Professional Documents

Culture Documents

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Uploaded by

John BuntalesCopyright:

Available Formats

You might also like

- Structural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1Document1 pageStructural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1roger100% (2)

- Hydraulics 1Document44 pagesHydraulics 1Rhia Roxas100% (1)

- Principles of Flight Practice ExamDocument12 pagesPrinciples of Flight Practice ExamthowmasNo ratings yet

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- Lub Oil System FinalDocument44 pagesLub Oil System FinalNitish Kumar100% (3)

- 01 - ValvesDocument25 pages01 - ValvesMahmoud Ahmed Ali Abdelrazik100% (1)

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing CalculationAbelardo ContrerasNo ratings yet

- Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007Document1 pageSaudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007John BuntalesNo ratings yet

- Saudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PDocument1 pageSaudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PJohn BuntalesNo ratings yet

- R789973005X0Document1 pageR789973005X0ankeshkatochNo ratings yet

- Notes:: Piping Design Conditions TAG# EH-1Document1 pageNotes:: Piping Design Conditions TAG# EH-1omarNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesLon OdiNo ratings yet

- Asbuilt Drawing Sbux MSCDocument41 pagesAsbuilt Drawing Sbux MSCbetawi digital printingNo ratings yet

- General Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahDocument3 pagesGeneral Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahRogerNo ratings yet

- TCX 1100 AbvDocument1 pageTCX 1100 AbvMarcoNo ratings yet

- FM-200 - 068-007 SHT of 1 Installation & Mounting DetailsDocument1 pageFM-200 - 068-007 SHT of 1 Installation & Mounting DetailsAhmed SweetNo ratings yet

- Detail A: PT Assy, Layout - JB34GDocument3 pagesDetail A: PT Assy, Layout - JB34GmatiasNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Notes:: Details Cast Iron Catch Basin With Side InletsDocument1 pageNotes:: Details Cast Iron Catch Basin With Side InletsJorge Garcia0% (1)

- Plano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Document2 pagesPlano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Andres BenitezNo ratings yet

- e C7330 - 1FDocument4 pagese C7330 - 1Fmina fawzyNo ratings yet

- STD WR 012Document1 pageSTD WR 012Tyburg R DhliwayoNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- HQ3 DN-B01-W04 C1Document1 pageHQ3 DN-B01-W04 C1llNo ratings yet

- 5 Integration Supersky PDFDocument4 pages5 Integration Supersky PDFnabaeisNo ratings yet

- General NotesDocument12 pagesGeneral NotesShekh Muhsen Uddin AhmedNo ratings yet

- Front View Front Interior Inner Side View Side View: ECB 150ADocument1 pageFront View Front Interior Inner Side View Side View: ECB 150ACharlie MendozaNo ratings yet

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- Saudi Arabian Oil Company: Indicates Information To Be Completed by PurchaserDocument2 pagesSaudi Arabian Oil Company: Indicates Information To Be Completed by PurchaserMohamed Wasim ShaikhNo ratings yet

- Notes:: OPEN AT 120° 5°Document1 pageNotes:: OPEN AT 120° 5°Yazan MohammadNo ratings yet

- Aa 036069 001 PDFDocument1 pageAa 036069 001 PDFprabaharan sNo ratings yet

- AB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCODocument1 pageAB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- Client: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDocument7 pagesClient: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDinesh GowdNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Ac 036437 001 - 05312022Document1 pageAc 036437 001 - 05312022JAWAHAR TNo ratings yet

- Akhilesh Tiwari Prda-ModelDocument1 pageAkhilesh Tiwari Prda-ModelSHUBHAM KUMARNo ratings yet

- HQ3 DN-B01-W03 C1Document1 pageHQ3 DN-B01-W03 C1llNo ratings yet

- Saudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Document1 pageSaudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Mohamed Wasim ShaikhNo ratings yet

