Professional Documents

Culture Documents

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Uploaded by

John BuntalesCopyright:

Available Formats

You might also like

- AntiCancer Drugs MCQsDocument25 pagesAntiCancer Drugs MCQssk91% (11)

- B48PFF3071T3M Service ManualDocument30 pagesB48PFF3071T3M Service Manualanton Gonzalez0% (1)

- Declaration of Surplus Property - 52-56 Charlton Ave WDocument4 pagesDeclaration of Surplus Property - 52-56 Charlton Ave WHamilton ReporterNo ratings yet

- Power Systems With Solutions PDFDocument92 pagesPower Systems With Solutions PDFVignesh Kumar67% (9)

- Saudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PDocument1 pageSaudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PJohn BuntalesNo ratings yet

- Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007Document1 pageSaudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007John BuntalesNo ratings yet

- 0860.0400-34-3022.ps.e-0 Swing Check Valves-300#Document2 pages0860.0400-34-3022.ps.e-0 Swing Check Valves-300#Jo MatNo ratings yet

- 15.1 000 7 SP 001Document7 pages15.1 000 7 SP 001Sumantra ChattopadhyayNo ratings yet

- Transformer Foundation 5Document1 pageTransformer Foundation 5A.K.M Shafiq MondolNo ratings yet

- US Motors 0,5HP 6P TUBULARDocument1 pageUS Motors 0,5HP 6P TUBULAREdwin RamirezNo ratings yet

- Orientation Plan (Hold) : TOP BottomDocument1 pageOrientation Plan (Hold) : TOP BottomSuneel MalpaniNo ratings yet

- AA-4L6-L501-80mm: Legend For LimitsDocument4 pagesAA-4L6-L501-80mm: Legend For Limitsmina fawzyNo ratings yet

- R789973005X0Document1 pageR789973005X0ankeshkatochNo ratings yet

- DBGVC2314NZ: ModelDocument2 pagesDBGVC2314NZ: ModelMiguel RojasNo ratings yet

- 15.4 000 7 SP 004Document7 pages15.4 000 7 SP 004Sumantra ChattopadhyayNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Notes:: Piping Design Conditions TAG# EH-1Document1 pageNotes:: Piping Design Conditions TAG# EH-1omarNo ratings yet

- Proyek Revitalisasi Pabrik Gula Rendeng: BencmarkDocument1 pageProyek Revitalisasi Pabrik Gula Rendeng: BencmarkIvanAnggiKharismaNo ratings yet

- Modeldbgfc 635-: Catalog Pagit NoDocument2 pagesModeldbgfc 635-: Catalog Pagit NoMiguel RojasNo ratings yet

- 1212-60062 PDDDocument1 page1212-60062 PDDsac.compuwestNo ratings yet

- AD-036916 - Refractory Repairs and Terminations - Saudi AramcoDocument1 pageAD-036916 - Refractory Repairs and Terminations - Saudi AramcoAkhil GeorgeNo ratings yet

- AS972BDocument3 pagesAS972Byannick minvielleNo ratings yet

- Sec 4C 6CC PDFDocument26 pagesSec 4C 6CC PDFThomas KrohNo ratings yet

- Ray Cap CR100-1796 Rev01Document3 pagesRay Cap CR100-1796 Rev01gmelendez2No ratings yet

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- Weigh Estimation - TANKS - Rev BDocument3 pagesWeigh Estimation - TANKS - Rev BAnonymous bySKOTNo ratings yet

- Revised Top ViewsDocument5 pagesRevised Top ViewsarslanahmedkhawajaNo ratings yet

- Clamp MediatorDocument2 pagesClamp Mediatorapi-349134962No ratings yet

- Aa1a32 02Document3 pagesAa1a32 02MramirezNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- Roads and Earthen FirewallsDocument1 pageRoads and Earthen FirewallsMohamed ElsaneeNo ratings yet

