Professional Documents

Culture Documents

Codeline Drawing 40L30N

Codeline Drawing 40L30N

Uploaded by

Armando Corral BlancoCopyright:

Available Formats

You might also like

- C3530 - C3525 - C3520 Series - Partscatalog - E - EURDocument144 pagesC3530 - C3525 - C3520 Series - Partscatalog - E - EURMario PađanNo ratings yet

- Internship Report On Compensation and Benefits Package of ACIDocument135 pagesInternship Report On Compensation and Benefits Package of ACIRajoshree Moni33% (3)

- One Steel ReoDataDocument40 pagesOne Steel ReoDatapete0980100% (1)

- Codeline Drawing 80S45Document3 pagesCodeline Drawing 80S45betow_No ratings yet

- Pressure Vessel-80S100Document2 pagesPressure Vessel-80S100IbrahimNo ratings yet

- Codeline Drawing 80S45 PDFDocument3 pagesCodeline Drawing 80S45 PDFHardik VavdiyaNo ratings yet

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFDocument2 pagesCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaNo ratings yet

- Codeline Drawing 80S30Document3 pagesCodeline Drawing 80S30Hardik VavdiyaNo ratings yet

- Codeline Drawing 40E100Document2 pagesCodeline Drawing 40E100Hoàng Anh Tuấn NguyễnNo ratings yet

- Drawing Codeline-80S30 PDFDocument3 pagesDrawing Codeline-80S30 PDFjohandi johandiNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dillip DasNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- Codeline 80S120Document3 pagesCodeline 80S120gulfengsolutionsNo ratings yet

- Appendix E - Drawings & Data SheetDocument21 pagesAppendix E - Drawings & Data SheetsajanchaudhariNo ratings yet

- Codeline Drawing 40S30 Non CodedDocument2 pagesCodeline Drawing 40S30 Non CodedHardik VavdiyaNo ratings yet

- Codeline Drawing 80S15Document3 pagesCodeline Drawing 80S15jugal ranaNo ratings yet

- Codeline Drawing 80E45Document2 pagesCodeline Drawing 80E45Deblina MukherjeeNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- VB 536 Ag DR: TypeDocument1 pageVB 536 Ag DR: TypeMaffone NumerounoNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30Aravind RaoNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- D-57Document2 pagesD-57Cristian CalleNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- 3M Spacing GuideDocument2 pages3M Spacing Guideadam.l.whippleNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- APA+PR L331C+Nordic+X Lam+Industrial+CLT+MattingDocument6 pagesAPA+PR L331C+Nordic+X Lam+Industrial+CLT+MattingandreskargNo ratings yet

- Splinker TycoDocument4 pagesSplinker Tycoref.mtu.533No ratings yet

- D1836 Series (Nas1836)Document1 pageD1836 Series (Nas1836)blackhawkNo ratings yet

- 147-168 62gb Series 62GB-57A14-15SNDocument22 pages147-168 62gb Series 62GB-57A14-15SNwiradesNo ratings yet

- Brocure FDB 407 40 - 150Document1 pageBrocure FDB 407 40 - 150mandahandriNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Package Information Including Surface Mount: Fast and Ls TTLDocument14 pagesPackage Information Including Surface Mount: Fast and Ls TTLMilka RamirezNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- Pressure Drop Calculation For Fan (Exf-Bsc-01)Document8 pagesPressure Drop Calculation For Fan (Exf-Bsc-01)ibnrafeeqNo ratings yet

- KF Series Ball Valve PDFDocument20 pagesKF Series Ball Valve PDFbloggerparthiNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- High Static Ducted Technical Manual 2016-Rev.4Document149 pagesHigh Static Ducted Technical Manual 2016-Rev.4soqhNo ratings yet

- Rapid Allweiler Data BookDocument6 pagesRapid Allweiler Data BookJoNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- Valvulas de RegulacionDocument71 pagesValvulas de RegulaciondanielNo ratings yet