- BD632MDocument13 pagesBD632MPRAKASHNo ratings yet

- A Proposed One-Storey Residential Building S1Document1 pageA Proposed One-Storey Residential Building S1Jezreel FlotildeNo ratings yet

- R789973004X0Document1 pageR789973004X0ankeshkatochNo ratings yet

- DWG. No. 117Document1 pageDWG. No. 117Mubashar Islam JadoonNo ratings yet

- S-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesDocument1 pageS-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesTAIQ MASROORNo ratings yet

- Details "B" BD 110: - Cadd Designer'SDocument1 pageDetails "B" BD 110: - Cadd Designer'SDileep K MahadevaiahNo ratings yet

- D - 01S190517-G Rev07 - AS BUILT-2Document1 pageD - 01S190517-G Rev07 - AS BUILT-2גרבר פליקסNo ratings yet

- Printed Board, Rigid-Digital Input/Output, (DIO) 60011970-2002Document4 pagesPrinted Board, Rigid-Digital Input/Output, (DIO) 60011970-2002n.poojaNo ratings yet

- APPROVAL DRAWING-ModelDocument1 pageAPPROVAL DRAWING-Modelnandkishormore1112No ratings yet

- A B C D: Reinforcement Detail of Roof LevelDocument1 pageA B C D: Reinforcement Detail of Roof LevelSampath S. WickramanayakaNo ratings yet

- St-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20Document1 pageSt-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20tarang patelNo ratings yet

- Notes:: Hinge DetailsDocument1 pageNotes:: Hinge DetailsYazan MohammadNo ratings yet

- C WatermarkedDocument2 pagesC WatermarkedNhật PhạmNo ratings yet

- KwakuDocument1 pageKwakuKwaku frimpongNo ratings yet

- Setting Out: NotesDocument1 pageSetting Out: NotesKwaku frimpongNo ratings yet

- Beam SideDocument1 pageBeam SideKwaku frimpongNo ratings yet

- 21A. GA & Structural Details of Stilling BasinDocument1 page21A. GA & Structural Details of Stilling BasinManoranjan SethiNo ratings yet

- 6612 - SM21-000-0010 - Rev02 - 01weightDocument67 pages6612 - SM21-000-0010 - Rev02 - 01weightjannsinkyNo ratings yet

- Ta-249813-023 - C - P&id - Caustic Injection PacakgeDocument1 pageTa-249813-023 - C - P&id - Caustic Injection Pacakgerizwan.zamanNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- Basic GDT 1Document1 pageBasic GDT 1vjd5wzx92xNo ratings yet

- Ca 477021 003Document1 pageCa 477021 003Sehna SerajNo ratings yet

- e C7328 - 1F PDFDocument6 pagese C7328 - 1F PDFmina fawzyNo ratings yet

- Ae 036265 001 - 05312022Document1 pageAe 036265 001 - 05312022JAWAHAR TNo ratings yet

- Section A-A: See Detail CDocument2 pagesSection A-A: See Detail CGalva decoNo ratings yet

- Orientation Plan (Hold) : TOP BottomDocument1 pageOrientation Plan (Hold) : TOP BottomSuneel MalpaniNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Q&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeDocument1 pageQ&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeJohn BuntalesNo ratings yet

- Appendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyDocument1 pageAppendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-7 Stress Summary: Saudi Arabian Oil CompanyDocument1 pageAppendix-7 Stress Summary: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- Door & Frame Types Louver TypesDocument1 pageDoor & Frame Types Louver TypesJohn BuntalesNo ratings yet

- PIP CTSE1000-2018 DatasheetsDocument2 pagesPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Pip Adg004-2014Document15 pagesPip Adg004-2014John BuntalesNo ratings yet

- Pip Adg005 Specification For Developing Data Forms For PracticesDocument20 pagesPip Adg005 Specification For Developing Data Forms For PracticesJohn BuntalesNo ratings yet

