Professional Documents

Culture Documents

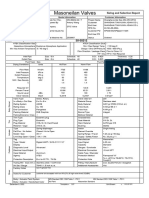

Customer Application Data Customer Application Data Customer Application Data Customer Application Data

Customer Application Data Customer Application Data Customer Application Data Customer Application Data

Uploaded by

adkon mksOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Application Data Customer Application Data Customer Application Data Customer Application Data

Customer Application Data Customer Application Data Customer Application Data Customer Application Data

Uploaded by

adkon mksCopyright:

Available Formats

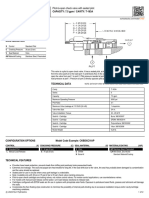

Soot Blower

In a Power Station, boiler water is converted into steam by using pulverized coal. The coal leaves a soot deposit

on the tubes, which restricts the energy transfer, and therefore the required heat of the steam for the turbine to op-

erate efficiently may not be reached. To remove this build-up, boiler Bleed off Steam is bled off the system and

directed to a nozzle arrangement that will flush the pipes. The valve that controls this feed is called the Soot

Blower Valve. Depending on the number and type of Soot Blowers being used the steam requirement varies con-

siderably.

Customer Application Data

The customer wanted the valve to operate under the following conditions:

• Max flow rate - 3 kg/s

• Min flow rate - 1 kg/s

• Inlet pressure-norm - 190 bar ( a )

• Inlet pressure-max - 172 bar ( a )

• Norm pressure drop - 160 bar ( a )

• Max pressure drop - 174 bar ( a )

• Temperature - 540°C

• Fail Action - ( o pen under spring tension with no air )

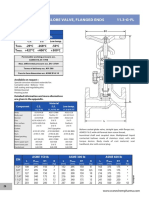

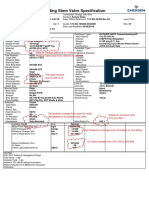

Description of Valve Supplied

TRIM BODY

Type : StSt Energy Dissipating Disk Stack x 10 Size : 2” - 50mm

Plug Material : Stellite coated 316 StSt Style Valve : Globe Control Valve

Seat Material : Stellite coated 316 StSt Material : Cr Mo (WC6)

Seat diameter : 20mm Flange type : Butt Weld

CV Selected : 5.5 Flange rating : ANSI 2500#

Flow direction: Under

Leakage rate : ANSI V

BONNET ACTUATOR

Kendal Power Station Material : Cr Mo Type : Pneumatic Piston

Guide-Upper : StSt/ Grafoil Fail position : Open - spring

Guide-Lower : Stellite

Packing : Graphite braid

Gaskets : StSt / Grafoil POSITIONER

Live Loading : Yes Type : Pneumatic /Pneumatic

PREVIOUS VALVE USED FOR APPLICATION PROBLEMS EXPERIENCED

Cage Guided Globe Control Valve Body cracked due to wrong material (StSt) used

Trim lasted only a short time period due to only having

a single pressure drop

www.spiraxsarco.com/za +27 11 230 1300

You might also like

- ARGO-SC e HP 120-127-135 WQDocument62 pagesARGO-SC e HP 120-127-135 WQf.simula50% (2)

- Cargo Oil Pump TurbineDocument16 pagesCargo Oil Pump TurbineNikolay KirovNo ratings yet

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDocument5 pagesRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavNo ratings yet

- Description of Valve Supplied Description of Valve Supplied Description of Valve Supplied Description of Valve SuppliedDocument1 pageDescription of Valve Supplied Description of Valve Supplied Description of Valve Supplied Description of Valve SuppliednaidooriNo ratings yet

- Catalogo 2 WHxrbcyDocument2 pagesCatalogo 2 WHxrbcyOmar Equihua LinaresNo ratings yet

- Ebara Vertical Inline Pump - LPDADocument8 pagesEbara Vertical Inline Pump - LPDAGeorge CobraNo ratings yet

- Product Data Sheet: HV Gate Valve, Series 140, DN 100 (ID 4'') Ordering No. 14040-PE44Document2 pagesProduct Data Sheet: HV Gate Valve, Series 140, DN 100 (ID 4'') Ordering No. 14040-PE44Ken NgNo ratings yet

- WW ACC PILOT Model 3HC - 1Document1 pageWW ACC PILOT Model 3HC - 1agieyogaswaraNo ratings yet

- Item 40Document10 pagesItem 40Đình TânNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Acv ZW205FPDocument3 pagesAcv ZW205FPSamy El-BeheryNo ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- Technical Specifications Customer:: Alstom Finland OyDocument8 pagesTechnical Specifications Customer:: Alstom Finland OyAlex BaciuNo ratings yet

- Data Sheet - : Firemiks® FM 6000-Rp-FDocument3 pagesData Sheet - : Firemiks® FM 6000-Rp-Fzepol051No ratings yet

