Professional Documents

Culture Documents

PG TrackTypeTractor D7R

PG TrackTypeTractor D7R

Uploaded by

Bruce LiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PG TrackTypeTractor D7R

PG TrackTypeTractor D7R

Uploaded by

Bruce LiCopyright:

Available Formats

Power Generation - St.

Johns River Power Park - Bulk Materials Standards

TRACK-TYPE TRACTOR D7R LGP

I. GENERAL:

This standard is intended to provide specifications for the procurement of a Caterpillar Model D7R,

Low Ground Pressure (LGP) Series 2 Track-Type Tractors that meets the specific area operational

requirements for the St. Johns River Power Park Landfill Site. This Track-Type Tractor shall be

utilized for moving by-products to meet operational and environmental requirements for two coal fired

630 Net Megawatt Units.

II. DESCRIPTIONS FOR CATERPILLAR MODEL D7R LPG SERIES 2 TRACK-TYPE

TRACTOR

The following shall be provided:

II.1. ENGINE

The Cat 3176C engine shall meet or exceed all EPA Tier 3/EU Stage IIIa emission

specifications for the U.S through 2010.

II.1.1. Engine Model: ...................................... Cat 3176C ACERT

II.1.2. Gross Power: ....................................... 258 hp

II.1.3. Net Power: ........................................... 240hp

II.1.4. Bore: .................................................... 4.9 in

II.1.5. Stroke: ................................................. 5.5 in

II.1.6. Displacement: ...................................... 629 in³

II.2. TRANSMISSION

II.2.1. Forward 1:............................................ 2.19 mph

II.2.2. Forward 2:............................................ 3.79 mph

II.2.3. Forward 3:............................................ 6.55 mph

II.2.4. Reverse 1: ........................................... 2.82 mph

II.2.5. Reverse 2: ........................................... 4.88 mph

II.2.6. Reverse 3: ........................................... 8.44 mph

III. SERVICE REFILL CAPACITIES

III.1. Fuel Tank: ......................................... 126.5 gal

III.2. Cooling System: ................................ 20.4 gal

III.3. Engine Crankcase: ............................ 8.2 gal

III.4. Power Train: ...................................... 47 gal

III.5. Final Drives (each): ........................... 3.4 gal

III.6. Roller Frames (each): ....................... 6.5 gal

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 1 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

III.7. Pivot Shaft Compartment: ................. 0.5 gal

III.8. Hydraulic Tank: ................................. 14.3 gal

IV. STEERING AND BRAKES

Differential Steering allowing tracks to run at different speeds, under full power to accomplish

steering. Brakes meet the standard SAE J/ISO 10265 March 1999

V. UNDERCARRIAGE

V.1. Shoe Type: ........................................ LGP, Moderate Service

V.2. Width of Shoe: ................................... 36 in

V.3. Shoes per side: ................................. 43

V.4. Grouser Height: ................................. 2.8 in

V.5. Pitch: ................................................. 8.5 in

V.6. Ground Clearance: ............................ 19.5 in

V.7. Track Gauge:..................................... 88 in

V.8. Length of track on Ground: ................ 125 in.

V.9. Ground Contact Area: ....................... 9,000 in2

V.10. Track Rollers per Side ....................... 7

V.11. Number of Carrier Rollers: ................ 1 per side (optional)

VI. TRACK ROLLER FRAME

VI.1. Oscillation

VII. HYDRAULIC CONTROLS

VII.1. Pump Type: ....................................... Gear Driven

VII.2. Lift Cylinder Flow: .............................. 47.6 gal/min

VII.3. Tilt Cylinder Flow: .............................. 21.1 gal/min

VII.4. Bulldozer Relief Valve Setting: .......... 3,307psi

VII.5. Tilt Cylinder Relief Valve Setting: ...... 2,498 psi

VII.6. Ripper (Lift) Relief Valve Setting: ...... 3,000 psi

VII.7. Ripper (Pitch) Relief Valve Setting: ... 3,000 psi

VII.8. Tank Capacity: .................................. 14.3 gal

Pump output measured at 2100 rpm and 1015 psi

Hydraulic pilot valve assists operation of dozer controls. Hydraulic system includes valves

for use with blade.