- Pip Adg003 Specification For Editing Practices: Work ProcessesDocument34 pagesPip Adg003 Specification For Editing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Appendix-2 Pipe Data Input: Saudi Arabian Oil CompanyDocument1 pageAppendix-2 Pipe Data Input: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-5 Displacement Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-5 Displacement Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-6 Stress Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-6 Stress Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-4 Restraint Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-4 Restraint Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Structural Calculation - Excavation ShoringDocument9 pagesStructural Calculation - Excavation ShoringJohn BuntalesNo ratings yet

- Design Engineer: Certified byDocument4 pagesDesign Engineer: Certified byJohn BuntalesNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Franklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byDocument1 pageFranklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byJohn BuntalesNo ratings yet

- Design of Structural Member Soldier Pile: Design Engineer Certified byDocument3 pagesDesign of Structural Member Soldier Pile: Design Engineer Certified byJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument2 pagesProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- NMR 601 For GATE VALVE Rev.00Document13 pagesNMR 601 For GATE VALVE Rev.00John BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument1 pageProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Zamil Warehouse: Original Date Prepared by Checked by Approved byDocument2 pagesZamil Warehouse: Original Date Prepared by Checked by Approved byJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Guadalupe Guerrero100% (2)

- A Simplified Model Predicting The Kelvin-Helmholtz Instability Frequency For - Simoni Et AlDocument6 pagesA Simplified Model Predicting The Kelvin-Helmholtz Instability Frequency For - Simoni Et Al赵伯驹No ratings yet

- Hydrostatics & Manometry Lab ReportDocument6 pagesHydrostatics & Manometry Lab ReportMatauka.F. MufungulwaNo ratings yet

- EPC PracticeDocument4 pagesEPC PracticeSaid Ahmed SalemNo ratings yet

- 1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Document157 pages1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Daniel PricopNo ratings yet

- Fundamentals of Fluid Mechanics: Chapter 8: Flow in PipesDocument92 pagesFundamentals of Fluid Mechanics: Chapter 8: Flow in Pipesintern kncesbNo ratings yet

- WeeklyDocument84 pagesWeeklysdan100% (1)

- 2015 07 23 Homework PhysioEx 5 KeyDocument3 pages2015 07 23 Homework PhysioEx 5 KeyMonica Sario Policina100% (1)

- Pipe and Tube Sizing: Butch G. Bataller Lecture On Che 192Document25 pagesPipe and Tube Sizing: Butch G. Bataller Lecture On Che 192MEME123No ratings yet

- III-1 & III-2 Specifications Volume 2Document588 pagesIII-1 & III-2 Specifications Volume 2saleem buksh100% (1)

- GIRPI - Katalog CPVC - STEPENDocument84 pagesGIRPI - Katalog CPVC - STEPENDragan VojinovicNo ratings yet

- Chapter 5 CFDDocument12 pagesChapter 5 CFDvadiyalaNo ratings yet

- The Hydraulic GradientDocument7 pagesThe Hydraulic GradientAl Patrick Dela CalzadaNo ratings yet

- Fluid Mechanics: Steady Incompressible Flow in Pipe SystemsDocument26 pagesFluid Mechanics: Steady Incompressible Flow in Pipe SystemsEkala XuhalxNo ratings yet

- Lesson 4: Pressure Control Valves: Basic Hydraulic SystemsDocument24 pagesLesson 4: Pressure Control Valves: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- RB - Specifications Piping MaterialsDocument21 pagesRB - Specifications Piping MaterialsFalcon PeregrinusNo ratings yet

- Myths of Rheology An StuffDocument10 pagesMyths of Rheology An StuffjamesNo ratings yet

- The LIFT FormulaDocument4 pagesThe LIFT FormulaJoséMendesNo ratings yet

- Relief Valves For Transports and Delivery TrucksDocument8 pagesRelief Valves For Transports and Delivery Truckswilfredo macoNo ratings yet