- MSA Ball Valves PDFDocument20 pagesMSA Ball Valves PDFAli FardidNo ratings yet

- MSA Ball Valves enDocument20 pagesMSA Ball Valves enBiswajit DeyNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument17 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Type 656 Diaphragm ActuatorDocument4 pagesType 656 Diaphragm Actuatorapi-37549310% (1)

- VB 537 Ag BR: FiguraDocument1 pageVB 537 Ag BR: FiguraMaffone NumerounoNo ratings yet

- Description: Terminals ChartDocument1 pageDescription: Terminals Chartdip461No ratings yet

- Ducted Blower Split Systems: Models: MDB 200 - 750 B MDB 075 - 500 DDocument155 pagesDucted Blower Split Systems: Models: MDB 200 - 750 B MDB 075 - 500 DNisar AhmedNo ratings yet

- NTC55 Product Guide Imperial PDFDocument44 pagesNTC55 Product Guide Imperial PDFnelson_casallas_3No ratings yet

- RFG50N06, RFP50N06, RF1S50N06SM: 50A, 60V, 0.022 Ohm, N-Channel Power Mosfets FeaturesDocument8 pagesRFG50N06, RFP50N06, RF1S50N06SM: 50A, 60V, 0.022 Ohm, N-Channel Power Mosfets FeaturesRoberto DiazNo ratings yet

- Piping Class Spec. - 1c23pe (Lurgi)Document5 pagesPiping Class Spec. - 1c23pe (Lurgi)otezgidenNo ratings yet

- Rhino Valves CatalogueDocument174 pagesRhino Valves CatalogueLizaDuPlessisNo ratings yet

- Section 2 Hydraulic/Mechanical Systems: To CoverDocument12 pagesSection 2 Hydraulic/Mechanical Systems: To CoverAlvaro Restrepo GarciaNo ratings yet

- Empaquetaduras Bombas Triplex.Document40 pagesEmpaquetaduras Bombas Triplex.pabloasotoNo ratings yet

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya Jain100% (1)

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSNo ratings yet

- PICOD - 131 - AK DatasheetDocument2 pagesPICOD - 131 - AK DatasheetWarr SteelNo ratings yet

- Power Amplifiers: Models HTA125A and HTA250ADocument2 pagesPower Amplifiers: Models HTA125A and HTA250AArmando Corral BlancoNo ratings yet

- Datasheet Codeline Ecoline 40L30NDocument2 pagesDatasheet Codeline Ecoline 40L30NArmando Corral BlancoNo ratings yet

- 100 HPDocument1 page100 HPArmando Corral BlancoNo ratings yet

- Ac Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Document2 pagesAc Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Armando Corral BlancoNo ratings yet

- Minitherm Bulletin 6.16Document2 pagesMinitherm Bulletin 6.16Armando Corral BlancoNo ratings yet

- The Metallurgy of Power BoilersDocument4 pagesThe Metallurgy of Power Boilersagniva dattaNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Switchgear Vs SwitchboardDocument20 pagesSwitchgear Vs SwitchboardJuan MoralesNo ratings yet

- MiningGuideFinalVersion 141218Document23 pagesMiningGuideFinalVersion 141218BudKh100% (2)

- 206-00 General InfoDocument16 pages206-00 General InfoMiguel AngelNo ratings yet

- CFM Equipped Fleet AtlanticDocument34 pagesCFM Equipped Fleet AtlanticJohn KevinNo ratings yet

- 1394 SERCOS Interface Multi-Axis Motion Control System: (Catalog Numbers 1394C-SJT05-D, 1394C-SJT10-D, 1394C-SJT22-D)Document87 pages1394 SERCOS Interface Multi-Axis Motion Control System: (Catalog Numbers 1394C-SJT05-D, 1394C-SJT10-D, 1394C-SJT22-D)angelpadronaNo ratings yet

- OS Switch Fuses ABBDocument32 pagesOS Switch Fuses ABBTrường NguyenNo ratings yet

