Professional Documents

Culture Documents

SIL99-2C: Service Information Letter

SIL99-2C: Service Information Letter

Uploaded by

sandyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIL99-2C: Service Information Letter

SIL99-2C: Service Information Letter

Uploaded by

sandyCopyright:

Available Formats

CONTINENTAL MOTORS® AIRCRAFT ENGINE CATEGORY 5

SERVICE INFORMATION LETTER SIL99-2C

S upe rs ede s SIL99-2B

Contains Useful Information Pertaining To Your Aircraft Engine TE CHN ICA L P O RTI O NS

FA A AP PROVE D

SUBJECT: SEALANTS, LUBRICANTS, AND ADHESIVES

AUTHORIZED BY CMI

PURPOSE: Provide current application of sealants, threading, lubricants, and adhesives.

COMPLIANCE: During engine installation, maintenance, overhaul or component repair or

replacement.

MODELS

AFFECTED: All CMI engine models operating with AVGAS (gasoline based) fuel.

I. General Information

Lubricating oils qualified for use in Continental Motors, Inc. (CMI) gasoline engines are required to

meet Society of Automotive Engineers (SAE) specifications.

NOTE: Continental Motors, Inc. listing of accepted SAE J 1899

oils by manufacturer and brand name is provided only for the

convenience of our customers. Always refer to the manufacturer’s

label on the oil to ensure that the oil meets the appropriate SAE

specification.

Major sections within this document: Page

I. General Information 1

II. Oil Change Intervals 3

III. Additives 3

IV. Recommended Sealants, Lubricants, and Adhesives 4

V. Manufacturer/Distributor Supplemental Product Information 10

VI. General Sealant Applications and Threading Procedures (typical) 11

SAE specification J 1899 (formerly MIL-L-22851) is the approval authority for aircraft piston

engine ashless-dispersant lubricating oil.

SAE specification J 1966 (formerly MIL-L-6082E) is the approval authority for aircraft piston

engine non-dispersant mineral oil.

QPL-J 1899: Qualified Products list is available from:

SAE Headquarters

400 Commonwealth Drive

Warrendale, PA 15096-0001

The Naval Air Systems Command is required to maintain QPL-J-1899 and QPL-J-1966.

Naval Air Systems Command

47123 Buse Road

Building 2272, Suite 540

Patuxent River, MD 20670

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

1 of 22 SIL99-2 C

©2014 Continental Motors, Inc. All other product or company names that may be mentioned in this publication are trade names, trademarks, or registered

trademarks of their respective owners.

Recommended Oil Grade:

• Above 40°F ambient air, sea level SAE 50 or multi-viscosity

• Below 40°F ambient air, sea level SAE 30 or multi-viscosity

NOTE: See SIL99-1 (latest version) for preservation information.

The marketers of the aviation lubricating oil listed below (Table 1) have supplied data to

Continental Motors, Inc. (CMI) indicating their products conform to all the requirements of CMI

Specification MHS-24, Lubricating Oil, Ashless Dispersant.

In listing the product names, CMI makes no claim of verification of marketer's statements or

claims. The listing is made alphabetically and is provided only for the convenience of the user.

Table 1. Qualified SAE J-1899 Ashless Dispersant Engine Oil

Supplier Brand

Air BP Lubricants Castrol Aviator AD Oil

Castrol Aviator A Oil

ChevronTexaco ChevronTexaco Aero Oil AD

ChevronTexaco Aero Oil AD SAE 20W-50

Delta Petroleum Company Delta Avoil Oil

Exxon Company, USA Exxon Aviation Oil EE

Exxon Elite

Gulf Oil Company Gulfpride Aviation AD

Mobil Oil Company Mobil Aero Oil

NYCO S.A. Turbonycoil 3570

Pennzoil Company Pennzoil Aircraft Engine Oil

Phillips 66 Phillips 66 Type A 100 AD, 120 AD

Phillips 66 X/C Aviation Oil SAE 20W-50, SAE 25W-60

Phillips 66 Victory Aviation Oil 100AW

Quaker State Oil & Refining Co. Quaker State AD Aviation Oil

Red Ram Limited (Canada) Red Ram X/C Aviation Oil 20W-50

Shell Aviation Aeroshell Oil, (Mineral) 65, 80, 100, 2F Anti Corrosion Formula

Aeroshell Multi-grade Oil AD, 15W - 50

Aeroshell Oil W65, W80, W100

Aeroshell Oil W80 Plus, W100 Plus Anti Corrosion Formula

Sinclair Oil Company Sinclair Avoil

Total France Total Aero DM 15W - 50

Table 2. Break-in Oil

Type Equivalent Application

MIL-C-6529 Type II Corrosion

Fly-away oil

preventive mineral oil1 First 25 hours of engine operation

Non-dispersant mineral oil for or until oil consumption stabilizes

SAE J-1966 Aviation Oil

piston aircraft engines

1. Mineral oil conforming to MIL-C-6529 Type II contains a corrosion preventive additive and must not be used for

more than 25 hours or six months, whichever occurs first. If oil consumption has not stabilized within this time, drain

the mineral oil, replace the oil filter, and replace discarded mineral oil with SAE J-1966 aviation oil.

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

2 of 22 SIL99-2 C

Table 3. Preservative Oil

Type Equivalent Application

Grade 1 Oil, Non-Rust VCI-105

MIL-P46002 Temporary or Indefinite Storage

Motorstor Oil Preservative

II. Oil Change Intervals

Refer to the engine maintenance manual and/or the aircraft manufacturers or Supplemental Type

Certificate (STC) holders AFM/POH for fuel specifications, specified oil change intervals and

inspection procedures.

