosocpyDocument21 pagesUnit 5-Lecture 2 - IR SpectrosocpyLadliNo ratings yet

- Casp DR - ZakaDocument36 pagesCasp DR - ZakaAsghar AliNo ratings yet

- Scifinder®: Task HistoryDocument9 pagesScifinder®: Task HistoryNguyen Quyet100% (1)

- Atomic StructureDocument101 pagesAtomic StructureSHAWN TAKAONANo ratings yet

- Emeralds From The Kafubu Area Zambia PDFDocument33 pagesEmeralds From The Kafubu Area Zambia PDFMonica Molly KunjeNo ratings yet

- Atomic Absorption SpectrosDocument9 pagesAtomic Absorption SpectrosKishore CivilNo ratings yet

- Analysis of Polymers ATR FTIR AN PDFDocument3 pagesAnalysis of Polymers ATR FTIR AN PDFHasan MahmudNo ratings yet

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Uploaded by

KumbamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Combustion of Kerosene in A Supersonic Stream: Flalne 13. 4. 51

Uploaded by

KumbamCopyright:

Available Formats

(c)2000 American Institute of Aeronautics & Astronautics or published with permission of author(s) and/or author(s)’ sponsoring organization.

Combustion of Kerosene in a Supersonic Stream

Jian-Guo Li*, Gong Yu *, Xin-Yu Zhang*, Qing-Sheng Huang**

Institute of Mechanics, Chinese Academy of Sciences

Beijing, 100080 P. R. China

Abstract additional igniting and flame-holding elements should

The investigations on characteristics of be installed in the channel. Pilot hydrogen flame

sel tignition and sustaining of kerosene-hydrogen with sufficiently high concentration of active radicals

dual fuel were conducted in a direct-connect was usually used as an ignitor and the primary fuel

supersonic combustor with a fixed entrance Mach (hydrocarbons) was injected after or before the pilot 1

flalne 13. 4. 51 Many studies demonstrated the mixing

7T

-.. The experiments were conducted with

stagnation temperature varied from 1416K to 1700 and flame-holding benefits of using a rearward-facing

K and stagnation pressure kept in 1.8 MPa. The step with fuel injection downstream or upstream of the

gep I4. -5. 7. 81

average droplet diameters of kerosene spray were

measured by using of a laser particle sizer. Four In this study the pilot hydrogen was injected

types of integrated modular structure of pilot from the base of a rearward-facing step and was

llame and recessed cavity flameholder with parallel to the airstream. Downstream of the pilot

different configurations were tested to seek the flame, kerosene was injected normally from the

required minimum hydrogen equivalence ratio for bottom of the recessed cavity. The chemical

kerosene ignition and combustion sustaining. reactions of kerosene are expected being accelerated

Under combined promotion of pilot hydrogen by the pilot hydrogen flame and promoted by the low

tlame and recessed cavity, the required minimum speed recirculation flow, which provides longer

hydrogen equivalence ratio of 0.03 was found in residence time. The minimum equivalence ratios of

an optimized condition. Performances of the the pilot-hydrogen, which were required for ignition

combustor were preliminarily estimated by using of liquid kerosene, were investigated in different

of the

home-developed code SSC-3. A conditions as follows: I) the distance between the

combustion efficiency of 50% was obtained in a liquid kerosene injectior and pilot hydrogen injector; 2)

combustor with length of 425 mm. The effects stagnation temperature of vitiated air flow; 3) recessed

of configuration of integrated modular structure cavity. A modified code SSC-3 I91 was used to

. on combustor performances were discussed. analyze the experimental data.

Introduction Experimental facility

.

l.iquid hydrocarbons, such as kerosene, are The Schematic of experimental facility is shown

attractive candidates for fueling the scramjet in the in figure I. Details of the facility have been

tlight regime of M<8 due to its simplicity of described in Ref. IO. In the experimentation, high

operation and management [‘. *I. However, except temperature vitiated test air was produced by burning

the difficulties of atomization, vaporization and hydrogen, oxygen, and air in a heater, with the

Inixing, the relatively slow chemical reaction resulting oxygen volume fraction equal to that ot

kinetics of the pure kerosene, which is two or three normal air. The heater can provide air LIP to its

orders of magnitude slower than that of hydrogen, maximum capability with a temperature of 2200 K, a

becomes the major barrier in the realization of pressure of 4.5 MPa, and a flow rate of I .5 kg/s. The

liquid hydrocarbon scramjet. In order to ignite nozzle with contour walls produces a two-dimensional

hydrocarbons and stabilize the combustion, supersonic airflow of Mach 2.5. The supersonic

combustion chamber is a rectangular duct with an

* Research professor entrance cross section of 30X 30 mm. The duct is

* * Graduate student composed of two sections, which have lengths of 125

Copyright 0 American Institute of Aeronautics mm and 300 mm respectively. Their side-walls are

