Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

110 viewsReduce Lead Time in Logistics

Reduce Lead Time in Logistics

Uploaded by

shashi singh1. Remove unreliable suppliers from the supply chain to reduce lead times. Ensure enough inventory during the changeover and that new suppliers can start shipping immediately.

2. Prioritize vendors located close to warehouses to reduce lead times and complications from international shipping.

3. Share demand forecasts with suppliers early to prepare them for larger orders and ensure quick fulfillment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- BI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareDocument1 pageBI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareJanet CafrancaNo ratings yet

- The GoalDocument4 pagesThe GoalSESSHAN N SNo ratings yet

- Case Study MBADocument13 pagesCase Study MBAAlly Coralde100% (2)

- A Report of Pizza Hut OnDocument20 pagesA Report of Pizza Hut OnHema Agarwal100% (18)

- Voucher Entry & Practical Problem - TallyDocument7 pagesVoucher Entry & Practical Problem - TallyBackiyalakshmi Venkatraman92% (12)

- Business Development Manager 1553823084Document2 pagesBusiness Development Manager 1553823084shashi singhNo ratings yet

- Operation Management Case StudyDocument8 pagesOperation Management Case StudyArsalan HaiderNo ratings yet

- Donner CompanyDocument35 pagesDonner CompanyZunaira GullNo ratings yet

- Salesforce Case Study 2Document4 pagesSalesforce Case Study 2hasanhayatNo ratings yet

- The Boeing Company: Organizational StructureDocument10 pagesThe Boeing Company: Organizational StructureprashantNo ratings yet

- Detailed Analysis of Lead Time in Inventory ManagementDocument6 pagesDetailed Analysis of Lead Time in Inventory ManagementTambe Chalomine AgborNo ratings yet

- Product FlowDocument22 pagesProduct FlowMeklit KiarNo ratings yet

- Time To MarketDocument4 pagesTime To MarketMy SelfNo ratings yet

- Transitioning To Lean SystemDocument8 pagesTransitioning To Lean SystemDonita SotolomboNo ratings yet

- Lean IntroDocument12 pagesLean IntroShirley OmbrogNo ratings yet

- Work Measurement: Work Measurement Can Be Applied in A Workplace by Helping UncoverDocument8 pagesWork Measurement: Work Measurement Can Be Applied in A Workplace by Helping UncoverJessuel Larn-epsNo ratings yet

- PlanningDocument4 pagesPlanningRajat SonkarNo ratings yet

- Categories of Goods: Inventory Management Component of InventoryDocument17 pagesCategories of Goods: Inventory Management Component of InventoryEva Zunaida KurniawantiNo ratings yet

- 7 WastesssDocument4 pages7 WastessskirstendelNo ratings yet

- SCM Assignment No. 2 Q 1. Importance of Workflow Automation. AnswerDocument3 pagesSCM Assignment No. 2 Q 1. Importance of Workflow Automation. Answer46 Gaurav PawarNo ratings yet

- 7 Best Practices For Inventory Management For WarehousesDocument3 pages7 Best Practices For Inventory Management For WarehousesTauqeer IqbalNo ratings yet

- 5 Ways For Lead Time ReductionDocument5 pages5 Ways For Lead Time ReductionYamini ShamiNo ratings yet

- Lean Manufacturing (JIT)Document5 pagesLean Manufacturing (JIT)Carl Jessner NarioNo ratings yet

- Operations SchedulingDocument14 pagesOperations Schedulingbezawit mamuyeNo ratings yet

- Stock Management Module 4Document5 pagesStock Management Module 4librarianNo ratings yet

- Lead TimeDocument35 pagesLead TimeMURALINo ratings yet

- Steps To Improve QualityDocument10 pagesSteps To Improve Qualityabhijit612No ratings yet

- Inventory Management SummaryDocument5 pagesInventory Management Summarykathleen tanzilNo ratings yet

- The Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectDocument4 pagesThe Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectjustingordanNo ratings yet

- Sourcing DecisionsDocument6 pagesSourcing DecisionsSakhawat HossainNo ratings yet

