Professional Documents

Culture Documents

Trouble Shooting

Trouble Shooting

Uploaded by

Siddharth GhorpadeCopyright:

Available Formats

You might also like

- GRP Tank Calculator, Sands Civil Services Estimation To BS 4994Document2 pagesGRP Tank Calculator, Sands Civil Services Estimation To BS 4994Sung Woong Moon100% (1)

- Standard Wire Gauge (SWG) Conversion To MetricDocument1 pageStandard Wire Gauge (SWG) Conversion To Metricmani317No ratings yet

- Datasheet 1x19 Stainless Steel Strand Wire RopeDocument1 pageDatasheet 1x19 Stainless Steel Strand Wire RopePrattyNo ratings yet

- Questions On HealthDocument3 pagesQuestions On HealthDario RomoNo ratings yet

- Exp 14 GraphDocument3 pagesExp 14 GraphnazurahainurNo ratings yet

- American Conductor StrandingDocument1 pageAmerican Conductor Strandingkariboo karibooxNo ratings yet

- Ohm's Law IDocument6 pagesOhm's Law IAndre JohnsonNo ratings yet

- Enthalpy of Dilution of Acids: H, The Negative of TheDocument1 pageEnthalpy of Dilution of Acids: H, The Negative of TheantonioNo ratings yet

- A. Steel Reinforcement Information: A.1. ASTM Standard Reinforcing BarsDocument4 pagesA. Steel Reinforcement Information: A.1. ASTM Standard Reinforcing Barsnick gomezNo ratings yet

- Curva de Calibración: Concentracion G/LDocument5 pagesCurva de Calibración: Concentracion G/LmariNo ratings yet

- Correccion: 6.00 7.00 F (X) 0.726895698x + 0.0736424496 R 0.9883306912 Correccion Linear (Correccion)Document9 pagesCorreccion: 6.00 7.00 F (X) 0.726895698x + 0.0736424496 R 0.9883306912 Correccion Linear (Correccion)lolaNo ratings yet

- Frigate ResistanceDocument2 pagesFrigate ResistancemxNoNameNo ratings yet

- Voltage Drop in Transmission LinesDocument1 pageVoltage Drop in Transmission LinesPradeep SinghNo ratings yet

- Wind Tunnel ReportDocument15 pagesWind Tunnel ReportedmundcyqNo ratings yet

- Examen PracticaDocument3 pagesExamen PracticaWendy Paola Chica SimancaNo ratings yet

- Wire Gauges - Current RatingsDocument1 pageWire Gauges - Current RatingsluixfoNo ratings yet

- Indicators NoDocument5 pagesIndicators NoDario RomoNo ratings yet

- 0.029 F (X) 0.2133695052x - 0.1360856179 R 0.9952345266: Voltaje (V)Document4 pages0.029 F (X) 0.2133695052x - 0.1360856179 R 0.9952345266: Voltaje (V)Angie Mendoza VargasNo ratings yet

- Stress Strain Curve-1Document5 pagesStress Strain Curve-1AsadNo ratings yet

- Software Exercise 1Document14 pagesSoftware Exercise 1MeraNo ratings yet

- Graficas de TermodinamicaDocument3 pagesGraficas de TermodinamicaKevin GarciaNo ratings yet

- 1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4Document8 pages1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4jdserpa.0617No ratings yet

- American Strand ConstructionDocument1 pageAmerican Strand Constructionpratul acharyaNo ratings yet

- V E Denta: Chart TitleDocument45 pagesV E Denta: Chart TitleThị Hoa Nhài LêNo ratings yet

- FORM VDrop - CalculationDocument9 pagesFORM VDrop - Calculationef.sofyaNo ratings yet

- T Distribution TableDocument1 pageT Distribution TableEesha MusicNo ratings yet

- Assignment Fluid2Document8 pagesAssignment Fluid2Amier AziziNo ratings yet

- Resistance Calculations.: Delft Series ('98)Document2 pagesResistance Calculations.: Delft Series ('98)Joseph IsraelNo ratings yet

- EIRT Siswa EvaluasiDocument351 pagesEIRT Siswa EvaluasiDimas Fadili RohmanNo ratings yet

- Curva de Margules: P (MMHG) X1 Y1 X2 Y2 Ɣ1 Ɣ2Document17 pagesCurva de Margules: P (MMHG) X1 Y1 X2 Y2 Ɣ1 Ɣ2José Leonardo Fernández BalderaNo ratings yet

- Detailed Description of Electronics MenuDocument37 pagesDetailed Description of Electronics MenuSmart BiomedicalNo ratings yet

- Chart Title: Data SD NGDocument14 pagesChart Title: Data SD NGapi-909072No ratings yet

- Poro-Perm GraphDocument7 pagesPoro-Perm GraphJordan WongNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Laying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex EDocument2 pagesLaying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex Elk RentalNo ratings yet

