Professional Documents

Culture Documents

Workshop Understanding The Distribution Center Layout Lliana Solarte

Workshop Understanding The Distribution Center Layout Lliana Solarte

Uploaded by

Alexis SalazarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop Understanding The Distribution Center Layout Lliana Solarte

Workshop Understanding The Distribution Center Layout Lliana Solarte

Uploaded by

Alexis SalazarCopyright:

Available Formats

Workshop: Understanding the distribution center layout

Aprendices

Jhonathan Fernando Vanegas

Edisson Alexis Salazar Beltran

Sena 2021

Instructora

Liliana Solarte

Workshop: Understanding the distribution center layout

Your warehouse or distribution center layout greatly affects the performance of

your business. In fact, without a properly configured warehouse layout, you

could face capacity issues and

even a decrease in productivity. Complete the following activities in order to

understand the importance of the layout when designing a Distribution Center or

warehouse.

1. Getting familiar with Distribution Centers

Read and match. Read the definition for each of the areas that a distribution

center may include and match the definition with the name of such area.

1. Supply chain (B) A. That is where the commodity or product is stored in the

cellar until the supplier requires.

2. Inventory ( G) B. It is a network of facilities and distribution means whose

function is to obtain materials, processing of these

materials into intermediate and finished products and

distribution of these finished products to consumers.

3. Wholesaler ( E) C. It is the area that supports and guides in case of loss or

damage to the product.

4. Storage ( A) D. This is the place where the goods are stored prior to

use, distribution or sale.

5. Loss and damage E. Someone who is dedicated to buy and sell wholesale

claim support ( C) products.

6. Network (H) F. Transportation or shipping, storage and related

logistics, which are provided by companies employed to

undertake tasks that were previously performed by the

customer services.

7. Shipping ( F) G. It is the list of goods, products and other valuables

things that belong to a company

8. Warehouse ( D) H. An interconnected group or system.

2. Describing a Distribution Center

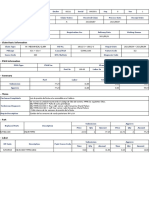

Following, you’ll see the very basic design of any Distribution Center. Check the

image and answer the questions:

1. Make sure you have enough pallets to store all your goods

_____on_______ them.

in / on / at

2. There should be enough space for your equipment or machinery to move

through the warehouse. by / near / through

3. The machinery or equipment station must be far the shipping and

receiving area in order to load and unload freight trucks. far / below

/ close to

4. The offices must be located_ in front of the warehouse racking for you

to supervise the activity within the warehouse. in front of / under /

above

3. Write sentences to describe the next distribution center. Do not forget to

use prepositions to describe their location. Check the example:

Let’s check another example of a distribution center. Pay attention to the

different areas within this distribution center and answer the questions below:

Where is the…? Answer

Where is the Loading area? The loading area is next to the

freezer.

Where is the Value-Added services area?

The Value Added services area is just

behind refrigerated sproducts

Where is the Reverse Logistics area?

The reverse logistics area is ahead of

put-to-store

Where is the Quality auditing area?

stands on the shelf in front of the

batch selection

Where are the trucks? the trucks are in the area of yard

management

1. Critical thinking – Making decisions

Pros and Cons. Read the following statements about Distribution Center Design

and decide in your agree or disagree with the statement. Do some research on

the topic and provide pros and cons for each statement. Dar su opinión (está de

acuerdo o en desacuerdo) y dar pros y contras de los enunciados propuestos.

Your opinion:

I disagree. I think Distribution Centers must

have a specific design that helps the regular

non-changing flow of goods.

Example: PROS:

The layout in your warehouse must -With flexible Distribution Centers you

be flexible can ensure your facilities are ready for

anything that comes in the future.

CONS:

-Flexible Distribution Centers tends to be more

disorganized. It is hard to keep control of the

changes.

1. Cram as many pallet racks into your Your opinion: Your opinion: there are areas

warehouse as possible

that do not have a good space for their

work

PROS: we have to have more capacity to store

merchandise

CONS: the other areas are reduced can affect

the supply chain and logistics

2. Have an aisle map

Your opinion: I agree, with a distribution center

map you can contribute in the order and best

location of the aisles for the storage of

merchandise

PROS: more orderly location for employees by

streamlining the marking readiness process

CONS: In case of making a poorly prepared

map, it can generate reprocessing and

uncoordination in the plant

3. Rely only on manual processes and Your opinion:

manual labor to get product in and through

the center and the customer orders out the No estoy de acuerdo, esto debe ser

door.