Oil change intervals published in this manual are minimum requirements. Continental Motors,

Inc. (CMI) believes more frequent oil and filter changes enhance engine service life. CMI

recommends engine oil be drained and replenished every 25 hours of operation or 4 months for

engines that incorporate an oil screen. Engines with full flow oil filters, either large or small,

should have the oil changed every 50 hours or 4 months.

NOTE: When using the small oil filter (4.80 inch high) do not

exceed 50 hours and/or 6 months between oil and filter changes.

When using the larger oil filter (5.80 inch high) do not exceed 100

hours and/or 6 months between oil and filter changes. Oil screens

and oil filter elements must be inspected for contaminates at each

oil change. Oil analysis may be used in addition to the oil screen or

filter element inspection, but not as a replacement for it.

III. Additives

We often receive inquiries regarding the potential use of alternative fuel and oil additives and/or

concentrates (formulated primarily for automotive and industrial engine applications) for use in

our aircraft engines. Most of these additives and concentrates are not compatible with air-cooled,

light aircraft engines in their operating environments. With the exception of the use of isopropyl

alcohol or diethylene glycol monomethyl ether (DiEGME) compound (described in the following

paragraph), we do not recommend the use of additives or concentrates in any of our aircraft

engines. The use of unapproved additives may void the engine warranty. Use only recommended

fuels and lubricants.

WARNING

Mixing of DiEGME compound with fuel concentration in

excess of the recommended (0.15% volume maximum) could

have a harmful effect on engine components. Use only the

manufacturer’s recommended blending equipment and

procedures to achieve proper proportioning.

Under certain ambient conditions of temperature and humidity, sufficient quantities of water may

exist in the fuel to create restrictive ice formation in the fuel supply. To alleviate this occurrence,

it is permitted to add no more than 3% (by volume) isopropyl alcohol to the fuel supply. Also,

DiEGME conforming to military specification MIL-DTL-85470B, if approved by the aircraft

manufacturer, may be added for this purpose. DiEGME compound must be carefully mixed with

the fuel in concentrations not to exceed 0.15% (by volume).

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

3 of 22 SIL99-2 C

IV. Recommended Sealants, Lubricants, and Adhesives

Table 4. Sealants

Item P/N Type Application Remarks

Non-beaded gaskets; Apply both

sides of starter gasket, oil cooler

adapter gasket, vacuum pump

adapter gasket, and fuel pump pad

cover gasket.

Beaded gasket; Apply to non- 0200D, X

beaded side of starter gasket, oil

cooler adapter gasket, vacuum

pump adapter gasket, and fuel

pump pad cover gasket.

All press type plugs (Hubbard etc.)

All models

Intake manifold gasket

ACC case to crankcase C-90, O200, IO240, O300,

(crankcase side only) IO360, LTSIO360, TSIO360

Oil drain back tubes C-90, O200, O300

CRC Copper Coat 401504 Oil cooler (both sides) IO360, LTSIO360, TSIO360

1 642188 Oil seal accessory drive (O.D. only) IO360, LTSIO360, TSIO360

Gasket Sealant

2 bolt suction tube gasket 470, 520 and 550 (where

(both sides) applicable)

470, 520, 550 (Sandcast), and

Gasket and oil filler neck holes

GTSIO520

Cam bore cover gasket 470, 520, 550, GTSIO520,

(except beaded gasket) IO240

Idler pin gasket 470, 520, 550, GTSIO520

Sump to crankcase or sump to

In parting line area of 3-way joints crankcase to accessory case

All gaskets (both sides) except

magneto gasket and gaskets

between intake manifold and

cylinder head. Tiara 6-285, 6-230

Oil seal at alternator drive

(O.D. only)

F/I Sealant All pipe thread fittings in fuel

2 646940 injection system (except pipe plug See Figure 2

Loctite 569 Hydraulic Sealant threads in throttle body units)

Crankcase parting face Where applicable

Engine nose seal, scavenge oil

pump covers, between crankcase All models, where applicable

and sump gasket, oil pump covers

Gasket Maker

Between starter adapter gasket &

3 646942 Loctite 515 Gasket Eliminator crankcase All Permold crankcase models

Flange Sealant

Between oil sump and sump gasket Non-beaded gaskets only

642910 oil seal, O.D. of all

uncoated oil seals, except fuel All models, where applicable

pump adapter seal

Data plate screw installation on

4 649246 Loctite 290 Sealant throttle bodies All models, where applicable

5 653692 Loctite LocQuic Primer 7649 Crankshaft nose oil seal area All models

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

4 of 22 SIL99-2 C

Table 4. Sealants

Item P/N Type Application Remarks

Crankcase parting face

Loctite 1522029 Gasket Starter adapter to accessory case

Apply according to assembly

6 654663 Sealant Accessory drive adapter instructions

(with P/N 641543 Silk Thread) Pressure oil pump covers

Pressure scavenge pump covers

7 657042 Loctite 565 Adhesive Sealant Use on all pipe threads to oil All models (use sparingly on

coolers and other oil sources male threads only)

Ignition harness terminals at

8 N/A Miller-Stephenson MS-122AD magneto block end & spark plug / All models

ECU terminals

Use on all pipe threads except as

noted elsewhere

All pressure relief valve housing

All models, where applicable

Loctite 592 Teflon PS/T Pipe threads

9 N/A Permold 2 studs engine mount 1-3-

Sealant

5 side bottom

All threaded fasteners installed in a Apply before installing threaded

stud hole through to an oil source fastener

Table 5. Lubricants

Item P/N Type Application Remarks

Fuel injector nozzles See Figure 2

(at cylinder head)

Mechanical tachometer drive

housing threads not connected

through to an oil source.