- Pka Grupo 12Document6 pagesPka Grupo 12Patricia Mora NicolásNo ratings yet

- Variance Explained: Dimensions / ItemsDocument14 pagesVariance Explained: Dimensions / ItemsAditi AgrawalNo ratings yet

- Sheet Metal and English Standard Wire Gauge, SWG Sheet Metal and English Standard Wire Gauge, SWGDocument1 pageSheet Metal and English Standard Wire Gauge, SWG Sheet Metal and English Standard Wire Gauge, SWGbalabaskaran1983No ratings yet

- Valvulas de ControlDocument6 pagesValvulas de ControlMoufid AbdulNo ratings yet

- Gráfico 1. SO2-Aire-AguaDocument8 pagesGráfico 1. SO2-Aire-AguaRamon CruzNo ratings yet

- Resistance According To Delft Series ('98) : V V FN RF RR Rtotal PeDocument2 pagesResistance According To Delft Series ('98) : V V FN RF RR Rtotal Pegreicel marianjas sihombingNo ratings yet

- Alloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)Document5 pagesAlloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)SachinNo ratings yet

- Preliminary Result - 04dec22Document2 pagesPreliminary Result - 04dec22Wison YangNo ratings yet

- سيف الدين خالد قاسم 1Document1 pageسيف الدين خالد قاسم 1Saif QasemNo ratings yet

- Case SCAL Minggu 1 - Ahmad Akbar - 012 - Plug GDocument57 pagesCase SCAL Minggu 1 - Ahmad Akbar - 012 - Plug GFREE ZONENo ratings yet

- 207.52 STT Thời gian (phút) Khối lượng khay và VL (g) Khối lượng VL (g) W MDocument13 pages207.52 STT Thời gian (phút) Khối lượng khay và VL (g) Khối lượng VL (g) W MNguyễn PhanNo ratings yet

- Obs. TableDocument2 pagesObs. Tablemanoj_varma_1No ratings yet

- Spears - PIPE SCH80Document1 pageSpears - PIPE SCH80F. AhmadNo ratings yet

- Fkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224Document3 pagesFkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224GregoriusTimothyNo ratings yet

- Referensi Wire - Enamel Wire Type (Thickness STD) - 20160302Document4 pagesReferensi Wire - Enamel Wire Type (Thickness STD) - 20160302Fahmi Januar AnugrahNo ratings yet

- Laying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex EDocument2 pagesLaying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex Elk RentalNo ratings yet

- 168Document1 page168Raed fouadNo ratings yet

- Chart TitleDocument3 pagesChart Title方宣詠No ratings yet

- NDS - Dilution Conversion Chart PDFDocument1 pageNDS - Dilution Conversion Chart PDFwahyu perdanaNo ratings yet

- Gráficos 3Document4 pagesGráficos 3Juan CampusanoNo ratings yet

- Gráficos 3Document4 pagesGráficos 3Juan CampusanoNo ratings yet

- Gráficos 27Document4 pagesGráficos 27Juan CampusanoNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Part Tree-052016Document1 pagePart Tree-052016Siddharth GhorpadeNo ratings yet

- Experimental StressDocument18 pagesExperimental Stresssuganthi1711No ratings yet

- Liquid Cooling - Thermal Analysis of A Cold PlateDocument2 pagesLiquid Cooling - Thermal Analysis of A Cold PlateSiddharth GhorpadeNo ratings yet

- Analytical Estimation of Elastic Properties of Polypropylene Fiber Matrix Composite by Finite Element AnalysisDocument8 pagesAnalytical Estimation of Elastic Properties of Polypropylene Fiber Matrix Composite by Finite Element AnalysisSiddharth GhorpadeNo ratings yet

- Introduction To Stiffness AnalysisDocument40 pagesIntroduction To Stiffness AnalysisSiddharth GhorpadeNo ratings yet

- Intellectual Property Rights: Theory & Indian Practice: Garima Gupta & Avih RastogiDocument11 pagesIntellectual Property Rights: Theory & Indian Practice: Garima Gupta & Avih RastogiLEX-57 the lex engineNo ratings yet

- Ipasset ManagementDocument48 pagesIpasset ManagementSiddharth GhorpadeNo ratings yet

- Different Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsDocument2 pagesDifferent Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsSiddharth GhorpadeNo ratings yet

- Fundamentals of CADD PDFDocument4 pagesFundamentals of CADD PDFSiddharth GhorpadeNo ratings yet

- Waterborne Coatings: Regulatory ChangesDocument4 pagesWaterborne Coatings: Regulatory ChangesSiddharth GhorpadeNo ratings yet

- The Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaDocument11 pagesThe Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaSiddharth GhorpadeNo ratings yet

- Inspection Tutorial Sheet Metal PartDocument16 pagesInspection Tutorial Sheet Metal PartPaulo Roberto SilvaNo ratings yet

- Astm F2019Document13 pagesAstm F2019Mohammadreza KiyanNo ratings yet

- Candy Ce823tDocument19 pagesCandy Ce823tAdrian CastelliNo ratings yet

- Syphon Aqueduct Type IIIDocument10 pagesSyphon Aqueduct Type IIIBibhuti Bhusan SahooNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- Shaker Tables 2Document37 pagesShaker Tables 2William Wehner100% (10)

- Mortar and GroutDocument47 pagesMortar and GroutSangwa StevenNo ratings yet

- Multispan DesignDocument4 pagesMultispan DesignJohn WayneNo ratings yet

- Series Abo 300: DN 50 - DN 600 (2" - 24") PN 10Document12 pagesSeries Abo 300: DN 50 - DN 600 (2" - 24") PN 10Vignesh NadimuthuNo ratings yet

- BOQ From (HVAC)Document26 pagesBOQ From (HVAC)Neeta Samir Munj ParkarNo ratings yet

- 1 VFVFFDocument10 pages1 VFVFFIslam M. RedaNo ratings yet

- ErmetoDocument28 pagesErmetoRickson Viahul Rayan C100% (1)

- Ebarra Pump SpecsDocument13 pagesEbarra Pump SpecsLiz BargolaNo ratings yet

- Lecture 9 PPE Extra Practice Questions Set 2Document2 pagesLecture 9 PPE Extra Practice Questions Set 2xu xuanNo ratings yet

- Applsci 12 03547Document26 pagesApplsci 12 03547Bahaa HussainNo ratings yet

- GH10 Series 303 Stainless SteelDocument3 pagesGH10 Series 303 Stainless SteelUsman ArshadNo ratings yet

- Site Analysis: Floyd Zimmerman, FASLADocument11 pagesSite Analysis: Floyd Zimmerman, FASLAJames Joel Mendoza Santa CruzNo ratings yet

- Hoke 79 Series Rotary Air Control ValveDocument3 pagesHoke 79 Series Rotary Air Control ValveDaniel QuirozNo ratings yet

- Cost Estimation For HighwaysDocument162 pagesCost Estimation For HighwaysWaqar Ahmad MalikNo ratings yet

- Ultimate Load Capacity of Reinforced Concrete SlabDocument8 pagesUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- Section 1 PDFDocument438 pagesSection 1 PDFAnfal BarbhuiyaNo ratings yet

- Environmental Protection and ManagementDocument10 pagesEnvironmental Protection and ManagementparathasiNo ratings yet

- Botai Stage Truss Price List 2023-1Document6 pagesBotai Stage Truss Price List 2023-1Vlady ZamoranoNo ratings yet

- Kalani 1C XLPE CableDocument3 pagesKalani 1C XLPE CableNawarathna Engineering Dept.No ratings yet

- Mah. Act 3 of 2007 The Maha. Fire Prevention & LSM Act-2006Document63 pagesMah. Act 3 of 2007 The Maha. Fire Prevention & LSM Act-2006Priya Vishvanathan AjayNo ratings yet

- Engineer Estimate ManualDocument24 pagesEngineer Estimate ManualNes-tValdezNo ratings yet

- Geomtric DesignDocument41 pagesGeomtric DesignOshada AttygalleNo ratings yet

- Solarban 60 Short Form Specs Final 11 23 20Document10 pagesSolarban 60 Short Form Specs Final 11 23 20Jesse TarrNo ratings yet

- Skid Strength Calculation (1St Saddle)Document1 pageSkid Strength Calculation (1St Saddle)cwkimNo ratings yet

- Form NEW TSR 2016Document2 pagesForm NEW TSR 2016Ega YudhaNo ratings yet

Trouble Shooting

Trouble Shooting

Uploaded by

Siddharth GhorpadeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble Shooting

Trouble Shooting

Uploaded by

Siddharth GhorpadeCopyright:

Available Formats

Tube selection and Ref. No.

H09821

Trouble shooting guide Release. Apr.2008

the right connection

General Recommendations for Tubes

Steel Type St 37.4

Tensile Strength 340 N/mm2

Yield point 235 N/mm2

Condition Seamless, Cold drawn, normal annealed as per DIN 2391C, Part 2

Stainless Steel 1.4571

Tensile Strength 500 N/mm2

Yield point 245 N/mm2

Condition Seamless, Cold drawn, free of scale as per DIN 17458 tab.6

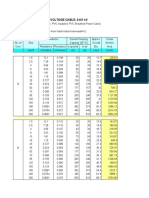

Seamless Steel Tubes Material : St. 37.4

Tolerances DIN 2391, part 1

Design Pressure (bar)

