Professional Documents

Culture Documents

Hornbill Property Developers

Hornbill Property Developers

Uploaded by

Smiley SureshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hornbill Property Developers

Hornbill Property Developers

Uploaded by

Smiley SureshCopyright:

Available Formats

Unit IG2: Risk assessment

Declaration: By submitting this assessment (Parts 1 – 4) for marking I declare that it is entirely my own work. I understand that falsely claiming that

the work is my own is malpractice and can lead to NEBOSH imposing severe penalties (see the NEBOSH Malpractice Policy for further information).

Important note: You must refer to the document ‘Unit IG2: risk assessment – Guidance and information for learners and Learning Partners’ while

completing all parts of this assessment. Your Learning Partner should provide you with a copy, but it can also be downloaded from the relevant

resources section for this qualification on the NEBOSH website.

Part 1: Background

You should aim to complete this section in 150 - 200 words.

Topic Comments

Name of organisation* Hornbill Property Developers

Site location* Hyderabad

Number of workers 350

Hornbill Property Developers involved in construction of Residential apartments, Villas and

commercial buildings. Currently we are constructing “Universal apartments” as their project which

spreads over by 10 acres in Hyderabad. The project site using various types of machineries such as

Excavators, Tower Cranes, Forklifts, MEWP’s, Cement mixers, Dumper trucks, Jack hammers and

other electrical tools. Both the hot and cold work taking place inside the construction area. Currently

General description of the organisation Concreting and the building construction works are undergoing at the project premises. Main

purpose of this inspection is to ensure the workplace and work equipment meets minimum legal

standards such as construction safety by direct visit to workplace and analyse the construction area

and work equipment. Workers working in 2 shift pattern in weekly six days’ basis and shift timing are

9 hours. The work activities take place in both indoor and outdoor areas.

Description of the area to be included in the This risk assessment covers the activities carried out at Main admin building and apartments

risk assessment named Venus and Mercury construction area of universal apartment.

The Project manager of Hornbill Property Developers – “Universal apartments” is overall

Any other relevant information responsible and accountable for Health and Safety at site.

* If you’re worried about confidentiality, you can invent a false name and location for your organisation but, all other information provided must be

factual.

Learner number: Learner name: Page 1 of 20

You should aim to complete this section in 100 - 200 words.

Note: this section can be completed after you have competed your risk assessment.

I have referred British safety standards https://www.hse.gov.uk/pubns/books/hsg150.htm “Health and

Safety in construction “for the resources and standards to complete this risk assessment.

Outline how the risk

assessment was carried out I have discussed with workmen and supervisor at different activity site to know about their competency level to

this should include: execute the construction activity and safety culture and other safety procedure implemented at the project.

sources of information

consulted; Then I was carried out direct site visit to identify hazards its associated risks and implemented control measures

effectiveness and Cross checked of effective implementation of emergency response procedures as per local

who you spoke to; and

and international standards. I have analysed OHS statistical data of project safe man-hours worked, Observation

how you identified: details, first aid and near miss data, Incident investigation details and statutory compliance register.

- the hazards;

- what is already For the recommendation of control measures, I have referred ILO Website, which is having the specific

being done; and requirement and information as a control measures which should be adhered by an employer at the

- any additional construction site. Example Below

controls/actions that

may be required. As per ILO article no 26 of C167 for “Electricity”.

https://www.ilo.org/dyn/normlex/en/f?p=NORMLEXPUB:12100:::NO:12100:P12100_ILO_CODE:C167:NO

Learner number: Learner name: Page 2 of 20

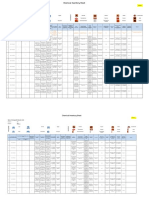

Part 2: Risk Assessment

Organization name: Hornbill PropertyDevelopers

Date of assessment: 13 January 2021

Scope of risk assessment: Construction activity at Main admin Building, Venus and Mercury building of “Universal Apartments”

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Manual Workers involving in this Responsible supervisor Work activity must be stopped 2 hours Site Engineer

Handling activity may get harmed deputed to supervise and no load beyond the

the job. prescription level shall be

Observed Consequences: allowed to exceed.

workmen are Proper PPE’s issued

lifting and Lifting the heavy loads and worn by workmen. Material handling equipment 15 Days Site Engineer

shifting the manually will cause the such as mobile crane and fork

heavy musculoskeletal Hazard related posters lift shall be arranged to shift the

reinforcement disorders if workmen kept at work place to heavy loads.

steel beyond the continue the same in long alert the workmen.

approved limits. time period. Also it will Manual handling weight limits 1 week Site

lead to muscle cramp, posters and signage to be Supervisor

joint pain and fall of placed at work area.

material on foot which

cause serious personal Work specific training must be 1 week

injuries. imparted to all workmen about Safety Officer

the risk and safety work

practices of manual handling.

Monitoring program for Regular Project

workmen health on Manager

musculoskeletal injuries and

disorders shall be done.