- GP3 Flow in Open Channel Lab ReportDocument30 pagesGP3 Flow in Open Channel Lab ReportArif AfifiNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Anti-Seismic Gas Installation Systems For Households: ContactDocument2 pagesAnti-Seismic Gas Installation Systems For Households: ContactCak NhassNo ratings yet

- CE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileDocument11 pagesCE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileMashal Shah JehanNo ratings yet

- Aero Ae2251 - Aerodynamics - IDocument10 pagesAero Ae2251 - Aerodynamics - IKalpit KauraseNo ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Uploaded by

John BuntalesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Saudi Arabian Oil Company: SIS 270 A TE-116318 01 006 OF 007

Uploaded by

John BuntalesCopyright:

Available Formats

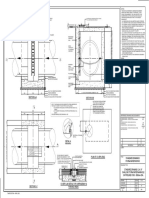

Saudi Aramco 2616-ENG (11/2010)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

NOTE: THE INTENT OF THIS SHEET IS TO SHOW ALL CALCULATION AND

REFERENCE DOCUMENTS THAT WERE USED TO GENERATE THE SIS SHEET

REVISION DESCRIPTION

AS-BUILT

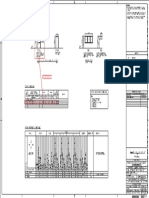

1.0 MAX. ALLOW. OPERATING PRESS. (NEW): 1,365 PSIG

1.1 MAX. ALLOW. PRESS FOR CLASS #600 FLANGE

FOR 3 IN.X0.3 IN. W.T. API 5L Gr. B, INT. CTG. SMLS PIPE IS 1364.8 PSIG AT 196 DEG. F (GROUP 1.1 MATERIALS, ASME B16.5)

1.2 MAX. ALLOW. PRESS FOR CLASS #600 VALVE

2 X 35,000 X 0.300 X 1.00 X 0.72 X 1.000 IS 1364.8 PSIG AT 196 DEG. F (GROUP 1.1 MATERIALS, ASME B16.34)

Pc =

3.500 1.3 MAX. ALLOW. PRESS FOR ASME CLASS #800 VENT VALVE

IS 1985.6 PSIG AT 196 DEG. F (GROUP 2.8 MATERIALS, ASME B16.34)

= 4,320 PSIG 1.4 THE MAXIMUM ALLOWABLE OPERATING PRESSURE (MAOP) FOR

INTERNAL FBE COATING AS PER 09-SAMSS-091= 3000 PSIG

03/21/21

DATE

11-18000-8174

1.5 THE MAX. ALLOW. PRESS. FOR THE PIPE

JOB ORDER/EWO NO.

2 X SMYS X tn X E X F X T

Pc = AS PER (ASME B31.8)

Do

SMYS = SPECIFIED MININUM YIELD STRESS

REV. NO.

tn = NOMINAL WALL THICKNESS

01

F = CONSTRUCTION TYPE DESIGN FACTOR

E = JOINT EFFICIENCY FACTOR

T = TEMPERATURE DERATING FACTOR

Do = OUTSIDE PIPE DIAMETER

4320 PSIG > 3000 PSIG > 1985.6 PSIG > 1364.8 PSIG = 1364.8 PSIG

BY/DATE

OTHER

SYSTEM MAOP = MAX. ALLOW. OPER. PRESS. = 1,350 PSIG

2.0 INITIAL TEST PRESSURE: 2,225 PSIG 2.1 AS PER ASME B16.5, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

FOR 3 IN.X0.3 IN. W.T. API 5L Gr. B, INT. CTG. SMLS PIPE FOR CLASS 600# FLANGE IS 2225 PSIG. (GROUP 1.1)

2.2 AS PER ASME B16.34, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

2 X 0.9 X 35,000 X 0.300 FOR CLASS 600# VALVE IS 2225 PSIG. (GROUP 1.1)

Pt =

OPERATIONS/DATE

3.500 2.3 AS PER ASME B16.34, MAXIMUM ALLOWABLE TEST PRESSURE (MATP)

