Professional Documents

Culture Documents

COMSOL Bangalore 2019 SoumaDhar

COMSOL Bangalore 2019 SoumaDhar

Uploaded by

Elbahi DjaalabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COMSOL Bangalore 2019 SoumaDhar

COMSOL Bangalore 2019 SoumaDhar

Uploaded by

Elbahi DjaalabCopyright:

Available Formats

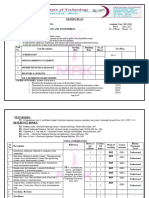

Comparison of Dispersion Models for Spheres of Varying Geometry

S. S. Dhar1, S. K. Mishra1,M. R. Kalane1,V. S. Shenoy1,S. D. Patwardhan1,N. Sakpal2,A. Agwan2

1. School of Petroleum Engineering, MIT-WPU, Pune, MH, India

2. Techniche, Pune, MH, India

INTRODUCTION: 20L sphere is a standard RESULTS: The time dependent study of pressure is

instrument used for performing experiments on studied in this case and compared with perfect

Nano dust explosion. An updated version of the spherical vessel. The results both on final and initial

conventional instrument is tested in CFD simulation. stage shows very minor change of about 15%

The effect of explosion is compared from a perfect pressure contour on the straight section of the vessel

spherical vessel to a vessel containing a straight otherwise the entire vessel is containing

section of the wall between two hemispheres. homogeneous pressure contour.

Final stage

Figure 1. Actual vessel of 20L sphere

Initial stage

Figure 3. Pressure distribution inside the sphere at the starting and

final stage of explosion

COMPUTATIONAL METHODS: As there is no

special algorithm for simulation of explosion in CONCLUSIONS: The study is interpreted as, there will

COMSOL Multiphysics® , we created a geometry not be any significant effect of explosion in the

and kept the pressure difference of 1000 atm in modified vessel, this modified vessel can be used for

the centre and periphery of the vessel so that it implementing the entry point of the dust particles or

can depict an explosion. The material is chosen as implementing more sensors for study. Ultimately, it

propane, and the meshing is done finer in size. can be concluded as the vessel can be successfully

The physical model is chosen as compressible and updated with no difficulties for further experiments

turbulent fluid flow model. related to dust explosion.

REFERENCES:

1. Kenneth L Cashdollar, Overview of Dust Explosion, Journal of Loss Prevention in the Process

Industries(2000)

2. Tasneem Abbasi, S.A. Abbasi,Dust explosions–Cases, causes, consequences, and control,

Journal of Hazardous Materials, Volume 140, Pages 7-44(2007)

3. Carlos Murilloa, Olivier Dufaudb, Omar Lópezc, Laurent Perrinb, Alexis Vignesd,

Felipe Muñoza., CFD Modelling of Nanoparticles Dispersion in a Dust Explosion Apparatus,

14th EFCE International Conference on Loss Prevention and Safety, Volume: 31(2013)

4. Noor Ain Ab Kadira, RiszaRuslia, AzizulBuanga, Nur Shamimi Abdul Rahima 2016

,Investigation of the Explosion Behaviour Affected by the Changes of Particle Size,

Procedia Engineering, Volume 148, Pages 1156-1161(2016)

Figure 2. Geometry and meshing of the updated vessel

Excerpt from the Proceedings of the 2019 COMSOL Conference in Bangalore

You might also like

- Global Reporting System User Manual GRS-Rig V4.0: TitleDocument161 pagesGlobal Reporting System User Manual GRS-Rig V4.0: Titlevikrant911No ratings yet

- 10 1016@j Jenvrad 2016 05 027Document10 pages10 1016@j Jenvrad 2016 05 027Prasanna BakshiNo ratings yet

- 2017 18 - WebAERMechanical Engineering Annual Report 2019Document12 pages2017 18 - WebAERMechanical Engineering Annual Report 2019dohajdaira1No ratings yet

- Atmospheric Pollution Research: N.S. Keita, A. Mehel, F. Murzyn, A. Taniere, B. Arcen, B. Diourte TDocument9 pagesAtmospheric Pollution Research: N.S. Keita, A. Mehel, F. Murzyn, A. Taniere, B. Arcen, B. Diourte TKhaled ChekroubaNo ratings yet