Complete system consists of pump, tank with filter, oil cooler, valves, lines, linkage and

control levers.

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 2 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

VIII. BLADE

VIII.1. Type: ................................................. 7S LGP

VIII.2. Capacity (SAE J1265): ...................... 7.7 yd3

VIII.3. Width (over end bits): ........................ 14.11 ft

VIII.4. Height:............................................... 4’.5”

VIII.5. Digging Depth: .................................. 26.3 in

VIII.6. Ground Clearance: ............................ 45 in

VIII.7. Maximum Tilt: .................................... 27 in

VIII.8. Blade Weight:* .................................. 8,229 lb (without hydraulic controls)

VIII.9. Total Machine Operating Weight:** ... 65,036 lb

(with blade)

Total Operating Weight:: Includes power shift arrangement, lubricants, coolant, full fuel tank,

hydraulic controls, blade tilt cylinder, ROPS canopy, multi shank ripper (one shank) and 36”

shoes for LGP and operator.

IX. STANDARD EQUIPMENT

The following standard equipment shall be provided for the D7R LPG Series 2 Track-Type Tractor:

IX.1. ELECTRICAL

IX.1.1. Alternator, 95 Amp

IX.1.2. Back up alarm

IX.1.3. Batteries, 2, Maintenance Free12-volt (24 volt system)

IX.1.4. Converter, 12-volt, 10-amp

IX.1.5. Diagnostic connector

IX.1.6. Horn, forward warning

IX.1.7. Lighting system, Halogen (2 forward, 2 rear)

IX.1.8. Starting Receptacle

IX.2. OPERATOR ENVIRONMENT

IX.2.1. Advisor-electronic monitoring system

IX.2.2. Adjustable Armrest

IX.2.3. ROPS/FOPS Cab

IX.2.4. Controls, electronic implement with lockout

IX.2.5. Decelerator pedal

IX.2.6. Tiller lever for steering.

IX.2.7. Electronic Engine Speed Control

IX.2.8. Hydraulic system, pilot operated controls with electronic deactivation switch for

bulldozer control

IX.2.9. Rearview Mirror

IX.2.10. Radio-ready cab

IX.2.11. Adjustable contour suspension (gray fabric) seat

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 3 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

IX.2.12. 3 in. Retractable Seatbelt

IX.2.13. Heavy-duty Steps and Handles

IX.2.14. Intermittent Windshield Wipers,

IX.3. UNDERCARRIAGE

IX.3.1. 36 inch moderate service grouser with sealed and lubricated PPR track (43 section)

IX.3.2. Lifetime lubricated rollers and idlers

IX.3.3. Replaceable sprocket rim segments

IX.3.4. Suspension-type undercarriage, seven-roller tubular track roller frame

IX.3.5. Hydraulic track adjusters

IX.3.6. Track guides

IX.3.7. Two-piece master links

IX.4. POWER TRAIN

IX.4.1. 3176C with ACERT Technology

IX.4.2. 24-volt electric start

IX.4.3. Advanced Modular Cooling System (AMCOS) 6 steel fins per inch (1”)

IX.4.4. After cooler, two cores of the radiator shall be dedicated to the after cooler. After

cooler shall be provided with a dedicated water pump

IX.4.5. Air filters, dual with pre-cleaner

IX.4.6. Extended life Coolant

IX.4.7. Directional shift management

IX.4.8. Automatic ether starting aid

IX.4.9. Fan, blower, direct drive

IX.4.10. Fuel priming pump

IX.4.11. Grid, radiator core protection

IX.4.12. Muffler with rain cap

IX.4.13. Parking brake

IX.4.14. Pre-screener

IX.4.15. Water/fuel Separator

IX.4.16. Thermal shields

IX.4.17. Torque converter

IX.4.18. Transmission, powershift, ECPC, (3F/3R)

