Professional Documents

Culture Documents

Certificate: TUV Approved

Certificate: TUV Approved

Uploaded by

Siwat KiokaewOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate: TUV Approved

Certificate: TUV Approved

Uploaded by

Siwat KiokaewCopyright:

Available Formats

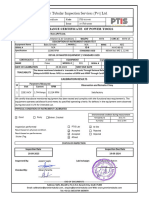

CERTIFICATE

TUV Approved

Certificate number: 0000039773_06

Manufacturer: Pollution s.r.l., 40054 Budrio, Italy

Product: Portable AMS Polaris FID and Polaris FID SE

Component: Total Organic Carbon (TOC)

Measuring ranges: 0 – 15 mg/m³ / 0 – 500 mg/m³

Test Report: 936/21217069 dated 29 July 2013

Valid until: 2023-09-03

The measuring equipment was suitability tested and certified

in accordance with the "TUV Approved" Guidelines of the TÜV Rheinland Group

based on technical requirements of EN 12619:1999 and EN 13526:2002.

Polaris FID was tested according to MCERTS performance standard

for portable Emission monitoring systems Version 3.1:2010

Tested AMS

Regular

Surveillance

www.tuv.com

ID 0000039773

Köln, 2019-03-01

Dipl.-Ing. Guido Baum Dipl.-Ing. Carsten Röllig

www.umwelt-tuv.de / www.enviro-tuv.com TÜV Rheinland Energy GmbH

TRE@umwelt-tuv.de Am Grauen Stein

Tel. +49 - 221 - 806 - 5200 51105 Köln

Test institute accredited to EN ISO/IEC 17025:2005 by DAkkS (German Accreditation Body).

This accreditation is limited to the accreditation scope defined in the enclosure to the certificate D-PL-11120-02-00.

TRE-ID : 3172205_001 0000039773_06 page 1 of 3

Overview:

The performance test of the Polaris FID measuring system for the component Total organic

carbon was performed in accordance with the guidelines for continuous emission monitoring

and the MCERTS Performance Standard for Portable Emission Monitoring Systems, Version

3.1. Since the MCERTS standard does not include any special requirements for FIDs, the

standards EN 12619:1999 and EN 13526:2002 which are specific for FIDS, were taken into

account (where this was deemed reasonable regarding portable instruments). The test was

carried out for the following components and ranges:

Component Certification range Supplementary range Unit

Total organic carbon 0 - 15 0 - 500 mg/m³

In conformity with the applicable standards, the following performance criteria were tested in

the laboratory:

Check of general requirements according to 5.1 of MCERTS Performance Std. for

Portable Emission Monitoring Systems Version 3.1,

Determination of warm-up time,

Determination of response time,

Repeatability at zero and at span point,

Lack-of-fit,

Influence of ambient temperature,

Influence of voltage variation (additionally),

Cross-sensitivity, incl. influence of oxygen,

Short-term drift (1 hour) at zero and at span point,

Degrees of protection provided by enclosures,

Check of test gas mixture according to EN 12619:1999,

Determination of response factors according to EN 12619:1999 and EN 13526:2002.

Based on the results of the lab test the total expanded uncertainty for the measuring of TOC

was calculated (with and without influence of response factor determination results).

A field test was carried out over a period of three days in the exhaust gas of a plant for syn-

thetic resin, with two complete and identical measuring systems of the type Polaris FID. With-

in the field test the following criterions have been tested:

Calibration ability according to EN 14181,

Determination of response time,

Lack-of-fit.

Minimum requirements of MCERTS Performance Standard for Portable Emission Monitoring

Systems, Version 3.1 have been fulfilled during performance testing. When determining the

response factors, all data lay within the specific ranges, except for dichloromethane. The

manufacturing process of the Polaris FID of Pollution s.r.l. is controlled within the auditing

procedure of the MCERTS Performance Standard for Portable Emission Monitoring Sys-

tems, Version 3.1. Feb. 2010 which is equal to EN 15267-2: 2009. The initial audit for the

certification was performed in July 2013. Validity of the certificate is linked to an annual sur-

veillance audit at the manufacturing site of Pollution s.r.l.