and Astronautics, Inc. All rights reserved. parallel to the two-dimensional nozzle with boundary-

the second sector, a non-swirling injector substitute was The OH* chemiluminescence in the ultraviolet spectral

installed, which had the same effective area as the injector but range around 310 nm was recorded with a HighSpeedStar 6

no fuel injection. The injector was co-axially fuel-staged, with camera connected to the second high-speed image intensifier

an air blast atomizer for both the pilot and main burners. At (HS IRO 25). The camera resolution was 1024 x 1024 pixels,

altitude relight conditions, the pilot stage was the only fueled and the exposure time was set to 100 µs. A Nikon lens (type

stage of the injector. The igniter installed in the combustion UV-Nikkor f/4.5, f=105 mm) was mounted on the image

chamber was a standard capacitor driven aircraft engine igniter, intensifier together with two interference filters. The OH*

producing sparks with duration of about 200 µs at a rate of up chemiluminescence from the flame was deflected by two high-

to 2 Hz. The igniter was mounted flush with the inner top reflecting mirrors in order to reduce signal contributions from

surface of the combustion chamber in the centre-plane of the the kerosene fluorescence and from the radiative soot particles.

fuel injector.

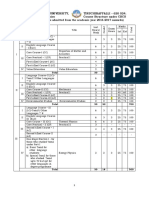

This article presents some experimental results primarily

by means of four exemplary flames: A1, A2, B1, and B2. The

corresponding combustor operating conditions are listed in

Table 2.

Table 2. Combustor operating conditions.

Flame A1 A2 B1 B2

5.9 5.9 7.9 7.9

Air pressure (psia)

± 0.2 ± 0.2 ± 0.2 ± 0.2

265 265 278 278

Air temperature (K)

±1 ±1 ±2 ±2

288 288 290 290

Fuel temperature (K)

±1 ±1 ±3 ±3

0.357 0.5 0.357 0.5

Normalized air mass flow

± 0.007 ± 0.01 ± 0.007 ± 0.01

0.08 0.055 0.08 0.055

Fuel-to-air ratio

± 0.001 ± 0.001 ± 0.001 ± 0.001

MEASUREMENT TECHNIQUES

A photo and a schematic of the experimental set-up for the

high-speed imaging and for the optical emission spectroscopy

are shown in Figure 2. A part of the RR test rig also is shown,

including the fuel pump system installed by RR to enable easier

changeovers between the different fuels.

Three high-speed cameras and two image intensifiers from

LaVision were used to perform simultaneous measurements of

the OH* and CH* chemiluminescence, and of the broadband

luminosity at a repetition rate of 3500 Hz. The camera systems

were arranged almost perpendicular to the flow direction.

A high-speed camera (HighSpeedStar 5) was used for

imaging the broadband luminosity during the flame initiation

and stabilization. The camera resolution was 1024 x 912 pixels Figure 2. Photo and schematic of the experimental set-up.

and the exposure time was set to 40 or 100 µs. A Nikon lens

(type Nikkor MF, f/1.4, f=85 mm) was mounted on the camera. For the safety of the image intensifier, it was necessary to

The lens aperture was varied during the measurement ensure the entire recording time was less than 500 ms to avoid

campaign. imaging the subsequent spark. The timing between ignition,

The CH* chemiluminescence in the blue spectral range camera start (trigger) plus image intensifier disable line, and

around 430 nm was recorded with the second HighSpeedStar 5 gate opening was synchronized using a high-speed

camera connected to a high-speed image intensifier programmable timing unit (HS PTU 9).

(HS IRO 25). The camera resolution was 1024 x 912 pixels, One uncertainty in the images results from the gate of the

and the exposure time was set to 100 µs. A Tokina lens (type image intensifiers (the exposure time), which was set to 100 µs

AT-X PRO MACRO 100 F2.8D, f/2.8, f=100 mm) was for both intensifiers. That means that the luminescence from

mounted on the image intensifier together with an interference particles or regions moving with velocities of 10 m/s appears

filter and a short pass filter. smeared over one millimeter in the image. Note that the

3 Copyright © 20xx by ASME

volume-averaged OH* chemiluminescence intensity recorded combustor equivalence ratio range investigated in our research.

by the high-speed camera system. Both spectra show the Note that soot is only present in fuel-rich regions and its

typical appearance of hydrocarbon flames, with strong luminosity depends on soot concentration and temperature.

chemiluminescence bands of the electronically excited radicals According to the Stefan-Boltzmann law, the soot luminosity is

OH*, CH* and C2* (The asterisk indicates an excited proportional to the fourth power of the soot temperature.

molecule.), originating from the combustion processes [14-17]. Therefore, the luminosity contributions from soot particles at

The spectra are superposed by a broad CO2* high temperatures are over-represented in the recorded volume-

chemiluminescence band ranging from 250 nm to 600 nm. averaged flame emission spectra.