Tube Wall Tube Burst

DIN2413 DIN 2413 Weight

O.D Tolerance Thickness I.D Pressure

I III kg/m

(mm) (mm) (mm) (bar)

Static Dynamic

4 0.50 3.0 313 273 1160 0.047

4 ±0.08 0.75 2.5 409 391 1820 0.063

4 1.00 2.0 522 500 2700 0.074

5 ±0.08 1.00 3.0 432 416 2120 0.099

6 0.75 4.5 333 288 1150 0.103

6 1.00 4.0 389 372 1650 0.123

6 ±0.08 1.50 3.0 549 526 2550 0.166

6 2.00 2.0 692 662 >3500 0.197

6 2.50 1.0 757 725 >3500 0.208

8 1.00 6.0 333 288 1175 0.222

8 1.50 5.0 431 412 1925 0.240

±0.08

8 2.00 4.0 549 526 2500 0.296

8 2.50 3.0 658 630 2650 0.339

10 1.00 8.0 282 248 900 0.222

10 1.50 7.0 373 357 1450 0.314

10 ±0.08 2.00 6.0 478 458 2025 0.395

10 2.50 5.0 576 551 2675 0.462

10 3.00 4.0 666 638 >3500 0.518

12 1.00 10.0 253 209 750 0.271

12 1.50 9.0 353 303 1150 0.388

12 2.00 8.0 409 391 1600 0.493

±0.08

12 2.50 7.0 495 474 2025 0.586

12 3.00 6.0 576 551 2600 0.666

12 3.50 5.0 651 624 --- 0.734

14 1.50 11.0 302 264 975 0.462

14 2.00 10.0 357 342 1325 0.592

14 ±0.08 2.50 9.0 434 415 1650 0.709

14 3.00 8.0 507 485 2200 0.814

14 3.50 7.0 576 551 2625 0.906

15 1.00 13.0 188 170 575 0.345

15 1.50 12.0 282 248 950 0.499

±0.08

15 2.00 11.0 336 321 1275 0.641

15 3.00 9.0 478 458 2000 0.888

16 1.50 13.0 264 233 850 0.536

16 2.00 12.0 353 303 1175 0.691

±0.08

16 2.50 11.0 386 370 1500 0.832

16 3.00 10.0 452 433 1850 0.962

18 1.00 16.0 157 143 450 0.419

18 1.50 15.0 235 209 700 0.610

18 ±0.08 2.00 14.0 313 273 975 0.789

18 2.50 13.0 348 333 1300 0.956

18 3.00 12.0 409 391 1575 1.111

88, Machhe Industrial Estate, Machhe, Belgaum 590 014

Tel : +91 831 241 2777 Fax : +91 831 241 2784

An ISO 9001 : 2000 and ISO 14001 : 2004 Copany e-mail : sales@hyloc.co.in web : www.hyloc.co.in

Tube selection and Ref. No. H09821

Trouble shooting guide Release. Apr.2008

the right connection

Seamless Steel Tubes (continued) Material : St. 37.4

Tolerances DIN 2391, part 1

Design Pressure (bar)

Tube Wall Tube Burst

DIN2413 DIN 2413 Weight

O.D Tolerance thickness I.D Pressure

1 III kg/m

(mm) (mm) (mm) (bar)

Static Dynamic

20 1.50 17 212 190 675 0.648

20 2.00 16 282 248 900 0.888

20 2.50 15 353 303 1100 1.079

20 3.00 14 373 357 1400 1.258

20 3.50 13 426 408 1650 1.424

20 ±0.08 4.00 12 478 458 2000 1.578

22 1.50 19 192 173 550 0.758

22 2.00 18 256 227 775 0.986

22 2.50 17 320 278 1025 1.202

22 ±0.08 3.00 16 343 328 1175 1.406

25 2.00 21 226 201 725 1.134

25 2.50 20 282 248 850 1.387

25 3.00 19 338 292 1025 1.628

25 4.00 17 394 378 1500 2.072

25 ±0.08 4.50 16 437 418 1625 2.275

28 1.50 25 151 138 425 0.98

28 2.00 24 201 181 600 1.282

28 2.50 23 252 223 750 1.572

28 ±0.08 3.00 22 302 264 900 1.85

30 ±0.08 2.00 26 188 170 575 1.381

30 2.50 25 235 209 725 1.695

30 3.00 24 282 248 850 1.998

30 4.00 22 336 321 1175 2.565

30 5.00 20 409 391 1600 3.083

35 2.00 31 161 147 450 1.628

35 2.50 30 201 181 600 2.004

35 3.00 29 242 215 700 2.367

35 ±0.15 4.00 27 322 280 960 3.058

38 2.50 33 186 168 550 2.189

38 3.00 32 223 199 675 2.589

38 4.00 30 297 260 900 3.354

38 5.00 28 332 318 1150 4.069

38 6.00 26 390 373 --- 4.735

38 ±0.15 7.00 24 446 427 1700 5.325

42 2.00 38 134 123 375 1.973

42 3.00 36 201 181 575 2.885

42 ±0.2 4.00 34 269 237 850 3.749

50 ±0.2 6.00 38 338 292 --- 6.511

65 ±0.3 8.00 49 347 299 --- 11.246

Surface finish:

Phosphated and Oiled.