TRE-ID : 3172205_001 0000039773_06 page 2 of 3

Field of Application

The portable AMS Polaris FID can be used for measurements at combustion plants accord-

ing to EN 12619:1999 and at plants according to EN 13526:2002 taking into account the

specific findings and conditions documented inside the relevant test report 936/21217069

dated 29 July 2013.

Description of the AMS tested:

The instrument is designed to be resistant to samples with high temperature and humidity:

this is a typical working condition with hot samples during stack monitoring. The detector

manifold, the sampling lines and all the valves are integrated into a single block and uniform-

ly heated, in order to eliminate all possible cold spots and avoid local sample condensation.

The compact hydrogen storage cartridge (with an innovative metal-hydride technology) is in-

tegrated into the instrument and self-desorbs the hydrogen fuel to the flame detector at ap-

propriate pressure and flow.

The instrument incorporates everything needed for analysis: batteries, hydrogen storage ac-

cumulator, pump and activated charcoal filter for the flame air, span gas cylinder for the cali-

bration and technical air cylinder for high accuracy and precision. The instrument has a dis-

play and several buttons to control the unit and read the measured values and instrument

status.

The integrated microprocessor automatically controls several parameters: ignition and flame

monitoring, setup of parameters chosen by the user according to the analytical method, di-

agnostic checks, life monitoring of the gas cans and energy reserves, sampling lines, clean-

ing cycles and calibration procedures.

Special features:

The Polaris FID does not use an in-line pump; rather it operates by dosing the quantity of the

sample by sequential volume pumping at constant pressure with accurately adjusted tem-

perature values. This allows strictly repeatable samples regardless of the pressure at the

sampling point or the kinematic viscosity of the sample and external temperature.

The system operates in cycles, moving constant volumes at constant intervals so as to simu-

late low frequency pumping, thereby creating a heated head system with no membrane in

contact with the fluid being analysed. Delivery compression to the detector is realized with

zero grade air, which therefore acts as the sample carrier. This allows for continual auto-

zeroing of the analyser. A suction pump continuously takes up a significant flow of sample in

order to continually call up a new sample in the appliance and reduce response times.

The tested AMS consists of the following parts:

- Analyser module Polaris FID

- Sampling system: Sampling probe PF 18025 – 03 probe with heated filter and 2 m

heated (100 °C), PTFE Sampling line (6 mm).

The heated line and filter do not operate with batteries. A constant power supply is needed in

order to work with the heated line and filter.

TRE-ID : 3172205_001 0000039773_06 page 3 of 3

You might also like

- Principles of Communications 7th Edition Ziemer Solutions ManualDocument25 pagesPrinciples of Communications 7th Edition Ziemer Solutions ManualVanessaGriffinmrik85% (47)

- ME 1a - TOPIC 2 First Law of ThermodynamicsDocument10 pagesME 1a - TOPIC 2 First Law of Thermodynamicsjohn reyche garsuta100% (3)

- GMW 15634Document20 pagesGMW 15634Carlos Andrés Quevedo Fernández100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- FM CODEL GCEM40xx Ap12 PDFDocument6 pagesFM CODEL GCEM40xx Ap12 PDFCandi.nntppNo ratings yet

- D 5149 - 02 - Ozone in AtmosphereDocument5 pagesD 5149 - 02 - Ozone in AtmosphereAny DBs'uNoNo ratings yet

- Worldwide Engineering Standards: Procedures For High Humidity TestDocument3 pagesWorldwide Engineering Standards: Procedures For High Humidity TestAkmal NizametdinovNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Carbon Monoxide in The Atmosphere (Continuous Measurement by Nondispersive Infrared Spectrometry)Document6 pagesCarbon Monoxide in The Atmosphere (Continuous Measurement by Nondispersive Infrared Spectrometry)Any DBs'uNoNo ratings yet

- 34 Samss 514Document10 pages34 Samss 514naruto256100% (1)

- 4 - Report On Gas Analysis in Cement Plant PDFDocument77 pages4 - Report On Gas Analysis in Cement Plant PDFTin Nguyen0% (1)

- Astm D4239 18Document6 pagesAstm D4239 18سامح الانصارىNo ratings yet

- ESM Andersen BrochureDocument12 pagesESM Andersen BrochureGezgin BiriNo ratings yet