- Element Filter & StrainerDocument2 pagesElement Filter & StrainerSalvador RocaNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- Hook Up Layout For Heat Generation and Fuel Tank System: Iranian Petroleum StandardsDocument5 pagesHook Up Layout For Heat Generation and Fuel Tank System: Iranian Petroleum StandardsMahdiNo ratings yet

- BD632MDocument13 pagesBD632MPRAKASHNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- 30600-G-G0002 4 Instr ListDocument58 pages30600-G-G0002 4 Instr Listmohamed abourayaNo ratings yet

- 1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374Document1 page1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374shravan Kumar SinghNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- DW HCVersion FINAL WebsiteDocument36 pagesDW HCVersion FINAL WebsiteSikandar Haidar KhanNo ratings yet

- 506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModelDocument1 page506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModellewihonawiNo ratings yet

- 5 Integration Supersky PDFDocument4 pages5 Integration Supersky PDFnabaeisNo ratings yet

- Key Plan: Reinforcement Plan Unit Substation PlanDocument1 pageKey Plan: Reinforcement Plan Unit Substation PlanAyman SaberNo ratings yet

- Piping Class Especificacion de Tuberias 2Document1 pagePiping Class Especificacion de Tuberias 2dimolinaNo ratings yet

- 100 GPM Fire Pump Approval Pressure Range 130-234 Ul & FM 3555 6x4x11F 8100 A-8477-1 Impeller Data P-3770 11,6 0.70 6.5 19.6in2 6Document1 page100 GPM Fire Pump Approval Pressure Range 130-234 Ul & FM 3555 6x4x11F 8100 A-8477-1 Impeller Data P-3770 11,6 0.70 6.5 19.6in2 6Fernando Raul Blas MirandaNo ratings yet

- Iiza 1AJ: Modeldbgfcc635Document2 pagesIiza 1AJ: Modeldbgfcc635dieselmotorsbogotasasNo ratings yet

- Protractor x2Document3 pagesProtractor x2api-349134962No ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Dbgi?C: Customer Part NoDocument2 pagesDbgi?C: Customer Part Nojohnny sabinNo ratings yet

- Ga Pondasi Pompa P701 RevoDocument3 pagesGa Pondasi Pompa P701 RevoMaria OsawaNo ratings yet

- Heat and Mass Balance Table Case 1 Early Life - Max Gas (TSB Gas Only)Document1 pageHeat and Mass Balance Table Case 1 Early Life - Max Gas (TSB Gas Only)sumathi@1985No ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- SMA Jack Endlaunch GenoutlineDocument1 pageSMA Jack Endlaunch GenoutlineMRousstiaNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDocument3 pagesC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajNo ratings yet

- Saudi Arabian Oil Company: Calculation SheetDocument1 pageSaudi Arabian Oil Company: Calculation SheetJohn BuntalesNo ratings yet

- Sec 4G 6CC PDFDocument8 pagesSec 4G 6CC PDFThomas KrohNo ratings yet

- SESA DrawingpdfDocument1 pageSESA Drawingpdfunios4444No ratings yet

- Pressure / Temperature Ratings Soft SeatDocument1 pagePressure / Temperature Ratings Soft Seatkyeong cheol leeNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Q&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeDocument1 pageQ&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeJohn BuntalesNo ratings yet

- Appendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyDocument1 pageAppendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-7 Stress Summary: Saudi Arabian Oil CompanyDocument1 pageAppendix-7 Stress Summary: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- Door & Frame Types Louver TypesDocument1 pageDoor & Frame Types Louver TypesJohn BuntalesNo ratings yet

- PIP CTSE1000-2018 DatasheetsDocument2 pagesPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Pip Adg004-2014Document15 pagesPip Adg004-2014John BuntalesNo ratings yet

- Pip Adg005 Specification For Developing Data Forms For PracticesDocument20 pagesPip Adg005 Specification For Developing Data Forms For PracticesJohn BuntalesNo ratings yet