- Insulation Jacket BrochureDocument6 pagesInsulation Jacket BrochureLeDzungNo ratings yet

- PT2313L PDFDocument3 pagesPT2313L PDFMaugrys Castillo100% (1)

- Lab 1Document10 pagesLab 1DaniNo ratings yet

- 4 - Mike ShandDocument6 pages4 - Mike ShandPieter Vd MerweNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalDocument3 pagesSaudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalOmer aliNo ratings yet

- 2010 Oregon Mechanical Specialty Code IxDocument4 pages2010 Oregon Mechanical Specialty Code IxbooboosdadNo ratings yet

- Ds Erhard Roco WaveDocument27 pagesDs Erhard Roco Wavekad-7No ratings yet

- CDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionDocument24 pagesCDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionBeroxi MihaiNo ratings yet

- SLB - Expandable Steel PatchDocument12 pagesSLB - Expandable Steel PatchMike du PlessisNo ratings yet

- Azimuth Co OrdinatorDocument2 pagesAzimuth Co OrdinatorGlen DonnellyNo ratings yet

- IBM Knowledge Center - SWIFT Message Block StructureDocument5 pagesIBM Knowledge Center - SWIFT Message Block StructureaNo ratings yet

- Car Body ConstructionDocument30 pagesCar Body ConstructionPethurajNo ratings yet

- Computer Network Individual ReportDocument2 pagesComputer Network Individual ReportWilson ChengNo ratings yet

- Time Management 101: Sreeram Kishore Chavali 14-November-2001Document25 pagesTime Management 101: Sreeram Kishore Chavali 14-November-2001manojmis2010No ratings yet

- Landed Cost ManagementDocument162 pagesLanded Cost Managementdsgandhi6006No ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- Swot of EmsDocument2 pagesSwot of EmsWaleed MorsyNo ratings yet

- M.Phil Syllabus - Bharathiyar UniversityDocument10 pagesM.Phil Syllabus - Bharathiyar UniversityArulsamy DanielNo ratings yet

- Aquasystem Aerator Karistirici Brosur PDFDocument8 pagesAquasystem Aerator Karistirici Brosur PDFMariusCapraNo ratings yet

- Generalscan R1000BT Specification enDocument2 pagesGeneralscan R1000BT Specification enAlejandro BacaNo ratings yet

Codeline Drawing 40L30N

Codeline Drawing 40L30N

Uploaded by

Armando Corral BlancoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Codeline Drawing 40L30N

Codeline Drawing 40L30N

Uploaded by

Armando Corral BlancoCopyright:

Available Formats

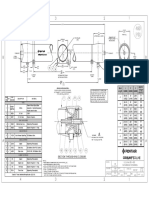

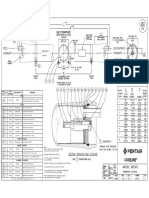

DWG PART Dash S

Approx

QTY DESCRIPTION MATERIAL L IN(MM) Weight

REF NUMBER Length IN(MM)

LB(KG)

SHELL 18.00 3

-B1 Any

Filament Wound Epoxy/Glass composites - (457) (1)

25.00 4

1 1 200016 SHELL Head locking grooves integrally wound in -C1

(635)

Any

(2)

place. 44.00 25 9

-1

HEAD (1118) (635) (4)

84.00 56 16

-2

2 2 95929 End plug Sub-assembly Engineering Thermoplastic. (2134) (1422) (7)

124.00 80 23

3 2 45317 Head Seal Ethylene Propylene - O - Ring -3

(3150) (2032) (11)

4 2 45296 PWT Seal Ethylene Propylene - O - Ring

HEAD INTERLOCK

5 2 46414 Retaining Ring SS 316 as per SA-479 ASME Edition 2015.

VESSEL SUPPORT

6 2 45058 Saddle-Optional Engineering Thermoplastic.

7 2 47459 Strap Assembly-Optional 304 Stainless Steel-PVC Cushion.

8 4 97821 Strap screw-Optional 5/16-18 UNC, 1.5" L, 18-8 Stainless Steel.