- TetraInc Product 387 1Document4 pagesTetraInc Product 387 1Ana RafaelNo ratings yet

- EPA Ireland Air Monitoring Guidance Note AG2 PDFDocument97 pagesEPA Ireland Air Monitoring Guidance Note AG2 PDFHelder DuraoNo ratings yet

- JFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91Document10 pagesJFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91am4rNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- Environmental Product Declaration: Registration Number in The International EPD System: S-P-00965Document16 pagesEnvironmental Product Declaration: Registration Number in The International EPD System: S-P-00965daniel vargasNo ratings yet

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Cert Ultramat6 GB Metrol Sira Mcerts Mc040034 07Document8 pagesCert Ultramat6 GB Metrol Sira Mcerts Mc040034 07Nicolae VisanNo ratings yet

- 01 Siemens LDS6 NH3 enDocument9 pages01 Siemens LDS6 NH3 enNicolae VisanNo ratings yet

- Determination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsDocument19 pagesDetermination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsJefferson CruzNo ratings yet

- Annex 2 Qualification of GC EquipmentDocument11 pagesAnnex 2 Qualification of GC EquipmentBrian Williams100% (1)

- Gcem 40eDocument6 pagesGcem 40eBình ĐặngNo ratings yet

- CMM AutoQAL QAL1 TUVDocument6 pagesCMM AutoQAL QAL1 TUVMuhamad JemadiNo ratings yet

- Abb El 3060Document20 pagesAbb El 3060రామకృష్ణ పాశలNo ratings yet

- 01 Siemens LDS6 HCL enDocument9 pages01 Siemens LDS6 HCL enNicolae VisanNo ratings yet

- Model 112 VOC or EC Analyzers 4 PG 807 3 GasDocument4 pagesModel 112 VOC or EC Analyzers 4 PG 807 3 GasDr. John " Jack" driscollNo ratings yet

- Online Dga PDFDocument8 pagesOnline Dga PDFromaoj671No ratings yet

- 11M013R0 PCDocument29 pages11M013R0 PCdaveleyconsNo ratings yet

- Materi Webinar CompressedAirQualificationforPharmaceuticalIndustry ArjunaSolusiSejahteraDocument43 pagesMateri Webinar CompressedAirQualificationforPharmaceuticalIndustry ArjunaSolusiSejahteraDavid Alberto ChristianNo ratings yet

- Sensor 08Document293 pagesSensor 08mmkattaNo ratings yet

- Astm D5191 22Document5 pagesAstm D5191 22vituruchNo ratings yet

- Flir Gas Detection GuidebookDocument40 pagesFlir Gas Detection Guidebookkcharles2003No ratings yet

- ISO3675Document14 pagesISO3675thanhhuyen100% (1)

- Environmental Product Declaration: Frescasa EcoDocument17 pagesEnvironmental Product Declaration: Frescasa EcoJairo EstebanNo ratings yet

- Medi-Gas Check Full Range CatalogueDocument20 pagesMedi-Gas Check Full Range CatalogueShamshad HussainNo ratings yet

- 02 Durag DR290 enDocument11 pages02 Durag DR290 ensyahrial ramadhanNo ratings yet

- PV 1303Document10 pagesPV 1303tufantasma100% (2)

- 34-SAMSS-514 - Dec. 26. 2013Document10 pages34-SAMSS-514 - Dec. 26. 2013LainhatanhNo ratings yet

- DatasheetDocument16 pagesDatasheetmarcosNo ratings yet

- AHU 2 Performance QualificationDocument5 pagesAHU 2 Performance Qualificationpravingaikwad100% (2)

- Cert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Document9 pagesCert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Nicolae VisanNo ratings yet

- Gigasft IrDocument8 pagesGigasft IrCesar BerruecoNo ratings yet

- Environmental Product Declaration: Frescasa EcoDocument16 pagesEnvironmental Product Declaration: Frescasa EcoMiguel Angel Huamaní VenturaNo ratings yet

- Solar PV Product and Ammonia Testing StandardsDocument3 pagesSolar PV Product and Ammonia Testing StandardsSylwia WojdanNo ratings yet