- Pip Adg003 Specification For Editing Practices: Work ProcessesDocument34 pagesPip Adg003 Specification For Editing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Appendix-2 Pipe Data Input: Saudi Arabian Oil CompanyDocument1 pageAppendix-2 Pipe Data Input: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-5 Displacement Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-5 Displacement Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-6 Stress Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-6 Stress Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-4 Restraint Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-4 Restraint Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Structural Calculation - Excavation ShoringDocument9 pagesStructural Calculation - Excavation ShoringJohn BuntalesNo ratings yet

- Design Engineer: Certified byDocument4 pagesDesign Engineer: Certified byJohn BuntalesNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Franklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byDocument1 pageFranklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byJohn BuntalesNo ratings yet

- Design of Structural Member Soldier Pile: Design Engineer Certified byDocument3 pagesDesign of Structural Member Soldier Pile: Design Engineer Certified byJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument2 pagesProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- NMR 601 For GATE VALVE Rev.00Document13 pagesNMR 601 For GATE VALVE Rev.00John BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument1 pageProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Zamil Warehouse: Original Date Prepared by Checked by Approved byDocument2 pagesZamil Warehouse: Original Date Prepared by Checked by Approved byJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- For Protein !: Say C HeeseDocument4 pagesFor Protein !: Say C HeeseJuan Sebastian CeleitaNo ratings yet

- Chapter IiDocument6 pagesChapter IiIbale, Arjay D.No ratings yet

- USMLE WORLD QUESTIONS QuizletDocument87 pagesUSMLE WORLD QUESTIONS QuizletPatricio AlexanderNo ratings yet

- DPV EC Cert of ConformityDocument1 pageDPV EC Cert of ConformityFelipe Gamboa GálvezNo ratings yet

- Week 7 ActivityDocument3 pagesWeek 7 ActivityARVIN CRUZNo ratings yet

- Lec 14 Insecticide ActDocument16 pagesLec 14 Insecticide ActPrudhvi RajNo ratings yet

- Fakir Apparels LTD Final Credit ReportDocument5 pagesFakir Apparels LTD Final Credit Reportfarabi1984No ratings yet

- đề 6Document20 pagesđề 6Lê ĐạtNo ratings yet

- CamBeads Si Usage InstructionsDocument5 pagesCamBeads Si Usage Instructionsrohit asilNo ratings yet

- Bell Mingun Sagaing Region Myanmar Mandalay Irrawaddy RiverDocument2 pagesBell Mingun Sagaing Region Myanmar Mandalay Irrawaddy RiverKaung Zaw HeinNo ratings yet

- Essay On Cigarette SmokingDocument6 pagesEssay On Cigarette Smokingfz5s2avw100% (2)

- Madworx Rate ProposalDocument3 pagesMadworx Rate ProposalNoriega LaneeNo ratings yet

- Tutorial 1 - Physical PropertiesDocument17 pagesTutorial 1 - Physical PropertiesZadrin TuckerNo ratings yet

- 058 Sambungan Rod - Atap Perkasa PDFDocument2 pages058 Sambungan Rod - Atap Perkasa PDFatap perkasa frezaNo ratings yet

- Detailed Lesson PlanDocument49 pagesDetailed Lesson PlanNaisy MagalonaNo ratings yet

- Orbino, Frances Anne N. 4th Rot FdarDocument2 pagesOrbino, Frances Anne N. 4th Rot FdarFrances OrbinoNo ratings yet

- Bakery's Open Hiring' Offers Anyone A Chance - New York TimesDocument2 pagesBakery's Open Hiring' Offers Anyone A Chance - New York TimesNavniNo ratings yet

- Pharmacogenetics Lecture NotesDocument5 pagesPharmacogenetics Lecture NotesMark Russel Sean LealNo ratings yet

- TUGAS PPT B. INGGRIS-editedDocument27 pagesTUGAS PPT B. INGGRIS-editedAlfiyan Dwi DarmawanNo ratings yet

- MK Thrombotic Disorders PDFDocument10 pagesMK Thrombotic Disorders PDFMoses Jr KazevuNo ratings yet