- Incubation Time and Cavitation Erosion Rate of Work-Hardening MaterialsDocument15 pagesIncubation Time and Cavitation Erosion Rate of Work-Hardening MaterialsКонстантин ФинниковNo ratings yet

- Marple Et Al. (1991) - A Microorifice Uniform Deposit Impactor MOUDI Description Calibration and UseDocument14 pagesMarple Et Al. (1991) - A Microorifice Uniform Deposit Impactor MOUDI Description Calibration and UsenimaaandmNo ratings yet

- Airborne Nanoparticle Exposures Associated With The Manual Handling of Nanoalumina and Nanosilver in Fume HoodsDocument15 pagesAirborne Nanoparticle Exposures Associated With The Manual Handling of Nanoalumina and Nanosilver in Fume Hoodseugene.commerellNo ratings yet

- Abdelfatah 2017Document16 pagesAbdelfatah 201710_DAVID_10No ratings yet

- Root Cavitation 2-2-3Document8 pagesRoot Cavitation 2-2-3장영훈No ratings yet

- Coupling CFD and Analytical Modeling For Investigation of Monolayer Particle Resuspension by Transient FlowsDocument12 pagesCoupling CFD and Analytical Modeling For Investigation of Monolayer Particle Resuspension by Transient FlowsKhaled ChekroubaNo ratings yet

- PhysRevLett 132 104004Document6 pagesPhysRevLett 132 104004lpn62261No ratings yet

- Dispersion in An Array of Buildings in Stable andDocument33 pagesDispersion in An Array of Buildings in Stable andhenryphan2004No ratings yet

- Aerothermodynamic and Stability Analyses of A Deployable Re-Entry CapsuleDocument13 pagesAerothermodynamic and Stability Analyses of A Deployable Re-Entry CapsuleDiego MVNo ratings yet

- Acoustic Measurement of The BubbleDocument5 pagesAcoustic Measurement of The BubbleIgnacioGonzalezNo ratings yet

- Bed Collapse Behavior of Pulsed Fluidized Beds of Nano-PowderDocument7 pagesBed Collapse Behavior of Pulsed Fluidized Beds of Nano-PowderAli BeetleNo ratings yet

- 051-063Vol91Q2018 9715 Kabwe1Document14 pages051-063Vol91Q2018 9715 Kabwe1syamsul hidayatNo ratings yet

- 1 s2.0 S0009250910007190 MainDocument16 pages1 s2.0 S0009250910007190 Mainzhengguihua2020No ratings yet

- Fneur 05 00253Document10 pagesFneur 05 00253Krayem WidoNo ratings yet

- Ultrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriDocument11 pagesUltrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriatulhbariNo ratings yet

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocument6 pagesGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNo ratings yet

- An Experimental Study On The in Uence of Uid Ow Pattern On Microbubble GenerationDocument9 pagesAn Experimental Study On The in Uence of Uid Ow Pattern On Microbubble Generationanthonychoong9No ratings yet

- Dust Explosions - CFD Modeling As A Tool To Characterize The Relevant Parameters of Dust DispersionDocument14 pagesDust Explosions - CFD Modeling As A Tool To Characterize The Relevant Parameters of Dust DispersionAnas SafwanNo ratings yet

- Advanced Fluid DynamicsDocument283 pagesAdvanced Fluid DynamicsΜαριαNo ratings yet

- Earthquake Resistant Buildings Dynamic Analyses Numerical Computations Codified Methods Case Studies and ExamplesDocument12 pagesEarthquake Resistant Buildings Dynamic Analyses Numerical Computations Codified Methods Case Studies and ExamplesSindura SwarnakariNo ratings yet

- Collection Efficiency and Interstage Loss of Nanoparticles in Microorifice - Based Cascade ImpactorsDocument9 pagesCollection Efficiency and Interstage Loss of Nanoparticles in Microorifice - Based Cascade Impactorscuc004No ratings yet

- Bivol 2019 J. Phys. Conf. Ser. 1147 012046Document8 pagesBivol 2019 J. Phys. Conf. Ser. 1147 012046Haowen WuNo ratings yet

- The MU-RAY Project: Volcano Radiography With Cosmic-Ray MuonsDocument4 pagesThe MU-RAY Project: Volcano Radiography With Cosmic-Ray MuonsJeremiah de los SantosNo ratings yet