Learner number: Learner name: Page 3 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Slip and Trips All workers, employees Hand rails installed at Spilled oils and grease shall be 2 hours Site engineer

and working at this area the access staircase. cleaned with proper surface

Observed oil and may have harmed. cleaners.

grease spilled on Staircase erected by

the steps of the Consequences: competent scaffolding Oils and grease must be stored 15 Days Project

main access team and approved by only in non-spill containers to Manager

staircase at Spillage of oil and scaffolding inspector. avoid spill at work site. Non spill

Venus Building. grease in walkways containers shall be procured

creates slippery surface and issued for usage.

will lead to workmen step

on it and fall on the floor No oil and grease bin are

which may results to allowed to stack at the access Immediate and Site engineer

Heal injuries, Broken way and staircase. regular

bones to workmen and

staffs. Regular cleaning schedule of

access staircase is to be done. 1 week Site Engineer

Slip and fall hazard related

posters shall be placed on the 1 week Safety officer

access staircase to alert the

workmen and staffs.

Health, Welfare All Employees and who Housekeeping team is Damaged wall surface must be 15 Days Project

and Work are all working at admin appointed to maintain repaired to restrict the water Manager

Environment building may get harm. the cleanliness inside seepage.

the admin building.

Observed admin Consequences: Formed fungus at wall surface 1 week Facility

building walls Proper ventilation shall be removed with proper manager

developed with Fungus formation can system implemented at disinfectant.

Fungus cause skin irritation like admin building.

formation due itches and bruises when

Learner number: Learner name: Page 4 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

to water personal came to Repainting of the wall must be 15 days Facility

seepage during contact with it and also Air fresheners are being done. Manager

monsoon creates bas odour inside sprayed to ensure the

season. the building. Fungus good odour inside the Plan to ensure the no seepage

formation will disturb the admin building. inside the building to be 15 Days Project

ambient air quality prepared during the monsoon Manager

inside the admin season and implemented.

building and damage

the wall surface. Schedule of daily

housekeeping shall be 15 Days Facility

prepared and implemented Manager

with the vigilance of supervisor.

Load Handling Workers, Operator and Full time supervisor Activity must be stopped. Immediate Site engineer

Equipment supervisors involved in deployed to supervise

the job may harmed the job.

Observed Riggers and signal man Mobile crane must have tested 1 Month Mechanical

Mobile crane Consequences: are deployed to secure by certified competent person Engineer

bearing Reg. load line and signalling for its load bearing capacity.

No. AP 03 HZ Using of mobile crane the mobile crane.

2345 is working without valid third party Mobile crane must be equipped 1 Month Mechanical

at mercury test certificate for lifting with Safe load indicator. Engineer

building area purpose may get

without valid toppled during lifting

third party load along with the load. It Mobile crane testing & 1 Month Mechanical

test certificates. will cause fall of material maintenance time sheet and Engineer

from height onto people register must be recorded for

and which may result in knowing the recommendation

fatal of workmen and of competent person.

property damage.

Learner number: Learner name: Page 5 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

1 Month Site

All lifting activity must be Supervisor

controlled by lifting work

permit.

Work All workers, supervisors Work activity is being Work activity must be Immediate Site Engineer

Equipment who involved in this monitored by competent suspended till completion of

activity. supervisor. below compliance.

It was observed

that protective Consequences All workmen are trained Robust guard system as per 1 week Electrical

guard in steel to execute the job. manufacturer design Engineer

cutting machine Working without guard recommendation must be fixed

is not available / in steel cutting machine with cutting machine.

fixed at will cause the blow of

reinforcement cutting wheel from All portable machines must be 15 days Site Engineer

area of “Mercury machinery and contact inspected and certified by the

Building”. of operative workmen electrical engineer.

into cutting machine

may results in cut Tagging system to identify the 15 days Site

injuries, fatal and healthiness of electrical tools Supervisor

serious injuries. must be implemented.

Inspection plan of portable 15 days Electrical

electrical tools must be Engineer

planned to ensure the

healthiness of electrical tools.

Learner number: Learner name: Page 6 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Working at Workmen and Scaffolding structures Robust toe board system must 1 week Site engineer

Height employees passing by erected by trained and be erected in scaffolding

may harm. certified scaffolding platform.

It was found that erector.

toe boards are Consequences:

not installed in Tagging system of the Entire scaffolding platform

working platform Working platform scaffolding is done. must be covered by materials 15 days Project

at Mercury without proper toe catching safety nets to arrest manager

building boards will lead to fall of the debris and fallen materials

construction construction materials

area. from height onto below

machineries and Scaffolding checklist must be 15 days Site Engineer

workmen which result in implemented to check the

serious personal injuries safety requirement of

and fatal, severe scaffolding platform.

property damage to

equipment’s and

machineries. Work area below the 1 week Site

scaffolding platform must be Supervisor

cordoned off in safe distance to

restrict the trespassing of

workmen and staffs into

hazardous zone.

Hazard related posters for fall 1 week

of materials hazards must be Safety Officer

placed to alert the workmen

and staffs.