- Agr244 AsigmentDocument6 pagesAgr244 AsigmentTracy OdangNo ratings yet

- Philippine Anti-Offloading Act of 2023 DraftDocument5 pagesPhilippine Anti-Offloading Act of 2023 DraftJeremy SalicNo ratings yet

- Bomba SKC 222 ManualDocument11 pagesBomba SKC 222 ManualEderson GuimaraesNo ratings yet

- Module 2 AnswersDocument6 pagesModule 2 AnswersJoy A. VisitacionNo ratings yet

- The Effect of Hydrotherapy On Blood Pressure of DOIDocument4 pagesThe Effect of Hydrotherapy On Blood Pressure of DOIPhocachinnoNo ratings yet

- Dal Fry RecipeDocument2 pagesDal Fry RecipejunkyardNo ratings yet

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Uploaded by

John BuntalesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007

Uploaded by

John BuntalesCopyright:

Available Formats

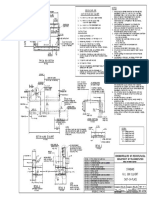

Saudi Aramco 2616-ENG (11/2010)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

NOTE: THE INTENT OF THIS SHEET IS TO SHOW ALL CALCULATION AND

REFERENCE DOCUMENTS THAT WERE USED TO GENERATE THE SIS SHEET

REVISION DESCRIPTION

AS-BUILT

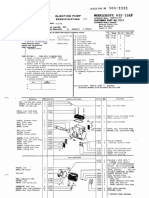

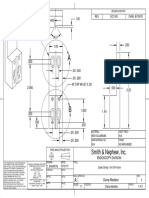

1.0 MAX. ALLOW. OPERATING PRESS. (NEW): 1,500 PSIG 1.1 MAX. ALLOW. PRESS FOR ASME CLASS #600 FLANGE

FOR 12 IN.X0.375 IN. W.T. API 5L X60, INT. CTG. ERW PIPE IS 1500 PSIG AT 196 DEG. F (GROUP 1.7 MATERIALS, ASME B16.5)

1.2 MAX. ALLOW. PRESS FOR ASME CLASS #600 VALVE

2 X 60,000 X 0.375 X 1.00 X 0.72 X 1.000 IS 1500 PSIG AT 196 DEG. F (GROUP 1.7 MATERIALS, ASME B16.34)

Pc =

12.750 1.3 MAX. ALLOW. PRESS FOR ASME CLASS #800 VENT VALVE

IS 1985.6 PSIG AT 196 DEG. F (GROUP 2.8 MATERIALS, ASME B16.34)

= 2,542 PSIG 1.4 THE MAXIMUM ALLOWABLE OPERATING PRESSURE (MAOP) FOR

INTERNAL FBE COATING AS PER 09-SAMSS-091= 3000 PSIG

03/21/21

DATE

11-18000-8174

1.5 THE MAX. ALLOW. PRESS. FOR THE PIPE

JOB ORDER/EWO NO.

2 X SMYS X tn X E X F X T

Pc = AS PER (ASME B31.8)

Do

SMYS = SPECIFIED MININUM YIELD STRESS

REV. NO.

tn = NOMINAL WALL THICKNESS

01

F = CONSTRUCTION TYPE DESIGN FACTOR

E = JOINT EFFICIENCY FACTOR

T = TEMPERATURE DERATING FACTOR

Do = OUTSIDE PIPE DIAMETER

3000 PSIG > 2542 PSIG > 1816.52 PSIG > 1500 PSIG = 1500 PSIG

BY/DATE

OTHER

SYSTEM MAOP = MAX. ALLOW. OPER. PRESS. = 1,350 PSIG

2.0 INITIAL TEST PRESSURE: 2,250 PSIG 2.1 AS PER ASME B16.5, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

FOR 12 IN.X0.375 IN. W.T. API 5L X60, INT. CTG. ERW PIPE FOR CLASS 600# FLANGE IS 2250 PSIG. (GROUP 1.7)

2.2 AS PER ASME B16.34, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

2 X 0.9 X 60,000 X 0.375 FOR CLASS 600# VALVE IS 2250 PSIG. (GROUP 1.7)

Pt =

OPERATIONS/DATE

12.750 2.3 AS PER ASME B16.34, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