50

CH* 2500

40

Relative intensity [-]

2000

soot

Temperature [K]

30

C2*

radiation 1500

C2*

20 OH* C2* 1000

Flame: B2

C2*

Fuel: Jet A-1

CO2* Estimated mean flame temperatures at 6 psia

10 CH* Measured spectrum 500 Estimated mean flame temperatures at 8 psia

OH* Planck's law other symbols: soot temperatures at 6 psia (red) and 8 psia (black)

0 0

300 400 500 600 700 800 0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6

Wavelength [nm] Global combustor equivalence ratio

35

CH* Figure 5. Soot temperatures derived from the soot thermal

30

Flame: B2 continuum emission, and estimated mean flame

Relative intensity [-]

25 Fuel: SPK-1

Measured spectrum temperatures. Symbols denote type of fuel: ■ Jet A-1,

20 Planck's law ● SPK-1, ▲ SPK-2, □ Blend-1, ○ Blend-2, Δ Blend-3.

15 OH* C2* Black and red symbols identify measurement results at

8 psia and 6 psia inlet air pressure respectively.

10 C2* C *

CO2*

CH* 2 soot radiation

5 OH* C2* Estimated mean flame temperatures are also plotted in

0 Figure 5 for both inlet air pressures. The temperatures are

300 400 500 600 700 800 calculated with a RR in-house chemistry tool for Jet A-1

Wavelength [nm]

kerosene assuming 100% combustion efficiency. Therefore, the

Figure 4. Measured spectra of a Jet A-1 fueled flame (upper actual mean flame temperatures may be lower than the

graph) and a SPK-1 fueled flame (lower graph). calculated temperatures but sporadic hot spots may be found in

the flames if richer pockets of mixture are combusted.

The most remarkable difference between both flame

1,0

emission spectra is a distinguishable soot luminosity appearing

C2*/CH* chemiluminescence ratio

as thermal continuum emission superposed on the 0,8

chemiluminescence. This reflects one important conclusion

from the optical emission spectroscopy measurements. The 0,6

spectra give indication of the soot creation dependence on the

operating conditions and fuel. For instance, Jet A-1 shows 0,4

significantly stronger soot luminosity than all investigated SPK

0,2

fuels. Quantification was performed by introducing a soot

coefficient (not presented here). The known tendency that the 0

soot luminosity increases with increasing air pressure and/or 0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6

fuel-to-air ratio was also found. Global combustor equivalence ratio

Moreover, black-body thermal radiation curves according Figure 6. Dependence of the C2*/CH* chemiluminescence

to Planck’s law were iteratively fitted to the infrared region ratio on the global combustor equivalence ratio. Symbols

between 625 nm and 850 nm for all measured spectra with denote type of fuel as indicated in the caption for Figure 5.

conspicuous soot radiation emissions, and the related black-

body thermodynamic temperatures (the soot particle In addition, it was found that the CH*/OH*, C2*/OH* and

temperatures) were determined. The derived soot temperatures the C2*/CH* chemiluminescence ratios are not sensitive to the

are plotted in Figure 5. It was found, that the soot temperatures global combustor equivalence ratio for all investigated fuels

are almost constant for all fuels and flames within the global and flames. The global combustor equivalence ratio is the ratio

5 Copyright © 20xx by ASME

intensity and the region of high soot luminous intensity are [7] Meyer, T. R., Roy, S., Gogineni, S.P., Belovich, V.M.,

clearly spatially separated in the average. Corporan, E., and Gord, J.R., 2004, “OH-PLIF and soot

The volume-averaged OH* chemiluminescence intensity volume fraction imaging in the reaction zone of a liquid-

shows a linear or at least a strict monotonic increasing fuelled model gas-turbine combustor”, Proceedings of the

dependency on the air mass flow. The chemiluminescence ASME Turbo Expo, GT2004-54318.

intensity divided by the fuel flow rate shows a monotonic [8] Stopper, U., Aigner, M., Ax, H., Meier, W., Sadanandan,

decreasing functional dependency on the global combustor R., Stöhr, M., and Bonaldo, A., 2010, “PIV, 2D-LIF and

equivalence ratio. Both dependencies are not strongly 1D-Raman measurements of flow field, composition and

influenced by the fuel or air pressure. The OH* temperature in premixed gas turbine flames”,

chemiluminescence is strongest at high air mass flows and/or Experimental Thermal and Fluid Science, Vol. 34, pp.

low global combustor equivalence ratios. 396-403.