Learner number: Learner name: Page 7 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Fire All staff, workmen and Fire extinguishers kept All dry grass and bushes must 1 week Site Engineer

visitors involved at next to the Electrical be removed around the main

Observed dry construction activity. distribution unit room. electrical distribution unit room.

grasses and

bushes next to Consequences Weather shielding Safe clearance area of two

the main arrangements are done meter shall be maintained 1 Month Site Engineer

Electrical Due to dry grass fire can at main electrical around electrical distribution

distribution unit happen at high distribution panel unit unit by filling metal crushed

room. temperature which may room. sands and 20 mm stones to

cause severe injuries make fire barrier.

and fatal to workmen

and staffs and severe

property damages of Monthly safety inspection for 1Month Electrical

distribution panels. main electrical distribution unit Engineer

shall be carried out; Fire safety

inspection shall be focused

during the inspection.

Fire Fighting training and mock 1 Month Safety officer

drill shall be conducted to

workmen and staffs working in

project shall be imparted to

meet fire emergency.

Working at Workmen, Engineers, Workmen are equipped Proper anchoring points must 1 Month Project

Height Supervisors involved in with full body harness be designed and installed in manager

this activity may harm. and instructed to secure safe interval at roof to fix the

Observed the harness while horizontal lifeline to secure the

proper Consequences: - accessing the roof. full body harness.

anchoring points

are not installed 1 Month Site engineer

Learner number: Learner name: Page 8 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

at the Roof Due to non-availability Only authorised Standard horizontal lifeline with

structures to of robust anchoring personal are allowed to rope grab fall arrester must be

anchor the points, workmen may access the tower. installed at roof.

lifeline at Main not able to secure his

admin building. full body harness while All height workmen 1 Month Safety officer

. doing maintenance work undergoing medical Necessary training on usage of

which lead workmen fall fitness certificates fall arrester and lifeline to be

from height which before engaging into imparted to workmen and staff.

results in Serious work. 1 Month Project

injuries, Paralysis and Rescue arrangement from roof Manager

fatal due to fall of of fallen or injured person to be

person from height. done.

1 week

Identified hazard related Safety officer

caution posters must be placed

at roof access area.

Lone working Workmen working at All workmen are No lone working policy must be 15 days Project

workplace may have properly inducted before planned and implemented. manager

Observed a harmed. engaging into work.

painting Personal Motion scout has to 5 days Site Engineer

workmen Consequences: Work specific PPE’s are be provided which produces an

working in room issued to all workmen. alarm frequency up to 2.6 – 3.0

of 8th floor alone Working alone at kHz

without proper workplace without

permit and proper permit and Buddy system shall be

information to supervisor by enforced to all works which not 1 week Site Engineer

supervisor. responsible person may required more workmen.

results in personal

injuries to workmen and

not able to treat him in

quick time. Regular Site Engineer

Learner number: Learner name: Page 9 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

All work activity must be

controlled by work permit

system.

1 week Site

Emergency contact number Supervisor

must be placed and available

with all workmen who are all

planned to carryout in lonely

workplace.

Hazardous Workmen, supervisors Nose mask and safety Fog cannon system should be 1 month Project

substance and staffs may have goggles issued to all implemented to reduce the Manager

(Dust) harmed. workforce to safeguard dust at construction area.

themselves from

Observed most Consequences: particulate matters. Dust suppression chemical 1 month Site Engineer

of the workplace shall be used during water

in the Inhalation of shall lead Water spraying by trucks sprinkling activity at across

construction to respiratory at access road for access road dust suppression

area found very discomfort, Asthma, suppressing dust is activity.

dusty and cause Irritation and lung being done on regular

air pollution. diseases. basis. Trucks and trailers which 1 week Site Engineer

transport construction materials

must be covered by protective

sheets to restrict dust

emission.

Water sprinklings by water 1 week Site Engineer

tanker to be done on regular

intervals.

Learner number: Learner name: Page 10 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Confined All staffs, Workmen and Ladders placed for Rescue equipment setup for 1 Month Project

Space involved in this activity access and egress. confined space shall be Manager

may cause harm. arranged as per standard.

Observed no Proper lighting

rescue Consequences: arrangement ensured. Multi gas testers shall be used 15 Days Site Engineer

equipment continuously to measures the

available at site Serious injuries and Work activity is being level of hazardous gas inside

to rescue Fatality to multiple monitored by the confined space.

trapped workmen can be responsible supervisor.

workmen inside resulted due to non- Work activity shall be 1 week Site Engineer

the confined availability of proper controlled by confined space

space, where rescue equipment to permit with all checklist.

multiple rescue the injured or

workmen trapped person from Confined space rescue plan 1 week Safety Officer

working inside cable trench. shall be incorporated into

the admin project emergency response

building cable plan.

trench for

welding activity. Mock drill for confined space 1 month Safety officer

rescue shall be planned and

conducted.

1 week Safety officer

All person involved in this

activity shall be trained for safe

working inside confined space.