- File KSB Etanorm Syt Thermal Oil Hot Water Pumps 96757Document24 pagesFile KSB Etanorm Syt Thermal Oil Hot Water Pumps 96757Abdullah MunawirNo ratings yet

- Single Pantry Faucet: LOW LeadDocument1 pageSingle Pantry Faucet: LOW LeadCasper John Nanas MuñozNo ratings yet

- En5922 6 - Db16621e 10Document2 pagesEn5922 6 - Db16621e 10markoNo ratings yet

- Litsie enDocument4 pagesLitsie enlesonspkNo ratings yet

- Etanorm Sya ModelDocument4 pagesEtanorm Sya ModelIna MeranNo ratings yet

- Datasheet 1803 enDocument2 pagesDatasheet 1803 enPhan Việt AnhNo ratings yet

- 2017 GST - Sant Retail Price List Dated 27.07.17 PDFDocument60 pages2017 GST - Sant Retail Price List Dated 27.07.17 PDFkoto group100% (1)

- Sant List April-2017Document61 pagesSant List April-2017Javed HasanNo ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- PU126TI E1F MotorDocument2 pagesPU126TI E1F MotorANGEL UQUILLASNo ratings yet

- GE25 MediumDuty Flowmeters and Flowmeter Regulators EnglishDocument2 pagesGE25 MediumDuty Flowmeters and Flowmeter Regulators English8nb9kdwg2mNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Types 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsDocument8 pagesTypes 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsAlberto CastellanosNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- Pipeline WeldingDocument61 pagesPipeline Weldingravi00098No ratings yet

- Control Valve and Steam Line PDFDocument19 pagesControl Valve and Steam Line PDFRofi MuhammadNo ratings yet

- Bellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBDocument4 pagesBellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBfranznelsonNo ratings yet

- Subros Ac XYLODocument36 pagesSubros Ac XYLOjag18718No ratings yet

- CKBDXCV ApDocument2 pagesCKBDXCV ApŁukasz OlszewskiNo ratings yet

- Forged Steel High Pressure ValvesDocument32 pagesForged Steel High Pressure ValvesMukiara LuffyNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Atlas Copco ZS Series BlowersDocument46 pagesAtlas Copco ZS Series BlowersMamta Raybage100% (1)

- PRIMEROYAL® K Dosing Pump: Main Mechanical CharacteristicsDocument2 pagesPRIMEROYAL® K Dosing Pump: Main Mechanical Characteristicstoan buiNo ratings yet

- 401-042825-01 Specifications & SizingDocument2 pages401-042825-01 Specifications & SizingJackNo ratings yet

- A-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils BrochureDocument2 pagesA-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils Brochurekeith dietrichNo ratings yet

- Fluid Cooling P-BAR: Industrial BOL SeriesDocument8 pagesFluid Cooling P-BAR: Industrial BOL SerieswilliamNo ratings yet

- 01-ME - 01.00.00 - Check Gates 2500 X 2500Document50 pages01-ME - 01.00.00 - Check Gates 2500 X 2500JonesNo ratings yet

- Valve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Document2 pagesValve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Tu PhamNo ratings yet

- Globe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"Document4 pagesGlobe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"dmitosNo ratings yet

- Self-Priming Pump T6A3 BDocument3 pagesSelf-Priming Pump T6A3 BArturoCastelloNo ratings yet

- VOSLP /F 34 (100) : Overcenter ValvesDocument2 pagesVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNo ratings yet

- Arita Katalog Building - SmallDocument16 pagesArita Katalog Building - SmallAlamsyah PutraNo ratings yet

- T070420 Spec (PCV2)Document12 pagesT070420 Spec (PCV2)Elias EliasNo ratings yet

- Asdfasr 2 Q 4235Document3 pagesAsdfasr 2 Q 4235Claire BernardNo ratings yet

- Type 119 Control Valve: Bulletin 51.1:119Document4 pagesType 119 Control Valve: Bulletin 51.1:119Fernando GiadansNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- VAIL 10 - PP: Pressure Relief ValvesDocument2 pagesVAIL 10 - PP: Pressure Relief ValvesSachin RamadasanNo ratings yet

- 1H000200 PDFDocument2 pages1H000200 PDFSachin RamadasanNo ratings yet

- Bombas Centrifugas KSB EtanormDocument11 pagesBombas Centrifugas KSB EtanormNajem SakorNo ratings yet

- D-Direct-Coupled Volute Pumps PDFDocument73 pagesD-Direct-Coupled Volute Pumps PDFMahfudz FauziNo ratings yet