IX.4.19. Three planet, double-reduction planetary final drives

IX.5. OTHER

IX.5.1. Corrosive resistant Air conditioning box

IX.5.2. CD TOM parts book

IX.5.3. Ecology drains: engine oil, coolant, hydraulic oil, torque divider, fuel tank, power

train case and transmission

IX.5.4. Engine enclosures

IX.5.5. Guards

IX.5.5.1. Bottom, hinged

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 4 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

IX.5.5.2. Crankcase

IX.5.5.3. Pivot shaft and seals

IX.5.5.4. Front towing device

IX.5.6. Implement gear pump compatible for Arctic conditions

IX.5.7. Product Link ready

IX.5.8. S●O●SSM SAMPLING PORTS

IX.5.9. Vandalism, protection

X. OPTIONAL EQUIPMENT

The following equipment shall be provided as an option for the D7R Series 2 Track-Type Tractor:

X.1. ELECTRICAL

X.1.1. Converter,24-volt to 12-volt additional 20-amp converter

X.1.2. Lights, supplemental:

X.1.2.1. Standard Halogen Lighting

X.2. OPERATOR ENVIRONMENT

X.2.1. ROPS Mounted Air conditioner

X.2.2. Glass, ultra-strength up to 40 psi

X.3. POWER TRAIN

X.3.1. Fast fuel system

X.3.2. Quick oil change system

X.4. UNDERCARRIAGE

X.4.1. Tracks, pair, Sealed and Lubricated:

X.4.2. Roller - Carrier rollers, pin-on (one per side)

X.5. RIPPERS

X.5.1.1. No Rippers are required.

X.6. OTHER ATTACHMENTS

X.6.1. Drawbar rigid

X.7 MACHINE PAINT

X.7.1 Dupont Imron paint in standard Caterpillar colors

X.I WARRANTY

The following warranties shall apply for the D7R LGP Series 2 Track-Type Tractor

X.I.1 12 months full machine warranty

X.I.2 60 months or 10,000 hours on Power Train and Hydraulics

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 5 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

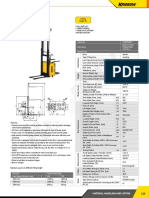

XI. DIMENSIONS

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 6 of 7

Power Generation - St. Johns River Power Park - Bulk Materials Standards

THIS PAGE INTENIONALLY LEFT BLANK

Revised: October 29th, 2009 Revised By: RHS Approved By: RHS

TRACK-TYPE TRACTOR D7R

Page 7 of 7

You might also like

- Statics - Centroid & Center of MassDocument8 pagesStatics - Centroid & Center of MassEuw Chaiwanont100% (1)

- PC35MR - Service ManualDocument8 pagesPC35MR - Service ManualJeffrey Evans50% (2)

- ATLAS COPCO New - Troubleshooting - GuideDocument245 pagesATLAS COPCO New - Troubleshooting - GuideBruce Li100% (11)

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- K700R Assistance Manual ENG Rev5Document175 pagesK700R Assistance Manual ENG Rev5Nuta Moisii75% (4)

- Komatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsDocument8 pagesKomatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsSergeyNo ratings yet

- Caterpillar 6015 Tech SpecsDocument10 pagesCaterpillar 6015 Tech SpecsMarkNo ratings yet

- PC2000 11Document6 pagesPC2000 11arun_anuNo ratings yet

- Service Manual: Four-Way CassetteDocument23 pagesService Manual: Four-Way CassettetaharNo ratings yet

- 2.1. Excav PC200 - 200LC-8 - CEN00049-09Document5 pages2.1. Excav PC200 - 200LC-8 - CEN00049-09adityadhNo ratings yet

- Wheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeDocument4 pagesWheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeRalf MaurerNo ratings yet

- Komatsu 730 eDocument4 pagesKomatsu 730 eFranco Rojas BozaNo ratings yet

- PC1250 7 SSheet AESS60800Document4 pagesPC1250 7 SSheet AESS60800Kang AdingNo ratings yet

- KG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerDocument4 pagesKG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerJavierPariNo ratings yet