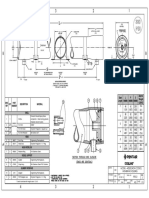

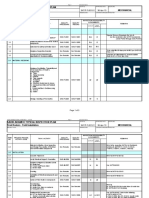

RATING: PRECAUTIONS: ORDERING:

DESIGN PRESSURE……………………………300 PSI DO…read, understand and follow all instructions; Using the chart below, please check the features Please note that we require your membrane

(2.07 Mpa) failure to take every precaution will void you require and fax them with your purchase brand and model number when ordering. If

MAX. OPERATING TEMP……...………………..120°F warranty and may result in vessel failure order to our customer service department for this information is not initially available,

(49°C) DO…mount the shell on horizontal members at span expedited processing. you may provide it at a later date by

MIN. OPERATING TEMP……...…………………..20°F “S” using complaint vessel supports furnished; For optional materials and/or features not listed checking the appropriate box below.

(-7°C) tighten hold down straps just snug below, please consult factory for pricing and

FACTORY TEST PRESSURE………………450 PSIG DO…provide flexibility in, and support for piping availability.

(3.10 MPa) manifolds so that vessel can grow in length

BURST PRESSURE……..………………….….1200 PSI under pressure without undue restraint; provide VESSEL LENGTH CODE – please check one

(8.27 MPa) additional flexible joints in large pipes leading to

manifold header ECOLINE MODEL 40L30N -B1 -C1 -1 -2 -3

INTENDED USE: DO…provide overpressure protection for vessel set

LENGTH

at not more than 105% of design pressure ELEMENT CAPACITY

The Ecoline Model 40L30N Fiberglass RO/UF Pressure CODE

DO…inspect end closures regularly; replace -B1 One 14” Direct Connect

Vessel is designed for continuous, long term use as

components that have deteriorated and correct -C1 One 21” Direct Connect

housing for reverse osmosis and ultrafiltration elements -1 One 40” Direct Connect

causes of corrosion

in typical industrial water treatment systems at pressures -2 Two 40” Direct Connect

up to 300 psi. Any make of four-inch nominal diameter -3 Three 40” Direct Connect

DO NOT…work on any component until first

spiral-wound element with a ¾’’ dia male product water

verifying that pressure is relieved from vessel

tube is easily accommodated.

DO NOT… make rigid piping connections to ports MEMBRANE BRAND AND MODEL – please check one and fill in information

or clamp vessel in any way that resists growth of

The Ecoline Model 40L30N must be installed, operated

and maintained in accordance with the listed precautions fiberglass shell under pressure; ∆DIA = 0.01 in. Please supply end plugs for the following membrane brand and specific model

and good industrial practice to assure safe operation over (0.25mm) and ∆L = 0.03 in. (0.8mm) for a length Brand_________________________Model_______________________

a long service life. code –1 vessel

DO NOT… hang piping manifolds from ports or use Membrane brand and model information is not available, but will be supplied to Pentair on or

The high performance reinforced plastic shell must be vessel in any way to support other components. before the following date _____/________/_______

allowed to expand under pressure; undue restraint at DO NOT… operate vessel at pressures and

support points or piping connections can cause leaks to temperatures in excess of its rating CERTIFICATION – please check one

develop in the shell. The end closures, incorporating DO NOT… operate vessel without element installed.

close-fitting, interlocking metal components, must be DO NOT… operate vessel with permeate pressure in CE Marked.(Not applicable for -1 vessel)

kept dry and free of corrosion; deterioration can lead to excess of 125 psi at 120°F (0.86 MPa @ 49°C)

catastrophic mechanical failure of the heads. DO NOT… overtighten the connection to the EXTERIOR FINISH

permeate port (hand-tighten plus one-quarter Standard – White high-gloss RAL 9003 polyurethane coating over sanded surface.