sistematizado, esto agiliza los procesos en

cuanto a recepción y envío

PROS:

You can have an agile process and surely that

would help us with the operational issue

CONS:

it may generate more delay in the processes,

there may be a serious logistical error

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FLIPKART MayankDocument65 pagesFLIPKART MayankNeeraj DwivediNo ratings yet

- Study of Home Services Platform-Urban CompanyDocument15 pagesStudy of Home Services Platform-Urban CompanyKHALKAR SWAPNILNo ratings yet

- The Nespresso Case: Value Articulation - A Framework For The Strategic Management of Intellectual PropertyDocument6 pagesThe Nespresso Case: Value Articulation - A Framework For The Strategic Management of Intellectual PropertyAna SiqueiraNo ratings yet

- Labstat Updates Vol12 4Document5 pagesLabstat Updates Vol12 4Dionne Carlo CamosaNo ratings yet

- Class 12 Eco Unit Test 2 2021-22Document13 pagesClass 12 Eco Unit Test 2 2021-22Ayush MishraNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLeonardo Albinagorta ParedesNo ratings yet

- PDF Mba 4th Sem Research Report PDFDocument78 pagesPDF Mba 4th Sem Research Report PDFSHREYA BBDUNo ratings yet

- Foundations in TurkeyDocument25 pagesFoundations in TurkeyOlcay Sanem SipahioğluNo ratings yet

- A Disaster Recovery Plan PDFDocument12 pagesA Disaster Recovery Plan PDFtekebaNo ratings yet

- Course 1: Global Financial Markets and AssetsDocument31 pagesCourse 1: Global Financial Markets and AssetsDhriti MalhotraNo ratings yet

- Statement XXXX XXXX 8218 16mar2024!11!51Document10 pagesStatement XXXX XXXX 8218 16mar2024!11!51daimimahesan65No ratings yet

- India Employment InstructionsDocument78 pagesIndia Employment InstructionsSatyapavankumar KatipomuNo ratings yet

- Free Version-UpdatedDocument16 pagesFree Version-Updatedyasmin.ojsNo ratings yet

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 22470 Flyer - Half Day Course On 22 MarchDocument2 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 22470 Flyer - Half Day Course On 22 MarchInstech Premier Sdn BhdNo ratings yet

- A2Z E-Commerce Website BRD: Bolt SolutionDocument54 pagesA2Z E-Commerce Website BRD: Bolt Solutionaspany loisNo ratings yet

- End Term Examination - EMBA Spring 2020Document3 pagesEnd Term Examination - EMBA Spring 2020yopNo ratings yet

- Eradicating Hardcore Povertyvia Zakat Distribution: A Case Studyamong Poorand Needy Asnafs in Sik, KedahDocument23 pagesEradicating Hardcore Povertyvia Zakat Distribution: A Case Studyamong Poorand Needy Asnafs in Sik, KedahIJAR JOURNALNo ratings yet

- Rasi ChartDocument2 pagesRasi ChartTeja Konduri100% (2)

- OJT Workbook - Week 1Document23 pagesOJT Workbook - Week 1AdityaKumarNo ratings yet

- Flexible WorkDocument29 pagesFlexible WorkWiji Lestari100% (1)

- WLP - Math2 Q1 W5 1 4Document10 pagesWLP - Math2 Q1 W5 1 4Vhince PiscoNo ratings yet

- SM ASSIGNMENT - M&M CaseDocument4 pagesSM ASSIGNMENT - M&M CaseAbhi AgarwalNo ratings yet

- The CHIBI AdventureDocument19 pagesThe CHIBI AdventureEmre UgurNo ratings yet

- OPP-20-6500125 Microtec Biocon Rev0Document18 pagesOPP-20-6500125 Microtec Biocon Rev0ROHIT MCNo ratings yet

- Kiona Co Set Up A Petty Cash Fund For PaymentsDocument1 pageKiona Co Set Up A Petty Cash Fund For PaymentsAmit PandeyNo ratings yet

- Final Leads - HighlandsDocument12 pagesFinal Leads - HighlandsEsther DelinaresNo ratings yet

- Ewealth Insurance - BrochureDocument16 pagesEwealth Insurance - BrochurerajendranrajendranNo ratings yet

- Capital MarketDocument16 pagesCapital MarketPriya MalhotraNo ratings yet

- Resume LayoutDocument3 pagesResume LayoutJere Mae MarananNo ratings yet

- Shoe Affair (Factory) - Po-000008724Document2 pagesShoe Affair (Factory) - Po-000008724talentacquistionretailcoordinaNo ratings yet