- Study On Bubble Formation at A Submerged Micro-HolDocument11 pagesStudy On Bubble Formation at A Submerged Micro-HolMarc LarreNo ratings yet

- Figuli 2016 IOP Conf. Ser. Earth Environ. Sci. 44 052051Document8 pagesFiguli 2016 IOP Conf. Ser. Earth Environ. Sci. 44 052051KowTeckshengNo ratings yet

- Gambar 1 Post RiftDocument8 pagesGambar 1 Post Riftsuci sagalaNo ratings yet

- Parameterizing The Formation Rate of New Particles The EffectDocument16 pagesParameterizing The Formation Rate of New Particles The Effectrubens.pereiraNo ratings yet

- Article1 KHATIB NabilDocument9 pagesArticle1 KHATIB NabilNabilNo ratings yet

- NF Separation of NaCl and MgCl2Document14 pagesNF Separation of NaCl and MgCl2ztwardowskiNo ratings yet

- B.13 Numerical Modelling of Sloshing in A Rectangular Tank Using General MovingDocument5 pagesB.13 Numerical Modelling of Sloshing in A Rectangular Tank Using General MovinghakanovaNo ratings yet

- Chaine For Literature PDFDocument14 pagesChaine For Literature PDFSiddhartha paudelNo ratings yet

- Mathematical Model of The Spatial Distributing of Density of Erosive Power of Multibubble CavitationDocument14 pagesMathematical Model of The Spatial Distributing of Density of Erosive Power of Multibubble CavitationaissaNo ratings yet

- Fneur 11 00090Document9 pagesFneur 11 00090Krayem WidoNo ratings yet

- Characterization of High-Pressure Water-Mist Sprays - Experimental Analysis of Droplet Size and DispersionDocument14 pagesCharacterization of High-Pressure Water-Mist Sprays - Experimental Analysis of Droplet Size and DispersionSolidarioNo ratings yet

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocument6 pagesGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNo ratings yet

- Field Investigation in The DetonatiDocument14 pagesField Investigation in The DetonaticrazeeboiNo ratings yet

- Experimental and Numerical Study of Fence Effects On Dust Emission Into Atmosphere From Open Storage PilesDocument9 pagesExperimental and Numerical Study of Fence Effects On Dust Emission Into Atmosphere From Open Storage PilesumangiiNo ratings yet

- 10 1016@j Tust 2018 09 031Document9 pages10 1016@j Tust 2018 09 031rikkysubhiNo ratings yet

- Water Cherenkov Muon Veto For The COSINUS Experiment: Design and Simulation OptimizationDocument29 pagesWater Cherenkov Muon Veto For The COSINUS Experiment: Design and Simulation Optimizationdq74mrhf8mNo ratings yet

- 65 19 ResponseDocument4 pages65 19 ResponseaekockautNo ratings yet

- 17c. CIM-PPalRoy-AirdeckingDocument6 pages17c. CIM-PPalRoy-Airdeckingsyamsul hidayatNo ratings yet

- Fujimura 1970Document5 pagesFujimura 1970Xavier SalazarNo ratings yet

- Research Article: Enhancing Fatigue Performance of Sandwich Composites With Nanophased CoreDocument8 pagesResearch Article: Enhancing Fatigue Performance of Sandwich Composites With Nanophased Coresreekrishnan2No ratings yet

- 1-s2.0-S1674775518305614-mainDocument16 pages1-s2.0-S1674775518305614-mainMaglio RamosNo ratings yet

- Assessment of Four Turbulence Models in Simulation of Large-Scale Pool Fires in The Presence of WindDocument14 pagesAssessment of Four Turbulence Models in Simulation of Large-Scale Pool Fires in The Presence of WindPACAO ANDRES. BARROS DIAZNo ratings yet

- Swelling Pressure of Soil Using A Predictive Tool: V.V.N.Prabhakara RaoDocument6 pagesSwelling Pressure of Soil Using A Predictive Tool: V.V.N.Prabhakara RaoMufqi BadarNo ratings yet

- Analysis of Air Blast Effect For Explosives in A Large Scale DetonationDocument7 pagesAnalysis of Air Blast Effect For Explosives in A Large Scale DetonationnguyenhNo ratings yet