Loctite 76732 Anti-Seize Exhaust studs (applied to nut end

1 646943 before torque), exhaust slip joints At engine assembly

Lubricant

Vernatherm plug

All 0.3125 and larger studs unless

otherwise noted

Throttle body air reference fittings Where applicable

Oil sump return fitting IO360ES3B & IO360HB9B

Fuel injection linkages At engine assembly

Shell #5 MIL-G-3545-C Grease

2 654468 (optional Lubriplate 630 AA or Apply at pivot points during

LPS 2) Throttle & mixture control linkages assembly and periodic

maintenance

CRC 336 Rust Preventative

3 654514 Compound Spray exhaust end of turbocharger After engine test

Light coat at contact point between All models, where applicable

nut seat and ignition lead ferrule

4 654561 Shell Alvania # 2 LTSIO360E, EB, RB;

Apply to oil seal lip only (alternator

seal) TSIO360E, EB, F, FB, GB, KB,

LB

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

5 of 22 SIL99-2 C

Table 5. Lubricants

Item P/N Type Application Remarks

Starter worm gear & bevel gear

teeth All models during engine

Needle bearings and ball bearings assembly

Valve stems

Accessory drive splines and

Where applicable

couplings

Idler gear and pin 470, 520, 550

5 656817 Super Molyshield Grease Magneto rubber drive bushings

All models

Oil seal lips only

Except 360, TSIO520D,

Fuel injection controls, o-rings,

GTSIO520K, which use 50W

springs, shafts, and bushings

motor oil

Coat gear cavity during pump

Oil pumps (pressure & scavenge) assembly

Adapter (tach reduction) TSIO & LTSIO360

Use only manufacturer’s

6 N/A recommended spark plug Spark plugs All models

thread lubricant

Chesterton #995 Release Induction system hoses and flex

7 N/A Agent duct connections, pipe plugs in All models

or WD-40 throttle body units

Rubber oil seal of spin-on oil filters

8 N/A Dow Corning No. 4 Governor pad gaskets (both sides) All models where applicable

Starter adapter cover o-rings

9 N/A Dow Corning G-N Paste Camshaft lobes and tappet faces During engine assembly

All models during valve guide

10 N/A Lubriplate 930 AA O.D. of valve guides

installation

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

6 of 22 SIL99-2 C

Table 5. Lubricants

Item P/N Type Application Remarks

Quill Shaft Springs GTSIO520

Crankshaft bearings

Connecting rod bearings

Prop driver, driven gears &

bearings

Camshaft bearings

Tachometer gears & adapters

Accessory spur gear teeth

Prop governor transfer collar & During engine assembly

sleeve

Starter cone, bushing & nut

Starter clutch spring (ID & OD)

SAE J-1966 Grade 50 Pistons, piston pins, & piston rings

11 N/A

MHS-27 Aviation Oil Thrust washers

Oil filter adapter seals

O-rings

Carburetor fuel connections Carburetor-equipped models

Valve guide seals Apply to sealing surface

V.T.C. unit pistons & centrifugal

valves, rocker arms, valves and Tiara 6-285, 6-230

tappets

Cylinder studs, through bolts,

crankcase studs, connecting rod

bolts and nuts; and engine Lubricate bolt thread and nut

accessory studs unless installed in seat before tightening nuts

blind or stud holes not through to

an oil supply or otherwise specified

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

7 of 22 SIL99-2 C

Table 6. Adhesives

Item P/N Type Application Remarks

Breakaway torque minimum

Cylinder deck studs

100 in-lbs. after two hours

470 & 520 (Sandcast) &

Crankcase breather tubes GTSIO520

Crankcase nose seal retainer bolts All models

Intake manifold mount studs C-75, C-85, C-90 & O-200

Mechanical tachometer drive studs

where applicable

trough to an oil source

IO360, LTSIO360, TSIO360,

O470, IO470, TSIO470,

Loctite 271 High Strength Oil gauge rod housing to crankcase IO520A, B, E, G, J, K, L,

Adhesive Sealant IO550D, E, F, TSIO520A, AE,

1 646941 (used with P/N 653693 AF, C, CE, G, H, M, P, R, T

Loctite 7471 Primer) Oil pump gear mounting pin in IO360, LTSIO360, TSIO360

accessory cover

IO240, IO360, LTSIO360,

Press fit breather and oil fill necks

TSIO360

Rocker cover studs, rocker arm

pivot studs, push rod retainer stud Tiara 6-285, 6-230

Timing indicator pin GTSIO-520

Top accessory drive gear (breather

slinger) bolts

Tiara 6-285, 6-230

V.T.C. unit bushing retainer screws

V.T.C. unit housing to crankshaft

Diverter valve assembly TSIO360MB, SB

(bracket to valve) IO360ES2B

Manifold valve to bracket screws All models

Coolant pump impeller ring screws All liquid cooled models

Studs 0.25 diameter and smaller All models

649306 Loctite 222 Sealant Manifold valve assembly data plate

All models

2 (optional (or optional Loctite Hydraulic screws

646940) Sealant 569) 0200, IO240, 0300, IO360,

Mag stud holes and stud holes LTSIO360, TSIO360, 470, 520,

through an oil source on accessory

end of crankcase 550 (apply when installing

studs)

All pipe thread fittings in fuel

injection system except pipe plug All models

threads in throttle body unit

Magneto housing pressurization

3 649366 Loctite 242 All models, where applicable

fitting

Coolant pump mechanical seal,

4 652983 Loctite 620 Adhesive Sealant standard repair on starter adapter All liquid cooled models

bearing bore

5 654495 Loctite 8531 Adhesive Sealant Starter clutch assembly bearing O200, O300, IO240

Bearing OD installed on starter

6 654562 Loctite 609 Adhesive / Sealant O200A, B, IO240A, B, O300A

clutch assembly

GIO550, GTSIO520, IO520,

7 655515 Adhesive Sealant (RTV) Alternator assembly IO550, IOF550, TSIOL550,

TSIOF550

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

8 of 22 SIL99-2 C

Table 6. Adhesives

Item P/N Type Application Remarks

IO360, TSIO360, LTSI360,

8 655700 PBC30 Adhesive Inter-cylinder baffles TSIO520, IO550, IOF550,

TSIO550 and TSIOF550

All FADEC (apply to gasket

9 800126 3M Super 77 Adhesive EMI Gasket before installing on ECU

IO360AF, ES; TSIO360MB, RB;