The Abel inversion post-processing technique was applied [9] Ax, H., Stopper, U., Meier, W., Aigner, M., and Güthe, F.,

to identify the main reaction zones of the stabilized flame in an 2009, “Experimental analysis of the combustion behavior

axial plane. The flames have two main reaction zones both of a gas turbine burner by laser measurement techniques“,

attached to the injector, a central zone and a quite small outer Proceedings of the ASME Turbo Expo, GT2009-59171.

zone. The appearance of the central and/or outer zone and the [10] Correa, S.M., 1992, “A review of NOx formation under

magnitude of the chemical activity in both zones are dependent gas-turbine combustion conditions”, Combustion Science

on the combustor operational parameter, but only slightly on and Technology, Vol. 87, pp. 329-362.

the fuels investigated here. [11] Pucher, G., Wang, G., Bardon, M.F., Gardiner, D.P.,

Namet-Allah, A.M., and Benaissa, A., 2001, “Enhanced

ACKNOWLEDGMENTS ignition systems for aircraft altitude relight”, 48th Annual

The authors would like to thank Darren Fyffe and Andrew Conference of the Canadian Aeronautics and Space

Payne from Rolls-Royce for the operation of the SARS test rig Institute.

as well as Allan Collard from Rolls-Royce for technical [12] Pucher, G., and Allan, W.D., 2004, “Turbine fuel ignition

assistance during the measurements. The financial support from and combustion facility for extremely low temperature

the Qatar Science & Technology Park Research Network conditions”, Proceedings of the ASME Turbo Expo,

Program within the research project “In-depth Characterisation GT2004-53620.

of Synthetic GTL Jet Fuel Combustion Performance in Current [13] Naegeli, D.W., and Dodge, L.G., 1991, “Ignition study in a

& Future Gas Turbine Engines” is gratefully acknowledged. gas turbine combustor”, Combustion Science and

Technology, Vol. 80, pp. 165-184.

REFERENCES [14] Smith, G.P., Luque, J., Park, C., Jeffries, J.B., and Crosley,

[1] Fyffe, D., Kannaiyan, K., Moran, J., Al-Sharshani, A., and D.R., 2002, “Low pressure flame determinations of rate

Sadr, R., 2011, Proceedings of the ASME Turbo Expo, constants for OH(A) and CH(A) chemiluminescence”,

GT2011-45487. Combustion and Flame, Vol. 131, pp. 59-69.

[2] Read, R.W., 2008, “Experimental investigations into high- [15] Kojima, J., Ikeda, Y., and Nakajima, T., 2005, “Basic

altitude relight of a gas turbine”, PhD thesis, University of aspects of OH(A), CH(A), and C2(d) chemiluminescence

Cambridge. in the reaction zone of laminar methane-air premixed

[3] Read, R.W., Rogerson, J.W., and Hochgreb, S., 2008, flames“, Combustion and Flame, Vol. 140, pp. 34-45.

“Relight imaging at low temperature, low pressure [16] Nori, V.N., and Seitzmann, J.M., 2007,

conditions”, Proceedings 46th AIAA Aerospace Sciences “Chemiluminescence measurements and modeling in

Meeting, AIAA 2008-0957. syngas, methane and Jet-A fueled combustors”,

[4] Mosbach, T., Sadanandan, R., and Meier, W., 2009, Proceedings 45th AIAA Aerospace Sciences Meeting,

“Report on the results of measurement campaigns at RR- AIAA 2007-466.

rig”, Deliverable D2.2.3a, EU Project No. AST5-CT- [17] Nori, V.N., 2008, “Modeling and analysis of

2006-030828. chemiluminescence sensing for syngas, methane and Jet-A

[5] Mosbach, T., Sadanandan, R., Meier, W., and Eggels R., combustion”, PhD thesis, Georgia Institute of Technology.

2010, “Experimental analysis of altitude relight under [18] Alvarez, R., Rodero, A., and Quintero M.C., 2002, ”An

realistic conditions using laser and high-speed video Abel inversion method for radially resolved measurements

techniques”, Proceedings of ASME Turbo Expo, GT2010- in the axial injection torch”, Spectrochimica Acta Part B,

22625. Vol. 57, pp. 1665-1680.

[6] Dreizler, A., and Janicka, J., 2002, “Diagnostic challenges [19] Bahr, L., and Lerch, R., 2008, “Beam Profile

for gas turbine combustor model validation”, in Kohse- Measurements Using Light Refractive Tomography”,

Höinghaus, K., and Jeffries, J. (Eds.), 2002, “Applied IEEE Transactions on Ultrasonics, Ferroelectrics, and

Combustion Diagnostics”, Taylor & Francis. Frequency Control, Vol. 55, pp. 405-414.

9 Copyright © 20xx by ASME

Flame

A1 A2 B1 B2

Fuel

Jet A-1

SPK-1

SPK-2

Blend-1

Blend-2

Blend-3

Figure 11. Dependence of the time-averaged OH* chemiluminescence distribution on the investigated fuels

for the four combustor operating conditions. Field-of-view is 135 x 103 mm.