- Cone Calorimeter: (ISO 5660 ASTM E 1354) The Most Comprehensive Bench Scale Fire TestDocument12 pagesCone Calorimeter: (ISO 5660 ASTM E 1354) The Most Comprehensive Bench Scale Fire TestGaurav KumarNo ratings yet

- Air Pointer 12pg BrochureDocument12 pagesAir Pointer 12pg BrochurechandakberaNo ratings yet

- 850-811250-En-R05 Operating Manual GD10P English Single Pages PDFDocument32 pages850-811250-En-R05 Operating Manual GD10P English Single Pages PDFsureshthuppallamNo ratings yet

- Iso 3675 1998Document9 pagesIso 3675 1998hossam alebrahimNo ratings yet

- Certificate: of Product Conformity (QAL1)Document7 pagesCertificate: of Product Conformity (QAL1)syahrial ramadhanNo ratings yet

- Eurofid Extractive AnalyzerDocument8 pagesEurofid Extractive AnalyzerCristian FernandezNo ratings yet

- Zirconia SensorDocument28 pagesZirconia Sensordeepak2003No ratings yet

- IMR 7500 - Continuous Emission Monitoring System (CEM) PDFDocument4 pagesIMR 7500 - Continuous Emission Monitoring System (CEM) PDFdejavu77No ratings yet

- Multi-Component FTIR Emission Monitoring System: Abb Measurement & Analytics - Data SheetDocument16 pagesMulti-Component FTIR Emission Monitoring System: Abb Measurement & Analytics - Data SheetRonaldo JuniorNo ratings yet

- Portable Gas Chromatographs From PID Analyzers, LLC 111515Document5 pagesPortable Gas Chromatographs From PID Analyzers, LLC 111515Dr. John " Jack" driscollNo ratings yet

- D 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Document21 pagesD 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Ruben Perez Ayo100% (1)

- Model SADP: Instruction ManualDocument24 pagesModel SADP: Instruction ManualMiguelNo ratings yet

- Reliability Investigation of LED Devices for Public Light ApplicationsFrom EverandReliability Investigation of LED Devices for Public Light ApplicationsNo ratings yet

- Faber PortlandDocument12 pagesFaber PortlandSiwat KiokaewNo ratings yet

- C S C S C S C S A Case Study A Case Study A Case Study A Case StudyDocument33 pagesC S C S C S C S A Case Study A Case Study A Case Study A Case StudySiwat KiokaewNo ratings yet

- KLAX Los Angeles Intl: Airport Navaids Runway SID Star Procedures Minima OthersDocument59 pagesKLAX Los Angeles Intl: Airport Navaids Runway SID Star Procedures Minima OthersSiwat KiokaewNo ratings yet

- Brochure Movialsa Gasification Plant EnglishDocument6 pagesBrochure Movialsa Gasification Plant EnglishSiwat Kiokaew100% (1)

- L Tj'U R Eh'U18F1111 F/11Lj 'Ua/I /1Lb1/1L BL.J Ll'1 Ffuu"'U'U V!°L1/L Ej U Bi 1N ( ) BLJ 1Tj'WDocument7 pagesL Tj'U R Eh'U18F1111 F/11Lj 'Ua/I /1Lb1/1L BL.J Ll'1 Ffuu"'U'U V!°L1/L Ej U Bi 1N ( ) BLJ 1Tj'WSiwat KiokaewNo ratings yet

- The 1st Aviation National SymposiumDocument8 pagesThe 1st Aviation National SymposiumSiwat KiokaewNo ratings yet

- 2007 02 12 GTZ - Sector Project Mechanical Biological Waste TreatmentDocument87 pages2007 02 12 GTZ - Sector Project Mechanical Biological Waste TreatmentSiwat KiokaewNo ratings yet

- Tcas FSFDocument48 pagesTcas FSFSiwat KiokaewNo ratings yet

- Airboard - Spec and InfoDocument11 pagesAirboard - Spec and InfoSiwat KiokaewNo ratings yet

- Certificate of Calibration and Conformance: OmicronDocument1 pageCertificate of Calibration and Conformance: OmicronNadiaNo ratings yet