Tubes with ID 1.5 to 5.0 mm, outside and inside oiled.

Tubes from 6mm ID, outside and inside, phosphated and oiled.

Zinc plated Yellow.

Coating thickness 8 to 12 microns.

88, Machhe Industrial Estate, Machhe, Belgaum 590 014

Tel : +91 831 241 2777 Fax : +91 831 241 2784

An ISO 9001 : 2000 and ISO 14001 : 2004 Copany e-mail : sales@hyloc.co.in web : www.hyloc.co.in

Tube selection and Ref. No. H09821

Trouble shooting guide Release. Apr.2008

the right connection

Seamless Stainless steel Tubes Material No. 1.4571/1.4541

Tolerances DIN 2391, part 1

1.4571 1.4571

Design Design 1.4571

Tube Wall Tube

Pressure Pressure Burst Weight

OD Tolerance thickness ID

(bar) (bar) Pressure kg/m

(mm) (mm) (mm)

DIN 2413-1 DIN 2413-1 (bar)

Static Static

4 ±0.08 1.0 2.0 600 539 0.075

6 1.0 4.0 426 383 1850 0.125

±0.08

6 1.5 3.0 600 539 2900 0.169

8 1.0 6.0 368 297 1300 0.175

±0.08

8 1.5 5.0 472 424 2050 0.244

10 1.0 8.0 294 242 950 0.225

10 ±0.08 1.5 7.0 389 349 1750 0.319

10 2.0 6.0 498 447 2400 0.401

12 1.0 10.0 245 205 850 0.275

12 ±0.08 1.5 9.0 368 297 1400 0.394

12 2.0 8.0 426 383 1900 0.501

14 1.5 11.0 315 258 1200 0.469

14 ±0.08 2.0 10.0 420 334 1550 0.601

14 2.5 9.0 452 406 2100 0.720

15 1.0 13.0 196 166 675 0.351

15 ±0.08 1.5 12.0 294 242 1100 0.507

15 2.0 11.0 392 314 1400 0.651

16 1.5 13.0 276 228 950 0.545

16 2.0 12.0 368 297 1300 0.701

±0.08

16 2.5 11.0 403 362 1850 0.845

16 3.0 10.0 472 424 2400 0.977

18 1.5 15.0 245 205 800 0.620

±0.08

18 2.0 14.0 327 267 1150 0.801

20 2.0 16.0 294 242 1050 0.901

20 ±0.08 2.5 15.0 368 297 1400 1.095

20 3.0 14.0 389 349 1800 1.277

22 1.5 19.0 200 170 650 0.770

±0.08

22 2.0 18.0 267 222 900 1.002

25 2.5 20.0 294 242 1050 1.408

±0.08

25 3.0 19.0 353 286 1275 1.653

28 1.5 25.0 158 135 550 0.995

±0.08

28 2.0 24.0 210 177 700 1.302

30 2.5 25.0 245 205 850 1.722

30 ±0.08 3.0 24.0 294 242 1150 2.028

30 4.0 22.0 392 314 1500 2.605

35 ±0.15 2.0 31.0 168 143 550 1.653

38 ±0.15 4.0 30.0 309 254 1150 3.405

42 2.0 38.0 140 121 475 2.003

±0.20

42 3.0 36.0 210 177 750 2.930

88, Machhe Industrial Estate, Machhe, Belgaum 590 014

Tel : +91 831 241 2777 Fax : +91 831 241 2784

An ISO 9001 : 2000 and ISO 14001 : 2004 Copany e-mail : sales@hyloc.co.in web : www.hyloc.co.in

Tube selection and Ref. No. H09821

Trouble shooting guide Release. Apr.2008

the right connection

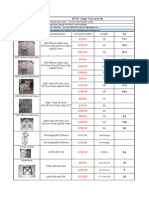

Trouble Shooting

Problem Probable Cause Suggested solution

Leak Tightening of the joint is not Tighten the nut according to the correct

adequate. assembly procedure.

Use suitable spanners and spanner

extensions especially for larger sizes.

Check visible collar after tightening.

Tube not bottomed into Cut tube to correct length.

fitting shoulder. Observe min. straight length before tube

bending.

Deburr tube ends – No heavy chamfers are

to be provided.

Damaged fitting Check for damage.

Handle all parts carefully.

Hidden cracks Check for cracks, replace if necessary.