Health, welfare All employees, workers Approved waste All Food waste kept in pantry Immediate Facility

and Work and visitors. management plan is must be closed with covers. Manager

Environment available,

Consequences: Weekly pantry inspection shall

Found food be planned, 1 week Project

waste bins kept Manager

Learner number: Learner name: Page 11 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

open and Health concern and Waste disposal by

without closet infection due to hygiene approved third party User observation/feedback

cover at pantry. of work environment, being complied, system shall be developed for 1 week Facility

and environmental non- pantry observation. Manager

compliance as per state Canteen inspection

pollution control board being done by fortnight Regular disinfection and proper

guideline. basis. cleaning activity to be carried Regular Facility

out at waste bin area Manager

Electricity Workmen, Engineers, Approved site electrical Electrical goal post to be 1 Month Project

Observed Supervisors involved in layout is available installed wherever vehicles and manager

electrical cables this activity may harm. equipments are passing the

routed through Only armoured cables overhead lines.

overhead by Consequences: - are used for supply

poles hanging at purpose. All poles shall be properly 15 days Site engineer

unsafe height. Construction vehicle grounded as per specification

which are all passing by Licensed electricians

this area may hit the are available at site for

overhead cables which all electrical related Electrical hazard poster with 15 days Site

may cause electrocution works. power/voltage ratings to be supervisor

to operators and other placed at all prominent places

workmen which results

in serious burn injuries,

property damage and

fatality.

Vibration Workers involving in this Responsible supervisor Proper hand gloves shall be 2 hours Site engineer

Observed activity may get harmed deputed to supervise given to workmen to carry out

workmen Consequences: the job. the job.

working without

wearing the Working with jack Workmen rest area is

proper hand hammer without hand available.

Learner number: Learner name: Page 12 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

gloves while gloves continuously will Vibration reducing handle bars 15 Days Mechanical

operating the cause the vibration white Welfare facilities such to be fixed in the jack hammer Engineer

jack hammers at fingers and hand as drinking area and machines.

precast yard. numbness due to heavy toilets provided.

vibration by the jack Monitoring system to be 1 Month Project

hammer. planned and implemented to manager

reduce the exposure of

workmen with Vibration

Work specific hazard related 1 week Safety officer

training to be imparted to all

workmen to restrict the unsafe

acts.

Hazard related posters and 1 week Site

signage to b e placed at work supervisor

area.

Work activity must be controlled Regular Site Engineer

by work permit system.

Learner number: Learner name: Page 13 of 20

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for

category and and how? required? further actions Responsible

hazard to be person’s job

completed title

(within …)

Learner number: Learner name: Page 14 of 20

Part 3: Prioritise 3 actions with justification for the selection

Suggested word counts

Moral and financial arguments for all actions: 300 to 350 words

For EACH action:

Specific legal arguments: 100 to 150 words

Likelihood AND severity: 75 to 150 words

How effective the action is likely to be in controlling the risk: 100 to 150 words

Moral and financial arguments for ALL actions

Moral: -

Moral, general legal and financial

arguments

Hornbill Properties Developers as an organization has moral responsibility to protect his workers

from hazard, risk & accident while working. As an esteemed organization if we failed to control the

construction activity with robust control measures and if failed to prevent the accidents workers

and employees may encounter with accidents and resulted personal injuries. Worker joining our

organization for the survival of their own and their family in means of financial. If we failed workers

will suffer from various injuries such as fire burn injury, eye injury, skin irritation, lungs irritation,

head injury, multiple bone fracture, neck injury, and spinal injury, fatal. Workers family, relative &

friends will suffer on his loss (fatal), disabilities. If workers suffer on injury or ill health, it will affect

co-worker’s morality in work as they will feel our construction site are not safe for their health and

safety. It reduces the productivity & quality of the project outcome.

Financial: -

If we failed to take above mentioned control measure, employer financially might be affected in

following cost,

In failure of these above categories the workplace will be unsafe and be more risk full will cause the

serious accident and lost such as fatalities, injuries, object lost and damaged property.

In result the employer will be prosecuted in criminal courts by the enforcement authority, the

successful prosecution may in results of fine in criminal courts and imprisonment.

And also the employer will face the serious damages need to be overcome because of various

direct and indirect costs following by the accident such as recruiting the new workers and it costs,

new training programs, and insurance coverage. So the management should focus and consider

Learner number: Learner name: Page 15 of 20

this activity as high prioritized and drawing up immediate control measures.

Around 50 thousand rupees shall be spent to carry out the third party load testing at site by

competent person and approximately 200 thousand to be spent to design and install robust

anchoring point at roof and standard lifelines and rope grab fall arrester and around 250 thousand

rupees shall be spent to raise purchase the confined space rescue equipments. Our company can

complete the control measure implementation work in 500000 INR to avoid huge loss. If company

fails to take additional control measure, company will face huge financial loss. Its cost around

5000000 times in INR. It is 10 times higher than additional control measure cost.

Justification for action 1

Action Mobile crane must have tested by certified competent person for its load bearing capacity

(Category – Load Handling Equipment)

As per ILO recommendation R175 clause no 22 “Lifting appliances and Gears”” National laws or

Specific legal arguments

regulations should prescribe the lifting appliances and items of lifting gear which should be examined

and tested by a competent person-”, (a) before being taken into use for the first time, (b) after erection

on a site, (c) subsequently at intervals prescribed by such national laws or regulations, (d) after any

substantial alteration or repair.

