Professional Documents

Culture Documents

HIRA, TCS-ACP Sheet Fixing

HIRA, TCS-ACP Sheet Fixing

Uploaded by

Gowtham KishoreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA, TCS-ACP Sheet Fixing

HIRA, TCS-ACP Sheet Fixing

Uploaded by

Gowtham KishoreCopyright:

Available Formats

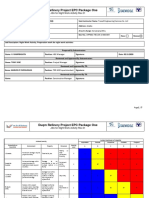

HARSHAL BUILDCON LLP.

TCS SP2 PROJECT, HINJEWADI PHASE 3,PUNE

HAZARD IDENTIFICATION AND RISK ASSESSMENT

HIRA NO:03

Activity: ACP Sheet Fixing

Perp. By Review by Approved by

Office / Site Contractor Client

Safety Comm. Team PMC/Client Ref. No-11L/SHE/HIRA/GFPL-03 Date - 06/11/2019

TCS SP2 GFPL TCE

Risk Assessment - With out control

Risk Assessment - With control measures Legal Statutory Additional

Sl. No Sub - activity Hazard Risk measures Existing Countol measures Action By

Compliance measures needed

S P RL Risk S P RL Risk

1) All vehicle document should be checked by security guard,.Driving

Road Accident, linceance,PUC,Insusrance and Vehicle documents etc.

2) signal man & reverse horn should checked & available for vehicle.

Untrained worker, 3)Vehicle should be park in parking area.

Personal injury, 4)after parking stopper should be provided.

Supervision

1 Manpower Mobilization lack of skill/awareness, 4 4 16 H 5)Competent person should be deployed. 3 2 6 L Site Engineer

provided .

Fatal 6) ladder should be provid for labour entry in vehicle.

over speed 7) Work permit shall be obtained before start of Work.

8)Matrieal unloding will done by manulley.

Unauthorized Driver/Psc 9)Material stacking by one by one .

10))Continuous & effective supervision should be available at workplace.

Slip & Trip 1)Trained persons deployed for the work. Access and egress should be

Shifting Brackets And Aluminum Personal Injury/Property Supervision

2 3 2 6 M marked and safe for person movement. 2 1 2 L Site Engineer

Section working Area damage provided .

Shrap eadge 2)Supervision for monitoring the work.

1) Damage hand tools should be not use.

2)Trained persons deployed for the work

Damage Handtools

3)Avoid over laping activity at work location

Personal Injury/Property 4)Monitor activity under close supervision. Supervision

Bracket Fixing Overlaping activity 4 4 16 H 3 2 6 L Site Engineer

damage 5)Provide training on safe material handling before start of activity. provided .

6)Only trained person deployed for the hadling Materials, Use of PPE's

uneven surface,

work place area should be even and safe access provided upto the work

place

1)Ensure that no worker can perform Drilling, cutting activity without use

3 of goggle.

2)Aware worker about job specific hazards during TBT

Flying particles/Che/Env Eye injury/Eye irritation 3)Monitor activity under close supervision.

4)Provide training on safe useing portable hadn tools handling before

Sharpe edge, Personal Injury/Property start of activity. Supervision

Drilling and Cutting of Aluminum 4 3 12 H 3 2 6 L Site Engineer

damage 5)Only trained person deployed for the hadling portable hand tools provided .

Noise machines

NITTS/NIPTS 6)area should be even and safe access provided upto the work place.

7)Use of required PPEs as per OSHA norms- safety shoes, safety helmet,

safety goggle, reflective jacket. etc.

8)Ensure good housekeeping at work place

1)Provided safe working platform with all side mid & top railing.

2)Use of F.B.S.H during the height work.

3)Provided height work training to the workers.

Using uninspected scaffolding

4) Used only inspected scaffolding ( green tag means - use to work & red

4 ACP Sheet fixing cut Injury/Personal Injury 3 2 6 M 2 1 2 L

tag means Scaffolding not in use ) & it same monitor by responsible

Sharpe edge,

person.

5)Use of required PPEs as per OSHA norms- safety shoes, safety helmet,

safety goggle, reflective jacket. etc.

1)Night work permit to be taken from concern engg.and safety dept.

2)Provided sufficent light at working area.

Illumination, Personal injury, 3)Electrical cable should lead min 2 m height. No exposed electrical

Supervision

5 Work during night shift 2 2 4 H wire.Earthing. 2 1 2 L Site Engineer

provided

fall of person, Damage to property 4)Route shall be illuminated .7)Continuous & effective supervision should

be available at workplace.

5)Ensure good housekeeping at work place.