LTSIO360RB; TSIO520BE;

10 658493 3M Scotch-Weld 1300 Induction manifolds, diverter valve IO550G, N, P, R; IOF550 ;

Adhesive bracket

TSIO550A, B, C, E, G, K, N;

TSIOF550

Table 7. Miscellaneous

Item P/N Type Application Remarks

Safety wire -.032 in dia. Steel

1 535011 Where safety wire is required N/A

Corrosion Resistant

Safety wire -.020 in dia. Steel

2 800154 Corrosion Resistant Where safety wire is required FADEC electronic control units

3 626531-1 Enamel - Gold (1 qt) High temperature paint for

N/A

cosmetic and corrosion protection

4 626531-2 Enamel - Gold (1 gal)

5 N/A “ACCELAGOLD” Corrosion protection interior and N/A

Turco Products exterior aluminum parts

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

9 of 22 SIL99-2 C

V. Manufacturer/Distributor Supplemental Product Information

Table 8. Supplemental Product Information

1

Manufacturer/Distributor Web Address

Recommended Products Address Phone FAX (http://www.)

American Lubricants / Moly 1227 Deeds 937-222-2851 618-534-5231 molymotoroil.com

Motor Oil Dayton, OH 45401

Super Molyshield

A.W Chesterton Company 500 Unicorn Park Drive 800-835-4135 781-438-8971 chesterton.com

Chesterton #995 Release Agent Woburn, MA 01801- 781-438-7000

3345

CRC Industries/Chemical 885 Louis Drive 800-272-4620 800-272-4560 crcindustries.com

Products Warminister, PA 18974 800-556-5074 215-674-2196

336 Rust Preventative Compound

Copper Coat 401504 Gasket

Sealant

Daubert Chemical 4700 South Central Ave 708-563-8325 708-496-7367 daubertchemical.com

MIL-P-46002A Grade 1 Oil Chicago, IL 60638

Non-Rust VCI-105

Dow Corning Corporation P.O. Box 994 989-496-4400 989-496-7879 dowcorning.com

Dow Corning No. 4 South Saginaw Road 800-662-0661

Dow Corning G-N Paste Midland, MI 48686

Graham Aircraft Engines PO Box 3214 770-252-4995 770-252-5270 highaero.com

Motorstor Oil Peachtree City, GA

30269

Henkel Aerospace 32100 Stephenson Hwy 248-583-9300 248-583-2976 henkel.com

ACCELAGOLD Turco Products Madison Heights, MI

48071

Loctite Industrial Products 1001 Trout Brook 860-571-5100 860-571-5465 loctite.com

Loctite 76732 Crossing 800-243-4874

Loctite 565 Adhesive Sealant Rocky Hill, CT 06067-

Loctite 569 Hydraulic Sealant 3910

Loctite 515 Gasket Eliminator

Loctite 290

LocQuic Primer 7649

Loctite 1522029 Gasket Sealant

Loctite 592 Teflon PS/T Pipe

Sealant

Loctite 222 Sealant

Loctite 271 HS

Loctite 242

Lubriplate 129 Lockwood St. 973-589-9150 973-589-4432 lubriplate.com

Lubriplate 930 AA Newark, NJ 07105 800-733-4755

Miller-Stephenson Chemical Co. 6348 Oakton St 847-966-2022 847-966-8468 miller-

MS-122AD (10400533) Morton Grove, IL 60053 800-992-2424 stephenson.com

Shell Oil Company P.O. Box 2463 713-241-4819 713-241-6511 shell-lubricants.com

Shell #5 Houston, TX 77252 800-332-6457

Shell Alvania #2

1. Unless otherwise indicated, type http://www. followed by the Web Address. shown

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

10 of 22 SIL99-2 C

VI. General Sealant Applications and Threading Procedures (typical)

CAUTION: Never use Teflon tape on fluid fittings or fuel nozzles.

Only apply sealants or lubricants to fitting tapered ends up to the first

two threads. Never apply to the first two threads to prevent

contaminating fuel supply.

Figure 1. General Anti-Seize Lubricant Application

Figure 2. General Fuel Injection Sealant Application

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

11 of 22 SIL99-2 C

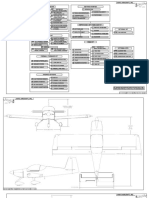

A. Crankcase Sealant and Threading Procedure for Four Cylinder Engines

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before

using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply P/N 654663 (gasket sealant) to 2-4 case half. Apply g a s k e t s e a l a n t p e r t h e

m a n u f a c t u r e r ’ s i n s t r u c t i o n s o n l y in areas where threading is indicated. When

applying, use short light brush strokes until an even thin coat is obtained. The gasket

sealant should be viscous enough that most of the brush marks disappear; if not, remove

old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading. Do not apply gasket sealant to crankshaft

nose seal area.

3. Apply a thin translucent coat of P/N 654942 (gasket maker), not to exceed 0.010 inch

thick, to t h e 1 -3 case half. Apply gasket maker in all areas that will mate against

areas where gasket sealant was applied on the matching 2-4 case half (except the through

bolt bosses).

4. Apply and position P/N 641543 (a continuous, single piece of grade “D” silk thread) on the

2-4 case half as specified (see Figures 3 and 4, page 13). Ensure the free ends of your

thread are covered by gaskets (except at the nose oil seal).

5. Clean crankcase crankshaft front oil seal land with P/N 653692 (LocQuic Primer “N”)

and apply an even coat of P/N 654942 (gasket maker).