Employers must be having the process to ensure the regular inspection and renewal of third party

inspection certificates of all lifting appliances.

Also employers shall appoint the designated engineer or in charge to carry out and ensure the

maintenance of all lifting equipment.

Using mobile crane without valid load test certificate may have deteriorated lifting gears and

Consideration of likelihood AND severity

malfunctioning load indicators. It will have high likelihood of operator cannot assess the load that is

being lifted and failure of lifting gears during lifting and toppling of mobile crane. The severity caused

by the incident is too high. This may result in serious and fatal injuries to operator and other multiple

workmen nearby because this work is being done at regular basis at the construction site. this will

lead to severe financial losses in means of material damage, insurance claim and other medical

expenses claim to the organisation.

Learner number: Learner name: Page 16 of 20

How effective the action is likely to be in

To avoid mobile crane toppling and failure of lifting gears mobile crane must have tested by certified

controlling the risk. This should include:

competent person for its load bearing capacity. During this time crane’s safe load indicators, Leakage

the intended impact of the action; in hydraulic parts, outriggers operation, and stability of crane also shall be checked and all findings

justification for the timescale that you must be recorded in inspection checklist with date and next test due date by competent person. These

indicated in your risk assessment; control measures shall reduce the high level risk into low level. I would give the project team 1 month

and of time to complete this task because the operators and workers are in direct risk. This control

whether you think the action will fully measures will not eliminate the risk but will reduce the risk level with other engineering and

control the risk. administrative controls safety of workers will be ensured.

Justification for action 2

Proper anchoring points must be designed and installed in safe interval at roof to fix the horizontal

Action

lifeline to secure the full body harness and standard lifeline & rope grab fall arrester to be installed

(Category – Working at Height)

As per ILO convention C167 article 18 “WORK AT HEIGHT INCLUDING ROOF WORKS” point

Specific legal arguments

1” Where necessary to guard against danger, or where the height of a structure or its slope

exceeds that prescribed by national laws or regulations, preventive measures shall be taken

against the fall of workers and tools or other objects or materials”.

Employers must ensure the proper anchoring points are designed by the expert team as per local

and international standards to ensure the rigidity of the anchoring points.

Also proper fall protection and prevention equipments shall be made available for the usage of

workers and staffs at site.

Allowing workers to carryout work in the roof without proper and robust anchoring points and lifeline

Consideration of likelihood AND severity

to hook the safe harness has high likelihood of fall of persons from roof at height. The severity and

result of fall of person from height is extreme because continuous height work activity is being carried

out at many places in this project. It will cause in serious head injuries, back injuries, Paralysis and

mostly fatal to multiple workers. Multiple injuries and fatalities will cost heavy financial loss to

company in terms of medical expenses and insurances claim.

How effective the action is likely to be in To avoid the fall of workers from roof, robust anchoring points to be designed and installed at roof in

controlling the risk. This should include: regular interval to anchor and install the lifeline. Also standard horizontal lifeline system with rope

grabs fall arrester to be installed in the anchoring point to secure the workmen full body harness. Also

Learner number: Learner name: Page 17 of 20

the intended impact of the action; proper training to height workmen shall be imparted to use the lifelines and fall arresters. All above

justification for the timescale that you proposed control measure shall reduce the risk. I would give 1 months of time to complete this activity

indicated in your risk assessment; because fall of person will results mostly in fatality.

and This control measures will not remove the high risk totally will reduce the risk level with other

whether you think the action will fully engineering and administrative controls safety of workers will be ensured.

control the risk.

Justification for action 3

Rescue equipment setup for confined space shall be arranged as per standard. (Category –

Action

Confined Space)

As per Indian Building and other construction workers act 1996 and central rules 1998 rule no 36

Specific legal arguments

“An employer shall ensure at a construction site of a building or other construction work that in case

more than five hundred building workers are employed at such construction site emergency action

plan to handle the emergencies”.

Employers or project manager must be arranging the necessary rescue equipments availability at

site.

Also all involved workers and staffs must be trained for the safe working inside the confined space

area and emergency mock drill shall be conducted on regular basis to meet and respond the

emergency situation effectively.

Working inside the confined space is having high likelihood of workmen affected by dangerous

Consideration of likelihood AND severity

atmosphere and other physical hazards. The severity of working inside confined space without proper

and standby rescue equipment is high. This may cause the time delay or unable to retrieve injured

or affected workmen in time. If we rescue person without proper equipment it will worsen the injury

or health condition of workers. So worker injury may be enlarged or even fatal can happen due to

time delay. This confined space activity will be carried out at main admin building and main control

building areas regularly by 5 to 10 workmen continuously.

How effective the action is likely to be in To avoid delay of rescuing injured or affected workmen from confined space, Rescue equipment

controlling the risk. This should include: setup for confined space shall be arranged as per standard and Multi gas testers shall be used

continuously to measures the level of hazardous gas inside the confined space. If sais measures are

the intended impact of the action;

implemented confined space atmosphere will be monitored regularly and in case of emergency

justification for the timescale that you injured person will be retrieved in time. I believe proposed additional control measures bring the high

indicated in your risk assessment; risk to acceptable level. I would give 1 month of time for purchasing of confined space rescue

and

Learner number: Learner name: Page 18 of 20

whether you think the action will fully equipment setup as per standards, because delay in recuing process will cause danger to multiple

control the risk. worker’s life.