REQUIRED (SAUDI ARAMCO)

= 5,400 PSIG FOR CLASS 800 VENT VALVE IS 3000 PSIG. (GROUP 2.8)

03/21/21

REVIEW FOR KEY DRAWINGS

KMA

2.4 THE MAXIMUM ALLOWABLE TEST PRESSURE (MATP) FOR INTERNAL

FBE COATING AS PER 09-SAMSS-091= 5575 PSIG

2.5 THE MAXIMUM ALLOWABLE TEST PRESSURE (MATP) FOR THE PIPE

2 X 0.9 X SMYS X tn

5575 PSIG > 5400 PSIG > 3000 PSIG > 2225 PSIG = 2225 PSIG Pt = AS PER (SAES-L-150)

Do

CONST. AGENCY/DATE

3.0 INITIAL TEST PRESSURE LIMITED BY: 3.1 SYSTEM MAX. ALLOW. OPER. PRESSURE LIMITED BY:

FLANGE CLASS #600 FLANGE CLASS #600

03/21/21

BMJ

5.0 SAFETY VALVE SET PRESSURE:2336 PSIG (STRENGTH TEST) 5.1 SAFETY VALVE SET PRESSURE FOR STRENGTH TEST

= 1.05 X 2,225 = 2,336 = 1.05 X INITIAL TEST PRESSURE (AS PER SAES-A-004 PRG. 5.7.1)

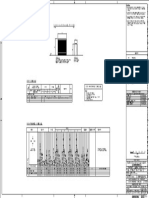

7.0 MINIMUM WALL THICKNESS CALCULATED 7.1 MINIMUM WALL THICKNESS CALCULATED

FOR 3 IN.X0.3 IN. W.T. API 5L Gr. B, INT. CTG. SMLS PIPE

CERTIFIED/DATE

1,350 X 3.500 P X D

Tm = Tm =

03/21/21

2 X 35,000 X 1.000 X 0.720 X 1.000 2 X SMYS X E X F X T

AMR

DESIGN CERTIFICATION

= 0.094 IN.

(DESIGN AGENCY)

AS PER SAES-L-410, TABLE 3: FOR 3 IN. PIPE

SELECTED WALL THICKNESS 'tn' IS 0.3 IN MINIMUM SELECTED NOMINAL WALL THICKNESS = 0.216 IN.

ENGG./DATE

03/21/21

JRB

8.0 PIPE Tca 8.1 AVAILABLE WALL THICKNESS

FOR 3 IN.X0.3 IN. W.T. API 5L Gr. B, INT. CTG. SMLS PIPE Tca = Tn - Tm

Tca = 0.300 - 0.094

= 0.206 IN.

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

REVISION VALIDATION

11-18000-8174-005

DRAWING COMPLETION CERTIFICATE NO.

01

THIS REVISION NO.

SIS FOR 3" PIPING DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

ANDR -476 MANIFOLD DIVERSION SIS 006

GOSP-1 & P/STN TIELINES (ADT-1) 270 A TE-116318 OF 01

AIN DAR SAUDI ARABIA 007

EKRD/2616-1110.XLS

You might also like

- Structural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1Document1 pageStructural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1roger100% (2)

- Hydraulics 1Document44 pagesHydraulics 1Rhia Roxas100% (1)

- Principles of Flight Practice ExamDocument12 pagesPrinciples of Flight Practice ExamthowmasNo ratings yet

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- Lub Oil System FinalDocument44 pagesLub Oil System FinalNitish Kumar100% (3)

- 01 - ValvesDocument25 pages01 - ValvesMahmoud Ahmed Ali Abdelrazik100% (1)

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing CalculationAbelardo ContrerasNo ratings yet

- Saudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007Document1 pageSaudi Arabian Oil Company: SIS 270 A TE-116318 01 003 OF 007John BuntalesNo ratings yet

- Saudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PDocument1 pageSaudi Arabian Oil Company: Sis For 4"-P-0104-9CS9PJohn BuntalesNo ratings yet

- R789973005X0Document1 pageR789973005X0ankeshkatochNo ratings yet

- Notes:: Piping Design Conditions TAG# EH-1Document1 pageNotes:: Piping Design Conditions TAG# EH-1omarNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesLon OdiNo ratings yet

- Asbuilt Drawing Sbux MSCDocument41 pagesAsbuilt Drawing Sbux MSCbetawi digital printingNo ratings yet

- General Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahDocument3 pagesGeneral Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahRogerNo ratings yet

- TCX 1100 AbvDocument1 pageTCX 1100 AbvMarcoNo ratings yet

- FM-200 - 068-007 SHT of 1 Installation & Mounting DetailsDocument1 pageFM-200 - 068-007 SHT of 1 Installation & Mounting DetailsAhmed SweetNo ratings yet

- Detail A: PT Assy, Layout - JB34GDocument3 pagesDetail A: PT Assy, Layout - JB34GmatiasNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Notes:: Details Cast Iron Catch Basin With Side InletsDocument1 pageNotes:: Details Cast Iron Catch Basin With Side InletsJorge Garcia0% (1)

- Plano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Document2 pagesPlano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Andres BenitezNo ratings yet

- e C7330 - 1FDocument4 pagese C7330 - 1Fmina fawzyNo ratings yet

- STD WR 012Document1 pageSTD WR 012Tyburg R DhliwayoNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- HQ3 DN-B01-W04 C1Document1 pageHQ3 DN-B01-W04 C1llNo ratings yet

- 5 Integration Supersky PDFDocument4 pages5 Integration Supersky PDFnabaeisNo ratings yet

- General NotesDocument12 pagesGeneral NotesShekh Muhsen Uddin AhmedNo ratings yet

- Front View Front Interior Inner Side View Side View: ECB 150ADocument1 pageFront View Front Interior Inner Side View Side View: ECB 150ACharlie MendozaNo ratings yet

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- Saudi Arabian Oil Company: Indicates Information To Be Completed by PurchaserDocument2 pagesSaudi Arabian Oil Company: Indicates Information To Be Completed by PurchaserMohamed Wasim ShaikhNo ratings yet

- Notes:: OPEN AT 120° 5°Document1 pageNotes:: OPEN AT 120° 5°Yazan MohammadNo ratings yet

- Aa 036069 001 PDFDocument1 pageAa 036069 001 PDFprabaharan sNo ratings yet

- AB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCODocument1 pageAB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- Client: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDocument7 pagesClient: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDinesh GowdNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Ac 036437 001 - 05312022Document1 pageAc 036437 001 - 05312022JAWAHAR TNo ratings yet

- Akhilesh Tiwari Prda-ModelDocument1 pageAkhilesh Tiwari Prda-ModelSHUBHAM KUMARNo ratings yet

- HQ3 DN-B01-W03 C1Document1 pageHQ3 DN-B01-W03 C1llNo ratings yet

- Saudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Document1 pageSaudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Mohamed Wasim ShaikhNo ratings yet

- BD632MDocument13 pagesBD632MPRAKASHNo ratings yet

- A Proposed One-Storey Residential Building S1Document1 pageA Proposed One-Storey Residential Building S1Jezreel FlotildeNo ratings yet

- R789973004X0Document1 pageR789973004X0ankeshkatochNo ratings yet

- DWG. No. 117Document1 pageDWG. No. 117Mubashar Islam JadoonNo ratings yet

- S-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesDocument1 pageS-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesTAIQ MASROORNo ratings yet

- Details "B" BD 110: - Cadd Designer'SDocument1 pageDetails "B" BD 110: - Cadd Designer'SDileep K MahadevaiahNo ratings yet

