Professional Documents

Culture Documents

Gewindebolzen m16 English Stand 130308

Gewindebolzen m16 English Stand 130308

Uploaded by

Jiangchang QiaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gewindebolzen m16 English Stand 130308

Gewindebolzen m16 English Stand 130308

Uploaded by

Jiangchang QiaoCopyright:

Available Formats

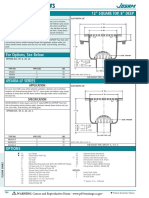

NOTES: THREADED BAR M 16 M1:5

- THREADED BARS, HEXAGON NUTS AND WASHERS

MUST BE FROM ONE SET OF THE SAME MANUFACTURER !! THREADED BAR M16 - 8.8 ISO 898-1

- ANCHOR BARS SHALL HAVE A MINIMUM LENGTH OF L > 2m WITH HEXAGON-NUT ISO 4032 - M16 - FKL 8

BETWEEN UPPER AND LOWER ANCHOR PLATE !!

- INCLINED OR HORIZONTAL ANCHOR BARS HAVE TO BE

AND WASHER ISO 7089 - 16 - 300 HV

PROTECTED FROM TRANSVERSE LOADS WITH APPROPRIATE PRE-STRESSING FORCE P = 70 KN

MEASURES (CALIBERS AND INTERMEDIATE SUPPORTS).

HOT-DIP-GALVANIZED ISO 10684

CONCRETE GRADE MIN. C30/37

EXCESS-LENGTH AND HEIGHT OF STEEL CAP HAVE

TEMPLATE T=8 SHALL BE CONNECTED TO ANCHOR-BARS

USING HEXAGON NUTS ON BOTH SIDES (AND BE CONNECTED

TO THE FORMWORK IF POSSIBLE)

INSTALL STEEL CAP AND GASKET ON ANCHOR PLATE USING

M8 5.6 AND FILL CAP WITH CORROSION PROTECTION COMPOUND

TO BE DEFINED INDIVIDUALLY.

BOLT TENSIONING DEVICE / JACK MADE BY AS TECH

TYPE HWS16112001 (ø50 x 80mm) OR SIMILAR

>100 130

CIRCULAR ANCHOR PLATE ø130 x 25 WITH BOREHOLE ø17

PLEASE NOTE:

CORROSION PROTECTION COMPOUND

25 10

65

BASE PLATE A x B x T WITH BOREHOLES ø60mm

LUBRICATED ON THE UNDERSIDE

65

65

TOP OF DENSO-TAPE

25

AFTER INSTALLATION AND ADJUSTMENT OF STEEL ø60

T

STRUCTURE FILL GAP BELOW BASEPLATE (D > 50mm) TOP OF FOUNDATION

D

WITH NON-SHRINK POURABLE MORTAR OR PAGEL

(MIN. C60/75). COMPLETE VENTING OF GAP MUST BE

ENSURED BY MEANS OF APPROPRIATE MEASURES.

SURFACE OF ANCHOR BAR SHALL BE WRAPPED WITH

2 LAYERS OF COLD PROCESSIBLE WAX-VASELINE TAPE

MADE OF ROT-RESISTANT SYNTHETIC FLEECE

(E.G. DENSO-TEC OR SIMILAR)

110

ADD.REINF.

HELICAL REINFORCEMENT 5 x ø8 BST 500S

35

35

LOWER ANCHOR PLATE 80 x 80 x 20 WITH BOREHOLE ø17

35

BOTTOM OF DENSO-TAPE

CONNECTED TO EACH OTHER WITH REBAR ø14 BST 500S

35

TOP OF ANCHOR PLATE

50

35

20

CONNECT ANCHOR PLATE TO ANCHOR-BARS USING

> 125

HEXAGON NUTS ON BOTH SIDES

BOTTOM OF FOUNDATION

> 230 > 170

1 : 10 11.03.2013

You might also like

- Hydrolysis of Nucleic AcidsDocument7 pagesHydrolysis of Nucleic Acidskeepersake81% (16)

- Katalog - Polyester Distribution Boxes BARTECDocument4 pagesKatalog - Polyester Distribution Boxes BARTECPedjaNo ratings yet

- List of Government WebsitesDocument1 pageList of Government Websitessumit-7No ratings yet

- Gewindebolzen m36 English Stand 130308Document1 pageGewindebolzen m36 English Stand 130308Jiangchang QiaoNo ratings yet

- SPANNGLIED WR36 ENGLISCH Stand 130308Document1 pageSPANNGLIED WR36 ENGLISCH Stand 130308Jiangchang QiaoNo ratings yet

- 2.l.t.protection KitDocument1 page2.l.t.protection KitSSK IndustriesNo ratings yet

- 2.l.t.protection KitDocument1 page2.l.t.protection KitsanjuNo ratings yet

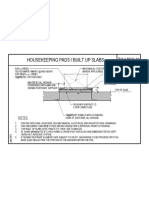

- Housekeeping Pads / Built Up Slabs TC-MISC-01: NotesDocument8 pagesHousekeeping Pads / Built Up Slabs TC-MISC-01: NoteshahaerNo ratings yet