S - Severity P - Probability Risk level (RL) = S X P

S - Significant ( Risk > 2) NS - Non-Significant ( Risk =< 2) LC - Legal Concem NA - Not Applicable

This ratings for severity and probability in the during HIRA assessment shall be taken from the following table

Severity of Hazard (S) Probability of Hazard (P)

Time

Rating severity Injury / Consequene Rating Probability Occurrence

Period

Near miss / First Aid OR Damage cost Highly Incident / accident observed at 1

1 Slightly Harmful 1 > 2years

(property) worth < Rs.50,000 unlikely workplace

Minor Accident OR Damage cost

< 2years & Incident / accident observed at 1

2 Harmful (property) worth > Rs.50,000 & < Rs. 2 Unlikely

> 1 Year workplace

1,00,000

Major Accident OR Damage cost Incident / accident observed at 1

3 Very Harmful 3 Likely > 1 Year

(property) worth > Rs. 1,00,000 workplace may happan

Prepaired Reviwed Approved

You might also like

- Risk Assessment For Anti Termite TreatmentDocument3 pagesRisk Assessment For Anti Termite TreatmentVictor81% (26)

- Risk Assessment Concrete Cutting - 02Document6 pagesRisk Assessment Concrete Cutting - 02kapsarc60% (5)

- Concrete & Form Work: Job Safety Analysis Pouring ConcreteDocument1 pageConcrete & Form Work: Job Safety Analysis Pouring ConcreteHortencio Samuel100% (5)

- Method Statement & Risk Assessment For Roller ShutterDocument3 pagesMethod Statement & Risk Assessment For Roller Shutterchandanprakash30100% (1)

- JSA-004 Bar Bending & Cutting WorkDocument3 pagesJSA-004 Bar Bending & Cutting Workba ratnaparkhe92% (12)

- Risk AssessDocument5 pagesRisk AssessAnonymous iI88Lt0% (1)

- Artifact 2Document7 pagesArtifact 2api-465941797100% (1)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- 97 Glass Removal and Replacement-JOB PROCEDUREDocument2 pages97 Glass Removal and Replacement-JOB PROCEDUREAmalia Dwi Aryanti100% (1)

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- SWMS - Glass PartitionDocument11 pagesSWMS - Glass PartitionParasNo ratings yet

- Rebar Installation: Job Safety AnalysisDocument1 pageRebar Installation: Job Safety AnalysisRetselisitsoe100% (3)

- Woodbarn Case Analysis PresentationDocument12 pagesWoodbarn Case Analysis PresentationNyein WaiNo ratings yet

- Free Money Utilizing YOUR Treasury Direct Accounts Birth CertificateStrawman TrustBond - UnderstandiDocument30 pagesFree Money Utilizing YOUR Treasury Direct Accounts Birth CertificateStrawman TrustBond - Understandilerosenoir100% (11)

- As 1755-2000 Conveyors - Safety RequirementsDocument8 pagesAs 1755-2000 Conveyors - Safety RequirementsSAI Global - APACNo ratings yet

- Risk Assessment For Aluminium Handrail InstallationDocument5 pagesRisk Assessment For Aluminium Handrail InstallationKalid Jmal100% (1)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- Dismantling of WallDocument1 pageDismantling of WallChandruNo ratings yet

- Risk Assessment For Plaster WorksDocument2 pagesRisk Assessment For Plaster WorksMuthukumar Jayaveerapandian100% (1)

- Mobile - Scaffolds JSADocument10 pagesMobile - Scaffolds JSABojie Abogadie100% (2)

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- Passenger Hoist LiftDocument1 pagePassenger Hoist LiftGyanendra Narayan Nayak100% (3)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- 9.JSA For Night Work Activity - Rev 01Document7 pages9.JSA For Night Work Activity - Rev 01ibrahim80% (10)

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- Jacksonville Jaguars Media PlanDocument14 pagesJacksonville Jaguars Media PlanOakenshield1100% (1)

- The Franchisor Feasibility StudyDocument12 pagesThe Franchisor Feasibility StudyLeighgendary CruzNo ratings yet

- Golf Resort Trend & ChallengesDocument8 pagesGolf Resort Trend & ChallengesAzmi Che LehNo ratings yet

- TQM PolaroidDocument36 pagesTQM Polaroiduttam.nift100% (1)

- HIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01Document21 pagesHIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01mahesh naik100% (1)

- 6.chain Pulley BlockDocument2 pages6.chain Pulley BlockFrancis Vinoj75% (4)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Risk Assessment For Back FillingDocument6 pagesRisk Assessment For Back FillingBhargav BbvsNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- False CeilingDocument1 pageFalse CeilingChandru60% (5)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (2)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh50% (2)