Contaminations between Keep all components clean.

sealing surfaces

Shallow bite Inspect for the turned up ridge of the

material. Failure to achieve this ridge can

be traced either to the nut not being

tightened enough or tube not being

bottomed against the stop.

Over set ferrule Too much pressure or more than

recommended turns from finger tight.This

type of assembly should be scrapped.

No bite If all of the prior checks have been made

and the ferrule still shows no sign of biting

the tube, it may be that the Tube is too

hard. This assembly should be scrapped.

Tube fractured Fatigue failure of tube under Verify assembly. Undertightening reduces

behind the nut vibration vibration resistance.

Use proper clamps at appropriate places.

Crack Tightening of the joint is not Tighten the nut according to the correct

adequate assembly procedure.

Use suitable spanners and spanner

extensions especially for larger sizes

Check visible collar after tightening.

88, Machhe Industrial Estate, Machhe, Belgaum 590 014

Tel : +91 831 241 2777 Fax : +91 831 241 2784

An ISO 9001 : 2000 and ISO 14001 : 2004 Copany e-mail : sales@hyloc.co.in web : www.hyloc.co.in

You might also like

- GRP Tank Calculator, Sands Civil Services Estimation To BS 4994Document2 pagesGRP Tank Calculator, Sands Civil Services Estimation To BS 4994Sung Woong Moon100% (1)

- Standard Wire Gauge (SWG) Conversion To MetricDocument1 pageStandard Wire Gauge (SWG) Conversion To Metricmani317No ratings yet

- Datasheet 1x19 Stainless Steel Strand Wire RopeDocument1 pageDatasheet 1x19 Stainless Steel Strand Wire RopePrattyNo ratings yet

- Questions On HealthDocument3 pagesQuestions On HealthDario RomoNo ratings yet

- Exp 14 GraphDocument3 pagesExp 14 GraphnazurahainurNo ratings yet

- American Conductor StrandingDocument1 pageAmerican Conductor Strandingkariboo karibooxNo ratings yet

- Ohm's Law IDocument6 pagesOhm's Law IAndre JohnsonNo ratings yet

- Enthalpy of Dilution of Acids: H, The Negative of TheDocument1 pageEnthalpy of Dilution of Acids: H, The Negative of TheantonioNo ratings yet

- A. Steel Reinforcement Information: A.1. ASTM Standard Reinforcing BarsDocument4 pagesA. Steel Reinforcement Information: A.1. ASTM Standard Reinforcing Barsnick gomezNo ratings yet

- Curva de Calibración: Concentracion G/LDocument5 pagesCurva de Calibración: Concentracion G/LmariNo ratings yet

- Correccion: 6.00 7.00 F (X) 0.726895698x + 0.0736424496 R 0.9883306912 Correccion Linear (Correccion)Document9 pagesCorreccion: 6.00 7.00 F (X) 0.726895698x + 0.0736424496 R 0.9883306912 Correccion Linear (Correccion)lolaNo ratings yet

- Frigate ResistanceDocument2 pagesFrigate ResistancemxNoNameNo ratings yet

- Voltage Drop in Transmission LinesDocument1 pageVoltage Drop in Transmission LinesPradeep SinghNo ratings yet

- Wind Tunnel ReportDocument15 pagesWind Tunnel ReportedmundcyqNo ratings yet

- Examen PracticaDocument3 pagesExamen PracticaWendy Paola Chica SimancaNo ratings yet

- Wire Gauges - Current RatingsDocument1 pageWire Gauges - Current RatingsluixfoNo ratings yet

- Indicators NoDocument5 pagesIndicators NoDario RomoNo ratings yet

- 0.029 F (X) 0.2133695052x - 0.1360856179 R 0.9952345266: Voltaje (V)Document4 pages0.029 F (X) 0.2133695052x - 0.1360856179 R 0.9952345266: Voltaje (V)Angie Mendoza VargasNo ratings yet

- Stress Strain Curve-1Document5 pagesStress Strain Curve-1AsadNo ratings yet

- Software Exercise 1Document14 pagesSoftware Exercise 1MeraNo ratings yet

- Graficas de TermodinamicaDocument3 pagesGraficas de TermodinamicaKevin GarciaNo ratings yet

- 1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4Document8 pages1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4jdserpa.0617No ratings yet

- American Strand ConstructionDocument1 pageAmerican Strand Constructionpratul acharyaNo ratings yet

- V E Denta: Chart TitleDocument45 pagesV E Denta: Chart TitleThị Hoa Nhài LêNo ratings yet

- FORM VDrop - CalculationDocument9 pagesFORM VDrop - Calculationef.sofyaNo ratings yet

- T Distribution TableDocument1 pageT Distribution TableEesha MusicNo ratings yet