REQUIRED (SAUDI ARAMCO)

= 3,177 PSIG FOR CLASS 800 VENT VALVE IS 3000 PSIG. (GROUP 2.8)

03/21/21

REVIEW FOR KEY DRAWINGS

KMA

2.4 THE MAXIMUM ALLOWABLE TEST PRESSURE (MATP) FOR INTERNAL

FBE COATING AS PER 09-SAMSS-091= 5575 PSIG

2.5 THE MAXIMUM ALLOWABLE TEST PRESSURE (MATP) FOR THE PIPE

2 X 0.9 X SMSY X tn

5575 PSIG > 3177 PSIG > 2975 PSIG > 2250 PSIG = 2250 PSIG Pt = AS PER (SAES-L-150)

Do

CONST. AGENCY/DATE

3.0 INITIAL TEST PRESSURE LIMITED BY: 4.0 SYSTEM MAX. ALLOW. OPER. PRESSURE LIMITED BY:

FLANGE CLASS #600 FLANGE CLASS #600

03/21/21

BMJ

5.0 SAFETY VALVE SET PRESSURE:2363 PSIG (STRENGTH TEST) 5.1 SAFETY VALVE SET PRESSURE FOR STRENGTH TEST

= 1.05 X 2,250 = 2,363 = 1.05 X INITIAL TEST PRESSURE (AS PER SAES-A-004 PRG. 5.7.1)

7.0 MINIMUM WALL THICKNESS CALCULATED 7.1 MINIMUM WALL THICKNESS CALCULATED

FOR 12 IN.X0.375 IN. W.T. API 5L X60, INT. CTG. ERW PIPE

CERTIFIED/DATE

1,350 X 12.750 P X D

Tm = Tm =

03/21/21

2 X 60,000 X 1.000 X 0.720 X 1.000 2 X SMYS X E X F X T

AMR

DESIGN CERTIFICATION

= 0.199 IN.

(DESIGN AGENCY)

AS PER SAES-L-410, TABLE 3: FOR 12 IN. PIPE

SELECTED WALL THICKNESS 'tn' IS 0.375 IN MINIMUM SELECTED NOMINAL WALL THICKNESS = 0.25 IN.

ENGG./DATE

03/21/21

JRB

8.0 PIPE Tca 8.1 AVAILABLE WALL THICKNESS

FOR 12 IN.X0.375 IN. W.T. API 5L X60, INT. CTG. ERW PIPE Tca = Tn - Tm

Tca = 0.375 - 0.199

= 0.176 IN.

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

REVISION VALIDATION

11-18000-8174-005

DRAWING COMPLETION CERTIFICATE NO.

01

THIS REVISION NO.

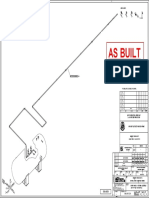

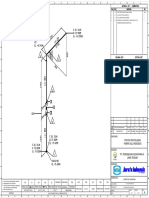

SIS FOR 12" PIPING DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

ANDR -476 MANIFOLD DIVERSION SIS 003

GOSP-1 & P/STN TIELINES (ADT-1) 270 A TE-116318 OF 01

AIN DAR SAUDI ARABIA 007

EKRD/2616-1110.XLS

You might also like

- AntiCancer Drugs MCQsDocument25 pagesAntiCancer Drugs MCQssk91% (11)

- B48PFF3071T3M Service ManualDocument30 pagesB48PFF3071T3M Service Manualanton Gonzalez0% (1)

- Declaration of Surplus Property - 52-56 Charlton Ave WDocument4 pagesDeclaration of Surplus Property - 52-56 Charlton Ave WHamilton ReporterNo ratings yet

- Power Systems With Solutions PDFDocument92 pagesPower Systems With Solutions PDFVignesh Kumar67% (9)

- Saudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PDocument1 pageSaudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PJohn BuntalesNo ratings yet

- Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007Document1 pageSaudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007John BuntalesNo ratings yet

- 0860.0400-34-3022.ps.e-0 Swing Check Valves-300#Document2 pages0860.0400-34-3022.ps.e-0 Swing Check Valves-300#Jo MatNo ratings yet

- 15.1 000 7 SP 001Document7 pages15.1 000 7 SP 001Sumantra ChattopadhyayNo ratings yet

- Transformer Foundation 5Document1 pageTransformer Foundation 5A.K.M Shafiq MondolNo ratings yet

- US Motors 0,5HP 6P TUBULARDocument1 pageUS Motors 0,5HP 6P TUBULAREdwin RamirezNo ratings yet

- Orientation Plan (Hold) : TOP BottomDocument1 pageOrientation Plan (Hold) : TOP BottomSuneel MalpaniNo ratings yet

- AA-4L6-L501-80mm: Legend For LimitsDocument4 pagesAA-4L6-L501-80mm: Legend For Limitsmina fawzyNo ratings yet

- R789973005X0Document1 pageR789973005X0ankeshkatochNo ratings yet

- DBGVC2314NZ: ModelDocument2 pagesDBGVC2314NZ: ModelMiguel RojasNo ratings yet

- 15.4 000 7 SP 004Document7 pages15.4 000 7 SP 004Sumantra ChattopadhyayNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Notes:: Piping Design Conditions TAG# EH-1Document1 pageNotes:: Piping Design Conditions TAG# EH-1omarNo ratings yet

- Proyek Revitalisasi Pabrik Gula Rendeng: BencmarkDocument1 pageProyek Revitalisasi Pabrik Gula Rendeng: BencmarkIvanAnggiKharismaNo ratings yet

- Modeldbgfc 635-: Catalog Pagit NoDocument2 pagesModeldbgfc 635-: Catalog Pagit NoMiguel RojasNo ratings yet

- 1212-60062 PDDDocument1 page1212-60062 PDDsac.compuwestNo ratings yet

- AD-036916 - Refractory Repairs and Terminations - Saudi AramcoDocument1 pageAD-036916 - Refractory Repairs and Terminations - Saudi AramcoAkhil GeorgeNo ratings yet

- AS972BDocument3 pagesAS972Byannick minvielleNo ratings yet

- Sec 4C 6CC PDFDocument26 pagesSec 4C 6CC PDFThomas KrohNo ratings yet

- Ray Cap CR100-1796 Rev01Document3 pagesRay Cap CR100-1796 Rev01gmelendez2No ratings yet

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- Weigh Estimation - TANKS - Rev BDocument3 pagesWeigh Estimation - TANKS - Rev BAnonymous bySKOTNo ratings yet

- Revised Top ViewsDocument5 pagesRevised Top ViewsarslanahmedkhawajaNo ratings yet

- Clamp MediatorDocument2 pagesClamp Mediatorapi-349134962No ratings yet

- Aa1a32 02Document3 pagesAa1a32 02MramirezNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- Roads and Earthen FirewallsDocument1 pageRoads and Earthen FirewallsMohamed ElsaneeNo ratings yet

- Element Filter & StrainerDocument2 pagesElement Filter & StrainerSalvador RocaNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- Hook Up Layout For Heat Generation and Fuel Tank System: Iranian Petroleum StandardsDocument5 pagesHook Up Layout For Heat Generation and Fuel Tank System: Iranian Petroleum StandardsMahdiNo ratings yet

- BD632MDocument13 pagesBD632MPRAKASHNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- 30600-G-G0002 4 Instr ListDocument58 pages30600-G-G0002 4 Instr Listmohamed abourayaNo ratings yet

- 1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374Document1 page1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374shravan Kumar SinghNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- DW HCVersion FINAL WebsiteDocument36 pagesDW HCVersion FINAL WebsiteSikandar Haidar KhanNo ratings yet

- 506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModelDocument1 page506-PPA.3101-ISO-001 Sheet 2 Drainage Roompad 3101-ModellewihonawiNo ratings yet

