Professional Documents

Culture Documents

Piping Material Specification: Pipe Data

Piping Material Specification: Pipe Data

Uploaded by

Bhaumik BhuvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Material Specification: Pipe Data

Piping Material Specification: Pipe Data

Uploaded by

Bhaumik BhuvaCopyright:

Available Formats

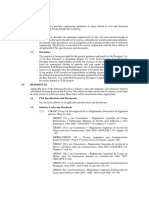

PAGE NO 80 OF 84

PIPING MATERIAL SPECIFICATION

SHEET NO

PROJECT : WIS-R PROCESS PLATFORM PROJECT

1 OF 3 D16

DESIGN CODE DOCUMENT NO : C19002-PP-GEN-SPE-001

MATERIAL CA CLASS NOTE REV

ASME B31.3 SERVICE RO FEED(RF), RO REJECT(RJ)

NO NO

SDSS NIL 600 #

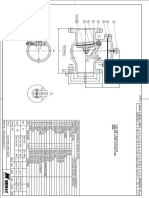

PIPE DATA

SIZE (NPS) 0.5 0.75 1 1.5 2 3 4 6 8 10 12 14 2

NEGATIVE MILL

12.50%

TOLERANCE

PIPE ASME B36.19 ASME B36.19

SCH 80S 40S 10S 40S

THK (MM) 3.73 3.91 4.55 5.08 3.91 3.05 3.05 7.11 8.18 9.27 9.53 9.53 5 & 11

SEAMLESS SEAMLESS EF WELDED WITH 100% RADIOGRAPHY

MOC

ASTM A790 Gr. UNS S 32750 ASTM A790 Gr. UNS S 32750 ASTM A 928 CLASS 1 Gr. UNS S32750

END PE BE

NIPPLE

ASME B36.19

(100 mm)

MOC

SEAMLESS 11

ASTM A790 Gr. UNS S 32750

END END TO SUIT PIPE

SWAGE MSS SP-95 MSS SP-95

SEAMLESS SEAMLESS

MOC ASTM A182 Gr. 5, 10

ASTM A182 Gr. F53 UNS S 32750 F53 UNS S

32750

& 11

END TO SUIT

END END TO SUIT PIPE

PIPE

FITTINGS ASME B16.11 ASME B16.9

MOC ASTM A182 Gr. F53 UNS S 32750 ASTM A815 Gr. UNS S 32750 WPS ASTM A815 Gr. UNS S 32750 WPWX 3, 4,

END BUTT WELD THICKNESS SAME AS PIPE THICKNESS / SCHEDULE

BUTT WELD THICKNESS SAME AS PIPE THICKNESS / 5,11 &

SOCKET WELD 3000#

SCHEDULE 17

TYPE ELBOW, TEE,COUPLING ELBOW (LR),TEE,REDUCER(CONC OR ECC) ELBOW (LR),TEE,REDUCER(CONC OR ECC)

OLET MSS SP- 97 MSS SP- 97

MOC ASTM A182 Gr. F53 UNS S 32750 ASTM A182 Gr. F53 UNS S 32750 11

TYPE SOCKOLET 3000# WELDOLET,THICKNESS SAME AS PIPE THICKNESS / SCHEDULE

FLANGE ASME B16.5 ASME B16.5

ASTM A182 Gr. F53 UNS S 32750 ASTM A182 Gr. F53 UNS S 32750 5,6&

MOC RF-SMOOTH FINISH 15

RF-SMOOTH FINISH (32 TO 63 µ INCH AARH)

(32 TO 63 µ INCH AARH)

END 600# SOCKET WELD 600#, WELD NECK ; BORE TO MATCH PIPE THICKNESS

BLIND

ASME B16.5 ASME B16.5

FLANGE

ASTM A182 Gr. F53 UNS S 32750 ASTM A182 Gr. F53 UNS S 32750 12

MOC 600# RF SMOOTH FINISH (32 TO 63 µ INCH 600# RF, SMOOTH FINISH (32 TO 63 µ INCH AARH)

AARH)

FLANGE

ASME B16.5 ASME B16.5

(OPTIONAL-1)

5,6&

ASTM A182 Gr. F53 UNS S 32750 ASTM A182 Gr. F53 UNS S 32750

MOC

RTJ (MAX. 63 µ INCH AARH) RTJ (MAX. 63 µ INCH AARH)

15

END 900# SOCKET WELD 900#,WELD NECK ; BORE TO MATCH PIPE THICKNESS

FLANGE

ASME B16.5

(OPTIONAL-2)

5,6,

ASTM A182 Gr. F53 UNS S 32750

MOC

15 &

FF-SMOOTH FINISH (32 TO 63 µ INCH AARH) 18

END 600#, WELD NECK ; BORE TO MATCH PIPE THICKNESS

LINE BLANK ASME B16.48

ASTM A182 Gr. F53 UNS S 32750 SMOOTH FINISH

MOC

(32 TO 63 µ INCH AARH)

TYPE SPECTACLE BLIND, 600# FF SPACER & BLIND, 600 # FF

STUD BOLT ASTM A453 Gr 660 CLASS A , ASME B 1.1

HEAVY

ASTM A453 Gr 660 CLASS A , ASME B 18.2.2

14

HEX NUT

SIZE (NPS) 0.5 0.75 1 1.5 2 3 4 6 8 10 12 14

600 # SPIRAL WOUND GASKET : WND: SDSS UNS S 32750, 4.5 mm THK CNAF FILLER CENTERING-SDSS INNER RING -SDSS,

GASKET DEFAULT SELECTION

ASME B 16.20 WITH 22 HRC MAX

CONNECTING TO FLANGE(OPTIONAL) 900 # ASME B 16.20 OCT RING SDSS UNS S 32750 WITH MAX HARDNESS OF 22 HRC

RING NO

R12 R14 R16 R 20 R24 R31 R37 R45 R49 R53 R57 R62

C1 23-08-2019 ISSUED FOR CLIENT COMMENTS ADU SN GSB

REV DATE DESCRIPTION PREPD CHECKD APPRD.

PAGE NO 81 OF 84

PIPING MATERIAL SPECIFICATION

PROJECT : WIS-R PROCESS PLATFORM PROJECT SHEET NO

2 OF 3

D16

DESIGN CODE DOCUMENT NO : C19002-PP-GEN-SPE-001

MATERIAL CA CLASS NOTE REV

ASME B31.3 SERVICE RO FEED(RF), RO REJECT(RJ)

NO NO

SDSS NIL 600 #

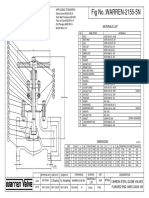

VALVE DATA

BODY- ASTM A182 Gr. F53/ A995 Gr. 5A

TRIM- DSS UNS S32750

SIZE (NPS) 0.5 0.75 1 1.5 2 3 4 6 8 10 12 14

TYPE BALL VALVE

TAG VB-233 VB-216

END 800#, PE 600#, RF, FLGD

TAG VB-233B 7

END 800#, PE X NPTM

TAG VB-233BS (FOR 0.5" ONLY)

END 800#, NPTM X NPTM

TYPE CHECK VALVE

TAG VC-233 VC-216 (SWING CHECK) 9

END 800#, SW 600#, RF, FLGD

TYPE GATE VALVE

TAG

END

TYPE GLOBE VALVE

TAG

END

TYPE BUTTERFLY VALVE

TAG VBF-216

END 600#, RF, WAFER- LUG TYPE

TYPE NEEDLE VALVE

TAG VN-233

END 800#, SW

C1 23-08-2019 ISSUED FOR CLIENT COMMENTS ADU SN GSB

REV DATE DESCRIPTION PREPD CHECKD APPRD.

PAGE NO 82 OF 84

PIPING MATERIAL SPECIFICATION

SHEET NO

PROJECT : WIS-R PROCESS PLATFORM PROJECT

3 OF 3 D16

DESIGN CODE DOCUMENT NO : C19002-PP-GEN-SPE-001

MATERIAL CA CLASS REV

ASME B31.3 SERVICE RO FEED(RF), RO REJECT(RJ)

NO

SDSS NIL 600 #

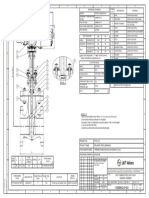

BRANCH TABLE : API RP 14 E MAX HYDROSTATIC TEST PRESSURE PRESSURE TEMPERATURE RATING

LEGEND DIMENSION STD Kg/cm²g PSIG TEMP °F PRESSURE , Kg/cm²

TK SOCKOLET 158.18 2250 -4 to 131 105.46

MSS SP-97

TW WELDOLET

LIMITED BY CONSIDERING FLANGE AS

T EQUAL TEE

ASME B16.11 & ASME B16.9 THE WEAKEST JOINT IN THE PIPING

RT REDUCING TEE SYSTEM

TS EQUAL TEE WITH SWAGE ASME B16.9 & MSS SP-95

0.5 T

0.75 RT T

1 RT RT T

1.5 RT RT RT T

RUN PIPE

2 TK TK TK TS T

3 TK TK TK TK RT T

4 TK TK TK TK RT RT T

6 TK TK TK TK TW RT RT T

8 TK TK TK TK TW TW RT RT T

10 TK TK TK TK TW TW TW RT RT T

12 TK TK TK TK TW TW TW RT RT RT T

14 TK TK TK TK TW TW TW TW RT RT RT T

0.5 0.75 1 1.5 2 3 4 6 8 10 12 14

BRANCH

TECHNICAL NOTES

NOTE NO RELATED DESCRIPTION

ALL PIPING SHALL MEET THE REQUIREMENTS OF ONGC FUNCTIONAL SPECIFICATION OF PIPING DESIGN 2004A REV. 9 AND READ IT CONJUCTION WITH

1 GENERAL

THE GENERAL NOTES OF THIS DOCUMENT.

MIN. NPS SHALL BE 3/4" EXCEPT FOR INSTRUMENT AIR, WATER AND VENDOR PACKAGE EQUIPMENT PIPING ( WHERE MANUFACTURER CANNOT

2 SIZE

PROVIDE >=3/4" CONNECTION).

3 COUPLING PIPE COUPLING SHALL BE USED WHEN CONNECTING PLAIN END PIPE

THE WALL THICKNESS OF REDUCING FITTING SHALL MATCH THE WALL THICKNESS OF THE HIGHER SCHEDULE PIPE WALL. THE FITTING WALL

4 REDUCED FITTINGS THICKNESS SHALL BE TAPERED AS A 1:4 GRADIENT TO ENSURE THAT THE PIPE FITTING WALL THICKNESS MATCHES THE LOWER SCHEDULE PIPE

WALL

5 BUTT WELD ALL BEVEL END SHALL BE PREPARED TO ASME B16.25

FLANGE

WHERE EVER LINE BLANK IS USED FOR 3" & ABOVE SIZES, ONE OF THE MATING FLANGES SHALL BE PROVIDED WITH TWO JACK SCREW HOLES

6 (FOR LINE BLANK

DRILLED ON THE FLANGE BOLT CIRCLE 180 ° APART COMPRISING OF 0.75" BOLT DIA .

CONNECTION)

SOCKET WELDED BALL VALVE SHALL BE PROVIDED WITH 120 mm NIPPLE ON BOTH SIDES, SCH/THK. TO MATCH PIPE ASTM A790 Gr. UNS S 32750

TYPE OF VALVE SHALL BE SELECTED AS PER P&ID REQUIREMENT.

7 BALL VALVE

BALL VALVE SHALL BE LEVER OPERATED FOR SIZES UP TO 3" AND GEAR OPERATED FOR SIZES 4" AND ABOVE & ALSO SATISFYING TORQUE

REQUIREMENT MENTIONED IN FS 2004A REV.9

ANY ONE FLANGE SHALL HAVE TWO JACK SCREW BOLT HOLES DRILLED ON THE FLANGE BOLT CIRCLE CENTER LINE AT 90 DEG FROM THE PRESSURE

8 ORIFICE FLANGE

TAPS. AS PER ASME B16.36, JACK SCREW BOLT DIA SHALL BE 3/4".

CHECK VALVES SHALL BE INSTALLED IN HORIZONTAL PIPE RUN. FOR SPECIFIC SITUATION THE CHECK VALVE CAN BE INSTALLED IN A VERTICAL PIPE

9 CHECK VALVE

RUN WHEN THE FLOW DIRECTION IS UPWARDS.

10 SWAGE FOR INSTRUMENT CONNECTION (3/4" X 1/2") CONCENTRIC SWAGE (PLE X TSE) SHALL BE USED.

11 THREADING THREADING FOR PIPE / NIPPLE / SWAGE AND PIPE FITTING IS ALLOWED FOR SIZE UPTO 0.75". RATING FOR THREADED FITTINGS SHALL BE 6000#.

BLIND FLANGE

12 (OPTIONAL)

2" BLIND FLANGE WITH 1/2" NPTF HOLE CAN BE USED FOR VESSEL MOUNTED INSTRUMENT CONNECTION.

GLOBE VALVE SHALL BE HAND WHEEL OPERATED FOR SIZES UP TO 4" AND GEAR OPERATED FOR SIZES 6" AND ABOVE & ALSO SATISFYING TORQUE

13 GLOBE VALVE

REQUIREMENT MENTIONED IN FS 2004A REV.9

TWO ADDITIONAL HEAVY HEXAGONAL JAM NUTS (AS PER ASME B 18.2.2 TABLE 10) SHALL BE PROVIDED FOR BOLT DIA 1.5" AND GREATER TO

14 HEAVY HEX NUT

FACILITATE BOLT TENSIONING.

15 FLANGE MINIMUM FLANGE GROOVE HARDNESS SHALL BE 24-25 HRC & GASKET CONTACT SURFACE SHALL HAVE A MAX. ROUGHNESS OF 63 AARH.

16 VALVE TYPE OF VALVE SHALL BE SELECTED AS PER P&ID REQUIREMENT.

17 FITTINGS WELDED FITTINGS SHALL BE 100% RADIOGRAPHED.

FLANGE

18 (OPTIONAL-2)

FLAT FACE FLANGE SHALL BE USED WHEN CONNECTING WITH GRP PIPING.

C1 23-08-2019 ISSUED FOR CLIENT COMMENTS ADU SN GSB

REV DATE DESCRIPTION PREPD CHECKD APPRD .

You might also like

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- TIO8243 Inclined Screen Parts Manual TIO8243-237-J1349Document20 pagesTIO8243 Inclined Screen Parts Manual TIO8243-237-J1349waltergvNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 1 - RA-631328-208-P00-FCN-2210-Welding MapDocument1 page1 - RA-631328-208-P00-FCN-2210-Welding Maphusnain aliNo ratings yet

- MS13Document5 pagesMS13Tommy ArjanggiNo ratings yet

- 8-1281-12 Pipe Class HF-2-9426-4Document7 pages8-1281-12 Pipe Class HF-2-9426-4Javier JimenezNo ratings yet

- LT11100300 TB No. 3 - Attachments PDFDocument67 pagesLT11100300 TB No. 3 - Attachments PDFVedran KosanovicNo ratings yet

- 8-1280-13 Pipe Class HF-1Document4 pages8-1280-13 Pipe Class HF-1Jesus MendezNo ratings yet

- Spec Report - 20150922Document1,507 pagesSpec Report - 20150922Midhun K Chandrabose100% (1)

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Piping Class - GR20Document3 pagesPiping Class - GR20Dmitriy RybakovNo ratings yet

- 3 Tail North 29 G4 Conn. To SKID-229/EQUI/GS-6901A/N1 W 1695.0 N 2650.0 EL +2970.0Document41 pages3 Tail North 29 G4 Conn. To SKID-229/EQUI/GS-6901A/N1 W 1695.0 N 2650.0 EL +2970.0cerebralnomadNo ratings yet

- Estimasi Piping Accessories and Bulk Material For First Firing Unit #1Document4 pagesEstimasi Piping Accessories and Bulk Material For First Firing Unit #1Arif BinorikaNo ratings yet

- 360 6S3R, C00 8 (-NRD3-VY1,) - ModelDocument1 page360 6S3R, C00 8 (-NRD3-VY1,) - ModelRajNo ratings yet

- Listado de Materiales Tag ManifoldDocument1 pageListado de Materiales Tag ManifoldLuis Miguel Vicente ValentinNo ratings yet

- Code Ansi: Pipes and Fittings CLASS 150Document3 pagesCode Ansi: Pipes and Fittings CLASS 150Eduardo Salabert RosaNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Document1 pageChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNo ratings yet

- GroomingDocument1 pageGroomingIkbal AlanisNo ratings yet

- MD 512 1a51 Iso WRW XXXX XXX 01 PDFDocument1 pageMD 512 1a51 Iso WRW XXXX XXX 01 PDFsarsan nedumkuzhiNo ratings yet

- EL +101840 4"NPD 3: Bill of MaterialDocument5 pagesEL +101840 4"NPD 3: Bill of MaterialDANLIN ENGINEERSNo ratings yet

- Chwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)Document1 pageChwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)vishwas salunkheNo ratings yet

- 8-1283-12 Pipe Class HF-5Document4 pages8-1283-12 Pipe Class HF-5Jesus MendezNo ratings yet

- Piping Class - FS20Document3 pagesPiping Class - FS20Dmitriy RybakovNo ratings yet

- 1CB2S40 Piping Material Class Specification: 000-SP-PI02-0191Document5 pages1CB2S40 Piping Material Class Specification: 000-SP-PI02-0191faber_tru2869No ratings yet

- FINAL BOQ-Civil-07052020Document1 pageFINAL BOQ-Civil-07052020vinoj chandranNo ratings yet

- Piping Class - AR75Document2 pagesPiping Class - AR75Дмитрий РыбаковNo ratings yet

- 3CM2S Piping Material Class Specification: 000-SP-PI02-0070Document5 pages3CM2S Piping Material Class Specification: 000-SP-PI02-0070Oswaldo GuerraNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Piping Material Data SheetDocument1 pagePiping Material Data SheetbrunorodorNo ratings yet

- Ipromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Document5 pagesIpromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Cristobal Leal ArandaNo ratings yet

- 2.V3 Gan A125Document1 page2.V3 Gan A125Arthur DeiparineNo ratings yet

- PGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFDocument7 pagesPGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFcasandraNo ratings yet

- 4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Document6 pages4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- ESLCS150-01 Pipe ScheduleDocument3 pagesESLCS150-01 Pipe Schedulethomas.jaggerNo ratings yet

- 2211Document4 pages2211liuyx866No ratings yet

- Piping Class - GS20Document3 pagesPiping Class - GS20Dmitriy RybakovNo ratings yet

- Colada 5306Document1 pageColada 5306Lizz EstradaNo ratings yet

- MSA Ball Valves enDocument20 pagesMSA Ball Valves enBiswajit DeyNo ratings yet

- MSA Ball Valves PDFDocument20 pagesMSA Ball Valves PDFAli FardidNo ratings yet

- Ins PT005Document1 pageIns PT005faisal hajjNo ratings yet

- 1CB1S50 Piping Material Class Specification: 000-SP-PI02-0189Document4 pages1CB1S50 Piping Material Class Specification: 000-SP-PI02-0189faber_tru2869No ratings yet

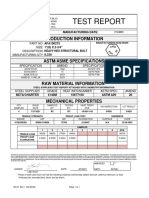

- Material Test Report: 600# W.N RF 3 SCH 80 H5292Document2 pagesMaterial Test Report: 600# W.N RF 3 SCH 80 H5292Gabriel De La FuenteNo ratings yet

- Butterfly Valves - 250 Psi: SIZE 2" - 8"Document2 pagesButterfly Valves - 250 Psi: SIZE 2" - 8"thilina lakhithaNo ratings yet

- Piping Class - AR71Document2 pagesPiping Class - AR71Дмитрий РыбаковNo ratings yet

- Tabla de SoldadurasDocument1 pageTabla de SoldadurasLuis Eduardo Hernández SalgadoNo ratings yet

- Pump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133Document1 pagePump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133AhmadNo ratings yet

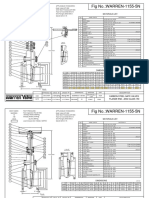

- Valvula Warren-2155-5nDocument2 pagesValvula Warren-2155-5nFernando castellano castroNo ratings yet

- PN09CS1S01Document5 pagesPN09CS1S01joana ramirezNo ratings yet

- Stud Bolts 2hex Nuts Weight Imperial SizesDocument12 pagesStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- Tata Consulting Engineers Limited: Piping Material SpecificationDocument3 pagesTata Consulting Engineers Limited: Piping Material SpecificationkasvikrajNo ratings yet

- Piping Class - AR20Document2 pagesPiping Class - AR20Дмитрий РыбаковNo ratings yet

- A303hal Aish L Mto 2001 A3Document7 pagesA303hal Aish L Mto 2001 A3THOMASNo ratings yet

- Ev 752Document1 pageEv 752Guru MhetreNo ratings yet

- Piping Class - GD20Document3 pagesPiping Class - GD20Dmitriy RybakovNo ratings yet

- PIPE RACK PIP-Rev.1Document1 pagePIPE RACK PIP-Rev.1ardiansyah.tegalNo ratings yet

- 032 - SECTION 5 - WELD MAP Rev01Document5 pages032 - SECTION 5 - WELD MAP Rev01Mohd Effiezool YaserNo ratings yet

- Gate Valve FLG WCB 125Document1 pageGate Valve FLG WCB 125rawalepushkar123No ratings yet

- Cert Perno Hex A490 1 X 2-3.4Document8 pagesCert Perno Hex A490 1 X 2-3.4Abril SalinasNo ratings yet

- Fig No.:WARREN-1155-5N: Materials ListDocument2 pagesFig No.:WARREN-1155-5N: Materials ListDiego OrtegaNo ratings yet

- WD 77132Document1 pageWD 77132Bhaumik BhuvaNo ratings yet

- WD 77131Document6 pagesWD 77131Bhaumik BhuvaNo ratings yet

- Analytical Modelling and Experimental Validation of 2017 International JourDocument9 pagesAnalytical Modelling and Experimental Validation of 2017 International JourBhaumik BhuvaNo ratings yet

- Gujarat Technological University Civil (Structural Engineering)Document2 pagesGujarat Technological University Civil (Structural Engineering)Bhaumik BhuvaNo ratings yet

- 3kl R 002ADocument3 pages3kl R 002ABhaumik BhuvaNo ratings yet

- N.V. Dale, C. Y. Biaku, M. D. Mann, H. Salehfar, A. J. PetersDocument8 pagesN.V. Dale, C. Y. Biaku, M. D. Mann, H. Salehfar, A. J. PetersBhaumik BhuvaNo ratings yet

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Document26 pages019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- 3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesDocument1 page3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesBhaumik BhuvaNo ratings yet

- STRAINER - MEE - Cooling Water PumpDocument2 pagesSTRAINER - MEE - Cooling Water PumpBhaumik BhuvaNo ratings yet

- 3.2 Design & Procure Ment DataDocument8 pages3.2 Design & Procure Ment DataBhaumik BhuvaNo ratings yet

- 1970 MECh 19 03 - R0 (E504)Document1 page1970 MECh 19 03 - R0 (E504)Bhaumik BhuvaNo ratings yet

- Sr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CDocument3 pagesSr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CBhaumik BhuvaNo ratings yet

- Sr. No. Particulars Value Unit of Measurement: DCBH - Static Mixer-16SM001Document1 pageSr. No. Particulars Value Unit of Measurement: DCBH - Static Mixer-16SM001Bhaumik BhuvaNo ratings yet

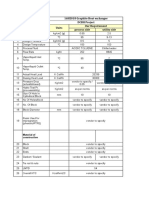

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- #0 e Scan ProtectedDocument1 page#0 e Scan ProtectedBhaumik BhuvaNo ratings yet

- Intro 2 NetlabDocument10 pagesIntro 2 NetlabBhaumik BhuvaNo ratings yet

- Hydrant Valve Service ManualDocument40 pagesHydrant Valve Service Manualbassokay_sam8145No ratings yet

- API 521 2020 Extract Hydraulic ReliefDocument6 pagesAPI 521 2020 Extract Hydraulic ReliefT. LimNo ratings yet

- Engineering Information: Spur GearsDocument6 pagesEngineering Information: Spur GearsLuis MarcosNo ratings yet

- B Shifting ToolDocument6 pagesB Shifting ToolzbhdzpNo ratings yet

- One Machine, Multiple Solutions: Case Manual Vs Vertidrive M7 Time People CostsDocument2 pagesOne Machine, Multiple Solutions: Case Manual Vs Vertidrive M7 Time People CostsJhonnatan Quispe FrancoNo ratings yet

- MagwayDocument148 pagesMagwayKyaw LionNo ratings yet

- S36 IR Rockdrill: Item P/N Qty Description Item P/N Qty Description Item P/N Qty DescriptionDocument2 pagesS36 IR Rockdrill: Item P/N Qty Description Item P/N Qty Description Item P/N Qty DescriptionwilsonNo ratings yet

- 1 Input Data: Profis Anchor 2.8.8Document7 pages1 Input Data: Profis Anchor 2.8.8Con CanNo ratings yet

- S01 Hydraulic CartridgesDocument18 pagesS01 Hydraulic CartridgesESRANo ratings yet

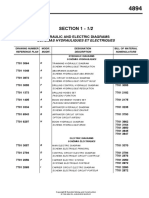

- 10753-Ep 4-1-1Document37 pages10753-Ep 4-1-1FcosmeNo ratings yet

- Spiral Freezer & Chiller: Frigoscandia Gyrocompact 40Document4 pagesSpiral Freezer & Chiller: Frigoscandia Gyrocompact 40Gerardo Sepulveda ToledoNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 24 25Document2 pagesAtlas Copco GA 15 To GA 30 Part List 24 25RICHARDNo ratings yet

- Shortage List For BC Rev.3Document5 pagesShortage List For BC Rev.3ehsan_mekanikNo ratings yet

- Masonry Materials-II: (Concrete Masonry Units, Natural Stone, and Glass Masonry Units)Document21 pagesMasonry Materials-II: (Concrete Masonry Units, Natural Stone, and Glass Masonry Units)derejkNo ratings yet

- Haulpack HD 730EDocument79 pagesHaulpack HD 730EdwiNo ratings yet

- Errors in Gears PDFDocument8 pagesErrors in Gears PDFSanjay Mehrishi100% (1)

- Spare Parts LOGICDocument47 pagesSpare Parts LOGICmeharatif3832No ratings yet

- Instrumentation Quick-Connect Bodies: SS-QC6-B-4PFDocument2 pagesInstrumentation Quick-Connect Bodies: SS-QC6-B-4PFAdeilton CabocloNo ratings yet

- Table: Concrete Design 2 - Beam Summary Data - EUROCODE 2Document22 pagesTable: Concrete Design 2 - Beam Summary Data - EUROCODE 2girumNo ratings yet

- SC 30TL 05Document52 pagesSC 30TL 05jorge.jimglezNo ratings yet

- Industrial Suppliers Pvt. LTD.: Authorised Distributor ForDocument1 pageIndustrial Suppliers Pvt. LTD.: Authorised Distributor ForkamatamoghNo ratings yet

- S30-31 Rec Spec (Detail)Document1 pageS30-31 Rec Spec (Detail)Lll LopezNo ratings yet

- Reejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. MasonryDocument1 pageReejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. Masonryreejoy1994No ratings yet

- Hibbeler Statics and Mechanics of Materials Global Ed SolDocument77 pagesHibbeler Statics and Mechanics of Materials Global Ed SolAaron PinedaNo ratings yet

- Q7 & Q8 @trial 2021Document61 pagesQ7 & Q8 @trial 2021nuraliahNo ratings yet

- Hand ToolsDocument21 pagesHand ToolsDdoum OgxNo ratings yet

- HRSG 02 OperationDocument23 pagesHRSG 02 OperationPremadi SetyokoNo ratings yet

- PC Frame Unit (C) Parts ManualDocument42 pagesPC Frame Unit (C) Parts ManualCopy CenterNo ratings yet

- Product Catalogue Product Catalogue: Ventilation Ventilation Heads HeadsDocument22 pagesProduct Catalogue Product Catalogue: Ventilation Ventilation Heads HeadsING JORGE MIGUELNo ratings yet