- 10 Single Drum WinchesDocument54 pages10 Single Drum Wincheskelvinyeoh100% (3)

- Dux Scaler Spec Sheet - Fix Cab PDFDocument2 pagesDux Scaler Spec Sheet - Fix Cab PDFvivalpsNo ratings yet

- Bobcat S130 SkidsteerDocument6 pagesBobcat S130 SkidsteerBruno PilieciNo ratings yet

- 644J 4WD LoaderDocument8 pages644J 4WD Loaderwalk01No ratings yet

- KG 850,650 LB: Maximum GVWDocument4 pagesKG 850,650 LB: Maximum GVWVasquez EjvbNo ratings yet

- Ex 210LCHDocument2 pagesEx 210LCHMamta RaybageNo ratings yet

- PC400 6 (1.8m3, 20C, Sandy Arrang) ENGDocument12 pagesPC400 6 (1.8m3, 20C, Sandy Arrang) ENGRahmawati AyudiaNo ratings yet

- Komatsu-Haulpak 830E DC: EngineDocument7 pagesKomatsu-Haulpak 830E DC: EngineArmando ShamanNo ratings yet

- KG 1,106,670 LB: Maximum GVWDocument4 pagesKG 1,106,670 LB: Maximum GVWcoke31No ratings yet

- Dozer: 10 50J Waste HandlerDocument6 pagesDozer: 10 50J Waste Handlerwalk01No ratings yet

- Komatsu Pala Pc4000Document8 pagesKomatsu Pala Pc4000Franco Rojas BozaNo ratings yet

- SV 17 ExDocument10 pagesSV 17 ExankitsarvaiyaNo ratings yet

- 544J 4WD LoaderDocument8 pages544J 4WD Loaderwalk01No ratings yet

- Bobcat s250Document3 pagesBobcat s250Tarek TorbeyNo ratings yet

- S250 S - S L S: KID Teer Oader PecificationsDocument6 pagesS250 S - S L S: KID Teer Oader Pecificationsarmando vara chavezNo ratings yet

- Foreløpig Brosjyre Komatsu PC88MR 10Document4 pagesForeløpig Brosjyre Komatsu PC88MR 10LU YONo ratings yet

- PC8000 (English)Document8 pagesPC8000 (English)CarlosBacaTorres100% (1)

- Volvo Excavator: BE Backhoe EquipmentDocument6 pagesVolvo Excavator: BE Backhoe EquipmentAbduNo ratings yet

- Daikin ChillersDocument79 pagesDaikin ChillersDaniela Barbu100% (1)

- PC40MR-2: IntroductoryDocument2 pagesPC40MR-2: IntroductoryFrederikusNo ratings yet

- EC210BDocument16 pagesEC210BAna100% (1)

- Excavator VolvoDocument12 pagesExcavator VolvoSaran KlNo ratings yet

- 724J 4WD LoaderDocument8 pages724J 4WD Loaderwalk01No ratings yet

- V Ec290b D7D Eae2 2124351643 2002-09Document12 pagesV Ec290b D7D Eae2 2124351643 2002-09filipericardodi124780% (5)

- Komatsu PC490LC-10Document12 pagesKomatsu PC490LC-10isprengelNo ratings yet

- D375A 5 (S U, - G R, 710mm, 20C) ENGDocument18 pagesD375A 5 (S U, - G R, 710mm, 20C) ENGHari SusandiNo ratings yet

- Spec EC210B INT EN 30E4351641Document12 pagesSpec EC210B INT EN 30E4351641Min Min SoeNo ratings yet

- Daikin Chiller (EUWA-KBZW1) Air Cooled Technical Data BookDocument79 pagesDaikin Chiller (EUWA-KBZW1) Air Cooled Technical Data BookAlysonPW100% (1)

- 33 Metric Tonne 36.4 Short Ton Payload - 19.6 M 25.7 Yd CapacityDocument2 pages33 Metric Tonne 36.4 Short Ton Payload - 19.6 M 25.7 Yd CapacitynambiiasNo ratings yet