11

You might also like

- IB Chemistry AnswersDocument20 pagesIB Chemistry Answerssh50% (2)

- A Beginner's Guide To Mass Spectral InterpretationDocument240 pagesA Beginner's Guide To Mass Spectral Interpretationastroguille80% (5)

- Amity Institute of Pharmacy: B Pharm Ist Semester Pharmaceutical Analysis Pawan Kumar GuptaDocument35 pagesAmity Institute of Pharmacy: B Pharm Ist Semester Pharmaceutical Analysis Pawan Kumar Guptapawan kumar guptaNo ratings yet

- Purification of Crude Glycerol Using Acidification PDFDocument7 pagesPurification of Crude Glycerol Using Acidification PDFNestor Armando Marin Solano100% (1)

- Whole Pattern Fitting and Rietveld Refinement: Sr0.33Mnla0.67O2.91 (Xs (?) 876 (151), LC - 0.936)Document1 pageWhole Pattern Fitting and Rietveld Refinement: Sr0.33Mnla0.67O2.91 (Xs (?) 876 (151), LC - 0.936)baokeliNo ratings yet

- A Methodology For Afterburner EvaluationDocument12 pagesA Methodology For Afterburner EvaluationAbdul QaderNo ratings yet

- Numerical Modeling of Steady Burning Characteristics of Spherical Ethanol Particles in A Spray EnvironmentDocument6 pagesNumerical Modeling of Steady Burning Characteristics of Spherical Ethanol Particles in A Spray EnvironmentRISHA RAJUNo ratings yet

- Ramped Temperature Oxidation Testing and in Situ Combustion ProjectsDocument17 pagesRamped Temperature Oxidation Testing and in Situ Combustion ProjectsNeetish Kumar MauryaNo ratings yet

- Broman 1961Document13 pagesBroman 1961Muhammed Cm SönmezNo ratings yet

- May 2020 Experimental Investigation of The Influence of Ignition System ParametersDocument14 pagesMay 2020 Experimental Investigation of The Influence of Ignition System ParameterscahyaniwindartoNo ratings yet

- Study On Plasma Combustion Process in Aero Engine Combustor: Journal of Physics: Conference SeriesDocument13 pagesStudy On Plasma Combustion Process in Aero Engine Combustor: Journal of Physics: Conference SeriesSwarniv ChandraNo ratings yet

- Combustion Modes Periodical Transition in A Hydrogen-Fueled Scramjet Combustor With Rearwall-Expansion Cavity FlameholderDocument7 pagesCombustion Modes Periodical Transition in A Hydrogen-Fueled Scramjet Combustor With Rearwall-Expansion Cavity FlameholderSouhardya BanerjeeNo ratings yet

- CFD Modeling of The Hydrodynamics and Reaction Kinetics of Fkuidized Bed ReactorDocument10 pagesCFD Modeling of The Hydrodynamics and Reaction Kinetics of Fkuidized Bed ReactorfaheemNo ratings yet

- Acsomega 8b03405Document11 pagesAcsomega 8b03405sachinNo ratings yet

- EbulliscopicDocument3 pagesEbulliscopicAlexandra Rondán LizanaNo ratings yet

- An Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetsDocument9 pagesAn Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetskangsungjinNo ratings yet

- Combustion LES of A Multi-Burner Annular Aero-Engine Combustor Using A Skeletal Reaction Mechanism For Jet-A Air MixturesDocument19 pagesCombustion LES of A Multi-Burner Annular Aero-Engine Combustor Using A Skeletal Reaction Mechanism For Jet-A Air MixturesstepanovatvNo ratings yet

- Experimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketDocument8 pagesExperimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketAzeem KhanNo ratings yet

- Aerospace 10 00410 1Document15 pagesAerospace 10 00410 1animeshdonikar11No ratings yet

- 2 1 1621237268 4ijaerdjun20214Document22 pages2 1 1621237268 4ijaerdjun20214TJPRC PublicationsNo ratings yet

- Thermodynamic Behavior of Hydrogen NaturDocument6 pagesThermodynamic Behavior of Hydrogen NaturisvpNo ratings yet

- Research On Copper Erosion in Hydrogen Peroxide - Kerosene Bipropellant Thrust ChamberDocument13 pagesResearch On Copper Erosion in Hydrogen Peroxide - Kerosene Bipropellant Thrust ChamberDarius MaximusNo ratings yet

- Strategy To Synthesize Integrated Solar Energy Coproduction Processes With Optimal Process IntensificationDocument1 pageStrategy To Synthesize Integrated Solar Energy Coproduction Processes With Optimal Process IntensificationGiovanna JimenezNo ratings yet

- Beerer 2008Document8 pagesBeerer 2008Ally EnemmyNo ratings yet

- Analysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorDocument10 pagesAnalysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorSangHao NgNo ratings yet

- Combustion Science and TechnologyDocument12 pagesCombustion Science and TechnologySyafiqahNo ratings yet