Pentair will assist the purchaser in determining the turn, check for leaks) Optional – Grey high-gloss RAL 7011 polyurethane coating over sanded surface.

suitability of this standard vessel for their specific DO NOT… tolerate leaks or allow end closures to Serial number Opposite

operating conditions. The final determination however, be routinely wetted in any way End End PERMEATE PORT CONFIGURATION

including evaluation of the standard material of DO NOT… pressurize vessel until double-checking Standard – ½’’ NPT Female (Standard per drawing)

construction for compatibility with the specific corrosive to verify that the retaining ring is completely Optional - ½’’ BSPT/JISPT Female

environment, shall be the responsibility of the purchaser. inside the groove

Alternate materials with enhanced corrosion resistance DO NOT… operate outside the pH range 3-11 FEED PORT CONFIGURATION

are available on special order. Standard – ¾” NPT Female (Standard per drawing)

Optional – ¾’’ BSPT/JISPT Female

Specifications are subject to change without notice. Optional – ½’’ NPT Female

CAUTION: END PLUG MATERIALS

EYE PROTECTION SHOULD BE WORN WHEN Standard – Noryl ¾’’ NPT Female FC port & ½” NPT Female Permport connection (P/N 96288)

REMOVING OR INSTALLING RETAINING RINGS. Optional - PVC ½” NPT Female FC port & ½” NPT Female Permport connection (P/N 97592)

NOTE KEEP FINGERS CLEAR FROM RETAINING RING

Spiral Retaining Ring Removal Tool (50303) WHILE INSTALLING LAST OF TWO TURNS. RING

Recommended to open and close vessel. NOTE:- PVC end plug only with ½” NPT FC port.

MAY SNAP INTO POSITION POSSIBLY PINCHING

FINGERS.

For complete information on proper use of the vessel

Please refer to 40L30N USER’S GUIDE - 95207

DWG. NO. 99373-F. © PENTAIR PAGE 2 OF 2.

You might also like

- C3530 - C3525 - C3520 Series - Partscatalog - E - EURDocument144 pagesC3530 - C3525 - C3520 Series - Partscatalog - E - EURMario PađanNo ratings yet

- Internship Report On Compensation and Benefits Package of ACIDocument135 pagesInternship Report On Compensation and Benefits Package of ACIRajoshree Moni33% (3)

- One Steel ReoDataDocument40 pagesOne Steel ReoDatapete0980100% (1)

- Codeline Drawing 80S45Document3 pagesCodeline Drawing 80S45betow_No ratings yet

- Pressure Vessel-80S100Document2 pagesPressure Vessel-80S100IbrahimNo ratings yet

- Codeline Drawing 80S45 PDFDocument3 pagesCodeline Drawing 80S45 PDFHardik VavdiyaNo ratings yet

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFDocument2 pagesCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaNo ratings yet

- Codeline Drawing 80S30Document3 pagesCodeline Drawing 80S30Hardik VavdiyaNo ratings yet

- Codeline Drawing 40E100Document2 pagesCodeline Drawing 40E100Hoàng Anh Tuấn NguyễnNo ratings yet

- Drawing Codeline-80S30 PDFDocument3 pagesDrawing Codeline-80S30 PDFjohandi johandiNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dillip DasNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- Codeline 80S120Document3 pagesCodeline 80S120gulfengsolutionsNo ratings yet

- Appendix E - Drawings & Data SheetDocument21 pagesAppendix E - Drawings & Data SheetsajanchaudhariNo ratings yet

- Codeline Drawing 40S30 Non CodedDocument2 pagesCodeline Drawing 40S30 Non CodedHardik VavdiyaNo ratings yet

- Codeline Drawing 80S15Document3 pagesCodeline Drawing 80S15jugal ranaNo ratings yet

- Codeline Drawing 80E45Document2 pagesCodeline Drawing 80E45Deblina MukherjeeNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- VB 536 Ag DR: TypeDocument1 pageVB 536 Ag DR: TypeMaffone NumerounoNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30Aravind RaoNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- D-57Document2 pagesD-57Cristian CalleNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- 3M Spacing GuideDocument2 pages3M Spacing Guideadam.l.whippleNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- APA+PR L331C+Nordic+X Lam+Industrial+CLT+MattingDocument6 pagesAPA+PR L331C+Nordic+X Lam+Industrial+CLT+MattingandreskargNo ratings yet