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocument4 pagesBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNo ratings yet

- Mi Jack Reach Stackers Spec A2ce6bDocument2 pagesMi Jack Reach Stackers Spec A2ce6bRami AbdelaalNo ratings yet

- Service Manual: Change For LifeDocument47 pagesService Manual: Change For LifeluigigerulaNo ratings yet

- Operator'S Instructions AND Machine InformationDocument10 pagesOperator'S Instructions AND Machine InformationPeetNo ratings yet

- EC290B LC Ec290B NLC: Monoblock/2-Piece BoomDocument12 pagesEC290B LC Ec290B NLC: Monoblock/2-Piece BoomClaret CastroNo ratings yet

- Komatsu Pc200 7 SpecDocument2 pagesKomatsu Pc200 7 Specchristopher ng'ang'a kamauNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument10 pagesTechnical Specifications: Hydraulic ExcavatorMuhammad ShofaNo ratings yet

- Carte Tehnica Excavator VolvoDocument12 pagesCarte Tehnica Excavator VolvoCiufudean AdrianNo ratings yet

- Catalogo PC4000 PDFDocument8 pagesCatalogo PC4000 PDFErick Parra100% (1)

- Cce LB 590superms2 SsDocument6 pagesCce LB 590superms2 SszaidsantoyoNo ratings yet

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Passive RF and Microwave Integrated CircuitsFrom EverandPassive RF and Microwave Integrated CircuitsRating: 5 out of 5 stars5/5 (1)

- Active Matrix Liquid Crystal Displays: Fundamentals and ApplicationsFrom EverandActive Matrix Liquid Crystal Displays: Fundamentals and ApplicationsRating: 4 out of 5 stars4/5 (2)

- How To Fill A Fountain Pen - Instructions For Filling Fountain Pens - LevengerDocument6 pagesHow To Fill A Fountain Pen - Instructions For Filling Fountain Pens - LevengerBruce LiNo ratings yet

- Hyundai Special VehiclesDocument1 pageHyundai Special VehiclesBruce LiNo ratings yet

- Duties & Responsibilities of A Construction Safety OfficerDocument4 pagesDuties & Responsibilities of A Construction Safety OfficerBruce LiNo ratings yet

- Safety Data Sheet - SampleDocument1 pageSafety Data Sheet - SampleBruce LiNo ratings yet

- Downloaded From Manuals Search EngineDocument161 pagesDownloaded From Manuals Search EngineBruce Li100% (1)

- TADANO 80ton GR-800EX - Specification & Load Chart PDFDocument13 pagesTADANO 80ton GR-800EX - Specification & Load Chart PDFBruce Li0% (1)

- PZ-series Portable RadioPZ-400, PZ-100 - Maintenance ManualDocument26 pagesPZ-series Portable RadioPZ-400, PZ-100 - Maintenance ManualBruce LiNo ratings yet

- Portable Radio - UNIMO PZ-S Series Users-Manual-1398105Document29 pagesPortable Radio - UNIMO PZ-S Series Users-Manual-1398105Bruce LiNo ratings yet

- SKF Bearing CatalogDocument40 pagesSKF Bearing CatalogBruce LiNo ratings yet

- Duplex Drum Compactor LP6505 - HATZ 1D41 1D42 1D50 1D81 1D50 Diesel Operator ManualDocument104 pagesDuplex Drum Compactor LP6505 - HATZ 1D41 1D42 1D50 1D81 1D50 Diesel Operator ManualBruce LiNo ratings yet

- Duplex Drum Compactor LP6505 - SpecificationDocument3 pagesDuplex Drum Compactor LP6505 - SpecificationBruce LiNo ratings yet

- Duplex Drum Compactor LP6505 - SpecificationDocument3 pagesDuplex Drum Compactor LP6505 - SpecificationBruce LiNo ratings yet

- Kobelco CKE2500 PDFDocument8 pagesKobelco CKE2500 PDFUmanath Yadav Umanath Yadav100% (2)