- CFD MissileCombustion Scramjet DRDL 001 PDFDocument9 pagesCFD MissileCombustion Scramjet DRDL 001 PDFSai Santhosh ManepallyNo ratings yet

- Occurrence of Mists in A Chemical Engineering Process PlantDocument3 pagesOccurrence of Mists in A Chemical Engineering Process PlantRashaM.AtwiNo ratings yet

- Acetic Acid ZgasDocument4 pagesAcetic Acid ZgasPatrice PariNo ratings yet

- FT9908600567Document4 pagesFT9908600567baizidiNo ratings yet

- A Comparison of Numerical Predictions of Supersonic Combustion of Hydrogen Using Different Chemistry Models in A Model CombustorDocument9 pagesA Comparison of Numerical Predictions of Supersonic Combustion of Hydrogen Using Different Chemistry Models in A Model CombustoraruntnjNo ratings yet

- Design and Simulation of Gas Burner Ejectors - Pichler (2021)Document8 pagesDesign and Simulation of Gas Burner Ejectors - Pichler (2021)John SMithNo ratings yet

- On-Board Inert Gas Generating System (OBIGGS) P/N: 3261151-0101Document2 pagesOn-Board Inert Gas Generating System (OBIGGS) P/N: 3261151-0101DANIEL ENRIQUE ALDANA LOPERANo ratings yet

- Published ShcherbanevDocument11 pagesPublished ShcherbanevsoroushNo ratings yet

- Processes: PEM Fuel Cell Voltage Neural Control Based On Hydrogen Pressure RegulationDocument15 pagesProcesses: PEM Fuel Cell Voltage Neural Control Based On Hydrogen Pressure RegulationShashi KumarNo ratings yet

- Mathematical Modeling of Ethane Cracking PDFDocument14 pagesMathematical Modeling of Ethane Cracking PDFAlfonso BlancoNo ratings yet

- Joint 27-29,: June INDocument8 pagesJoint 27-29,: June INAIEIMANo ratings yet

- Gamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsDocument13 pagesGamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsBOURECHAK TayebNo ratings yet

- 1-S2.0-S1359431121011376-MainDocument13 pages1-S2.0-S1359431121011376-MainFurqanNo ratings yet

- Reactor Physics Experiment For Advanced Nuclear Reactor System at Kyoto University Critical Assembly (KUCA)Document8 pagesReactor Physics Experiment For Advanced Nuclear Reactor System at Kyoto University Critical Assembly (KUCA)amyounisNo ratings yet

- SPE 70053 Evaluation of Displacement Efficiency in Volatile Oil Reservoirs Under Nitrogen InjectionDocument9 pagesSPE 70053 Evaluation of Displacement Efficiency in Volatile Oil Reservoirs Under Nitrogen InjectionMIGUEL ANGEL MARCOS CERVANTESNo ratings yet

- Ford 1964Document8 pagesFord 1964Luiggi Silvestre MuchaNo ratings yet

- Combustion and Flame: K. Kumaran, V. BabuDocument8 pagesCombustion and Flame: K. Kumaran, V. BabuaruntnjNo ratings yet

- C3h8flame Counter Flow PitzDocument6 pagesC3h8flame Counter Flow Pitzsudar4No ratings yet

- Dept. of Mechanical Engineering Krishna Engineering CollegeDocument16 pagesDept. of Mechanical Engineering Krishna Engineering CollegebharatNo ratings yet

- A Jet Fuel Surrogate Formulated by RealDocument7 pagesA Jet Fuel Surrogate Formulated by Realdarelho mouraNo ratings yet

- Effect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorDocument17 pagesEffect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorCristianNo ratings yet

- Combustion in SituDocument9 pagesCombustion in SitujcNo ratings yet

- Spe 24336 MSDocument8 pagesSpe 24336 MSAwaiizNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument5 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityKumbamNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument10 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityaruntnjNo ratings yet

- Orca Share Media1666854183242 6991293168192527483Document6 pagesOrca Share Media1666854183242 6991293168192527483阿尔坎塔拉约翰·肯尼斯No ratings yet

- Experimental Investigation of Solid Rocket ScramjeDocument12 pagesExperimental Investigation of Solid Rocket Scramjeravideo2007No ratings yet

- Thesis Title Defence (Ali Anjum)Document17 pagesThesis Title Defence (Ali Anjum)HusnainNo ratings yet

- Pasini 2008Document9 pagesPasini 2008Aybüke BekmezciNo ratings yet

- Flow Induced Paper-4Document9 pagesFlow Induced Paper-4Suresh KumarNo ratings yet

- 1002550-becht-1Document3 pages1002550-becht-1Eslam MetwalyNo ratings yet

- Applied Energy: Antonio Mariani, Fabrice FoucherDocument11 pagesApplied Energy: Antonio Mariani, Fabrice Fouchermanu binodNo ratings yet