- 5 Integration Supersky PDFDocument4 pages5 Integration Supersky PDFnabaeisNo ratings yet

- Key Plan: Reinforcement Plan Unit Substation PlanDocument1 pageKey Plan: Reinforcement Plan Unit Substation PlanAyman SaberNo ratings yet

- Piping Class Especificacion de Tuberias 2Document1 pagePiping Class Especificacion de Tuberias 2dimolinaNo ratings yet

- 100 GPM Fire Pump Approval Pressure Range 130-234 Ul & FM 3555 6x4x11F 8100 A-8477-1 Impeller Data P-3770 11,6 0.70 6.5 19.6in2 6Document1 page100 GPM Fire Pump Approval Pressure Range 130-234 Ul & FM 3555 6x4x11F 8100 A-8477-1 Impeller Data P-3770 11,6 0.70 6.5 19.6in2 6Fernando Raul Blas MirandaNo ratings yet

- Iiza 1AJ: Modeldbgfcc635Document2 pagesIiza 1AJ: Modeldbgfcc635dieselmotorsbogotasasNo ratings yet

- Protractor x2Document3 pagesProtractor x2api-349134962No ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Dbgi?C: Customer Part NoDocument2 pagesDbgi?C: Customer Part Nojohnny sabinNo ratings yet

- Ga Pondasi Pompa P701 RevoDocument3 pagesGa Pondasi Pompa P701 RevoMaria OsawaNo ratings yet

- Heat and Mass Balance Table Case 1 Early Life - Max Gas (TSB Gas Only)Document1 pageHeat and Mass Balance Table Case 1 Early Life - Max Gas (TSB Gas Only)sumathi@1985No ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- SMA Jack Endlaunch GenoutlineDocument1 pageSMA Jack Endlaunch GenoutlineMRousstiaNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDocument3 pagesC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajNo ratings yet

- Saudi Arabian Oil Company: Calculation SheetDocument1 pageSaudi Arabian Oil Company: Calculation SheetJohn BuntalesNo ratings yet

- Sec 4G 6CC PDFDocument8 pagesSec 4G 6CC PDFThomas KrohNo ratings yet

- SESA DrawingpdfDocument1 pageSESA Drawingpdfunios4444No ratings yet

- Pressure / Temperature Ratings Soft SeatDocument1 pagePressure / Temperature Ratings Soft Seatkyeong cheol leeNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Q&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeDocument1 pageQ&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeJohn BuntalesNo ratings yet

- Appendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyDocument1 pageAppendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-7 Stress Summary: Saudi Arabian Oil CompanyDocument1 pageAppendix-7 Stress Summary: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- Door & Frame Types Louver TypesDocument1 pageDoor & Frame Types Louver TypesJohn BuntalesNo ratings yet

- PIP CTSE1000-2018 DatasheetsDocument2 pagesPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Pip Adg004-2014Document15 pagesPip Adg004-2014John BuntalesNo ratings yet

- Pip Adg005 Specification For Developing Data Forms For PracticesDocument20 pagesPip Adg005 Specification For Developing Data Forms For PracticesJohn BuntalesNo ratings yet

- Pip Adg003 Specification For Editing Practices: Work ProcessesDocument34 pagesPip Adg003 Specification For Editing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Appendix-2 Pipe Data Input: Saudi Arabian Oil CompanyDocument1 pageAppendix-2 Pipe Data Input: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-5 Displacement Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-5 Displacement Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-6 Stress Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-6 Stress Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-4 Restraint Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-4 Restraint Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Structural Calculation - Excavation ShoringDocument9 pagesStructural Calculation - Excavation ShoringJohn BuntalesNo ratings yet

- Design Engineer: Certified byDocument4 pagesDesign Engineer: Certified byJohn BuntalesNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Franklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byDocument1 pageFranklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byJohn BuntalesNo ratings yet