- The EI SLP Therapy BundleDocument14 pagesThe EI SLP Therapy BundlelevyNo ratings yet

- Brazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Document135 pagesBrazil Is Samba: Rhythm, Percussion, and Samba in The Formation of Brazilian National Identity (1902-1958)Carlos Barrientos100% (1)

- Economists' Corner: Weighing The Procompetitive and Anticompetitive Effects of RPM Under The Rule of ReasonDocument3 pagesEconomists' Corner: Weighing The Procompetitive and Anticompetitive Effects of RPM Under The Rule of ReasonHarsh GandhiNo ratings yet

- Curriculum Ucv SedapalDocument2 pagesCurriculum Ucv SedapalSheyler Alvarado SanchezNo ratings yet

- Weebly Homework Article Review Standard 2Document11 pagesWeebly Homework Article Review Standard 2api-289106854No ratings yet

- 50 Programing QuotesDocument3 pages50 Programing QuotesFreddy MoncadaNo ratings yet

- Chapter 24 Practice QuestionsDocument7 pagesChapter 24 Practice QuestionsArlene F. Montalbo100% (1)

- Arizona's Top Kitchen & Bath Remodeling ContractorDocument8 pagesArizona's Top Kitchen & Bath Remodeling ContractorPremier Kitchen and BathNo ratings yet

- MiddlemarchDocument2 pagesMiddlemarchKanad Prajna DasNo ratings yet

- Torrent WorkingDocument7 pagesTorrent WorkingsirmadamstudNo ratings yet

- Selection of Fuses For The Protection of TransformersDocument14 pagesSelection of Fuses For The Protection of Transformersgalaxyebn100% (11)

- Electric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationDocument1 pageElectric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationAsty RikyNo ratings yet

- The Challenges of TodayDocument5 pagesThe Challenges of TodayqamaradeelNo ratings yet

- Skills Test Unit 1 BDocument5 pagesSkills Test Unit 1 BOsama CanaanNo ratings yet

- BKKM 1931 Week 04Document105 pagesBKKM 1931 Week 04quirkycactusNo ratings yet

- Adverb Worksheet For Class 4 With AnswersDocument10 pagesAdverb Worksheet For Class 4 With Answersrodolfo penaredondoNo ratings yet

- Israel's Agriculture BookletDocument58 pagesIsrael's Agriculture BookletShrikant KajaleNo ratings yet

- Submarine Diesel EngineDocument106 pagesSubmarine Diesel EngineDharma Gita Surya PrayogaNo ratings yet

- MATHEMATICS WEEK3 2nd GRADE 4Document11 pagesMATHEMATICS WEEK3 2nd GRADE 4Jonah A. RecioNo ratings yet

- Utpaladeva's Lost Vivrti On The Ishwara Pratyabhijna Karika - Raffaele TorellaDocument12 pagesUtpaladeva's Lost Vivrti On The Ishwara Pratyabhijna Karika - Raffaele Torellaraffaeletorella100% (1)

- Into Thy Word Bible Study in HebrewsDocument6 pagesInto Thy Word Bible Study in Hebrewsrichard5049No ratings yet

- Advanced Management Accounting PDFDocument204 pagesAdvanced Management Accounting PDFptgo100% (1)

- Stamens PDFDocument10 pagesStamens PDFAmeya KannamwarNo ratings yet

- D 12332Document108 pagesD 12332jesus_hfNo ratings yet

- Kirk Summers Clinical Field Experience A Program Leader Interview Summary and ReflectionDocument4 pagesKirk Summers Clinical Field Experience A Program Leader Interview Summary and ReflectionKirk Summers100% (1)

- Global Wine IndustryDocument134 pagesGlobal Wine IndustrySaifur Rahman Steve100% (2)

- Peb6c5kubDocument6 pagesPeb6c5kubNandar Min HtetNo ratings yet

- 2intro To LLMDDocument2 pages2intro To LLMDKristal ManriqueNo ratings yet

- ATS Kingston Heath CustomerDocument63 pagesATS Kingston Heath CustomerDevNo ratings yet