- Delay Analysis Using TDocument8 pagesDelay Analysis Using TAnkurSinghNo ratings yet

- Lean Six Sigma (Part A)Document17 pagesLean Six Sigma (Part A)Punniavel PNo ratings yet

- Kelebihan Dan KekuranganDocument4 pagesKelebihan Dan KekuranganRayendanNo ratings yet

- Unidad IV Supplier Certification and DevelopmentDocument12 pagesUnidad IV Supplier Certification and DevelopmentCaptian BenettsNo ratings yet

- EAN Anufacturing: Reported By: Uly Reyes & Mheng BanzonDocument64 pagesEAN Anufacturing: Reported By: Uly Reyes & Mheng BanzongoldenridgeNo ratings yet

- Top Company ReportDocument6 pagesTop Company ReportManjesh RNo ratings yet

- Midterm ExamDocument167 pagesMidterm Examapi-297834433No ratings yet

- Asynchronous 13Document5 pagesAsynchronous 13Charles John DolNo ratings yet

- Critical Path - Management Brief - FastReact - Evolve PDFDocument6 pagesCritical Path - Management Brief - FastReact - Evolve PDFSiddharth JhaNo ratings yet

- Frequent Discrepancies That Lead To Expediting Fees.: Question: Signs of Inventory ProblemsDocument11 pagesFrequent Discrepancies That Lead To Expediting Fees.: Question: Signs of Inventory ProblemsKevin ObaraNo ratings yet

- Glovia Lean ManufacturingDocument16 pagesGlovia Lean ManufacturingALEJANDRANo ratings yet

- Logistics 355 Yashana LalwaniDocument6 pagesLogistics 355 Yashana LalwaniYashana LalwaniNo ratings yet

- Process ManagementDocument11 pagesProcess Managementzoref333No ratings yet

- ReportsssDocument6 pagesReportsssVia SahipaNo ratings yet

- P & O Case AtudyDocument17 pagesP & O Case AtudySalar SikandarNo ratings yet

- Inventory System Thesis Documentation SampleDocument5 pagesInventory System Thesis Documentation SampleWriteAnEssayPaterson100% (2)

- 05TaskPerformance1 AISDocument1 page05TaskPerformance1 AISAilaJeanineNo ratings yet

- Chapter 12 Inventory Control Review and Discussion QuestionsDocument3 pagesChapter 12 Inventory Control Review and Discussion QuestionsDennis MpoNo ratings yet

- Literature Review On Lead Time ManagementDocument4 pagesLiterature Review On Lead Time Managementafdtszfwb100% (1)

- Operational Management AK-7-B SENTDocument10 pagesOperational Management AK-7-B SENTPratham KochharNo ratings yet

- BottleneckDocument6 pagesBottleneckvijayakum arNo ratings yet

- The 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsDocument6 pagesThe 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsRam KumarNo ratings yet

- Optimizing Efficiency: FabricationDocument7 pagesOptimizing Efficiency: FabricationVivek Kumar SinghNo ratings yet

- The 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsDocument6 pagesThe 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsRam Kumar100% (1)

- 8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Document8 pages8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Muhammad UsmanNo ratings yet

- 6 Inventory Control TechniquesDocument8 pages6 Inventory Control TechniquesAngel TagudNo ratings yet

- KAIZEN 10PsDocument3 pagesKAIZEN 10PsCassandra AldovinoNo ratings yet

- Process Design: Learning OutcomesDocument12 pagesProcess Design: Learning OutcomesMejidana, Rica Mae N.No ratings yet

- Module 4-1Document13 pagesModule 4-1saskiaNo ratings yet

- Job Shop Scheduling SecretDocument6 pagesJob Shop Scheduling SecretsauravNo ratings yet

- Benefits of ERP by Alexis Leon DemystifiedDocument7 pagesBenefits of ERP by Alexis Leon DemystifiedAniket KillekarNo ratings yet

- Lean Manufacturing & JITDocument42 pagesLean Manufacturing & JITMangesh GhandatNo ratings yet