6. Assemble crankcase halves; install and torque all crankcase hardware in proper sequence in

accordance with the applicable overhaul manual as soon as possible.

NOTE: Take care to prevent displacement or damage to the

crankshaft oil seal and silk thread. Insure thrust washer halves and

bearing halves remain in place.

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

12 of 22 SIL99-2 C

Figure 3. Threading Diagram, C75, C85, C90, O200 Crankcase

Figure 4. Threading Diagram, 240, IO240 Crankcase

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

13 of 22 SIL99-2 C

B. Crankcase Sealant and Threading Procedure for Six Cylinder Engines

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before

using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply P/N 654663 (gasket sealant) to 2-4-6 case half. Apply g a s k e t s e a l a n t p e r

t h e m a n u f a c t u r e r ’ s i n s t r u c t i o n s only in areas where threading is indicated.

When applying, use short light brush strokes until an even thin coat is obtained. The

gasket sealant should be viscous enough that most of the brush marks disappear; if not,

remove old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading. Do not apply gasket sealant to crankshaft

nose seal area.

3. Apply a thin translucent coat of P/N 654942 (gasket maker), not to exceed 0.010 inch

thick, to t h e 1 -3-5 case half. Apply gasket maker in all areas that will mate against

areas where gasket sealant was applied on the matching 2-4-6 case half (except the through

bolt bosses).

4. Apply and position P/N 641543 (a continuous, single piece of grade “D” silk thread) on the

2-4-6 case half as specified (see Figures 5 through 8, pages 15-16). Ensure the free ends

of your thread are covered by gaskets (except at the nose oil seal).

5. Clean crankcase crankshaft front oil seal land with P/N 653692 (LocQuic Primer “N”)

and apply an even coat of P/N 654942 (gasket maker).

6. Assemble crankcase halves; install and torque all crankcase hardware in proper sequence in

accordance with the applicable overhaul manual as soon as possible.

NOTE: Take care to prevent displacement or damage to the

crankshaft oil seal and silk thread. Insure thrust washer halves and

bearing halves remain in place.

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

14 of 22 SIL99-2 C

Figure 5. Threading Diagram, IO360, LTSIO360 Crankcase

Figure 6. Threading Diagram, IO520, TSIO520, IO550, IOF550, TSIO550, TSIOL550 Permold Crankcase

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

15 of 22 SIL99-2 C

Figure 7. Threading Diagram, O470, IO470, LIO520, LTSIO520, IO550 Sandcast Crankcase

Figure 8. Threading Diagram, GTSIO520 Crankcase

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

16 of 22 SIL99-2 C

C. Sealant and Threading Procedure for Scavenger Pump Bodies

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before

using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply gasket sealant p e r t h e m a n u f a c t u r e r ’ s i n s t r u c t i o n s only in areas

where threading is indicated. When applying, use short light brush strokes until an even

thin coat is obtained. The gasket sealant should be viscous enough that most of the brush

marks disappear; if not, remove old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading.

3. Apply a thin translucent coat of P/N 654942 (gasket maker), not to exceed 0.010 inch

thick in all areas that will mate against areas where gasket sealant was applied on the

matching surfaces.

4. Apply P/N 641543 (a continuous, single piece of grade “D” silk thread) as shown by the

dashed lines in Figure 9.

5. Assemble and torque as soon as possible in accordance with the applicable overhaul

manual.

Figure 9. Threading Diagram, Scavenge Pump Bodies 640741, 652019, 652019, & 655713

(used on starter adapters 642087 & corresponding 0.015 oversize adapters)

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

17 of 22 SIL99-2 C

D. Sealant and Threading Procedure for Oil Pump Assemblies

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply gasket sealant p e r t h e m a n u f a c t u r e r ’ s i n s t r u c t i o n s only in areas

where threading is indicated. When applying, use short light brush strokes until an even

thin coat is obtained. The gasket sealant should be viscous enough that most of the brush

marks disappear; if not, remove old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading.

3. Apply a thin translucent coat of P/N 654942 (gasket maker), not to exceed 0.010 inch

thick in all areas that will mate against areas where gasket sealant was applied on the

matching surfaces.

4. Apply P/N 641543 (a continuous, single piece of grade “D” silk thread) as shown by the

dashed lines in Figures 10 through 14, pages 18-20).

5. Assemble and torque as soon as possible in accordance with the applicable overhaul manual.

Figure 10. Threading Diagram, Oil Pump Assembly 632623

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

18 of 22 SIL99-2 C

Figure 11. Threading Diagram, Oil Pump Assembly 631713, 632481, 632563, & 641993

Figure 12. Threading Diagram, Oil Pump Assemblies 646194, 653536, 655121, & 643527

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

19 of 22 SIL99-2 C

Figure 13. Threading Diagram, Oil Pump Assemblies 643716, 643717, 643743, 643778, 643779,

653494, 653538, 653542, 653542, 653553, 655117, 655119, 655123, 655124, & 655127

Figure 14. Threading Diagram, Oil Pump Assemblies 631149, 632970, 632977, 654437, 655349, &

655680

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

20 of 22 SIL99-2 C

E. Sealant and Threading Procedure for Starter Adapter Assemblies

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before

using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply gasket sealant p e r t h e m a n u f a c t u r e r ’ s i n s t r u c t i o n s only in areas

where threading is indicated. When applying, use short light brush strokes until an even

thin coat is obtained. The gasket sealant should be viscous enough that most of the brush

marks disappear; if not, remove old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading.

3. Apply a thin translucent coat of P/N 654942 (gasket maker), not to exceed 0.010 inch

thick in all areas that will mate against areas where gasket sealant was applied on the

matching surfaces.

4. Apply P/N 641543 (a continuous, single piece of grade “D” silk thread) as shown by the

dashed lines in Figure 15.