- Assignment Fluid2Document8 pagesAssignment Fluid2Amier AziziNo ratings yet

- Resistance Calculations.: Delft Series ('98)Document2 pagesResistance Calculations.: Delft Series ('98)Joseph IsraelNo ratings yet

- EIRT Siswa EvaluasiDocument351 pagesEIRT Siswa EvaluasiDimas Fadili RohmanNo ratings yet

- Curva de Margules: P (MMHG) X1 Y1 X2 Y2 Ɣ1 Ɣ2Document17 pagesCurva de Margules: P (MMHG) X1 Y1 X2 Y2 Ɣ1 Ɣ2José Leonardo Fernández BalderaNo ratings yet

- Detailed Description of Electronics MenuDocument37 pagesDetailed Description of Electronics MenuSmart BiomedicalNo ratings yet

- Chart Title: Data SD NGDocument14 pagesChart Title: Data SD NGapi-909072No ratings yet

- Poro-Perm GraphDocument7 pagesPoro-Perm GraphJordan WongNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Laying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex EDocument2 pagesLaying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex Elk RentalNo ratings yet

- Pka Grupo 12Document6 pagesPka Grupo 12Patricia Mora NicolásNo ratings yet

- Variance Explained: Dimensions / ItemsDocument14 pagesVariance Explained: Dimensions / ItemsAditi AgrawalNo ratings yet

- Sheet Metal and English Standard Wire Gauge, SWG Sheet Metal and English Standard Wire Gauge, SWGDocument1 pageSheet Metal and English Standard Wire Gauge, SWG Sheet Metal and English Standard Wire Gauge, SWGbalabaskaran1983No ratings yet

- Valvulas de ControlDocument6 pagesValvulas de ControlMoufid AbdulNo ratings yet

- Gráfico 1. SO2-Aire-AguaDocument8 pagesGráfico 1. SO2-Aire-AguaRamon CruzNo ratings yet

- Resistance According To Delft Series ('98) : V V FN RF RR Rtotal PeDocument2 pagesResistance According To Delft Series ('98) : V V FN RF RR Rtotal Pegreicel marianjas sihombingNo ratings yet

- Alloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)Document5 pagesAlloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)SachinNo ratings yet

- Preliminary Result - 04dec22Document2 pagesPreliminary Result - 04dec22Wison YangNo ratings yet

- سيف الدين خالد قاسم 1Document1 pageسيف الدين خالد قاسم 1Saif QasemNo ratings yet

- Case SCAL Minggu 1 - Ahmad Akbar - 012 - Plug GDocument57 pagesCase SCAL Minggu 1 - Ahmad Akbar - 012 - Plug GFREE ZONENo ratings yet

- 207.52 STT Thời gian (phút) Khối lượng khay và VL (g) Khối lượng VL (g) W MDocument13 pages207.52 STT Thời gian (phút) Khối lượng khay và VL (g) Khối lượng VL (g) W MNguyễn PhanNo ratings yet

- Obs. TableDocument2 pagesObs. Tablemanoj_varma_1No ratings yet

- Spears - PIPE SCH80Document1 pageSpears - PIPE SCH80F. AhmadNo ratings yet

- Fkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224Document3 pagesFkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224GregoriusTimothyNo ratings yet

- Referensi Wire - Enamel Wire Type (Thickness STD) - 20160302Document4 pagesReferensi Wire - Enamel Wire Type (Thickness STD) - 20160302Fahmi Januar AnugrahNo ratings yet

- Laying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex EDocument2 pagesLaying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex Elk RentalNo ratings yet

- 168Document1 page168Raed fouadNo ratings yet

- Chart TitleDocument3 pagesChart Title方宣詠No ratings yet

- NDS - Dilution Conversion Chart PDFDocument1 pageNDS - Dilution Conversion Chart PDFwahyu perdanaNo ratings yet

- Gráficos 3Document4 pagesGráficos 3Juan CampusanoNo ratings yet

- Gráficos 3Document4 pagesGráficos 3Juan CampusanoNo ratings yet

- Gráficos 27Document4 pagesGráficos 27Juan CampusanoNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Part Tree-052016Document1 pagePart Tree-052016Siddharth GhorpadeNo ratings yet

- Experimental StressDocument18 pagesExperimental Stresssuganthi1711No ratings yet

- Liquid Cooling - Thermal Analysis of A Cold PlateDocument2 pagesLiquid Cooling - Thermal Analysis of A Cold PlateSiddharth GhorpadeNo ratings yet

- Analytical Estimation of Elastic Properties of Polypropylene Fiber Matrix Composite by Finite Element AnalysisDocument8 pagesAnalytical Estimation of Elastic Properties of Polypropylene Fiber Matrix Composite by Finite Element AnalysisSiddharth GhorpadeNo ratings yet

- Introduction To Stiffness AnalysisDocument40 pagesIntroduction To Stiffness AnalysisSiddharth GhorpadeNo ratings yet