This control measures will not remove the high risk totally will reduce the risk level with other

engineering controls and continuous training to workers will ensure safety of workers will be ensured.

Part 4: Review, communicate and check

Suggested word counts for each section:

Planned review date or period and reasoning for this: 50 - 100 words

How the risk assessment findings will be communicated and who needs to know the information: 100 - 150 words?

Follow up on the risk assessment: 100 - 150 words.

Planned review date/period with This risk assessment review should be taken on 12.06.2021

reasoning All approved risk assessment shall be reviewed once in six months as per organization

policy.

All risk assessment shall be subjected to be reviewed due to below reasons.

New management has changed,

New work procedures and equipment changed,

Any legal requirement and changes in occupational laws.

In case any incident happened

How the risk assessment findings will be After preparation of risk assessment in details safety committee meeting will be arranged along with

communicated AND who you need to tell all committee members and responsible person. Finding of the risk assessment its likelihood,

severity and possible outcomes will be explained to all persons. Then identified and prosed control

measures, responsible person to complete the task and time limit to complete the task will be

communicated. This risk assessment will be circulated to top management through official E-mail to

all concerned persons. Also hard copy of risk assessment will be displayed at notice boards and

critical control measures shall be displayed in posters and signage. Awareness session shall be

conducted to all supervisors, engineers, site manager on this risk assessment to enable the site

execution team. All workers will be informed through regular workplace training and tool box

meeting about the findings and control measures of this risk assessment.

How you will follow up on the risk I set two days in a month to contact each responsible person to know the status of additional

assessment to check that the actions control measure implementation. I try to visit the site to know & check the status of risk assessment

have been carried out If there is any lack in implement process or delay in implementing the risk assessment, I should to

get the reason for the lacking from the responsible or delay of implementation like lack of man

Learner number: Learner name: Page 19 of 20

power to construct, lack of resource (financially), lack of dealer to buy the material such as crane

rope, lifeline. I would assist the purchase manager to get dealer to buy the material in good quality,

I assist operation manager & top management to support financially through tell the importance of

implementation & consequences of accident, financial loss on accident.

Learner number: Learner name: Page 20 of 20

You might also like

- IG2 Risk Assessment Al Hajri OverseasDocument16 pagesIG2 Risk Assessment Al Hajri OverseasMuhammad Farooq Awan94% (17)

- Unit IG2: Risk Assessment Part 1: BackgroundDocument23 pagesUnit IG2: Risk Assessment Part 1: Backgroundjimmy62% (13)

- Unit IG2: Risk Assessment Part 1: Background: 00267373 Sarath Babu. RDocument9 pagesUnit IG2: Risk Assessment Part 1: Background: 00267373 Sarath Babu. RSarath Babu82% (17)

- Deepa 2Document21 pagesDeepa 2Ershad Akhtar88% (17)

- IG2 - Risk Profiling - Muhammad Numan 00548699Document16 pagesIG2 - Risk Profiling - Muhammad Numan 00548699Nomi Noor100% (9)

- Ig2 Report Muhammad ArslanDocument18 pagesIg2 Report Muhammad ArslanShaheen Himalyn salt88% (8)

- IG2 New Updated FormatDocument9 pagesIG2 New Updated FormatSafety PECPL43% (7)

- Unit IG2: Risk AssessmentDocument24 pagesUnit IG2: Risk AssessmentNowfal Habeeb86% (14)

- Aswin Ashok 00601664 IG2Document17 pagesAswin Ashok 00601664 IG2BALAJI. B100% (7)

- Report NeboshDocument12 pagesReport NeboshAhsan Khan100% (6)

- Muhammad Numan (Ig2-Forms-Electronic-Submission) ReportDocument14 pagesMuhammad Numan (Ig2-Forms-Electronic-Submission) ReportNomi Noor100% (6)

- K S Zamreen 00761734 Tciq ProjectDocument19 pagesK S Zamreen 00761734 Tciq ProjectNikhil Nixon100% (2)

- Nebosh Igc Risk Assesment February 2020Document16 pagesNebosh Igc Risk Assesment February 2020Nathan Tankwal64% (14)

- NEBOSH IG2BH-4th August RealDocument15 pagesNEBOSH IG2BH-4th August RealAlbert88% (8)

- A.sahaya Pratheesh Fero 1Document29 pagesA.sahaya Pratheesh Fero 1Arun Godson63% (8)

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document19 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Abdur82% (11)

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document37 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Remya70% (10)

- Ig2-Form - MD Shadab Anwar ProjectDocument21 pagesIg2-Form - MD Shadab Anwar Projectmd shadab anwarNo ratings yet

- Rweteba Nelson Risk Assessment WorkDocument26 pagesRweteba Nelson Risk Assessment WorkKofi Sam100% (9)

- Unit IG2: Risk Assessment Part 1: BackgroundDocument17 pagesUnit IG2: Risk Assessment Part 1: BackgroundStven Smith100% (6)

- Secrets of Passing the Nebosh Exams: Don’T Study Hard, Just Study SmartFrom EverandSecrets of Passing the Nebosh Exams: Don’T Study Hard, Just Study SmartRating: 4.5 out of 5 stars4.5/5 (6)

- IG2 Project Risk Assessment RoughDocument21 pagesIG2 Project Risk Assessment RoughRemya83% (6)

- Unit IG2 Risk AssessmentDocument17 pagesUnit IG2 Risk AssessmentAli Alahma100% (2)

- IGC2-submission Hazanur - RevDocument12 pagesIGC2-submission Hazanur - RevDjoko Sugihato60% (5)

- Unit IG2: Risk AssessmentDocument14 pagesUnit IG2: Risk Assessmentamin100% (1)

- IG2, Jamal Shah, 00657859, Besi PVT Ltd.Document17 pagesIG2, Jamal Shah, 00657859, Besi PVT Ltd.saqib ali80% (5)

- Ig2 Example v4Document19 pagesIg2 Example v4shamnad qtv75% (4)

- Risk Assesssment IG2 ReportDocument18 pagesRisk Assesssment IG2 ReportRashid Jamil33% (6)

- Firoz IGCDocument19 pagesFiroz IGCErshad Akhtar80% (5)

- Ahmad Munir, 00704652,1644-Rewaq Ousha Educational InstitutDocument19 pagesAhmad Munir, 00704652,1644-Rewaq Ousha Educational Institutsdsdjs sdh100% (1)

- Rinesh Vallassery Suresh BabuDocument27 pagesRinesh Vallassery Suresh BabuAnshif RayinNo ratings yet

- IG2 68J S.J Steel PVT LTD 1 - 084932Document16 pagesIG2 68J S.J Steel PVT LTD 1 - 084932Muhammad Farooq Malik100% (1)

- Risk Assesment of Workplace.Document17 pagesRisk Assesment of Workplace.Sufyan SufyanNo ratings yet

- #36 IG2-forms-electronic-submissionDocument6 pages#36 IG2-forms-electronic-submissionHassan Alawami100% (3)

- Unit IA - Course Exercise & AssignmentDocument77 pagesUnit IA - Course Exercise & AssignmentChandra Kumar100% (1)

- Unit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDocument17 pagesUnit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsMuhammad FaiSal100% (6)

- Unit IG2: Risk AssessmentDocument22 pagesUnit IG2: Risk Assessmentprijith j100% (6)

- Ig2 ProjectDocument18 pagesIg2 Projectvivek vjNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document16 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1vivek vj67% (3)

- Unit IG2 Risk AssessmentDocument13 pagesUnit IG2 Risk AssessmentAbdulla KurupkarNo ratings yet

- Ig2 Example v4Document19 pagesIg2 Example v4blv sai ramNo ratings yet

- PLPE-Property VAS Ver 0.4Document14 pagesPLPE-Property VAS Ver 0.4Gaurav KumarNo ratings yet

- IGC 2 - Installation of Automatic Fare Gate System - SubmissionDocument18 pagesIGC 2 - Installation of Automatic Fare Gate System - SubmissionVivek Vj67% (3)

- Nebosh-IGC-1 Sample PaperDocument11 pagesNebosh-IGC-1 Sample Paperosmanrb70% (10)

- Integrated ISO 14001+18001 Awareness Training (1day)Document95 pagesIntegrated ISO 14001+18001 Awareness Training (1day)Stephen Lim Kean Jin100% (3)

- Ig2 Forms Electronic Submission v3Document12 pagesIg2 Forms Electronic Submission v3Nowfal Habeeb100% (1)

- Chandu Raveendran 00643493Document13 pagesChandu Raveendran 00643493rah uaeNo ratings yet

- Faizan Ahmed KhanDocument14 pagesFaizan Ahmed KhanFaizan Ahmed KhanNo ratings yet

- Ig2 Forms Electronic Submission v2Document13 pagesIg2 Forms Electronic Submission v2Musaddiq J.67% (3)

- Sample - Majan Glass Company OmanDocument21 pagesSample - Majan Glass Company OmanRizwan Hameed100% (1)

- Unit IG2: Risk Assessment Part 1: BackgroundDocument17 pagesUnit IG2: Risk Assessment Part 1: BackgroundNIRANJANMURTHY ASST.EXECUTVIE ENGINEERNo ratings yet

- Unit IG2: Risk Assessment Part 1: BackgroundDocument9 pagesUnit IG2: Risk Assessment Part 1: BackgroundREVANTH KUMARNo ratings yet

- Shaikh, Arsalan, Ayub, 00626820,1446 GulfacademyDocument24 pagesShaikh, Arsalan, Ayub, 00626820,1446 GulfacademyMohammad Awees Sanadi100% (1)