- Jiang 2021Document16 pagesJiang 2021Badis GueloulNo ratings yet

- Kinetics of Liquid Phase Oxidation of Cumene in Bubble Column"Document7 pagesKinetics of Liquid Phase Oxidation of Cumene in Bubble Column"Sergio Alejandro Leon AngaritaNo ratings yet

- Me 1023Document6 pagesMe 1023Shahfin Ahmed IftiNo ratings yet

- Fuel and Energy Abstracts Volume 38 Issue 5 1997 Utilization of Coal-Water Fuels in Fire-Tube BoilersDocument1 pageFuel and Energy Abstracts Volume 38 Issue 5 1997 Utilization of Coal-Water Fuels in Fire-Tube BoilerssergioteroNo ratings yet

- Mixing and Cooling Modelling of Cryogenic Fuel in Liquid Fuel Rocket Engine TanksDocument5 pagesMixing and Cooling Modelling of Cryogenic Fuel in Liquid Fuel Rocket Engine Tanksait oubella marouaneNo ratings yet

- Affect of Recombiner Location On Its Performance in Closed Containment Under Dry and Steam ConditionsDocument17 pagesAffect of Recombiner Location On Its Performance in Closed Containment Under Dry and Steam ConditionsArun MurthyNo ratings yet

- Atomization Liquid in Supersonic: FuelsDocument1 pageAtomization Liquid in Supersonic: FuelsKumbamNo ratings yet

- A Acc Cap: C'iloDocument1 pageA Acc Cap: C'iloKumbamNo ratings yet

- AB AA-92-8338: As AsDocument1 pageAB AA-92-8338: As AsKumbamNo ratings yet

- Numerical Study of Hydrogen Jet Flames in Supersonic Flows: Effect of Shock WavesDocument1 pageNumerical Study of Hydrogen Jet Flames in Supersonic Flows: Effect of Shock WavesKumbamNo ratings yet

- On The Numerical Simulation of Supersonic Combustion: AIAA-97-1914Document1 pageOn The Numerical Simulation of Supersonic Combustion: AIAA-97-1914KumbamNo ratings yet

- Numerical Investigation of Hydrogen Strut Injections: Into Supersonic Air FlowsDocument1 pageNumerical Investigation of Hydrogen Strut Injections: Into Supersonic Air FlowsKumbamNo ratings yet

- AA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerDocument1 pageAA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerKumbamNo ratings yet

- Numerical Investigation of Radiation and Turbulence Interactions in Supersonically Expanded Hydrogen Diffusion FlamesDocument1 pageNumerical Investigation of Radiation and Turbulence Interactions in Supersonically Expanded Hydrogen Diffusion FlamesKumbamNo ratings yet

- Numerical Investigation of Shock/Vortex Interaction in Hypersonic Thermochemical Nonequilibrium FlowDocument1 pageNumerical Investigation of Shock/Vortex Interaction in Hypersonic Thermochemical Nonequilibrium FlowKumbamNo ratings yet

- Numerical Study Mixing in Supersonic Combustors With Hypermixing InjectorsDocument1 pageNumerical Study Mixing in Supersonic Combustors With Hypermixing InjectorsKumbamNo ratings yet

- Scramjets and Surfboards: Some Forgotten HistoryDocument1 pageScramjets and Surfboards: Some Forgotten HistoryKumbamNo ratings yet

- Structure and Penetration of A Transverse Fluid Jet Injected at Supercritical Pressure in Supersonic HowDocument1 pageStructure and Penetration of A Transverse Fluid Jet Injected at Supercritical Pressure in Supersonic HowKumbamNo ratings yet

- Gasdyna-C In: Kef?Osee E Cctl3L'S1I@4 Chamj3EeDocument1 pageGasdyna-C In: Kef?Osee E Cctl3L'S1I@4 Chamj3EeKumbamNo ratings yet

- Spray Characteristics of Fischer-Tropsch Alternate Jet FuelsDocument6 pagesSpray Characteristics of Fischer-Tropsch Alternate Jet FuelsKumbamNo ratings yet

- Experimental Study of Near-Field Flow Structure in Hollow Cone Pressure Swirl SpraysDocument1 pageExperimental Study of Near-Field Flow Structure in Hollow Cone Pressure Swirl SpraysKumbamNo ratings yet

- A Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsDocument1 pageA Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsKumbamNo ratings yet

- Simulation of Transverse Gaseous Injection Through Diamond Ports Into Supersonic FreestreamDocument1 pageSimulation of Transverse Gaseous Injection Through Diamond Ports Into Supersonic FreestreamKumbamNo ratings yet

- Applied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangDocument6 pagesApplied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangKumbamNo ratings yet

- Jet Fuel Oxidation Involves A Very Large Number Reaction Species, Thus A Large Number of DifferentialDocument1 pageJet Fuel Oxidation Involves A Very Large Number Reaction Species, Thus A Large Number of DifferentialKumbamNo ratings yet

