Professional Documents

Culture Documents

Potential Hazards Safeguard/ Controls To Be Put in Place Responsibility Sequence of Basic Job Steps

Potential Hazards Safeguard/ Controls To Be Put in Place Responsibility Sequence of Basic Job Steps

Uploaded by

amitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Potential Hazards Safeguard/ Controls To Be Put in Place Responsibility Sequence of Basic Job Steps

Potential Hazards Safeguard/ Controls To Be Put in Place Responsibility Sequence of Basic Job Steps

Uploaded by

amitCopyright:

Available Formats

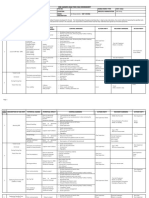

M/s Chitrasen Mahakud

JOB HAZARD ANALYSIS

Doc No. QEHSMS/CSMS/JHA/01 REV: 02.00 EFF Date: 03/03/2017

W.O. No: 4700036930/962

Department &

Section OMQ,NIM, Noamundi

Location of Job: Mining Area

Job Description Safe Vehicle Operation of Bolero Campher

Team: Proprietor,Site Supervisor,Safety Officer

Sequence of

Potential Hazards Safeguard/ Controls to be put in place Responsibility

Basic Job Steps

Unauthorized 1. Contolled site entry.

Uncontrolled vehicle operation leading to

Driver taking 2. Gate Pass system in place Proprietor/TSL Incharge

collosion

Charge of Vehicle

1. Contolled site entry.

Alcoholic Uncontrolled vehicle operation leading to 2. Gate Pass system in place

Site Management

condition of driver collosion 3. Alcoholic test carried out at site entrance gate

1. Proper rotation of shift to be followed

Tiredness of driver Uncontrolled vehicle operation leading to

2. Number of drivers for no. of shifts to Site Management

while driving collosion

be employed

Vehicle Parked

Rolling down of Vehicle/Collosion to other

without applying Training awarness/Behavioural based safety check Driver

structures/run over

Hand Barakes

1. Proper functioning of temperature meter

2.Timely servicing at authorized servicing center

Malfunctioning of

3. Use of manufacturer recommended coolent

Temperature Chances of Fire due to overheating of engine Management

4. Vehicle check at startup using systematic

indicator

checklist

1. Routine servicing & check up

2. Proper maintenance of defect Log book

Vehicle steering Wheel movement not synchronized with the

3. Preventive maintenance at the manufacuturers Management

system not steering rotation which may lead to accident

recommended timeframe or detection of problem

functioning whichever is earlier

properly

1. Maintaining of defect Log book

2. Preventive maintenance at the manufacturers

AC system not Chances of Fire. It may be due to

recommended timeframe or detection of problem

functioning malfunctioning of temperature switch leading to Management

whichever is earlier

properly failure in startup of engine cooling system

3. Routine servicing and checkup at the startup of

vehicle using checklist

1. Assessment of the surrounding location and below

of the vehicle

2. Putting of the reverse gear without releasing the

Reversing of hand brakes

Run over/Collosion/upturning of vehicle Management

vehicle 3. Actuation of reverse alarm

4. Person should be instructed/discouraged from

getting around from the rear side of vehicle after

getting down

1. The vehicle must be checked before starting the

Vehicle started drive for peoples to be completely in or out of

while the people vehicle Supervisor/Safety

run over/injury to persons

getting down or 2. Training to be imparted to driver Officer

into the vehicle 3. Behavioural based safety to be assessed for the

driver

1. Training/Instruction to the driver

Overspeeding of 2. GPS system for speed monitoring installed in Supervisor/Safety

Run over/Collosion/upturning of vehicle

Vehicle vehicle Officer

3. Consequence management system in place

Poor Visibility due

1. Vehicle to be cleaned after each shift

to dust in the Run over/Collosion/upturning of vehicle Management

2. duster, cleaning shampoo provided in vehicle

windscreen

1. S.O.P. for tyre replacement to be followed

2. Screw jack to be placed directly under chassis of

Crushing of hand/feet under direct load due to the vehicle. Management

Replacement of

improper placement of screw Jack beneath the 3. Spanner to be used to loose the nuts of wheel by /Supervisor