- Data Sheet Firemiks FM 4000 GP F Aut 2016-11-14Document3 pagesData Sheet Firemiks FM 4000 GP F Aut 2016-11-14muthuvelaaNo ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- Mooney 2 LP FLowgrid Shutoff ValveDocument2 pagesMooney 2 LP FLowgrid Shutoff ValveLuis mario Castillo olveraNo ratings yet

- Product Data Sheet: Vacuum Gate Valve, Series 121, DN 100 (ID 4'') Ordering No. 12140-PA03Document1 pageProduct Data Sheet: Vacuum Gate Valve, Series 121, DN 100 (ID 4'') Ordering No. 12140-PA03Fabio VallejoNo ratings yet

- Screwpump Series: Product DescriptionDocument12 pagesScrewpump Series: Product DescriptionMick VNo ratings yet

- Course Outline and Content - Renewable - EnergyDocument2 pagesCourse Outline and Content - Renewable - EnergyAshik AhmedNo ratings yet

- Outline MET-362 StaticsDocument1 pageOutline MET-362 StaticsSajid YasinNo ratings yet

- Part I Fundamentals of Fluid DynamicsDocument42 pagesPart I Fundamentals of Fluid Dynamicsmike100% (1)

- Copeland CR Series Compressors en SG 4857976Document8 pagesCopeland CR Series Compressors en SG 4857976udai singhNo ratings yet

- Single Drum Vibratory Rollers: BW124-40 SeriesDocument4 pagesSingle Drum Vibratory Rollers: BW124-40 SeriesVlad SuteuNo ratings yet

- SDA-835TAB: 8" Tablet Tableta de 8" Tablet 8" 8 吋平板電腦 Tablet 8" 8 8Document56 pagesSDA-835TAB: 8" Tablet Tableta de 8" Tablet 8" 8 吋平板電腦 Tablet 8" 8 8dianaNo ratings yet

- Aterramento Da EstaçãoDocument185 pagesAterramento Da EstaçãoAnízio Luiz Freitas de MesquitaNo ratings yet

- 6.thermodynamics: Material Downloaded From SUPERCOP 1/8Document8 pages6.thermodynamics: Material Downloaded From SUPERCOP 1/8Abhinash MahapatroNo ratings yet

- VibrationDocument18 pagesVibrationKamille NayraNo ratings yet

- Corrosion - Electrochemical MethodsDocument1 pageCorrosion - Electrochemical MethodsjuegyiNo ratings yet

- DIL Series Reed Relays: D I L 0 0 - 0 X 0 0 - 0 0 XDocument3 pagesDIL Series Reed Relays: D I L 0 0 - 0 X 0 0 - 0 0 Xjuan manuel patiño moralesNo ratings yet

- Applied Thermal Engineering: SciencedirectDocument14 pagesApplied Thermal Engineering: SciencedirectArlen GutierrezNo ratings yet

- HVAC System Selection ReportDocument16 pagesHVAC System Selection ReportArman Ul Nasar100% (1)

- 3MS Course NotesDocument84 pages3MS Course NotesJimmy WuNo ratings yet

- Chemistry Electrolysis DeconstructionDocument11 pagesChemistry Electrolysis DeconstructionGhostNo ratings yet

- Transformer XII B Physics Shivam Beda InvestigatoryDocument14 pagesTransformer XII B Physics Shivam Beda InvestigatoryJohn SamuelNo ratings yet

- Olatunji AdewaleDocument125 pagesOlatunji AdewaleEbenezer Amoah-KyeiNo ratings yet

- JS750 Concrete MixerDocument5 pagesJS750 Concrete MixerErikNo ratings yet

- 2005 Deep Snow - 9919302Document308 pages2005 Deep Snow - 9919302bentwrenchNo ratings yet

- Well Cementation: SynopsisDocument18 pagesWell Cementation: SynopsisHolger PinzonNo ratings yet

- HVACR416 - Design: Heat Loss / Heat GainDocument35 pagesHVACR416 - Design: Heat Loss / Heat GainAdhanom G.No ratings yet

- Mock Exam Subject 3 - Part 2Document12 pagesMock Exam Subject 3 - Part 2KitzNo ratings yet

- Pengolahan Limbah Cair Tahu Menjadi Biogas Sebagai BahanDocument13 pagesPengolahan Limbah Cair Tahu Menjadi Biogas Sebagai BahanEka PratiwiNo ratings yet

- D352004107 MKT 001 PDFDocument20 pagesD352004107 MKT 001 PDFEloy Lardet LafiNo ratings yet

- Combustible Gas Detector Datasheet PDFDocument4 pagesCombustible Gas Detector Datasheet PDFUğur ZoroğluNo ratings yet

- LA SpecificationDocument3 pagesLA SpecificationVino VinoNo ratings yet

- Neutron Radiography: What Is NDT?Document4 pagesNeutron Radiography: What Is NDT?mohamedNo ratings yet