- D - 01S190517-G Rev07 - AS BUILT-2Document1 pageD - 01S190517-G Rev07 - AS BUILT-2גרבר פליקסNo ratings yet

- Printed Board, Rigid-Digital Input/Output, (DIO) 60011970-2002Document4 pagesPrinted Board, Rigid-Digital Input/Output, (DIO) 60011970-2002n.poojaNo ratings yet

- APPROVAL DRAWING-ModelDocument1 pageAPPROVAL DRAWING-Modelnandkishormore1112No ratings yet

- A B C D: Reinforcement Detail of Roof LevelDocument1 pageA B C D: Reinforcement Detail of Roof LevelSampath S. WickramanayakaNo ratings yet

- St-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20Document1 pageSt-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20tarang patelNo ratings yet

- Notes:: Hinge DetailsDocument1 pageNotes:: Hinge DetailsYazan MohammadNo ratings yet

- C WatermarkedDocument2 pagesC WatermarkedNhật PhạmNo ratings yet

- KwakuDocument1 pageKwakuKwaku frimpongNo ratings yet

- Setting Out: NotesDocument1 pageSetting Out: NotesKwaku frimpongNo ratings yet

- Beam SideDocument1 pageBeam SideKwaku frimpongNo ratings yet

- 21A. GA & Structural Details of Stilling BasinDocument1 page21A. GA & Structural Details of Stilling BasinManoranjan SethiNo ratings yet

- 6612 - SM21-000-0010 - Rev02 - 01weightDocument67 pages6612 - SM21-000-0010 - Rev02 - 01weightjannsinkyNo ratings yet

- Ta-249813-023 - C - P&id - Caustic Injection PacakgeDocument1 pageTa-249813-023 - C - P&id - Caustic Injection Pacakgerizwan.zamanNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- Basic GDT 1Document1 pageBasic GDT 1vjd5wzx92xNo ratings yet

- Ca 477021 003Document1 pageCa 477021 003Sehna SerajNo ratings yet

- e C7328 - 1F PDFDocument6 pagese C7328 - 1F PDFmina fawzyNo ratings yet

- Ae 036265 001 - 05312022Document1 pageAe 036265 001 - 05312022JAWAHAR TNo ratings yet

- Section A-A: See Detail CDocument2 pagesSection A-A: See Detail CGalva decoNo ratings yet

- Orientation Plan (Hold) : TOP BottomDocument1 pageOrientation Plan (Hold) : TOP BottomSuneel MalpaniNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Q&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeDocument1 pageQ&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeJohn BuntalesNo ratings yet

- Appendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyDocument1 pageAppendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-7 Stress Summary: Saudi Arabian Oil CompanyDocument1 pageAppendix-7 Stress Summary: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- Door & Frame Types Louver TypesDocument1 pageDoor & Frame Types Louver TypesJohn BuntalesNo ratings yet

- PIP CTSE1000-2018 DatasheetsDocument2 pagesPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Pip Adg004-2014Document15 pagesPip Adg004-2014John BuntalesNo ratings yet

- Pip Adg005 Specification For Developing Data Forms For PracticesDocument20 pagesPip Adg005 Specification For Developing Data Forms For PracticesJohn BuntalesNo ratings yet

- Pip Adg003 Specification For Editing Practices: Work ProcessesDocument34 pagesPip Adg003 Specification For Editing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Appendix-2 Pipe Data Input: Saudi Arabian Oil CompanyDocument1 pageAppendix-2 Pipe Data Input: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-5 Displacement Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-5 Displacement Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-6 Stress Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-6 Stress Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-4 Restraint Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-4 Restraint Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Structural Calculation - Excavation ShoringDocument9 pagesStructural Calculation - Excavation ShoringJohn BuntalesNo ratings yet