Tyres

vehicle. Slippage of spanner leading to injury placing wheels under load and then employing the /Safety officer

screw jacks

4.Training/instruction to be given to drivers

1. Training/Instruction to the driver

Management

2. Consequence management system in place

Unsafe driving Run over/Collosion/upturning of vehicle /Supervisor

3. Seat belt to be used

/Safety officer

1. Trained driver to be employed

2. Vehicle should be vaccated in case there is

disbalancing

Unsafe dry road

Upturning of Vehicles 3. Emergency contact no. to be made readily Management

Condition

available

4. Flags mounted on vehicle for the easy

identification on the unlevelled areas

1. Trained driver to be employed

2. Vehicle should be vaccated in case there is

disbalancing

3. Emergency contact no. to be made readily

Muddy road Upturning of Vehicles/slippage and Supervisor/Safety

available

conditions collosion/sinking in the mud and getting stuck Officer

4. Flags mounted on vehicle for the easy

identification on the unlevelled areas

5. Rout hazards to be assessed in case of doubt

6. Speed to be mainatained at 20 Km/hr

1. Vehicle to be vaccated in gas station before filling

of diesel

Filling of diesel at Fire due to static electricity/Fire due to external 2. Mobile phone required to be switched off

Management

gas station source of fire 3. Smoking orother open source of flame to be

discouraged at gas station.

4. SOP to be made and delivered

1. Consequence management system to be

Using Mobile implemented

phones and text 2. SOP to be made and delivered

Collosion/accident Management

messaging while 3. Complain logging system to be incorporated

driving 4.Assessment tool for behavioural based safety to be

implemented

1. General traffic safety to be followed

2. Safe distance from other vehicle to be maintained

3. Trained driver with sufficient experience to be

Driving way back

Collosion/accident employed Management

to home

4. Road safety awarness by training/instruction to be

made

GPS system to be incorporated

1. Daily checkup system for lights to be

Malfunctioning of

incorporated

Lights/indicators

Collosion/accident 2. All Lights to be replaced immediatelty Management

during night

3. Fault complain log system to be incorporated

driving

PPEs: Safety Shoe, High Visibility reflective vests,Safety Tools: spanner, screw jack

helmets, nose mask, goggles

Approved By:

You might also like

- TAC Guideline-Fire Protection MANUALDocument81 pagesTAC Guideline-Fire Protection MANUALamit92% (13)

- PPR Pipe LossDocument86 pagesPPR Pipe Lossbernardsilvano71% (7)

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- General Lifting JHA SummaryDocument1 pageGeneral Lifting JHA Summarysujith s pNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- STD 184 Replacement of PpeDocument28 pagesSTD 184 Replacement of Ppeamit100% (1)

- Highway EngineeringDocument17 pagesHighway Engineeringnina lyn baladjay50% (6)

- Job Hazard Analysis (Jsa) WorksheetDocument5 pagesJob Hazard Analysis (Jsa) WorksheetAnson Chew Wai YinNo ratings yet

- Forklift Jha Move Pallets Loads Around YardDocument5 pagesForklift Jha Move Pallets Loads Around YardAhsan IqbalNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Rekap Ins PDFDocument1 pageRekap Ins PDFRachel Aurora ChrismeliaNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- HIRARC Update - HR CanteenDocument6 pagesHIRARC Update - HR CanteenDon McleanNo ratings yet

- Toolbox Talks 2Document100 pagesToolbox Talks 2Shafick GabungaNo ratings yet

- 3.ceiling Installation JSA ADocument2 pages3.ceiling Installation JSA APijah AhmadNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- HSE Bulletin # 78: "Preventing Snake Bites at Work"Document1 pageHSE Bulletin # 78: "Preventing Snake Bites at Work"Syed Faisal Hassan100% (2)

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Chemical Hazard Bulletin: Chemtronics Pow-R-Wash VZDocument1 pageChemical Hazard Bulletin: Chemtronics Pow-R-Wash VZHaleemUrRashidBangashNo ratings yet