- Ig2 Forms Electronic Submission v3Document21 pagesIg2 Forms Electronic Submission v3Sajo JoseNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- Mohammad Shahbaz Ali - IG2Document23 pagesMohammad Shahbaz Ali - IG2NIRANJANMURTHY ASST.EXECUTVIE ENGINEERNo ratings yet

- Al Jazeera PAINTsDocument18 pagesAl Jazeera PAINTsdilshad khanNo ratings yet

- Unit IG2: Risk AssessmentDocument14 pagesUnit IG2: Risk AssessmentSardar100% (2)

- Red River Valley Conservation Work Risk Assessment For Bell Lake Marsh RRRDocument3 pagesRed River Valley Conservation Work Risk Assessment For Bell Lake Marsh RRRapi-19576182340% (5)

- Igc 2 - Examination Paper - 1Document25 pagesIgc 2 - Examination Paper - 1SAPTAGIRI100% (1)

- Unit IG2: Risk Assessment Part 1: Background: WWW - Hse.gov - UkDocument8 pagesUnit IG2: Risk Assessment Part 1: Background: WWW - Hse.gov - UkNomi NoorNo ratings yet

- Unit IG2 Tony BabuDocument14 pagesUnit IG2 Tony Babujithin shankar100% (3)

- Waqar Ali 00735038 IG2 829 Induction CenterDocument19 pagesWaqar Ali 00735038 IG2 829 Induction CenterAlb AklbNo ratings yet

- BentoniteDocument4 pagesBentonitesajad gohariNo ratings yet

- Ardrox 6333 MsdsDocument9 pagesArdrox 6333 MsdsPutra Temas ToyebNo ratings yet

- Benchmarking Research Paper PDFDocument8 pagesBenchmarking Research Paper PDFnachiappanmNo ratings yet

- Man8 PDFDocument72 pagesMan8 PDFCarel De JagerNo ratings yet

- QP LSC Q1120 Consignment Booking AssistantDocument31 pagesQP LSC Q1120 Consignment Booking Assistantshivam choudharyNo ratings yet

- Safety PolicyDocument15 pagesSafety PolicyMoazzam NaqeebNo ratings yet

- Green Glue Material Safety DataDocument4 pagesGreen Glue Material Safety DatawilldoyeahNo ratings yet

- Ge700 2020 GC01Document2 pagesGe700 2020 GC01John ConstanceNo ratings yet

- VF SDS Canola OilDocument7 pagesVF SDS Canola OilAlex Ogbe ElbjornNo ratings yet

- V2 SITXWHS003 Student Assessment Guide11Document58 pagesV2 SITXWHS003 Student Assessment Guide11Sujal KutalNo ratings yet

- Visi Misi DK3NDocument21 pagesVisi Misi DK3NtemterNo ratings yet

- Contractor Safety Management: Getting StartedDocument3 pagesContractor Safety Management: Getting StartedAntonius Dwi Putranto NNo ratings yet

- IPTC 11222 REACH and The HSE Case For Formate BrinesDocument11 pagesIPTC 11222 REACH and The HSE Case For Formate BrinesAminNo ratings yet

- Safety, Health and Environment Manual and ProceduresDocument20 pagesSafety, Health and Environment Manual and ProceduresYan's Senora BescoroNo ratings yet

- Organic Sulphonic Acid Salts IIDocument3 pagesOrganic Sulphonic Acid Salts IINermeen AhmedNo ratings yet

- TR - Organic Agriculture Production NC II - Nov192012Document93 pagesTR - Organic Agriculture Production NC II - Nov192012974695790% (20)

- Msds - Potassium ChlorideDocument7 pagesMsds - Potassium ChlorideMikiNo ratings yet

- OHS-PR-02-01 Leadership, Responsibility and Accountability (Updated)Document20 pagesOHS-PR-02-01 Leadership, Responsibility and Accountability (Updated)مهندس محمد مباركNo ratings yet

- COSHH Awareness TrainingDocument52 pagesCOSHH Awareness TrainingSubroto Ghosh100% (2)

- BlaceMaster One Step Solvent Cement PDFDocument6 pagesBlaceMaster One Step Solvent Cement PDFPaola LopezNo ratings yet

- Ebook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaDocument127 pagesEbook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaAfrina DamyaNo ratings yet

- BA 89402175 001100 Innopack EN 00 PDFDocument293 pagesBA 89402175 001100 Innopack EN 00 PDFBruno GiffoniNo ratings yet

- Restaurant Employees: Workplace Safety & Health GuideDocument32 pagesRestaurant Employees: Workplace Safety & Health Guidehoodie alenNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument8 pagesSafety Data Sheet: 1. Product and Company IdentificationshoyebNo ratings yet

- Chemical Inventory Sheet: Name of Company/Production UnitDocument4 pagesChemical Inventory Sheet: Name of Company/Production UnitNur E Alam NuruNo ratings yet

- Checklist - Planning The Safe Set-Up and Operation of Personnel and Materials HoistsDocument8 pagesChecklist - Planning The Safe Set-Up and Operation of Personnel and Materials HoistsSajeewa LakmalNo ratings yet

- Industrial Safety Processes UdemyDocument1 pageIndustrial Safety Processes Udemysaumil.boghani53No ratings yet