5. Assemble and torque as soon as possible in accordance with the applicable overhaul

manual.

Figure 15. Threading Diagram, Starter Adapter Assemblies 641348, 646220, & 653074

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

21 of 22 SIL99-2 C

F. Sealant and Threading Procedure for Accessory Starter Drive Adapter Assemblies

1. Use full strength, non-thinned P/N 654663 (gasket sealant). Shake or mix well before

using.

CAUTION: Apply gasket sealant and threading (a continuous, single

piece) only as illustrated.

2. Apply gasket sealant p e r t h e m a n u f a c t u r e r ’ s i n s t r u c t i o n s only in areas

where threading is indicated. When applying, use short light brush strokes until an even

thin coat is obtained. The gasket sealant should be viscous enough that most of the brush

marks disappear; if not, remove old gasket sealant and reapply with new gasket sealant.

NOTE: Allow the gasket sealant to air dry to a tacky condition before

applying silk threading.

3. Apply P/N 641543 (a continuous, single piece of grade “D” silk thread) as shown by the

dashed lines in Figure 16.

4. Temporarily install the starter adapter to make an impression of the thread on the

accessory case.

5. Carefully remove the starter adapter so that the shaft gear does not pull out.

6. Inspect the thread impression for 100% contact between the adapter and accessory

case.

7. Wipe excess gasket maker off of accessory case and install starter adapter in accordance

with the applicable overhaul instructions.

Figure 16. Threading Diagram, Accessory Starter Drive Adapter Assemblies 641348 & 653074

ISSUED REVISED PAGE NO DOC NO REVISION

1999/03/29 2014/09/16

P.O. Box 90 Mobile, AL 251-436-8299

22 of 22 SIL99-2 C

You might also like

- Atm QuestionsDocument23 pagesAtm QuestionsAziz YoussoufouNo ratings yet

- 601-00182-034 Service Bulletin Ifd5xx-4xx Series Upgrade To 10.3.0.2Document18 pages601-00182-034 Service Bulletin Ifd5xx-4xx Series Upgrade To 10.3.0.2EjamesNo ratings yet

- 1845 Case Uni - PartsDocument50 pages1845 Case Uni - PartsJoseGarza100% (3)

- Kohler K Series Owners ManualDocument16 pagesKohler K Series Owners Manualapi-3721459100% (5)

- LHB Eog Power CarDocument41 pagesLHB Eog Power Carvishak MkNo ratings yet

- VANTAGE TruckALL and VanGO Series Operation and Service ManualDocument209 pagesVANTAGE TruckALL and VanGO Series Operation and Service ManualsandyNo ratings yet

- Embraer Legacy 600 Landing Gear: Inspection, Overhaul & RepairDocument2 pagesEmbraer Legacy 600 Landing Gear: Inspection, Overhaul & RepairHuda LestraNo ratings yet

- Service Letter: Single EngineDocument10 pagesService Letter: Single EnginesandyNo ratings yet

- 2007 04 19R1Document24 pages2007 04 19R1Yaşar AkyıldızNo ratings yet

- ND Bk117 FSX ManualDocument22 pagesND Bk117 FSX Manualกิตติทัต ศรีพละธรรมNo ratings yet

- Master SoCal Backcountry Airstrip GuideDocument10 pagesMaster SoCal Backcountry Airstrip GuideAnthonyNo ratings yet

- Extra 330Lx: U.S.Information ManualDocument284 pagesExtra 330Lx: U.S.Information ManualGourav DasNo ratings yet

- VOITH Torque ConverterDocument22 pagesVOITH Torque ConverterLTE002100% (1)

- Manual Deep Sea 520Document19 pagesManual Deep Sea 520MH..202367% (6)

- Caterpillar CB 534D Serie FGH Sist. ElectricoDocument6 pagesCaterpillar CB 534D Serie FGH Sist. ElectricoCarlos Irabedra100% (1)

- Understandthe EWS BMWDocument25 pagesUnderstandthe EWS BMWh3ll88% (8)

- MTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementDocument10 pagesMTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementGarrett ReeveNo ratings yet

- 190-00848-00 July 2014 Rev. FDocument17 pages190-00848-00 July 2014 Rev. Fjosue jetavionicsNo ratings yet

- Operator's ManualDocument177 pagesOperator's ManualMiamando GutyNo ratings yet

- Hartzell Propeller Inc.: One Propeller Place Piqua, Ohio 45356-2634 U.S.A. Telephone: 937.778.4200 Fax: 937.778.4215Document1,924 pagesHartzell Propeller Inc.: One Propeller Place Piqua, Ohio 45356-2634 U.S.A. Telephone: 937.778.4200 Fax: 937.778.4215gugu carterNo ratings yet

- Helicopter Final PresentationDocument28 pagesHelicopter Final Presentationbib demNo ratings yet

- Manual 152 Rev. 10Document675 pagesManual 152 Rev. 10Julio Alberto Vite PuescasNo ratings yet

- TCM Sid97-3fDocument28 pagesTCM Sid97-3fPaula Pulido MartínezNo ratings yet

- IO-540-J-K-M-N-P-R Parts Catalog PC-215-2Document122 pagesIO-540-J-K-M-N-P-R Parts Catalog PC-215-2Mark Jerome HernandezNo ratings yet

- (L) Io 360 M1a Parts Catalog PC Lio 360 M1aDocument81 pages(L) Io 360 M1a Parts Catalog PC Lio 360 M1aMo HoNo ratings yet

- Piper Cherokee Archer II - POHDocument212 pagesPiper Cherokee Archer II - POHJan TergenNo ratings yet

- Resumen C208BDocument9 pagesResumen C208BCosta BonanzaNo ratings yet

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocument36 pagesRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNo ratings yet

- Check List 209Document63 pagesCheck List 209ali sh100% (1)