- Ref.: Gil/cms/g3/0591 Date: 31/03/2011Document2 pagesRef.: Gil/cms/g3/0591 Date: 31/03/2011prati121No ratings yet

- Grounding Principle 3P-0036CDocument2 pagesGrounding Principle 3P-0036CAsif Majeed MalikNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 1Document15 pagesDrrdock Repair Jobs (Excluding DD Routines) No 1Amit Raj AnandNo ratings yet

- Ground Floor Plan: 80X320sDIDocument5 pagesGround Floor Plan: 80X320sDIkashish bhardwajNo ratings yet

- Industry Shed Joinery DetailsDocument1 pageIndustry Shed Joinery DetailsabhiNo ratings yet

- Assignment 03Document1 pageAssignment 03Abhishek SinghalNo ratings yet

- Connection Details-ModelDocument1 pageConnection Details-Modelkhem thapaNo ratings yet

- Irla Nala - Top PlanDocument1 pageIrla Nala - Top Plansamir bendreNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- P2 - 10c OVERDocument1 pageP2 - 10c OVERNhuVan NguyenNo ratings yet

- Bridge Well DrawingDocument4 pagesBridge Well DrawingBhargav LahonNo ratings yet

- Frameless Glazing Using Spider Fittins & Patch FittingsDocument22 pagesFrameless Glazing Using Spider Fittins & Patch FittingsJahnavi JayashankarNo ratings yet

- Poooooooooooooooooole Data SheetDocument1 pagePoooooooooooooooooole Data Sheetfathy.shehabNo ratings yet

- Demco Butterfly Valves BrochureDocument44 pagesDemco Butterfly Valves BrochureSai PrasathNo ratings yet

- ic2504d (3)Document1 pageic2504d (3)bkrfNo ratings yet

- Maintenance Stairway: Lockable Gate ForDocument1 pageMaintenance Stairway: Lockable Gate ForTsui DanielNo ratings yet

- Hollowcore Slab End Bearing On Wall TP-HOL-01Document17 pagesHollowcore Slab End Bearing On Wall TP-HOL-01hahaerNo ratings yet

- Section: Septic Tank Cover Slab DetailsDocument1 pageSection: Septic Tank Cover Slab DetailsDileep K MahadevaiahNo ratings yet

- Section: Septic Tank Cover Slab DetailsDocument1 pageSection: Septic Tank Cover Slab DetailsDileep K MahadevaiahNo ratings yet

- s44Document2 pagess44Alaa MansourNo ratings yet

- Bay Sect VillanuevaDocument2 pagesBay Sect VillanuevaRafaela VillanuevaNo ratings yet

- 1.11KV H.g.fuse Unit (Solid Core Type)Document1 page1.11KV H.g.fuse Unit (Solid Core Type)SSK IndustriesNo ratings yet

- DETAILSDocument1 pageDETAILSmustafa syedNo ratings yet

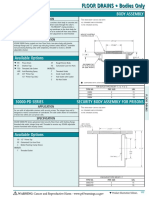

- Sanitary Floor SinksDocument2 pagesSanitary Floor SinksImtiyaz KhanNo ratings yet

- Car Park Shed DrawingDocument1 pageCar Park Shed DrawingNizamuddin AbdullahNo ratings yet

- Client: M/S. Tecno Doors PVT LTD., Project: Proposal Internal Fire Hydrant System QuotationDocument2 pagesClient: M/S. Tecno Doors PVT LTD., Project: Proposal Internal Fire Hydrant System Quotationcareers mahabinuNo ratings yet

- PR686 HSMT Connectors-No BorderDocument3 pagesPR686 HSMT Connectors-No BorderSateesh MahadasyamNo ratings yet

- Installation Collector Replacement Parts Conductor Bar SystemsDocument2 pagesInstallation Collector Replacement Parts Conductor Bar Systemsventas1No ratings yet

- s444Document2 pagess444Alaa MansourNo ratings yet

- XL KP104 01 - en USDocument2 pagesXL KP104 01 - en USPatricio G. ArrienNo ratings yet

- High Velocity Water Spray Nozzle: Models Hv-As & Hv-BsDocument6 pagesHigh Velocity Water Spray Nozzle: Models Hv-As & Hv-BsVipin SomasekharanNo ratings yet

- 3EX5 030 / 3EX5 050: Surge Counter / Surge MonitorDocument2 pages3EX5 030 / 3EX5 050: Surge Counter / Surge MonitorkarthikNo ratings yet

- Rim Seal Pourer Data SheetDocument3 pagesRim Seal Pourer Data Sheetadilmomin45No ratings yet

- Tank Specification Sheet PDFDocument1 pageTank Specification Sheet PDFRaj Bahadur YadavNo ratings yet

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakNo ratings yet

- s444Document2 pagess444Alaa MansourNo ratings yet

- Part L PagesDocument15 pagesPart L PagesAleksandar VelinovskiNo ratings yet

- Wall Design DavidSchwindDocument23 pagesWall Design DavidSchwindRawan ashrafNo ratings yet