- Splinker TycoDocument4 pagesSplinker Tycoref.mtu.533No ratings yet

- D1836 Series (Nas1836)Document1 pageD1836 Series (Nas1836)blackhawkNo ratings yet

- 147-168 62gb Series 62GB-57A14-15SNDocument22 pages147-168 62gb Series 62GB-57A14-15SNwiradesNo ratings yet

- Brocure FDB 407 40 - 150Document1 pageBrocure FDB 407 40 - 150mandahandriNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Package Information Including Surface Mount: Fast and Ls TTLDocument14 pagesPackage Information Including Surface Mount: Fast and Ls TTLMilka RamirezNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- Pressure Drop Calculation For Fan (Exf-Bsc-01)Document8 pagesPressure Drop Calculation For Fan (Exf-Bsc-01)ibnrafeeqNo ratings yet

- KF Series Ball Valve PDFDocument20 pagesKF Series Ball Valve PDFbloggerparthiNo ratings yet

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- High Static Ducted Technical Manual 2016-Rev.4Document149 pagesHigh Static Ducted Technical Manual 2016-Rev.4soqhNo ratings yet

- Rapid Allweiler Data BookDocument6 pagesRapid Allweiler Data BookJoNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- Valvulas de RegulacionDocument71 pagesValvulas de RegulaciondanielNo ratings yet

- MSA Ball Valves PDFDocument20 pagesMSA Ball Valves PDFAli FardidNo ratings yet

- MSA Ball Valves enDocument20 pagesMSA Ball Valves enBiswajit DeyNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument17 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Type 656 Diaphragm ActuatorDocument4 pagesType 656 Diaphragm Actuatorapi-37549310% (1)

- VB 537 Ag BR: FiguraDocument1 pageVB 537 Ag BR: FiguraMaffone NumerounoNo ratings yet

- Description: Terminals ChartDocument1 pageDescription: Terminals Chartdip461No ratings yet

- Ducted Blower Split Systems: Models: MDB 200 - 750 B MDB 075 - 500 DDocument155 pagesDucted Blower Split Systems: Models: MDB 200 - 750 B MDB 075 - 500 DNisar AhmedNo ratings yet

- NTC55 Product Guide Imperial PDFDocument44 pagesNTC55 Product Guide Imperial PDFnelson_casallas_3No ratings yet

- RFG50N06, RFP50N06, RF1S50N06SM: 50A, 60V, 0.022 Ohm, N-Channel Power Mosfets FeaturesDocument8 pagesRFG50N06, RFP50N06, RF1S50N06SM: 50A, 60V, 0.022 Ohm, N-Channel Power Mosfets FeaturesRoberto DiazNo ratings yet

- Piping Class Spec. - 1c23pe (Lurgi)Document5 pagesPiping Class Spec. - 1c23pe (Lurgi)otezgidenNo ratings yet

- Rhino Valves CatalogueDocument174 pagesRhino Valves CatalogueLizaDuPlessisNo ratings yet

- Section 2 Hydraulic/Mechanical Systems: To CoverDocument12 pagesSection 2 Hydraulic/Mechanical Systems: To CoverAlvaro Restrepo GarciaNo ratings yet

- Empaquetaduras Bombas Triplex.Document40 pagesEmpaquetaduras Bombas Triplex.pabloasotoNo ratings yet

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya Jain100% (1)

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSNo ratings yet

- PICOD - 131 - AK DatasheetDocument2 pagesPICOD - 131 - AK DatasheetWarr SteelNo ratings yet

- Power Amplifiers: Models HTA125A and HTA250ADocument2 pagesPower Amplifiers: Models HTA125A and HTA250AArmando Corral BlancoNo ratings yet