- PDF File: Manual Cessna 402 Short ReviewsDocument2 pagesPDF File: Manual Cessna 402 Short ReviewsQue Te importa100% (1)

- R172 SM D202716Document31 pagesR172 SM D202716Luz Analía Valdez CandiaNo ratings yet

- GMF AeroAsiaDocument4 pagesGMF AeroAsiaridwansadelyNo ratings yet

- 190 01115 01 - ApDocument944 pages190 01115 01 - ApAxel IvaniecNo ratings yet

- Restraint System Assembly: With Illustrated Parts ListDocument35 pagesRestraint System Assembly: With Illustrated Parts ListEdwar ZulmiNo ratings yet

- Advisory CircularDocument42 pagesAdvisory Circularnabawi24No ratings yet

- 0 235 0 290 - OperatorDocument100 pages0 235 0 290 - Operatortonny100% (1)

- Om 2101Document116 pagesOm 2101SAPTONo ratings yet

- Bell 430Document276 pagesBell 430Андрей Драгунов50% (2)

- Note 8Document7 pagesNote 8Alberto MolinaNo ratings yet

- Pageview As Id 33348Document109 pagesPageview As Id 33348long chenNo ratings yet

- Univair Catalog PDFDocument269 pagesUnivair Catalog PDFJessie O.BechaydaNo ratings yet

- H125 AMP Issue 01 Rev 0 Nov 21Document94 pagesH125 AMP Issue 01 Rev 0 Nov 21raviNo ratings yet

- AviationDocument204 pagesAviationReshma R KumarNo ratings yet

- Flight ControlsDocument65 pagesFlight ControlsIludiran KolaNo ratings yet

- Aircraft Maintenance Manual: Print Date: 2021-03-25Document8 pagesAircraft Maintenance Manual: Print Date: 2021-03-25CHIMONo ratings yet

- B300 B300C MX05 Environmentall Systems 04APR16Document88 pagesB300 B300C MX05 Environmentall Systems 04APR16Edison RestrepoNo ratings yet

- Check List Technam p2006tDocument4 pagesCheck List Technam p2006tGourav DasNo ratings yet

- List of Type Design Accepted by DGCA: (From April 2004 To 31 December 2020)Document21 pagesList of Type Design Accepted by DGCA: (From April 2004 To 31 December 2020)TusharRoyNo ratings yet

- Erick PDFDocument94 pagesErick PDFfateless 17100% (1)

- SUMMARY OF FAA STCs - TCM ENGINES - JAN 1998Document34 pagesSUMMARY OF FAA STCs - TCM ENGINES - JAN 1998Randy WaltonNo ratings yet

- 1967 C150G Owners Manual PDFDocument28 pages1967 C150G Owners Manual PDFalexred89No ratings yet

- Afm Emb-145Document10 pagesAfm Emb-145Jimmy SteepNo ratings yet

- Introduction To High Speed FlightDocument65 pagesIntroduction To High Speed FlightAdriel M.No ratings yet

- When You Own A Private Jet: N//Kelowna//Chicago//SeattleDocument14 pagesWhen You Own A Private Jet: N//Kelowna//Chicago//Seattlemehul da aviatorNo ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument5 pagesService Bulletin: Piper Considers Compliance MandatoryCarlos MNo ratings yet

- Cessna 208b Grand CaravanDocument2 pagesCessna 208b Grand CaravanMakhou LadoumNo ratings yet

- ch750 Manual EnglishDocument22 pagesch750 Manual EnglishJustinFlierNo ratings yet

- Maule M-7 POH MODIFIEDDocument31 pagesMaule M-7 POH MODIFIEDBeka KarumidzeNo ratings yet

- Presentation On B200, R44, R66Document19 pagesPresentation On B200, R44, R66Sangeeta PandaNo ratings yet

- Certificado Tipo Piper PA-25-235Document8 pagesCertificado Tipo Piper PA-25-235debe dallaNo ratings yet

- List of Consumables: ATA 61-90-00 (E-9000)Document6 pagesList of Consumables: ATA 61-90-00 (E-9000)kikeNo ratings yet

- C35 MANUAL - CNX80 Pilot Friendly GuideDocument47 pagesC35 MANUAL - CNX80 Pilot Friendly GuideblipNo ratings yet

- JDs CL - Kodiak 100 1.12.3Document4 pagesJDs CL - Kodiak 100 1.12.3Ashwin AlexNo ratings yet

- ATA Chapters PDFDocument1 pageATA Chapters PDFJewel Christian PuseNo ratings yet

- Pilot'S Operating Handbook: Robinson Helicopter CoDocument200 pagesPilot'S Operating Handbook: Robinson Helicopter CoJoseph BensonNo ratings yet

- Global 7500 - Fact SheetDocument2 pagesGlobal 7500 - Fact SheetMeriç ACARNo ratings yet

- S.I Nº 57-51-01Document2 pagesS.I Nº 57-51-01Pedro EdilNo ratings yet

- M600 SLS Halo BrochureDocument2 pagesM600 SLS Halo BrochuresandyNo ratings yet

- 2019 Specification Book: Cabin Class - Single-Engine - Pressurized TurbopropDocument5 pages2019 Specification Book: Cabin Class - Single-Engine - Pressurized Turbopropsandy100% (1)

- Welcome To The New Piper M-Class: in This IssueDocument12 pagesWelcome To The New Piper M-Class: in This IssuesandyNo ratings yet

- SB 1103BDocument5 pagesSB 1103BsandyNo ratings yet

- Current Online CatalogDocument376 pagesCurrent Online CatalogsandyNo ratings yet

- Service Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacerDocument9 pagesService Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacersandyNo ratings yet

- PR46BT: 115838449 Rev. A 2016-05-02Document41 pagesPR46BT: 115838449 Rev. A 2016-05-02sandyNo ratings yet