- Numerical Simulations of Impacts InvolvingDocument60 pagesNumerical Simulations of Impacts InvolvinghasanNo ratings yet

- Veysset Et Al-2016-Scientific Reports PDFDocument8 pagesVeysset Et Al-2016-Scientific Reports PDFKorabliki BlinNo ratings yet

- Applied Thermal Engineering: Research PaperDocument14 pagesApplied Thermal Engineering: Research PapermehrzadNo ratings yet

- A Modified Model To Calculate The Size of The Crushed Zone Around A Blast-Hole PDFDocument10 pagesA Modified Model To Calculate The Size of The Crushed Zone Around A Blast-Hole PDFmatias79No ratings yet

- High-Speed Imaging of The Ultrasonic Deagglomeration of Carbon Nanotubes in WaterDocument14 pagesHigh-Speed Imaging of The Ultrasonic Deagglomeration of Carbon Nanotubes in WaterPriya DasNo ratings yet

- Nanomaterials Assignment 3-1629031Document12 pagesNanomaterials Assignment 3-1629031Zack UwanNo ratings yet

- AIAA-2002-1368: S. Kukathasan and S. PellegrinoDocument11 pagesAIAA-2002-1368: S. Kukathasan and S. Pellegrinosushant kumarNo ratings yet

- Geology Laboratory: Universiti Teknologi MaraDocument4 pagesGeology Laboratory: Universiti Teknologi Maratahsim laptopNo ratings yet

- Jgeot 14 P 268Document12 pagesJgeot 14 P 268cmkohNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Comparative Simulation Study of Gas-Phase Propylene Polymerization in Uidized Bed Reactors Using Aspen Polymers and Two Phase ModelsDocument32 pagesComparative Simulation Study of Gas-Phase Propylene Polymerization in Uidized Bed Reactors Using Aspen Polymers and Two Phase ModelsElbahi DjaalabNo ratings yet

- Carbon 06 00052Document17 pagesCarbon 06 00052Elbahi DjaalabNo ratings yet

- Ostdoctoral Research AssociateDocument1 pageOstdoctoral Research AssociateElbahi DjaalabNo ratings yet

- Major DutiesDocument1 pageMajor DutiesElbahi DjaalabNo ratings yet

- Storage Tank Protection Using Aspen Hysys: Petroleum and Coal May 2019Document11 pagesStorage Tank Protection Using Aspen Hysys: Petroleum and Coal May 2019Elbahi DjaalabNo ratings yet

- Excel Program To Facilitate The Estimation of Critical Properties Using Group Contribution MethodsDocument2 pagesExcel Program To Facilitate The Estimation of Critical Properties Using Group Contribution MethodsElbahi DjaalabNo ratings yet

- 03 Condensate StabilizationDocument8 pages03 Condensate StabilizationElbahi DjaalabNo ratings yet

- Modeling and Simulation of Catalytic Reactors For Petroleum RefiningDocument1 pageModeling and Simulation of Catalytic Reactors For Petroleum RefiningElbahi DjaalabNo ratings yet

- Call For Papers PDFDocument1 pageCall For Papers PDFElbahi DjaalabNo ratings yet

- How Do You Calculate The Sensitivity in A Voltammetry AnalysisDocument11 pagesHow Do You Calculate The Sensitivity in A Voltammetry AnalysisElbahi DjaalabNo ratings yet

- Polyaniline AbstractDocument27 pagesPolyaniline AbstractElbahi DjaalabNo ratings yet

- Khoshandam2005 PDFDocument13 pagesKhoshandam2005 PDFElbahi DjaalabNo ratings yet

- Measurement and Prediction of The Density and Viscosity of Biodiesel BlendsDocument13 pagesMeasurement and Prediction of The Density and Viscosity of Biodiesel BlendsElbahi DjaalabNo ratings yet

- Mercury2 RemovalDocument27 pagesMercury2 RemovalElbahi DjaalabNo ratings yet

- Effect of Wide Band-Gap TCO Properties On The Bifacial CZTS Thin-Films Solar Cells PerformancesDocument2 pagesEffect of Wide Band-Gap TCO Properties On The Bifacial CZTS Thin-Films Solar Cells PerformancesElbahi DjaalabNo ratings yet

- Natural Gas Technology: Master of ScienceDocument32 pagesNatural Gas Technology: Master of ScienceElbahi Djaalab100% (1)