- The Waste of WaitingDocument4 pagesThe Waste of WaitingJerome DalisayNo ratings yet

- Lean NewsletterDocument3 pagesLean NewsletterKomal TagraNo ratings yet

- LEAN STARTUP: Navigating Entrepreneurial Success Through Iterative Prototyping and Customer Validation (2023 Guide for Beginners)From EverandLEAN STARTUP: Navigating Entrepreneurial Success Through Iterative Prototyping and Customer Validation (2023 Guide for Beginners)No ratings yet

- The IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysFrom EverandThe IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysNo ratings yet

- Modes of TransportationDocument8 pagesModes of Transportationshashi singh100% (1)

- Reverse LogisticsDocument5 pagesReverse Logisticsshashi singhNo ratings yet

- Role of Logistics in SCMDocument2 pagesRole of Logistics in SCMshashi singhNo ratings yet

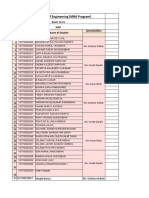

- Sigma Institute of Engineering - MBA ProgrammeDocument1 pageSigma Institute of Engineering - MBA Programmeshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Sigma Institute of Engineering - MBA ProgrammeDocument1 pageSigma Institute of Engineering - MBA Programmeshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- Bba Sem 3 PaperDocument1 pageBba Sem 3 Papershashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- MAP Project Report GroupDocument1 pageMAP Project Report Groupshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- SIP Institute CertificateDocument1 pageSIP Institute Certificateshashi singhNo ratings yet

- Journey of Steve JobsDocument6 pagesJourney of Steve Jobsshashi singhNo ratings yet

- Mr. Nirmal Jain: The UnbeatablesDocument7 pagesMr. Nirmal Jain: The Unbeatablesshashi singhNo ratings yet

- Mba PractDocument3 pagesMba Practshashi singhNo ratings yet

- Effects in Economic Decisions: Consumer EducationDocument53 pagesEffects in Economic Decisions: Consumer EducationJing KhaiNo ratings yet

- Riphah International College Associate Degree ProgramDocument5 pagesRiphah International College Associate Degree ProgramMuhammad HannanNo ratings yet

- Chapter 6Document18 pagesChapter 6Lydelle Mae CabaltejaNo ratings yet

- The Innovation Value Chain in Advanced Developing Countries: An Empirical Study of Taiwanese Manufacturing IndustryDocument38 pagesThe Innovation Value Chain in Advanced Developing Countries: An Empirical Study of Taiwanese Manufacturing IndustryEmbuhmas BroNo ratings yet

- Kay Pinkerton ResumeDocument2 pagesKay Pinkerton ResumeKay PinkertonNo ratings yet

- Chapter 3.1 Introduction To Industrial Hygiene and Occupational HealthDocument27 pagesChapter 3.1 Introduction To Industrial Hygiene and Occupational HealthHafizudin DaudNo ratings yet

- DR Nizam Latha Incorporated 2020 AFSDocument11 pagesDR Nizam Latha Incorporated 2020 AFShumayra.m16No ratings yet

- Call Center Manager ResumeDocument2 pagesCall Center Manager Resumefz74avg1No ratings yet

- The Corporate Form of Organization: Ordinary Shares Represent The Residual Corporate Interest That Bears The UltimateDocument3 pagesThe Corporate Form of Organization: Ordinary Shares Represent The Residual Corporate Interest That Bears The UltimateJihan Rahma IrianaNo ratings yet

- COGM Dan Income StatementDocument3 pagesCOGM Dan Income StatementABDUL KHALIQ BRUTUNo ratings yet

- ISYS6196005 FIN RCQuestionDocument5 pagesISYS6196005 FIN RCQuestionHana FebriantiNo ratings yet

- Differential Cost AnalysisDocument19 pagesDifferential Cost Analysisbobo kaNo ratings yet

- Islamic-Finance-Book Volume 4 Web PDFDocument166 pagesIslamic-Finance-Book Volume 4 Web PDFlarbiNo ratings yet

- Problems On Ratio AnalysisDocument5 pagesProblems On Ratio AnalysisPadyala Sriram100% (1)