- Elementary Kinetic Steps. Current Computational: O) F - O4 IJJDocument1 pageElementary Kinetic Steps. Current Computational: O) F - O4 IJJKumbamNo ratings yet

- Paper 4Document4 pagesPaper 4KumbamNo ratings yet

- Energy and Buildings: Madhavi Indraganti, Djamel BoussaaDocument5 pagesEnergy and Buildings: Madhavi Indraganti, Djamel BoussaaKumbamNo ratings yet

- Case Studies in Thermal Engineering: Thoranis Deethayat, Tanongkiat Kiatsiriroat, Chakkraphan ThawonngamyingsakulDocument5 pagesCase Studies in Thermal Engineering: Thoranis Deethayat, Tanongkiat Kiatsiriroat, Chakkraphan ThawonngamyingsakulKumbamNo ratings yet

- A Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsDocument1 pageA Simplified Reaction Mechanism For Prediction of NO, Emissions The Combustion of HydrocarbonsKumbamNo ratings yet

- Effect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityDocument5 pagesEffect of GTL-like Jet Fuel Composition On GT Engine Altitude Ignition Performance - Part I: Combustor OperabilityKumbamNo ratings yet

- Applied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaDocument10 pagesApplied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaKumbamNo ratings yet

- Applied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaDocument5 pagesApplied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaKumbamNo ratings yet

- Synthesis and Characterization of NanocompositesDocument6 pagesSynthesis and Characterization of NanocompositesN.R. ShirishaNo ratings yet

- 1454924281CHE P8 M21 E-TextDocument8 pages1454924281CHE P8 M21 E-TextAdam AlhusseniNo ratings yet

- 08 WS7 LowRes WavemeterDocument2 pages08 WS7 LowRes Wavemeterdan_fitz_3No ratings yet

- 2D-NMR SpectrosDocument25 pages2D-NMR Spectrosابراهيم الاسطىNo ratings yet

- 1.1 - 1.2 Engineering Chemistry (CSE, ECE, EEE and IT)Document5 pages1.1 - 1.2 Engineering Chemistry (CSE, ECE, EEE and IT)hgiri2007No ratings yet

- MSC Genetics SyllabusDocument36 pagesMSC Genetics SyllabusMohak SahuNo ratings yet

- Bharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSDocument27 pagesBharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSSarjithNo ratings yet

- Chapter 1-Fall-2022-2023-C411Document25 pagesChapter 1-Fall-2022-2023-C411hesham khaledNo ratings yet

- Set C: CouplingDocument7 pagesSet C: CouplingLuke Matthew MondaresNo ratings yet

- Biological Approach To Synthesize TiO2 Nanoparticles Using Staphylococcus Aureus For Antibacterial and Anti-Biofilm ApplicationsDocument8 pagesBiological Approach To Synthesize TiO2 Nanoparticles Using Staphylococcus Aureus For Antibacterial and Anti-Biofilm ApplicationsMainak GhosalNo ratings yet

- PhosphorescenceDocument14 pagesPhosphorescencejaanabhenchodNo ratings yet

- Gerald Pollack - WaterDocument44 pagesGerald Pollack - Watercrisolaris100% (6)

- 19p NMR Part 7 2Document26 pages19p NMR Part 7 2Go RikanNo ratings yet

- Quinine FluorescenceDocument4 pagesQuinine FluorescenceDrGajanan VaishnavNo ratings yet

- 2425finalreview PahlavanDocument4 pages2425finalreview PahlavanRicardo PascualNo ratings yet

- It GR18 RegulationsDocument82 pagesIt GR18 RegulationsSrinivas KanakalaNo ratings yet

- Ch6 - Diatomic Vibration SpectraDocument15 pagesCh6 - Diatomic Vibration SpectraKamsNo ratings yet

- Experiment 4-1Document7 pagesExperiment 4-1SajinNo ratings yet

- Unit 5-Lecture 2 - IR SpectrosocpyDocument21 pagesUnit 5-Lecture 2 - IR SpectrosocpyLadliNo ratings yet

- Casp DR - ZakaDocument36 pagesCasp DR - ZakaAsghar AliNo ratings yet

- Scifinder®: Task HistoryDocument9 pagesScifinder®: Task HistoryNguyen Quyet100% (1)

- Atomic StructureDocument101 pagesAtomic StructureSHAWN TAKAONANo ratings yet

- Emeralds From The Kafubu Area Zambia PDFDocument33 pagesEmeralds From The Kafubu Area Zambia PDFMonica Molly KunjeNo ratings yet

- Atomic Absorption SpectrosDocument9 pagesAtomic Absorption SpectrosKishore CivilNo ratings yet

- Analysis of Polymers ATR FTIR AN PDFDocument3 pagesAnalysis of Polymers ATR FTIR AN PDFHasan MahmudNo ratings yet