- IEC 60909 and ANSI Standards Comparison With ASCC Based Fault Calculations of Iraqi Power SystemDocument18 pagesIEC 60909 and ANSI Standards Comparison With ASCC Based Fault Calculations of Iraqi Power SystemIBA PUNo ratings yet

- Module 4 MemDocument18 pagesModule 4 MemHarshitha CNo ratings yet

- Giai Tich He Thong Dien - Nguyen Van Liem - Psa - Chapter 1 - IntroductionDocument38 pagesGiai Tich He Thong Dien - Nguyen Van Liem - Psa - Chapter 1 - IntroductionHuỳnh RoYalNo ratings yet

- Exercise 4.7: CH 4 SupplementalDocument12 pagesExercise 4.7: CH 4 SupplementalAngelica Diolata100% (1)

- James Ruse 2020 Physics Prelim Yearly & SolutionsDocument48 pagesJames Ruse 2020 Physics Prelim Yearly & Solutionsfortnitegamerpro123451No ratings yet

- U1 NotesDocument21 pagesU1 NotesSnigdha SVNo ratings yet

- Hasan Sayginel: Edexcel IAL Physics Unit 6Document55 pagesHasan Sayginel: Edexcel IAL Physics Unit 6Thangavel SarujanNo ratings yet

- Material and Energy Balances IIDocument15 pagesMaterial and Energy Balances IIOlumomi ElizabethNo ratings yet

- DV/DT Filter: User ManualDocument37 pagesDV/DT Filter: User ManualAhmadNo ratings yet

- L-2 Single and Composite Heat TransferDocument44 pagesL-2 Single and Composite Heat Transfer271758 ktr.chem.18No ratings yet

- REFRESHER (Differential-and-Integral-Calculus-with-answer)Document3 pagesREFRESHER (Differential-and-Integral-Calculus-with-answer)sadonNo ratings yet

- Xi Physics HHW 2023-24Document5 pagesXi Physics HHW 2023-24Nunu puNo ratings yet

- 6974-15 Baby GrinderDocument1 page6974-15 Baby Grinderabdulhanansamo65No ratings yet

- Is.10278.2009 Two Wheeler Max. SpeedDocument11 pagesIs.10278.2009 Two Wheeler Max. SpeedGurkaranNo ratings yet

- Net Force and Acceleration Practice WorksheetDocument2 pagesNet Force and Acceleration Practice WorksheetZyryl Zane100% (2)

- 3UG46251CW30 Datasheet enDocument5 pages3UG46251CW30 Datasheet enDante AlvesNo ratings yet

- 〈645〉 WATER CONDUCTIVITYDocument4 pages〈645〉 WATER CONDUCTIVITYliêmNo ratings yet

- See A3964SLB: Dual Full-Bridge PWM Motor DriverDocument8 pagesSee A3964SLB: Dual Full-Bridge PWM Motor DriverPaulo SwarosvishNo ratings yet

- 11th DPP 1D Kinematic-1Document5 pages11th DPP 1D Kinematic-1SaήjaγKsNo ratings yet

- Enthalpy: H U PV H U+PV TP UDocument3 pagesEnthalpy: H U PV H U+PV TP UAnshul TeotiaNo ratings yet

- AC CircuitDocument210 pagesAC CircuitRagilNo ratings yet

- Wind Turbine L9+L10 RevisedDocument111 pagesWind Turbine L9+L10 RevisedMohammed Al-OdatNo ratings yet

- New Trends in Icse Physics 7 1Document24 pagesNew Trends in Icse Physics 7 1Unique ArtNo ratings yet

- Listino Elitalia 2021 PASCODocument31 pagesListino Elitalia 2021 PASCORachele DaniNo ratings yet

- AdjustmentDocument24 pagesAdjustmentIzzeldin ZakiNo ratings yet

- List of All Physics Formulas of Inter 1st YearDocument6 pagesList of All Physics Formulas of Inter 1st YearnischayboyaNo ratings yet

- Powertech 9.0L Engine Engine Performance Curve: 60 HZ - 298Hp (222Kw) at 1800 RPMDocument4 pagesPowertech 9.0L Engine Engine Performance Curve: 60 HZ - 298Hp (222Kw) at 1800 RPMkman548No ratings yet