- A Study On Impact of Dividend Announcements On Stock Prices in IndiaDocument5 pagesA Study On Impact of Dividend Announcements On Stock Prices in IndiaManju MahanandiaNo ratings yet

- The Communications Mix: What's The Difference Between The Marketing Communications Mix and The Marketing Mix?Document4 pagesThe Communications Mix: What's The Difference Between The Marketing Communications Mix and The Marketing Mix?miriam kuriaNo ratings yet

- Ocean Freight USA - Glossary of Shipping Terms PDFDocument9 pagesOcean Freight USA - Glossary of Shipping Terms PDFshivam_dubey4004No ratings yet

- Consumer Perception Towards Indian Oil in KolarDocument91 pagesConsumer Perception Towards Indian Oil in KolarRachna Jayaraghav100% (2)

- Islamic Financial System Principles and Operations PDF 901 944Document44 pagesIslamic Financial System Principles and Operations PDF 901 944Asdelina R100% (1)

- Commissionerate of Municipality (CMA), Tamil Nadu Circular About Tender PublicityDocument4 pagesCommissionerate of Municipality (CMA), Tamil Nadu Circular About Tender PublicitykayalonthewebNo ratings yet

- Supertrendprofit PDFDocument14 pagesSupertrendprofit PDFAhmad RusyadiNo ratings yet

- Resume ASDocument1 pageResume ASSahaj PatelNo ratings yet

- ResumeAsamehHaider PDFDocument3 pagesResumeAsamehHaider PDFJenniferNo ratings yet

- DR - Sudhanshu Joshi - Research ProfileDocument12 pagesDR - Sudhanshu Joshi - Research Profileadarsh2k274No ratings yet

- Assessment of Purchasing Policy and Procedures in Case of Ethiopian Revenue and Customs Authority Dire Dawa BranchDocument47 pagesAssessment of Purchasing Policy and Procedures in Case of Ethiopian Revenue and Customs Authority Dire Dawa Branchbezawitwubshet100% (1)

Reduce Lead Time in Logistics

Reduce Lead Time in Logistics

Uploaded by

shashi singh0 ratings0% found this document useful (0 votes)

110 views4 pages1. Remove unreliable suppliers from the supply chain to reduce lead times. Ensure enough inventory during the changeover and that new suppliers can start shipping immediately.

2. Prioritize vendors located close to warehouses to reduce lead times and complications from international shipping.

3. Share demand forecasts with suppliers early to prepare them for larger orders and ensure quick fulfillment.

Original Description:

Original Title

reduce lead time in logistics

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Remove unreliable suppliers from the supply chain to reduce lead times. Ensure enough inventory during the changeover and that new suppliers can start shipping immediately.

2. Prioritize vendors located close to warehouses to reduce lead times and complications from international shipping.

3. Share demand forecasts with suppliers early to prepare them for larger orders and ensure quick fulfillment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

110 views4 pagesReduce Lead Time in Logistics

Reduce Lead Time in Logistics

Uploaded by

shashi singh1. Remove unreliable suppliers from the supply chain to reduce lead times. Ensure enough inventory during the changeover and that new suppliers can start shipping immediately.

2. Prioritize vendors located close to warehouses to reduce lead times and complications from international shipping.

3. Share demand forecasts with suppliers early to prepare them for larger orders and ensure quick fulfillment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

Reducing logistic lead time

1. Remove Unreliable Suppliers From Your Supply Chain

Do you routinely receive late shipments from certain

suppliers? Keeping them in your supply chain could be

costing you more than finding a different vendor.

However, if you do change suppliers to reduce your lead time,

make sure you’re stocked up with enough inventory to last

you through the changeover.

Furthermore, ensure that your new supplier is prepared to

start sending you products right away.

2. Choose Vendors That Are Closer to Your Warehouse

In today’s global marketplace, you have access to more

vendors than ever before.

Unfortunately, while chasing the best prices across the globe,

you may end up waiting weeks for products to be shipped

overseas. This not only makes your lead time longer but it

also complicates the process of returning faulty or unwanted

products.