- Design Engineer: Certified byDocument4 pagesDesign Engineer: Certified byJohn BuntalesNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Franklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byDocument1 pageFranklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byJohn BuntalesNo ratings yet

- Design of Structural Member Soldier Pile: Design Engineer Certified byDocument3 pagesDesign of Structural Member Soldier Pile: Design Engineer Certified byJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument2 pagesProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- NMR 601 For GATE VALVE Rev.00Document13 pagesNMR 601 For GATE VALVE Rev.00John BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument1 pageProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Zamil Warehouse: Original Date Prepared by Checked by Approved byDocument2 pagesZamil Warehouse: Original Date Prepared by Checked by Approved byJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Guadalupe Guerrero100% (2)

- A Simplified Model Predicting The Kelvin-Helmholtz Instability Frequency For - Simoni Et AlDocument6 pagesA Simplified Model Predicting The Kelvin-Helmholtz Instability Frequency For - Simoni Et Al赵伯驹No ratings yet

- Hydrostatics & Manometry Lab ReportDocument6 pagesHydrostatics & Manometry Lab ReportMatauka.F. MufungulwaNo ratings yet

- EPC PracticeDocument4 pagesEPC PracticeSaid Ahmed SalemNo ratings yet

- 1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Document157 pages1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Daniel PricopNo ratings yet

- Fundamentals of Fluid Mechanics: Chapter 8: Flow in PipesDocument92 pagesFundamentals of Fluid Mechanics: Chapter 8: Flow in Pipesintern kncesbNo ratings yet

- WeeklyDocument84 pagesWeeklysdan100% (1)

- 2015 07 23 Homework PhysioEx 5 KeyDocument3 pages2015 07 23 Homework PhysioEx 5 KeyMonica Sario Policina100% (1)

- Pipe and Tube Sizing: Butch G. Bataller Lecture On Che 192Document25 pagesPipe and Tube Sizing: Butch G. Bataller Lecture On Che 192MEME123No ratings yet

- III-1 & III-2 Specifications Volume 2Document588 pagesIII-1 & III-2 Specifications Volume 2saleem buksh100% (1)

- GIRPI - Katalog CPVC - STEPENDocument84 pagesGIRPI - Katalog CPVC - STEPENDragan VojinovicNo ratings yet

- Chapter 5 CFDDocument12 pagesChapter 5 CFDvadiyalaNo ratings yet

- The Hydraulic GradientDocument7 pagesThe Hydraulic GradientAl Patrick Dela CalzadaNo ratings yet

- Fluid Mechanics: Steady Incompressible Flow in Pipe SystemsDocument26 pagesFluid Mechanics: Steady Incompressible Flow in Pipe SystemsEkala XuhalxNo ratings yet

- Lesson 4: Pressure Control Valves: Basic Hydraulic SystemsDocument24 pagesLesson 4: Pressure Control Valves: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- RB - Specifications Piping MaterialsDocument21 pagesRB - Specifications Piping MaterialsFalcon PeregrinusNo ratings yet

- Myths of Rheology An StuffDocument10 pagesMyths of Rheology An StuffjamesNo ratings yet

- The LIFT FormulaDocument4 pagesThe LIFT FormulaJoséMendesNo ratings yet

- Relief Valves For Transports and Delivery TrucksDocument8 pagesRelief Valves For Transports and Delivery Truckswilfredo macoNo ratings yet

- GP3 Flow in Open Channel Lab ReportDocument30 pagesGP3 Flow in Open Channel Lab ReportArif AfifiNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Anti-Seismic Gas Installation Systems For Households: ContactDocument2 pagesAnti-Seismic Gas Installation Systems For Households: ContactCak NhassNo ratings yet

- CE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileDocument11 pagesCE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileMashal Shah JehanNo ratings yet

- Aero Ae2251 - Aerodynamics - IDocument10 pagesAero Ae2251 - Aerodynamics - IKalpit KauraseNo ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet