Professional Documents

Culture Documents

P3 Berger

P3 Berger

Uploaded by

Aabhas UpadhyayaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P3 Berger

P3 Berger

Uploaded by

Aabhas UpadhyayaCopyright:

Available Formats

BERGER PRODUCT SPECIFICATIONS

LUXAPRIME 1400

Alkyd Zinc Phosphate Primer

PRODUCT A single component high build multi-purpose alkyd primer formulated with high performance

modified zinc phosphate anti-corrosive pigmentation for use on steel substrates.

DESCRIPTION

DESIGN Post fabrication primer in new construction projects for either conventional, chlorinated rubber or

polyurethane systems.

FEATURES

Suitable for interior or exterior environments in moderately aggressive environments.

Excellent anti-corrosive properties that outperform conventional zinc phosphate based primers.

Can be applied to non-blast cleaned surfaces.

Suitable for use in applications where dry heat resistance up to 100ºC is required.

As a rapid recoatable primer when quick handling times are critical.

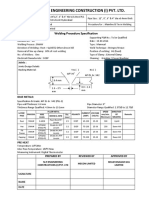

PHYSICAL Recommended Application Data Wet [µm] Dry [µm] m2/l

CHARACTERISTICS Theoretical Coverage 106 50 9.4

Volume solids 47% (based on ASTM D2697)

Dry Film Thickness Range 35 µm to 75 µm

Flash Point 25º C

Finish Matt

Colour Range Red Oxide / Grey

Standard Packing Size 5 litres

APPLICATION BRUSH OR ROLLER May be used. However, additional coats may be necessary to

achieve the recommended film thickness.

METHOD

CONVENTIONAL AIR May be used. Dilution may be required to achieve good

SPRAY atomisation

AIRLESS SPRAY May be used.

Tip size : 0.43 – 0.54 mm (17 – 21 thou)

Pressure : 110 –160 kg/cm2 (1600 – 2300 psi)

DRYING TIME Overcoating Interval

Substrate Touch Dry Hard Dry Self & Alkyds Polyurethanes

Temperature Min. Max. Max. Min.

15 °C 2 hours 24 hours 6 hours Indefinite 24 hours Indefinite

25 °C 1 hour 4 hours 2 hours Indefinite 12 hours Indefinite

35 °C 30 minutes 2 hours 1 hour Indefinite 6 hours Indefinite

USEFUL THINNER : SOLVALUX 7-25 (Maximum 10% addition)

INFORMATION

CLEANER : SOLVALUX 7-25

STORAGE : Store in a cool dry shaded area.

LUXAPRIME 1400 REVISION 03-2012

H4

BERGER PRODUCT SPECIFICATIONS

SURFACE The service life span and the service performance of Luxaprime 1400 are directly related to the

degree of surface preparation.

PREPARATION

STEEL

• Remove all wax, oil and grease by solvent cleaning in accordance to guidelines given by

SSPC-SP1.

• Dry brushing to remove soluble salts, dirt and dust.

• Freshwater jetting is required to remove all loose contaminants and soluble salt deposition.

• Remove scale by chipping, needle gun or spot blasting. Any loose or flaking coatings

should be taken back to a firm edge.

• Mechanically clean the surface using hand or power tools to a minimum standard of St 2

(ISO 8501-1:1988) or SSPC-SP2 taking care to avoid polishing the surface.

• For optimum performance an abrasive blast to Sa 2 or SSPC SP-6 (commercial blast) is

recommended with an average surface profile of 30 microns.

• Where necessary removes weld spatter and round off all rough weld seams and sharp

edges to a smooth surface.

To avoid condensation of moisture onto substrate prior to coating application, relative humidity

should not exceed 85% and substrate temperature should be more than 3°C above Dew Point.

SUITABLE

Luxol 1000

INTERMEDIATES

SUITABLE FINISHES Luxol 5000

NOTES • The coating specifications given above are typical. For specific recommendations to suit

individual applications, please refer to your Berger Paints representative.

• When applying by brush or roller care must be observed to prevent ‘pick up’ of recently

applied single pack coatings.

• This product is not suitable for immersed conditions.

• This product is not suitable for exposure to acidic or alkaline environments.

SAFETY Avoid contact with eyes and skin. Wear suitable protective clothing such as overalls, goggles,

dust mask and gloves. Use barrier cream.

PRECAUTION

This product contains low flash point solvents, do not use in poorly ventilated areas especially in

confined tank interiors.

Ensure that there is adequate ventilation in the area where the product is being applied. Do not

breathe in vapour or spray mist.

This product is flammable. Keep away from sources of ignition. Do not smoke.

Take precautionary measures against static discharge.

In case of fire, blanket flames with foam, carbon dioxide or dry chemicals.

FIRST AID Eyes : In the event of accidental splashes, flush eyes with warm water immediately

and seek medical advice.

Skin : Wash skin thoroughly with soap and water or approved industrial cleaner.

Do Not Use solvents or thinners.

Inhalation : Remove to fresh air, loosen collar and keep patient rested.

Ingestion : In case of accidental ingestion, DO NOT INDUCE VOMITING. Obtain

immediate medical attention.

For further safety information, please refer to our Material Safety Data Sheet (MSDS)

DISCLAIMER The information provided on this data sheet is not intended to be complete and is provided as general advice

only. It is the responsibility of the user to ensure that the product is suitable for the purpose for which he

wishes to use it. As we have no control over the treatment of the product, the standard of surface

preparation of the substrate, or other factors affecting the use of this product, we are not responsible for its

performance nor would we accept any liability whatsoever or howsoever arising from the use of this product

unless specifically agreed to in writing by us. The information contained in this data sheet may be modified

by us from time to time, and without notice, in the light of our experience and continuous product

development.

LUXAPRIME 1400 REVISION 03-2012

H4

You might also like

- AlticDocument8 pagesAlticyerrisiddappa KNo ratings yet

- Thermo Fisher Scientific XL3 XL2 Hardware OverviewDocument37 pagesThermo Fisher Scientific XL3 XL2 Hardware OverviewMAmar100% (1)

- Organic Chemistry, Second Edition Janice Gorzynski Smith, ch2Document16 pagesOrganic Chemistry, Second Edition Janice Gorzynski Smith, ch2sungyeon heoNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- Brochure HPX1 PLUS 201601Document8 pagesBrochure HPX1 PLUS 201601Serkan KılıçaslanNo ratings yet

- Zinc Rich Anticorrosive Primer PDFDocument53 pagesZinc Rich Anticorrosive Primer PDFDhruv SevakNo ratings yet

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- Operating Manual CrxvisionDocument45 pagesOperating Manual CrxvisionChandrashekhar ThiramdasuNo ratings yet

- Comparison Table of Standard Sieve SeriesDocument3 pagesComparison Table of Standard Sieve SeriesAlexander HillNo ratings yet

- Kit 138 New Bresle Salt PDFDocument2 pagesKit 138 New Bresle Salt PDFDian FaraNo ratings yet

- DHB Pipe Line Tester 80 80L 82Document2 pagesDHB Pipe Line Tester 80 80L 82smab2162094No ratings yet

- Surface Preparation & Painting Procedure: List of ContentDocument14 pagesSurface Preparation & Painting Procedure: List of ContentZafr O'Connell100% (1)

- SS 555-1-2010 - PreviewDocument14 pagesSS 555-1-2010 - PreviewSteven Hung0% (2)

- Ewert WCNDT Standards 2012 04Document38 pagesEwert WCNDT Standards 2012 04bladdeeNo ratings yet

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pages4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriNo ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- Impressor BarcolDocument8 pagesImpressor BarcolMarco CortésNo ratings yet

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- Astm A516 Grade 70Document1 pageAstm A516 Grade 70Javier Caamaño VillafañeNo ratings yet

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADocument12 pagesComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- ITP - Latticed Steel Tower - Type TestDocument3 pagesITP - Latticed Steel Tower - Type TestPrabhakar SvNo ratings yet

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDocument7 pagesHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- MSDS MtbeDocument5 pagesMSDS MtbeViệt HàNo ratings yet

- Spotleak 1007 PDFDocument7 pagesSpotleak 1007 PDFrandhyalejandroNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Radiographic Film InterpretationDocument5 pagesRadiographic Film Interpretationponnivalavans_994423No ratings yet

- PC 2569 Apcomin Industrial Rozc PrimerDocument3 pagesPC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalNo ratings yet

- Smoke & Fire Curtains CatalogDocument51 pagesSmoke & Fire Curtains CatalogNafis TyagiNo ratings yet

- TCW Tube CleaningDocument56 pagesTCW Tube CleaningMarcela Vargas GomezNo ratings yet

- ASME BPVC 2021 Section IXDocument6 pagesASME BPVC 2021 Section IXSwarup mishraNo ratings yet

- 15CrMo Alloy Steel TubeDocument5 pages15CrMo Alloy Steel TubeIbnu KhusnaNo ratings yet

- Field Practice SpecificationDocument20 pagesField Practice SpecificationRichart SembiringNo ratings yet

- Free Fire Risk Assessment Example PDFDocument17 pagesFree Fire Risk Assessment Example PDFFairoza AmalinnaNo ratings yet

- Productsheet Bristle Blaster P-033-EnDocument4 pagesProductsheet Bristle Blaster P-033-EnVijayaraj KumarNo ratings yet

- MSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapDocument7 pagesMSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapMakamu Max Las MokgaoganyiNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- West Qurna 1 Building Upgrades & Facilities WorkDocument19 pagesWest Qurna 1 Building Upgrades & Facilities WorkNoor A QasimNo ratings yet

- 3-PMI Test ProcedureDocument4 pages3-PMI Test ProcedureSezgin CkllıNo ratings yet

- Filmbadge and TLD ManualDocument2 pagesFilmbadge and TLD ManualAldrin Cabrera100% (1)

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- BS en 50194-1-2009Document26 pagesBS en 50194-1-2009damaso taracena100% (1)

- 2168.2-2009 Computerized Radiography Testing of Mettalic Materials Using X-Rays and Gamma RaysDocument25 pages2168.2-2009 Computerized Radiography Testing of Mettalic Materials Using X-Rays and Gamma RaysJoselito MagatNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- Uwe Zscherpel-Computed RadiographyDocument42 pagesUwe Zscherpel-Computed Radiographyrafeeq ahamedNo ratings yet

- HTLP Heat Shrinkable SleeveDocument2 pagesHTLP Heat Shrinkable SleeveGanesh EshwarNo ratings yet

- Series 3400 Fiberglass Epoxy Pipe Systems: Using Key-Lock® Mechanical Joint or Taper/Taper Adhesive JointDocument6 pagesSeries 3400 Fiberglass Epoxy Pipe Systems: Using Key-Lock® Mechanical Joint or Taper/Taper Adhesive JointanandakoeNo ratings yet

- AGFA G135 Dev Part A MSDS v1Document10 pagesAGFA G135 Dev Part A MSDS v1RenewiNo ratings yet

- 4422-VW-SG-001000000001 - B3-Painting & CoatingDocument203 pages4422-VW-SG-001000000001 - B3-Painting & CoatingPaul NieNo ratings yet

- t15b03-0102 - 0painting Specification For Whb&Steam DrumDocument36 pagest15b03-0102 - 0painting Specification For Whb&Steam DrumMuhammedHafisNo ratings yet

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDocument4 pagesHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNo ratings yet

- Testing of Geosynthetic Barriers - Clay BTTGDocument5 pagesTesting of Geosynthetic Barriers - Clay BTTGNomaan AsimNo ratings yet

- Basics - Dew Point Measurement - P60 P63 PDFDocument4 pagesBasics - Dew Point Measurement - P60 P63 PDFAnonymous o38k1iEKFNo ratings yet

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 pagesLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1200 Alkyd QD PrimerDocument2 pagesLuxaprime1200 Alkyd QD PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- Albond HS CastableDocument2 pagesAlbond HS CastableGurdeep Sungh AroraNo ratings yet

- Luxaprime1501 Etch PrimerDocument2 pagesLuxaprime1501 Etch PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1200 Alkyd QD PrimerDocument2 pagesLuxaprime1200 Alkyd QD PrimerGurdeep Sungh AroraNo ratings yet

- Albond and Alcast Extra HS MonolithicsDocument2 pagesAlbond and Alcast Extra HS MonolithicsGurdeep Sungh AroraNo ratings yet

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 pagesLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1500 Etching Wash PrimerDocument2 pagesLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraNo ratings yet

- Alcoat Data SheetDocument2 pagesAlcoat Data SheetGurdeep Sungh AroraNo ratings yet

- New Storage & Shelf Life Feb 2014 PDFDocument2 pagesNew Storage & Shelf Life Feb 2014 PDFGurdeep Sungh AroraNo ratings yet

- Pyro Bloc ModulesDocument2 pagesPyro Bloc ModulesGurdeep Sungh AroraNo ratings yet

- Jotamastic 90 Jotun PaintDocument6 pagesJotamastic 90 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Kaowool Papers Morgan CeramicsDocument3 pagesKaowool Papers Morgan CeramicsGurdeep Sungh AroraNo ratings yet

- Hydraulic Bolt Tensioners EnerpacDocument2 pagesHydraulic Bolt Tensioners EnerpacGurdeep Sungh AroraNo ratings yet

- Esab GasEquipment PDFDocument44 pagesEsab GasEquipment PDFGurdeep Sungh AroraNo ratings yet

- For V Shaped Pulleys: - Quick and Easy InstallationDocument3 pagesFor V Shaped Pulleys: - Quick and Easy InstallationGurdeep Sungh AroraNo ratings yet

- Barrier Smart Pack Jotun PaintDocument5 pagesBarrier Smart Pack Jotun PaintGurdeep Sungh AroraNo ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- Tankguard Plus Jotun PaintDocument5 pagesTankguard Plus Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard Plus Jotun PaintDocument5 pagesTankguard Plus Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard HB Classic Jotun PaintDocument5 pagesTankguard HB Classic Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard DW Jotun PaintDocument6 pagesTankguard DW Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard Special Ultra Jotun PaintDocument5 pagesTankguard Special Ultra Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- Background of Titrino 702 Automatic TitratorDocument4 pagesBackground of Titrino 702 Automatic TitratorbuttamanatNo ratings yet

- A Study On Some Durability Properties of Coconut Shell Aggregate ConcreteDocument13 pagesA Study On Some Durability Properties of Coconut Shell Aggregate ConcreteMa Victoria CaneteNo ratings yet

- Transport PhenomenonDocument29 pagesTransport PhenomenonSidharthNo ratings yet

- The Competition Problems From The International Chemistry OlympiadsDocument408 pagesThe Competition Problems From The International Chemistry Olympiadsnguyenchuong129No ratings yet

- Class X Half Yearly Exam Syllabus 2019 20Document6 pagesClass X Half Yearly Exam Syllabus 2019 20RahulNo ratings yet

- CAMAG Basic Equipment 08Document20 pagesCAMAG Basic Equipment 08Luděk SpurnýNo ratings yet

- A Reaction Is Second Order With Respect To A Reaction. How Is The Rate of Reaction Affected If The Concentration of The ReactantDocument1 pageA Reaction Is Second Order With Respect To A Reaction. How Is The Rate of Reaction Affected If The Concentration of The ReactantAakriti JainNo ratings yet

- Ioesolutions Esign Com NP Contents Sanitary Engineering Ce 656Document5 pagesIoesolutions Esign Com NP Contents Sanitary Engineering Ce 656Ranjit MahatoNo ratings yet

- Solvent-Free Polymerization of Citric Acid and D-SorbitolDocument9 pagesSolvent-Free Polymerization of Citric Acid and D-SorbitolAris SusantoNo ratings yet

- Get The Most From Your Fired HeaterDocument7 pagesGet The Most From Your Fired Heaterquercitron_7100% (1)

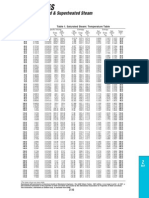

- Steam TablesDocument11 pagesSteam TablesARNOUXNo ratings yet

- Activity 8 Mass Transfer: B. Unsaturated Gas A. 1Document11 pagesActivity 8 Mass Transfer: B. Unsaturated Gas A. 1Jeanne Roselle Dulatre CortezNo ratings yet

- BR A Consumables Catalog ElecDocument31 pagesBR A Consumables Catalog Elecdweil1552No ratings yet

- MMO titanium anodes, cathodes, HHO Generator, Fuel Cell Kits, Dry Cell Kit , H2O statuary engines, fuel benefits pollution free exhaust, Water4gas, fuel saver, wate car, Hydrogen and Oxygen, Green Gas, Brown's Gas, Rhodes Gas, Bubbler, Hydrogen Generator, Water reservoir, dryer, Increase the Mileage, electrolyzer.Document24 pagesMMO titanium anodes, cathodes, HHO Generator, Fuel Cell Kits, Dry Cell Kit , H2O statuary engines, fuel benefits pollution free exhaust, Water4gas, fuel saver, wate car, Hydrogen and Oxygen, Green Gas, Brown's Gas, Rhodes Gas, Bubbler, Hydrogen Generator, Water reservoir, dryer, Increase the Mileage, electrolyzer.Mr. Velappan JeyakummarNo ratings yet

- Solved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsAB RanaNo ratings yet

- Time Date I. Objectives: A. Content StandardsDocument5 pagesTime Date I. Objectives: A. Content StandardsRod ReyesNo ratings yet

- Soalan KimiaDocument6 pagesSoalan KimiaFatimah Abdul RahmanNo ratings yet

- For Biology, Food & Cosmetics, Drug Discovery, Chemistry: Dolomite - A One-Stop Shop For Microfluidic SolutionsDocument11 pagesFor Biology, Food & Cosmetics, Drug Discovery, Chemistry: Dolomite - A One-Stop Shop For Microfluidic SolutionsWang CharlesNo ratings yet

- Vol1i7x ECCC RecommandationsDocument21 pagesVol1i7x ECCC RecommandationsRami GhorbelNo ratings yet

- Pid Area 280Document21 pagesPid Area 280ATALAYNo ratings yet

- The Corrosion Inhibitor Availability Model 51300 00034 SG PDFDocument13 pagesThe Corrosion Inhibitor Availability Model 51300 00034 SG PDFrachedNo ratings yet

- Chapter 6,8 BiologyDocument4 pagesChapter 6,8 BiologyParshvaNo ratings yet

- List of Packages As On 17.02.2018Document3 pagesList of Packages As On 17.02.2018mecon bhilaiNo ratings yet

- PH537/PI515: Astrostructure and Evolution: Answer With Examples and ReferencesDocument4 pagesPH537/PI515: Astrostructure and Evolution: Answer With Examples and ReferencesSDasNo ratings yet

- C1.welded Connection1 PDFDocument25 pagesC1.welded Connection1 PDFWindy GeeNo ratings yet

- The Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedDocument55 pagesThe Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedMiguel OcampoNo ratings yet

- ME 820 - Course PlanDocument2 pagesME 820 - Course PlanArun MahalingamNo ratings yet

- Misting Technology Is Based On The Principle ofDocument9 pagesMisting Technology Is Based On The Principle ofKhaled ShabanNo ratings yet

- G-03 Model Z05 Rigid Coupling - Rev N PDFDocument3 pagesG-03 Model Z05 Rigid Coupling - Rev N PDFDaniel SanNo ratings yet