One of the easiest lead time reduction strategies for suppliers

is to give priority to vendors that are located close to your

warehouse or manufacturing plant.

3. Share Your Demand Forecasts With Your Suppliers

If you’re in an industry that naturally fluctuates, your orders

may change from month to month.

In order to keep your suppliers prepared for larger-than-

normal orders, let them know that you’re expecting an

increase in demand as early as possible.

This helps to ensure that they’re not only prepared to handle

an exceedingly large order but also prepared to do so as

quickly as possible.

4. Bring External Processes In-House

Do you handle most but not all of your production processes

in-house? Consider increasing your own capabilities so you

don’t have to send your products out to a third party for

completion.

This requires a significant investment upfront, but the long-

term savings (and the permanent reduction in lead times)

generally make this a financially feasible option. Plus, you’ll

be establishing your infrastructure for growth.

5. Automate Your Order Processing Workflows

Once you have your raw materials and are ready to start

production, make sure that your own internal processes are up

to par as well. Consider:

How long it takes you to get customer purchase

orders into your system

How long it takes you to move engineering change

orders through production

How often the process gets held up as a result of

internal miscommunication

How often orders get lost entirely

If your performance is poor in any of these areas, your lead

times are likely suffering as a result.

Automating your order processing workflows can help you

get your finished products out the door more quickly.

6. Complete Multiple Processes at the Same Time

Certain processes have to be completed before others can be

started – and there’s just no way around it.

But, if you’re able to identify processes that different

individuals can complete at the same time, you can increase

productivity and reduce your lead time even further.

7. Improve Internal Communications

Order processing is an important process. If you’re not

collaborating well internally,

you may be creating unnecessary delays.

Let’s use order entry as an example.

If there are multiple steps in your process that require input

from several people, you could be spending extra time you

don’t have to.

This is especially true if you’re dealing with paper, which

can’t be tracked.

Paper-based projects left sitting on someone’s desk increases

your lead time, as well as the likelihood of lost documents.

Even though poor communication is a major challenge to

solve (and often a symptom of other, deeper issues),

manufacturers have several options for eliminating

bottlenecks. One option? A workflow system that

immediately routes order-related documents from one

department or user to the next, while immediately notifying

users that a project requires their attention.

8. Communicate More Effectively With Your Customers

So this doesn’t technically help you reduce your lead time, but

it does help you keep your customers up-to-date while they

wait for their orders.

Since studies have repeatedly found that communication is a

strong predictor of customer loyalty, it’s an important aspect

to consider.

You might also like

- BI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareDocument1 pageBI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareJanet CafrancaNo ratings yet

- The GoalDocument4 pagesThe GoalSESSHAN N SNo ratings yet

- Case Study MBADocument13 pagesCase Study MBAAlly Coralde100% (2)

- A Report of Pizza Hut OnDocument20 pagesA Report of Pizza Hut OnHema Agarwal100% (18)

- Voucher Entry & Practical Problem - TallyDocument7 pagesVoucher Entry & Practical Problem - TallyBackiyalakshmi Venkatraman92% (12)

- Business Development Manager 1553823084Document2 pagesBusiness Development Manager 1553823084shashi singhNo ratings yet

- Operation Management Case StudyDocument8 pagesOperation Management Case StudyArsalan HaiderNo ratings yet

- Donner CompanyDocument35 pagesDonner CompanyZunaira GullNo ratings yet

- Salesforce Case Study 2Document4 pagesSalesforce Case Study 2hasanhayatNo ratings yet

- The Boeing Company: Organizational StructureDocument10 pagesThe Boeing Company: Organizational StructureprashantNo ratings yet

- Detailed Analysis of Lead Time in Inventory ManagementDocument6 pagesDetailed Analysis of Lead Time in Inventory ManagementTambe Chalomine AgborNo ratings yet

- Product FlowDocument22 pagesProduct FlowMeklit KiarNo ratings yet

- Time To MarketDocument4 pagesTime To MarketMy SelfNo ratings yet

- Transitioning To Lean SystemDocument8 pagesTransitioning To Lean SystemDonita SotolomboNo ratings yet