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pages(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeep100% (1)

- Jsa For Brick WorkDocument4 pagesJsa For Brick WorkSushil Kumar YadavNo ratings yet

- HIRA - Carpentry Work-018Document8 pagesHIRA - Carpentry Work-018Satya Naidu100% (1)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkTigor Gurning100% (1)

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (2)

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Back FillingDocument2 pagesBack FillingChandru0% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- HIRA For Concrete Pouring of Diaphragm WallDocument4 pagesHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Mivan Risk AssessmentDocument3 pagesMivan Risk AssessmentBineeshNo ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- JSA - Non-Destructive Testing (NDT) - Magnetic Particle TestDocument7 pagesJSA - Non-Destructive Testing (NDT) - Magnetic Particle TestRajuNo ratings yet

- Practice 1 (TV)Document10 pagesPractice 1 (TV)Linh Truc VoNo ratings yet

- Quiz Techno Group1 ECEEEMEDocument2 pagesQuiz Techno Group1 ECEEEMEJohn Mark BallesterosNo ratings yet

- 1st Sem Result of BBA (B&I) Exam Held in Feb 2023Document33 pages1st Sem Result of BBA (B&I) Exam Held in Feb 2023HardikNo ratings yet

- Business and Education Advisory MembersDocument1 pageBusiness and Education Advisory MembersMichelle StubbsNo ratings yet

- GMAT Verbal and Quant Official Questions1Document3 pagesGMAT Verbal and Quant Official Questions1PratikJainNo ratings yet

- Challan Form PDFDocument2 pagesChallan Form PDFMuhammad JamilNo ratings yet

- Assignment On Monetary Policy in BangladeshDocument6 pagesAssignment On Monetary Policy in BangladeshAhmed ImtiazNo ratings yet

- Kajian Kadar Batas Optimum Optimum Cut-Off Grade Pada Penambangan Nikel Laterit-with-cover-page-V2Document7 pagesKajian Kadar Batas Optimum Optimum Cut-Off Grade Pada Penambangan Nikel Laterit-with-cover-page-V2Frek.3klp5.0195 Ariestasyariah C satuNo ratings yet

- MBA's Class of 2014: Amity UniversityDocument2 pagesMBA's Class of 2014: Amity UniversityAnuj HandaNo ratings yet

- MicroStrategy Education Catalog PDFDocument72 pagesMicroStrategy Education Catalog PDFgeoinsys100% (1)

- Admas University Bishoftu Campus: Course Title - Title: Group Assignment 2 Name ID Section Division DeptDocument6 pagesAdmas University Bishoftu Campus: Course Title - Title: Group Assignment 2 Name ID Section Division DeptKalkidan Mesfin sheferawNo ratings yet

- MGMT 375 Trial ExamDocument2 pagesMGMT 375 Trial ExamPrince-SimonJohnMwanzaNo ratings yet

- Working Jocil 06Document83 pagesWorking Jocil 06Phani Deepika Koritala0% (1)

- Introduction To AuditingDocument24 pagesIntroduction To AuditingVinayak SaxenaNo ratings yet

- Downstream Oil TheftDocument116 pagesDownstream Oil TheftThe Atlantic CouncilNo ratings yet

- 5 Characteristics-Defined ProjectDocument1 page5 Characteristics-Defined ProjectHarpreet SinghNo ratings yet

- IBM Cognos 8 4 1 Administration and Security GuideDocument841 pagesIBM Cognos 8 4 1 Administration and Security GuidecoolcapsiNo ratings yet

- Internet Marketing - Response and Database FoundationsDocument25 pagesInternet Marketing - Response and Database FoundationsDr Rushen SinghNo ratings yet

- 1 GTAG Assessing Cybersecurity RiskDocument31 pages1 GTAG Assessing Cybersecurity RiskWrafael Garcia100% (3)

- Tata Company Entering Into China Market: Module Title: Module Code: Module Leader's NameDocument31 pagesTata Company Entering Into China Market: Module Title: Module Code: Module Leader's NameSouradeep SadhukhanNo ratings yet

- Basic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaDocument20 pagesBasic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaVenky PragadaNo ratings yet

- JIMS International Conference Paper Sequence Details - Top Management Institute in India Delhi NCR Management International Events Seminars ConferencesDocument11 pagesJIMS International Conference Paper Sequence Details - Top Management Institute in India Delhi NCR Management International Events Seminars ConferencesJagan Institute of Management StudiesNo ratings yet