- Design of Structural Member Soldier Pile: Design Engineer Certified byDocument3 pagesDesign of Structural Member Soldier Pile: Design Engineer Certified byJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument2 pagesProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- NMR 601 For GATE VALVE Rev.00Document13 pagesNMR 601 For GATE VALVE Rev.00John BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument1 pageProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Zamil Warehouse: Original Date Prepared by Checked by Approved byDocument2 pagesZamil Warehouse: Original Date Prepared by Checked by Approved byJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- For Protein !: Say C HeeseDocument4 pagesFor Protein !: Say C HeeseJuan Sebastian CeleitaNo ratings yet

- Chapter IiDocument6 pagesChapter IiIbale, Arjay D.No ratings yet

- USMLE WORLD QUESTIONS QuizletDocument87 pagesUSMLE WORLD QUESTIONS QuizletPatricio AlexanderNo ratings yet

- DPV EC Cert of ConformityDocument1 pageDPV EC Cert of ConformityFelipe Gamboa GálvezNo ratings yet

- Week 7 ActivityDocument3 pagesWeek 7 ActivityARVIN CRUZNo ratings yet

- Lec 14 Insecticide ActDocument16 pagesLec 14 Insecticide ActPrudhvi RajNo ratings yet

- Fakir Apparels LTD Final Credit ReportDocument5 pagesFakir Apparels LTD Final Credit Reportfarabi1984No ratings yet

- đề 6Document20 pagesđề 6Lê ĐạtNo ratings yet

- CamBeads Si Usage InstructionsDocument5 pagesCamBeads Si Usage Instructionsrohit asilNo ratings yet

- Bell Mingun Sagaing Region Myanmar Mandalay Irrawaddy RiverDocument2 pagesBell Mingun Sagaing Region Myanmar Mandalay Irrawaddy RiverKaung Zaw HeinNo ratings yet

- Essay On Cigarette SmokingDocument6 pagesEssay On Cigarette Smokingfz5s2avw100% (2)

- Madworx Rate ProposalDocument3 pagesMadworx Rate ProposalNoriega LaneeNo ratings yet

- Tutorial 1 - Physical PropertiesDocument17 pagesTutorial 1 - Physical PropertiesZadrin TuckerNo ratings yet

- 058 Sambungan Rod - Atap Perkasa PDFDocument2 pages058 Sambungan Rod - Atap Perkasa PDFatap perkasa frezaNo ratings yet

- Detailed Lesson PlanDocument49 pagesDetailed Lesson PlanNaisy MagalonaNo ratings yet

- Orbino, Frances Anne N. 4th Rot FdarDocument2 pagesOrbino, Frances Anne N. 4th Rot FdarFrances OrbinoNo ratings yet

- Bakery's Open Hiring' Offers Anyone A Chance - New York TimesDocument2 pagesBakery's Open Hiring' Offers Anyone A Chance - New York TimesNavniNo ratings yet

- Pharmacogenetics Lecture NotesDocument5 pagesPharmacogenetics Lecture NotesMark Russel Sean LealNo ratings yet

- TUGAS PPT B. INGGRIS-editedDocument27 pagesTUGAS PPT B. INGGRIS-editedAlfiyan Dwi DarmawanNo ratings yet

- MK Thrombotic Disorders PDFDocument10 pagesMK Thrombotic Disorders PDFMoses Jr KazevuNo ratings yet

- Agr244 AsigmentDocument6 pagesAgr244 AsigmentTracy OdangNo ratings yet

- Philippine Anti-Offloading Act of 2023 DraftDocument5 pagesPhilippine Anti-Offloading Act of 2023 DraftJeremy SalicNo ratings yet

- Bomba SKC 222 ManualDocument11 pagesBomba SKC 222 ManualEderson GuimaraesNo ratings yet

- Module 2 AnswersDocument6 pagesModule 2 AnswersJoy A. VisitacionNo ratings yet

- The Effect of Hydrotherapy On Blood Pressure of DOIDocument4 pagesThe Effect of Hydrotherapy On Blood Pressure of DOIPhocachinnoNo ratings yet

- Dal Fry RecipeDocument2 pagesDal Fry RecipejunkyardNo ratings yet