- Lean IntroDocument12 pagesLean IntroShirley OmbrogNo ratings yet

- Work Measurement: Work Measurement Can Be Applied in A Workplace by Helping UncoverDocument8 pagesWork Measurement: Work Measurement Can Be Applied in A Workplace by Helping UncoverJessuel Larn-epsNo ratings yet

- PlanningDocument4 pagesPlanningRajat SonkarNo ratings yet

- Categories of Goods: Inventory Management Component of InventoryDocument17 pagesCategories of Goods: Inventory Management Component of InventoryEva Zunaida KurniawantiNo ratings yet

- 7 WastesssDocument4 pages7 WastessskirstendelNo ratings yet

- SCM Assignment No. 2 Q 1. Importance of Workflow Automation. AnswerDocument3 pagesSCM Assignment No. 2 Q 1. Importance of Workflow Automation. Answer46 Gaurav PawarNo ratings yet

- 7 Best Practices For Inventory Management For WarehousesDocument3 pages7 Best Practices For Inventory Management For WarehousesTauqeer IqbalNo ratings yet

- 5 Ways For Lead Time ReductionDocument5 pages5 Ways For Lead Time ReductionYamini ShamiNo ratings yet

- Lean Manufacturing (JIT)Document5 pagesLean Manufacturing (JIT)Carl Jessner NarioNo ratings yet

- Operations SchedulingDocument14 pagesOperations Schedulingbezawit mamuyeNo ratings yet

- Stock Management Module 4Document5 pagesStock Management Module 4librarianNo ratings yet

- Lead TimeDocument35 pagesLead TimeMURALINo ratings yet

- Steps To Improve QualityDocument10 pagesSteps To Improve Qualityabhijit612No ratings yet

- Inventory Management SummaryDocument5 pagesInventory Management Summarykathleen tanzilNo ratings yet

- The Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectDocument4 pagesThe Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectjustingordanNo ratings yet

- Sourcing DecisionsDocument6 pagesSourcing DecisionsSakhawat HossainNo ratings yet

- Delay Analysis Using TDocument8 pagesDelay Analysis Using TAnkurSinghNo ratings yet

- Lean Six Sigma (Part A)Document17 pagesLean Six Sigma (Part A)Punniavel PNo ratings yet

- Kelebihan Dan KekuranganDocument4 pagesKelebihan Dan KekuranganRayendanNo ratings yet

- Unidad IV Supplier Certification and DevelopmentDocument12 pagesUnidad IV Supplier Certification and DevelopmentCaptian BenettsNo ratings yet

- EAN Anufacturing: Reported By: Uly Reyes & Mheng BanzonDocument64 pagesEAN Anufacturing: Reported By: Uly Reyes & Mheng BanzongoldenridgeNo ratings yet

- Top Company ReportDocument6 pagesTop Company ReportManjesh RNo ratings yet

- Midterm ExamDocument167 pagesMidterm Examapi-297834433No ratings yet

- Asynchronous 13Document5 pagesAsynchronous 13Charles John DolNo ratings yet

- Critical Path - Management Brief - FastReact - Evolve PDFDocument6 pagesCritical Path - Management Brief - FastReact - Evolve PDFSiddharth JhaNo ratings yet

- Frequent Discrepancies That Lead To Expediting Fees.: Question: Signs of Inventory ProblemsDocument11 pagesFrequent Discrepancies That Lead To Expediting Fees.: Question: Signs of Inventory ProblemsKevin ObaraNo ratings yet

- Glovia Lean ManufacturingDocument16 pagesGlovia Lean ManufacturingALEJANDRANo ratings yet

- Logistics 355 Yashana LalwaniDocument6 pagesLogistics 355 Yashana LalwaniYashana LalwaniNo ratings yet

- Process ManagementDocument11 pagesProcess Managementzoref333No ratings yet

- ReportsssDocument6 pagesReportsssVia SahipaNo ratings yet

- P & O Case AtudyDocument17 pagesP & O Case AtudySalar SikandarNo ratings yet

- Inventory System Thesis Documentation SampleDocument5 pagesInventory System Thesis Documentation SampleWriteAnEssayPaterson100% (2)

- 05TaskPerformance1 AISDocument1 page05TaskPerformance1 AISAilaJeanineNo ratings yet

- Chapter 12 Inventory Control Review and Discussion QuestionsDocument3 pagesChapter 12 Inventory Control Review and Discussion QuestionsDennis MpoNo ratings yet

- Literature Review On Lead Time ManagementDocument4 pagesLiterature Review On Lead Time Managementafdtszfwb100% (1)

- Operational Management AK-7-B SENTDocument10 pagesOperational Management AK-7-B SENTPratham KochharNo ratings yet

- BottleneckDocument6 pagesBottleneckvijayakum arNo ratings yet

- The 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsDocument6 pagesThe 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsRam KumarNo ratings yet

- Optimizing Efficiency: FabricationDocument7 pagesOptimizing Efficiency: FabricationVivek Kumar SinghNo ratings yet

- The 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsDocument6 pagesThe 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsRam Kumar100% (1)

- 8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Document8 pages8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Muhammad UsmanNo ratings yet

- 6 Inventory Control TechniquesDocument8 pages6 Inventory Control TechniquesAngel TagudNo ratings yet

- KAIZEN 10PsDocument3 pagesKAIZEN 10PsCassandra AldovinoNo ratings yet

- Process Design: Learning OutcomesDocument12 pagesProcess Design: Learning OutcomesMejidana, Rica Mae N.No ratings yet

- Module 4-1Document13 pagesModule 4-1saskiaNo ratings yet

- Job Shop Scheduling SecretDocument6 pagesJob Shop Scheduling SecretsauravNo ratings yet

- Benefits of ERP by Alexis Leon DemystifiedDocument7 pagesBenefits of ERP by Alexis Leon DemystifiedAniket KillekarNo ratings yet

- Lean Manufacturing & JITDocument42 pagesLean Manufacturing & JITMangesh GhandatNo ratings yet

- The Waste of WaitingDocument4 pagesThe Waste of WaitingJerome DalisayNo ratings yet

- Lean NewsletterDocument3 pagesLean NewsletterKomal TagraNo ratings yet

- LEAN STARTUP: Navigating Entrepreneurial Success Through Iterative Prototyping and Customer Validation (2023 Guide for Beginners)From EverandLEAN STARTUP: Navigating Entrepreneurial Success Through Iterative Prototyping and Customer Validation (2023 Guide for Beginners)No ratings yet

- The IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysFrom EverandThe IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysNo ratings yet

- Modes of TransportationDocument8 pagesModes of Transportationshashi singh100% (1)

- Reverse LogisticsDocument5 pagesReverse Logisticsshashi singhNo ratings yet

- Role of Logistics in SCMDocument2 pagesRole of Logistics in SCMshashi singhNo ratings yet

- Sigma Institute of Engineering - MBA ProgrammeDocument1 pageSigma Institute of Engineering - MBA Programmeshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Sigma Institute of Engineering - MBA ProgrammeDocument1 pageSigma Institute of Engineering - MBA Programmeshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- Bba Sem 3 PaperDocument1 pageBba Sem 3 Papershashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- MAP Project Report GroupDocument1 pageMAP Project Report Groupshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityshashi singhNo ratings yet

- SIP Institute CertificateDocument1 pageSIP Institute Certificateshashi singhNo ratings yet

- Journey of Steve JobsDocument6 pagesJourney of Steve Jobsshashi singhNo ratings yet

- Mr. Nirmal Jain: The UnbeatablesDocument7 pagesMr. Nirmal Jain: The Unbeatablesshashi singhNo ratings yet

- Mba PractDocument3 pagesMba Practshashi singhNo ratings yet

- Effects in Economic Decisions: Consumer EducationDocument53 pagesEffects in Economic Decisions: Consumer EducationJing KhaiNo ratings yet