- Piper's M600 Personal Turboprop: For The Pilots of Owner-Flown, Cabin-Class AircraftDocument36 pagesPiper's M600 Personal Turboprop: For The Pilots of Owner-Flown, Cabin-Class AircraftsandyNo ratings yet

- ATP CatalogDocument158 pagesATP Catalogsandy100% (1)

- 230 203-Pa24 Inspection Report-Rev 20090401Document5 pages230 203-Pa24 Inspection Report-Rev 20090401sandyNo ratings yet

- Supplemental Type Aertificate: Bepartment of Transportation - Hederal Adiation AdministrationDocument26 pagesSupplemental Type Aertificate: Bepartment of Transportation - Hederal Adiation AdministrationsandyNo ratings yet

- Service Letter: Single EngineDocument10 pagesService Letter: Single EnginesandyNo ratings yet

- Chuck Guide Il 2 Cliffs of Dover He111Document91 pagesChuck Guide Il 2 Cliffs of Dover He111sandyNo ratings yet

- Airworthiness Bulletin: AWB Issue: Date: 1. ApplicabilityDocument2 pagesAirworthiness Bulletin: AWB Issue: Date: 1. ApplicabilitysandyNo ratings yet

- Current Revision Levels FOR Instructions For Continued Airworthiness (Ica), Flight Manual Supplements (FMS) and Sa52Document4 pagesCurrent Revision Levels FOR Instructions For Continued Airworthiness (Ica), Flight Manual Supplements (FMS) and Sa52sandyNo ratings yet

- Cessna ConquestDocument18 pagesCessna ConquestsandyNo ratings yet

- Piper Super Pacer: Pilots ManualDocument38 pagesPiper Super Pacer: Pilots ManualsandyNo ratings yet

- Just Flights PA-28R - Turbo - Arrow - III-IV - AF2 - ManualDocument64 pagesJust Flights PA-28R - Turbo - Arrow - III-IV - AF2 - ManualsandyNo ratings yet

- Vans Aircraft Building InstructionDocument6 pagesVans Aircraft Building Instructionsandy100% (1)

- Operator'S Manual: MODEL #76533 3800W Dual Fuel GeneratorDocument33 pagesOperator'S Manual: MODEL #76533 3800W Dual Fuel GeneratorsandyNo ratings yet

- TIPS Chapter Thirteen General Information: (Insurance, Ground Handling Etc.)Document31 pagesTIPS Chapter Thirteen General Information: (Insurance, Ground Handling Etc.)sandyNo ratings yet

- 1984 Mitsubishi MU-2B-60 MarquiseDocument10 pages1984 Mitsubishi MU-2B-60 Marquisesandy100% (2)

- EASA - IM.A.232 Issue 4 Piper Aircraft Piper PA-44-seriesDocument21 pagesEASA - IM.A.232 Issue 4 Piper Aircraft Piper PA-44-seriessandyNo ratings yet

- The Wheelair III-A: Yesterday's WingsDocument2 pagesThe Wheelair III-A: Yesterday's WingssandyNo ratings yet

- Traktorbx22d PDFDocument262 pagesTraktorbx22d PDFKemal Lisnik ArnautovicNo ratings yet

- Bajaj Wave 2011 - 51 - 14Document62 pagesBajaj Wave 2011 - 51 - 14HARSH AUTO CARESNo ratings yet

- Ariens Parts ManualDocument30 pagesAriens Parts ManualJames HornNo ratings yet

- Bullit Owner Manual Hero enDocument86 pagesBullit Owner Manual Hero enstefan.vince536No ratings yet

- Perkins 3.152 SpecsDocument12 pagesPerkins 3.152 SpecsMTU650No ratings yet

- Manual Husqvarna 36Document22 pagesManual Husqvarna 36José Manuel Arrojo MacíasNo ratings yet

- Hoja de Especificaciones JW6H-NLDocument2 pagesHoja de Especificaciones JW6H-NLosvaldoNo ratings yet

- enDocument31 pagesenRegistr Registr100% (5)

- Starter (6HK1)Document3 pagesStarter (6HK1)Oggy ToffyNo ratings yet

- ISM Lista de Partes PDFDocument154 pagesISM Lista de Partes PDFAnGel AmayaNo ratings yet

- 2021 PM 81805873-03 (L2z06151-Up)Document188 pages2021 PM 81805873-03 (L2z06151-Up)veeresh100% (2)

- 4VCR Engine Repair ManualDocument200 pages4VCR Engine Repair ManualGonçalo Pereira100% (1)

- We Build A Better Future: Tier II EngineDocument5 pagesWe Build A Better Future: Tier II EngineSergio FernandoNo ratings yet

- MDKBL BM BN Parts ManualDocument144 pagesMDKBL BM BN Parts ManualAhung100% (1)

- 6599892Document127 pages6599892Dino Martin Mercado QuispeNo ratings yet

- CAT 3408 - System OperationDocument62 pagesCAT 3408 - System OperationRaul FletcherNo ratings yet

- Reference: I L319 Engine TDV6, AJ126Document3 pagesReference: I L319 Engine TDV6, AJ126Ezreen MnasyeNo ratings yet

- CessnaDocument33 pagesCessnaemeramusixzNo ratings yet

- ST1000 PDFDocument32 pagesST1000 PDFFranNo ratings yet

- Cadillac: Operator'S ManualDocument63 pagesCadillac: Operator'S ManualRaj jainNo ratings yet

- CAT 926 - 3204 Engine TDC PDFDocument3 pagesCAT 926 - 3204 Engine TDC PDFferdyak1100% (1)

- 28N707Document17 pages28N707smsaktienNo ratings yet

- Kawasaki Fc150vDocument76 pagesKawasaki Fc150vAriciuAdrianNo ratings yet