- Application Note 14Document5 pagesApplication Note 14Elbahi DjaalabNo ratings yet

- Application Note 8Document2 pagesApplication Note 8Elbahi DjaalabNo ratings yet

- Catalogo Vidrio Mobicell DistribuidorDocument3 pagesCatalogo Vidrio Mobicell DistribuidorANTHONY SANCHEZNo ratings yet

- Nutricosmetics Apr08Document59 pagesNutricosmetics Apr08mayataNo ratings yet

- Evaluation of Antimicrobial and Antioxidant Activity of Crude Methanol Extract and Its Fractions of Mussaenda Philippica LeavesDocument14 pagesEvaluation of Antimicrobial and Antioxidant Activity of Crude Methanol Extract and Its Fractions of Mussaenda Philippica Leavesiaset123No ratings yet

- Introductory Entomology: Third Semester Lamjung CampusDocument206 pagesIntroductory Entomology: Third Semester Lamjung Campusnishan khatriNo ratings yet

- Lesson Plan Ds 8603Document7 pagesLesson Plan Ds 8603sramalingam288953No ratings yet

- Grade 8 Integrated Science Week 2 Lesson 2Document5 pagesGrade 8 Integrated Science Week 2 Lesson 2Balram HaroldNo ratings yet

- General Characteristics of Fungi. Details AbcdefDocument9 pagesGeneral Characteristics of Fungi. Details Abcdefabdul hadiNo ratings yet

- IT Practical FileDocument44 pagesIT Practical FileAtharva Watekar91% (11)

- License Plate RecognitionDocument3 pagesLicense Plate RecognitionSen PaiiNo ratings yet

- Bhubneshwor LeadsDocument4 pagesBhubneshwor LeadsCo2 RenuUNo ratings yet

- Pumy-P36 48nhmu Tech&Service Oc366c 7-25-08Document100 pagesPumy-P36 48nhmu Tech&Service Oc366c 7-25-08Chris KokkarasNo ratings yet

- Continuous Beam Lab G4Document11 pagesContinuous Beam Lab G4Najmuddin Aliff67% (3)

- Conviction in Cheque Bounce CaseDocument24 pagesConviction in Cheque Bounce CaseArvind PatilNo ratings yet

- Purpose - Device - Ravana - OSHODocument2 pagesPurpose - Device - Ravana - OSHOChitter SinghNo ratings yet

- Hizon, Czarina May CVDocument3 pagesHizon, Czarina May CVnotapernota101No ratings yet

- Ac Recovery Machine User Manual PDFDocument39 pagesAc Recovery Machine User Manual PDFmybdt1691No ratings yet

- Buildability ScoreDocument6 pagesBuildability ScoreVachara PeansupapNo ratings yet

- C Program To Store Records of Students in An ArrayDocument5 pagesC Program To Store Records of Students in An ArrayAsh RafNo ratings yet

- SPPU MA 2 SyllabusDocument43 pagesSPPU MA 2 SyllabusPranit JavirNo ratings yet

- Alternative Disposal of Polystyrene Fish BoxesDocument2 pagesAlternative Disposal of Polystyrene Fish Boxesهزاع الفارسNo ratings yet

- Foodtemp QuizDocument5 pagesFoodtemp QuizNorma Panares100% (2)

- Visualising Solid ShapesDocument24 pagesVisualising Solid Shapespk10117233% (9)

- hw4 SolDocument3 pageshw4 SoladvifulNo ratings yet

- Information Technology Research Paper TitlesDocument7 pagesInformation Technology Research Paper Titlesfzkk43h9100% (1)

- BELSummer Training ReportDocument33 pagesBELSummer Training ReportPalak MeenaNo ratings yet

- Reviewer in Pa 108Document14 pagesReviewer in Pa 108Madelyn OrfinadaNo ratings yet

- 304 118 ET V1 S1 - File1Document12 pages304 118 ET V1 S1 - File1Praveen BennurNo ratings yet

- 11 HUMSS JQR - Family Earthquake PreparednessDocument4 pages11 HUMSS JQR - Family Earthquake PreparednessCLARIZZE JAINE MANALONo ratings yet

- KHAMISDocument3 pagesKHAMISyouvarajNo ratings yet