- Riphah International College Associate Degree ProgramDocument5 pagesRiphah International College Associate Degree ProgramMuhammad HannanNo ratings yet

- Chapter 6Document18 pagesChapter 6Lydelle Mae CabaltejaNo ratings yet

- The Innovation Value Chain in Advanced Developing Countries: An Empirical Study of Taiwanese Manufacturing IndustryDocument38 pagesThe Innovation Value Chain in Advanced Developing Countries: An Empirical Study of Taiwanese Manufacturing IndustryEmbuhmas BroNo ratings yet

- Kay Pinkerton ResumeDocument2 pagesKay Pinkerton ResumeKay PinkertonNo ratings yet

- Chapter 3.1 Introduction To Industrial Hygiene and Occupational HealthDocument27 pagesChapter 3.1 Introduction To Industrial Hygiene and Occupational HealthHafizudin DaudNo ratings yet

- DR Nizam Latha Incorporated 2020 AFSDocument11 pagesDR Nizam Latha Incorporated 2020 AFShumayra.m16No ratings yet

- Call Center Manager ResumeDocument2 pagesCall Center Manager Resumefz74avg1No ratings yet

- The Corporate Form of Organization: Ordinary Shares Represent The Residual Corporate Interest That Bears The UltimateDocument3 pagesThe Corporate Form of Organization: Ordinary Shares Represent The Residual Corporate Interest That Bears The UltimateJihan Rahma IrianaNo ratings yet

- COGM Dan Income StatementDocument3 pagesCOGM Dan Income StatementABDUL KHALIQ BRUTUNo ratings yet

- ISYS6196005 FIN RCQuestionDocument5 pagesISYS6196005 FIN RCQuestionHana FebriantiNo ratings yet

- Differential Cost AnalysisDocument19 pagesDifferential Cost Analysisbobo kaNo ratings yet

- Islamic-Finance-Book Volume 4 Web PDFDocument166 pagesIslamic-Finance-Book Volume 4 Web PDFlarbiNo ratings yet

- Problems On Ratio AnalysisDocument5 pagesProblems On Ratio AnalysisPadyala Sriram100% (1)

- A Study On Impact of Dividend Announcements On Stock Prices in IndiaDocument5 pagesA Study On Impact of Dividend Announcements On Stock Prices in IndiaManju MahanandiaNo ratings yet

- The Communications Mix: What's The Difference Between The Marketing Communications Mix and The Marketing Mix?Document4 pagesThe Communications Mix: What's The Difference Between The Marketing Communications Mix and The Marketing Mix?miriam kuriaNo ratings yet

- Ocean Freight USA - Glossary of Shipping Terms PDFDocument9 pagesOcean Freight USA - Glossary of Shipping Terms PDFshivam_dubey4004No ratings yet

- Consumer Perception Towards Indian Oil in KolarDocument91 pagesConsumer Perception Towards Indian Oil in KolarRachna Jayaraghav100% (2)

- Islamic Financial System Principles and Operations PDF 901 944Document44 pagesIslamic Financial System Principles and Operations PDF 901 944Asdelina R100% (1)

- Commissionerate of Municipality (CMA), Tamil Nadu Circular About Tender PublicityDocument4 pagesCommissionerate of Municipality (CMA), Tamil Nadu Circular About Tender PublicitykayalonthewebNo ratings yet

- Supertrendprofit PDFDocument14 pagesSupertrendprofit PDFAhmad RusyadiNo ratings yet

- Resume ASDocument1 pageResume ASSahaj PatelNo ratings yet

- ResumeAsamehHaider PDFDocument3 pagesResumeAsamehHaider PDFJenniferNo ratings yet

- DR - Sudhanshu Joshi - Research ProfileDocument12 pagesDR - Sudhanshu Joshi - Research Profileadarsh2k274No ratings yet

- Assessment of Purchasing Policy and Procedures in Case of Ethiopian Revenue and Customs Authority Dire Dawa BranchDocument47 pagesAssessment of Purchasing Policy and Procedures in Case of Ethiopian Revenue and Customs Authority Dire Dawa Branchbezawitwubshet100% (1)