- High Velocity Spray Nozzle HV AsDocument6 pagesHigh Velocity Spray Nozzle HV AsmuhsinkrNo ratings yet

- Details Sample 4 Roof Eve PDFDocument1 pageDetails Sample 4 Roof Eve PDFNg TzewayNo ratings yet

- Brosur Mini Pile Uji Mutu Beton K-500 MULTI BETONDocument1 pageBrosur Mini Pile Uji Mutu Beton K-500 MULTI BETONbumilestari12No ratings yet

- Anillo de Concreto XL30 - 03Document1 pageAnillo de Concreto XL30 - 03Victor Hugo Sipion FernandezNo ratings yet

- Synconta 700 TDSDocument2 pagesSynconta 700 TDSRenan BarelaNo ratings yet

- 11 - Butterfly ValvesDocument22 pages11 - Butterfly ValvesLuisNo ratings yet

- P - 6c OVERDocument1 pageP - 6c OVERNhuVan NguyenNo ratings yet

- Ce 362 Plate 9Document1 pageCe 362 Plate 9lonyx27No ratings yet

- Flexiable Pipe Joints For Class H2Document1 pageFlexiable Pipe Joints For Class H2Denise2512No ratings yet

- FLOOR DRAINS - Bodies OnlyDocument1 pageFLOOR DRAINS - Bodies OnlyImtiyaz KhanNo ratings yet

- Catalogue 3ex5030 en 1400139 SIEMENSDocument2 pagesCatalogue 3ex5030 en 1400139 SIEMENSRodrigo RamirezNo ratings yet

- Catalogue 3ex5030 en 1400139Document2 pagesCatalogue 3ex5030 en 1400139Manuel MazariegosNo ratings yet

- GARLOCKSPIRALWOUNDDocument4 pagesGARLOCKSPIRALWOUNDjose manuel perez gomezNo ratings yet

- Window/ Water Curtain Nozzle: Model CN & CnsDocument4 pagesWindow/ Water Curtain Nozzle: Model CN & CnsWirat WitaphanNo ratings yet

- SectionDocument1 pageSectionMartin ScottNo ratings yet

- Gate-Valves Mud KingDocument13 pagesGate-Valves Mud KingWilson RiveraNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Quick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedDocument20 pagesQuick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedРоманКочневNo ratings yet

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- Design of Stair CaseDocument2 pagesDesign of Stair Casepathan is khanNo ratings yet

- Different Kinds of Meat ProductsDocument7 pagesDifferent Kinds of Meat ProductsYam MuhiNo ratings yet

- Find Me Phoenix Book 6 Stacey Kennedy Full ChapterDocument67 pagesFind Me Phoenix Book 6 Stacey Kennedy Full Chaptercatherine.anderegg828100% (21)

- (00 Cari) - Iso - 8466 1 1990Document5 pages(00 Cari) - Iso - 8466 1 1990faridsidikNo ratings yet

- Create Database Taller-AdalbertoDocument2 pagesCreate Database Taller-AdalbertoAdalberto GonzalezNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pages84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Bar Bending Schedule: Title: Commercial BLDG Cutting ListDocument22 pagesBar Bending Schedule: Title: Commercial BLDG Cutting ListJet ArcaNo ratings yet

- Revisit of Harriott's Method For Process ControlDocument3 pagesRevisit of Harriott's Method For Process ControlkiddhoNo ratings yet

- Английская грамматика в тестах - РомановаDocument152 pagesАнглийская грамматика в тестах - РомановаLi FeNo ratings yet

- CS FinalDocument52 pagesCS FinalLucky KhuhaNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- (LN) Orc Eroica - Volume 01 (YP)Document282 pages(LN) Orc Eroica - Volume 01 (YP)FBINo ratings yet

- 10 Best JobsitesDocument14 pages10 Best JobsitesHemansu PathakNo ratings yet

- Certificate ASHWINIDocument4 pagesCertificate ASHWINIbloodspray167No ratings yet

- Lesson Plan Sience - Body PartsDocument4 pagesLesson Plan Sience - Body Partsapi-307376252No ratings yet

- Electrical Circuit Lab ManualDocument38 pagesElectrical Circuit Lab Manualecessec67% (3)

- 2011 C1 CoMe ORGMIDocument8 pages2011 C1 CoMe ORGMIADJ ADJNo ratings yet

- Opening Your Own Bank Drops: Edited EditionDocument4 pagesOpening Your Own Bank Drops: Edited EditionGlenda83% (6)

- 2018 Weekly CalendarDocument3 pages2018 Weekly CalendarFabian FebianoNo ratings yet

- Respuestas Evaluacion 1Document9 pagesRespuestas Evaluacion 1Juan Carlos Ospina ReyesNo ratings yet

- Ericka Joyce O. Reynera: PERSONAL - INFORMATIONDocument2 pagesEricka Joyce O. Reynera: PERSONAL - INFORMATIONdead insideNo ratings yet

- Club Sport DatabaseDocument211 pagesClub Sport DatabaseIlankumaran kNo ratings yet