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- OB Afety NalysisDocument5 pagesOB Afety NalysisNaveed WarraichNo ratings yet

- Permit To Work.r3Document4 pagesPermit To Work.r3jovannigballonNo ratings yet

- JHA (Rev) - Install New Genset On SPLMDocument4 pagesJHA (Rev) - Install New Genset On SPLMAditya Permana PutraNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- Job Safety Analysis & Risk Assessment For Scrapping and Grading ActivityDocument1 pageJob Safety Analysis & Risk Assessment For Scrapping and Grading ActivityAzhar Mushtaq100% (1)

- Template Site Specific ESH Safety SSEP PlanDocument12 pagesTemplate Site Specific ESH Safety SSEP PlanNarendraNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Accident Incident InvestigationDocument3 pagesAccident Incident InvestigationrehanNo ratings yet

- M010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFDocument66 pagesM010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFEldhose VargheseNo ratings yet

- Confined Space Rescue Plan: Closed Drain Area Closed Drain Drum Pit, Work PlatformDocument1 pageConfined Space Rescue Plan: Closed Drain Area Closed Drain Drum Pit, Work PlatformMohammed AbdallaNo ratings yet

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- Emptying Roll-Off Container - JHA - 12-5-2022Document3 pagesEmptying Roll-Off Container - JHA - 12-5-2022luis VelozNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- JHA For Excavation - JackhammerDocument4 pagesJHA For Excavation - JackhammerawadudalhassanNo ratings yet

- HiraDocument30 pagesHiravijay kumar singhNo ratings yet

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoe100% (1)

- Plant and Equipment Safety ProceduresDocument19 pagesPlant and Equipment Safety ProceduresfairusNo ratings yet

- Full Body Harness Checklist 安全带检查清单Document1 pageFull Body Harness Checklist 安全带检查清单m5wd2xggjwNo ratings yet

- SOPDocument8 pagesSOPAilyn MercadoNo ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- SAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XDocument13 pagesSAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XWhina R Ayma100% (1)

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- Training Session 2011: Training Subject: Training RoomDocument17 pagesTraining Session 2011: Training Subject: Training RoomSrikanth0% (1)

- Toolbox Talk CylindersDocument1 pageToolbox Talk CylindersAdel SukerNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Job Safety Analysis: Air Compressor OperationDocument2 pagesJob Safety Analysis: Air Compressor OperationVi VekNo ratings yet

- OCP For Handling of MaterialsDocument3 pagesOCP For Handling of MaterialsTigor GurningNo ratings yet

- Camp Inspection ReportDocument4 pagesCamp Inspection ReportgkNo ratings yet

- Step Activity Potential Hazards Hazard Controls NoDocument2 pagesStep Activity Potential Hazards Hazard Controls NoKazeneza BMNo ratings yet

- Risk Assessment: Kitchen - HomeDocument5 pagesRisk Assessment: Kitchen - HomesonofoddinNo ratings yet

- Arc Welding - JSADocument6 pagesArc Welding - JSAdroffilcz27No ratings yet

- Monthly Mass Meeting Agenda + Invitation 12 PageDocument1 pageMonthly Mass Meeting Agenda + Invitation 12 PageamitNo ratings yet

- SHE Incident Investigation FormDocument3 pagesSHE Incident Investigation Formrozeena9824No ratings yet

- Job Safety Analysis (JSA) : DefinitionDocument5 pagesJob Safety Analysis (JSA) : DefinitionMesut MahmutogluNo ratings yet

- SWP Working Safely at Height Version 2.01Document7 pagesSWP Working Safely at Height Version 2.01marvinNo ratings yet

- Safe Use of Chemicals: 1.0 PurposeDocument10 pagesSafe Use of Chemicals: 1.0 PurposeFuzail AyazNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- Monthly Mass Meeting Agenda + Invitation 12 PageDocument1 pageMonthly Mass Meeting Agenda + Invitation 12 PageamitNo ratings yet

- Std-203-Operation and Maintenance of Hoisting EquipmentDocument18 pagesStd-203-Operation and Maintenance of Hoisting EquipmentamitNo ratings yet