- Datasheet Codeline Ecoline 40L30NDocument2 pagesDatasheet Codeline Ecoline 40L30NArmando Corral BlancoNo ratings yet

- 100 HPDocument1 page100 HPArmando Corral BlancoNo ratings yet

- Ac Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Document2 pagesAc Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Armando Corral BlancoNo ratings yet

- Minitherm Bulletin 6.16Document2 pagesMinitherm Bulletin 6.16Armando Corral BlancoNo ratings yet

- The Metallurgy of Power BoilersDocument4 pagesThe Metallurgy of Power Boilersagniva dattaNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Switchgear Vs SwitchboardDocument20 pagesSwitchgear Vs SwitchboardJuan MoralesNo ratings yet

- MiningGuideFinalVersion 141218Document23 pagesMiningGuideFinalVersion 141218BudKh100% (2)

- 206-00 General InfoDocument16 pages206-00 General InfoMiguel AngelNo ratings yet

- CFM Equipped Fleet AtlanticDocument34 pagesCFM Equipped Fleet AtlanticJohn KevinNo ratings yet

- 1394 SERCOS Interface Multi-Axis Motion Control System: (Catalog Numbers 1394C-SJT05-D, 1394C-SJT10-D, 1394C-SJT22-D)Document87 pages1394 SERCOS Interface Multi-Axis Motion Control System: (Catalog Numbers 1394C-SJT05-D, 1394C-SJT10-D, 1394C-SJT22-D)angelpadronaNo ratings yet

- OS Switch Fuses ABBDocument32 pagesOS Switch Fuses ABBTrường NguyenNo ratings yet

- Insulation Jacket BrochureDocument6 pagesInsulation Jacket BrochureLeDzungNo ratings yet

- PT2313L PDFDocument3 pagesPT2313L PDFMaugrys Castillo100% (1)

- Lab 1Document10 pagesLab 1DaniNo ratings yet

- 4 - Mike ShandDocument6 pages4 - Mike ShandPieter Vd MerweNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalDocument3 pagesSaudi Aramco Typical Inspection Plan: Fired Heaters - Field Installation MechanicalOmer aliNo ratings yet

- 2010 Oregon Mechanical Specialty Code IxDocument4 pages2010 Oregon Mechanical Specialty Code IxbooboosdadNo ratings yet

- Ds Erhard Roco WaveDocument27 pagesDs Erhard Roco Wavekad-7No ratings yet

- CDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionDocument24 pagesCDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionBeroxi MihaiNo ratings yet

- SLB - Expandable Steel PatchDocument12 pagesSLB - Expandable Steel PatchMike du PlessisNo ratings yet

- Azimuth Co OrdinatorDocument2 pagesAzimuth Co OrdinatorGlen DonnellyNo ratings yet

- IBM Knowledge Center - SWIFT Message Block StructureDocument5 pagesIBM Knowledge Center - SWIFT Message Block StructureaNo ratings yet

- Car Body ConstructionDocument30 pagesCar Body ConstructionPethurajNo ratings yet

- Computer Network Individual ReportDocument2 pagesComputer Network Individual ReportWilson ChengNo ratings yet

- Time Management 101: Sreeram Kishore Chavali 14-November-2001Document25 pagesTime Management 101: Sreeram Kishore Chavali 14-November-2001manojmis2010No ratings yet

- Landed Cost ManagementDocument162 pagesLanded Cost Managementdsgandhi6006No ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- Swot of EmsDocument2 pagesSwot of EmsWaleed MorsyNo ratings yet

- M.Phil Syllabus - Bharathiyar UniversityDocument10 pagesM.Phil Syllabus - Bharathiyar UniversityArulsamy DanielNo ratings yet

- Aquasystem Aerator Karistirici Brosur PDFDocument8 pagesAquasystem Aerator Karistirici Brosur PDFMariusCapraNo ratings yet

- Generalscan R1000BT Specification enDocument2 pagesGeneralscan R1000BT Specification enAlejandro BacaNo ratings yet