- Intellectual Property Rights: Theory & Indian Practice: Garima Gupta & Avih RastogiDocument11 pagesIntellectual Property Rights: Theory & Indian Practice: Garima Gupta & Avih RastogiLEX-57 the lex engineNo ratings yet

- Ipasset ManagementDocument48 pagesIpasset ManagementSiddharth GhorpadeNo ratings yet

- Different Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsDocument2 pagesDifferent Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsSiddharth GhorpadeNo ratings yet

- Fundamentals of CADD PDFDocument4 pagesFundamentals of CADD PDFSiddharth GhorpadeNo ratings yet

- Waterborne Coatings: Regulatory ChangesDocument4 pagesWaterborne Coatings: Regulatory ChangesSiddharth GhorpadeNo ratings yet

- The Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaDocument11 pagesThe Beginning of A New Chapter in India's Automotive Saga: Vikas Tiwari Pradeep VermaSiddharth GhorpadeNo ratings yet

- Inspection Tutorial Sheet Metal PartDocument16 pagesInspection Tutorial Sheet Metal PartPaulo Roberto SilvaNo ratings yet

- Astm F2019Document13 pagesAstm F2019Mohammadreza KiyanNo ratings yet

- Candy Ce823tDocument19 pagesCandy Ce823tAdrian CastelliNo ratings yet

- Syphon Aqueduct Type IIIDocument10 pagesSyphon Aqueduct Type IIIBibhuti Bhusan SahooNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- Shaker Tables 2Document37 pagesShaker Tables 2William Wehner100% (10)

- Mortar and GroutDocument47 pagesMortar and GroutSangwa StevenNo ratings yet

- Multispan DesignDocument4 pagesMultispan DesignJohn WayneNo ratings yet

- Series Abo 300: DN 50 - DN 600 (2" - 24") PN 10Document12 pagesSeries Abo 300: DN 50 - DN 600 (2" - 24") PN 10Vignesh NadimuthuNo ratings yet

- BOQ From (HVAC)Document26 pagesBOQ From (HVAC)Neeta Samir Munj ParkarNo ratings yet

- 1 VFVFFDocument10 pages1 VFVFFIslam M. RedaNo ratings yet

- ErmetoDocument28 pagesErmetoRickson Viahul Rayan C100% (1)

- Ebarra Pump SpecsDocument13 pagesEbarra Pump SpecsLiz BargolaNo ratings yet

- Lecture 9 PPE Extra Practice Questions Set 2Document2 pagesLecture 9 PPE Extra Practice Questions Set 2xu xuanNo ratings yet

- Applsci 12 03547Document26 pagesApplsci 12 03547Bahaa HussainNo ratings yet

- GH10 Series 303 Stainless SteelDocument3 pagesGH10 Series 303 Stainless SteelUsman ArshadNo ratings yet

- Site Analysis: Floyd Zimmerman, FASLADocument11 pagesSite Analysis: Floyd Zimmerman, FASLAJames Joel Mendoza Santa CruzNo ratings yet

- Hoke 79 Series Rotary Air Control ValveDocument3 pagesHoke 79 Series Rotary Air Control ValveDaniel QuirozNo ratings yet

- Cost Estimation For HighwaysDocument162 pagesCost Estimation For HighwaysWaqar Ahmad MalikNo ratings yet

- Ultimate Load Capacity of Reinforced Concrete SlabDocument8 pagesUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- Section 1 PDFDocument438 pagesSection 1 PDFAnfal BarbhuiyaNo ratings yet

- Environmental Protection and ManagementDocument10 pagesEnvironmental Protection and ManagementparathasiNo ratings yet

- Botai Stage Truss Price List 2023-1Document6 pagesBotai Stage Truss Price List 2023-1Vlady ZamoranoNo ratings yet

- Kalani 1C XLPE CableDocument3 pagesKalani 1C XLPE CableNawarathna Engineering Dept.No ratings yet

- Mah. Act 3 of 2007 The Maha. Fire Prevention & LSM Act-2006Document63 pagesMah. Act 3 of 2007 The Maha. Fire Prevention & LSM Act-2006Priya Vishvanathan AjayNo ratings yet

- Engineer Estimate ManualDocument24 pagesEngineer Estimate ManualNes-tValdezNo ratings yet

- Geomtric DesignDocument41 pagesGeomtric DesignOshada AttygalleNo ratings yet

- Solarban 60 Short Form Specs Final 11 23 20Document10 pagesSolarban 60 Short Form Specs Final 11 23 20Jesse TarrNo ratings yet

- Skid Strength Calculation (1St Saddle)Document1 pageSkid Strength Calculation (1St Saddle)cwkimNo ratings yet

- Form NEW TSR 2016Document2 pagesForm NEW TSR 2016Ega YudhaNo ratings yet