- Hira KSBDocument2 pagesHira KSBamitNo ratings yet

- STD 175 Cementing OperationsDocument31 pagesSTD 175 Cementing OperationsamitNo ratings yet

- STD 174 Well ControlDocument40 pagesSTD 174 Well ControlamitNo ratings yet

- Reactor 20Document1 pageReactor 20Kriengsak RuangdechNo ratings yet

- Service Manual: Washing Machine Frontloader AWL 643/2Document9 pagesService Manual: Washing Machine Frontloader AWL 643/2george-vinNo ratings yet

- Technically Suitable Antifreeze and Corrosion InhibitorsDocument3 pagesTechnically Suitable Antifreeze and Corrosion InhibitorsJerrin MathewNo ratings yet

- Seismic RetrofittingDocument21 pagesSeismic Retrofittinglisan2053No ratings yet

- Mini Table Saw ProjectDocument17 pagesMini Table Saw ProjectnageshNo ratings yet

- CH-1 Structural Design of RCC Building ComponentsDocument74 pagesCH-1 Structural Design of RCC Building ComponentsPrabhat Kumar100% (1)

- Performance Based Design For Fire SafetyDocument23 pagesPerformance Based Design For Fire SafetyTharanga Pradeep100% (1)

- Phase 1 Mechanical Addendum 1Document2 pagesPhase 1 Mechanical Addendum 1Amgad Yousri El RayaniNo ratings yet

- Formula R1 Racing - Explosionszeichnungen Und Adapter PDFDocument9 pagesFormula R1 Racing - Explosionszeichnungen Und Adapter PDFIBC_TobiNo ratings yet

- Schilthuis, R.J. Active Oil and Reservoir EnergyDocument20 pagesSchilthuis, R.J. Active Oil and Reservoir EnergySolenti D'nouNo ratings yet

- NPR040 Horizontal Bladder Tank SystemDocument6 pagesNPR040 Horizontal Bladder Tank SystemRomner CordovaNo ratings yet

- Review of Cylinder Blockvalve Plate Interface in ADocument24 pagesReview of Cylinder Blockvalve Plate Interface in Adaominhthongb2No ratings yet

- FULLPAPERDocument21 pagesFULLPAPERShir AtiaNo ratings yet

- TP 5941Document48 pagesTP 5941rickNo ratings yet

- Y-Strainer: Flanged EndsDocument2 pagesY-Strainer: Flanged Endsamir shokrNo ratings yet

- 410J Backhoe Loader IntroductionDocument7 pages410J Backhoe Loader IntroductionEgner Gustavo Quintero RiosNo ratings yet

- Briggs 13,5hp - 21B800 PDFDocument13 pagesBriggs 13,5hp - 21B800 PDFnarciso84traninNo ratings yet

- Basic Terms For Mechanical EngineeringDocument8 pagesBasic Terms For Mechanical EngineeringVivekavardhan RachakondaNo ratings yet

- SADT HT-225A User Manual PDFDocument20 pagesSADT HT-225A User Manual PDFDayane GomesNo ratings yet

- Effect of Dents in PipelinesDocument9 pagesEffect of Dents in PipelinesAnonymous avGU1iNo ratings yet

- Diltancy AngleDocument7 pagesDiltancy AngleGopal PNo ratings yet

- 02 SpecificationsDocument194 pages02 SpecificationsNabeel Adeeb Alshare100% (1)

- Lysaght W-Dek - User GuideDocument6 pagesLysaght W-Dek - User Guidemr_chowNo ratings yet

- Rolling MillsDocument11 pagesRolling MillsSudhir KumarNo ratings yet

- Article Understanding and Preventing Turbine OverspeedDocument14 pagesArticle Understanding and Preventing Turbine OverspeedTan Nguyen HuuNo ratings yet

- CHE 3313 - Lab 07 - Boiler EfficiencyDocument7 pagesCHE 3313 - Lab 07 - Boiler EfficiencykhalifaNo ratings yet

- PHL 500Document4 pagesPHL 500dharwinNo ratings yet

- Heat Engines ME111Document43 pagesHeat Engines ME111Arct John Alfante Zamora100% (1)