Professional Documents

Culture Documents

LG SW 440 GR

LG SW 440 GR

Uploaded by

kylealamangoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LG SW 440 GR

LG SW 440 GR

Uploaded by

kylealamangoCopyright:

Available Formats

High Rejection

Seawater Reverse Osmosis (RO) Element

LG SW 440 GR

Overview

LG Chem’s thin-film nanocomposite (TFN) membranes lower water treatment

costs by improving energy efficiency and productivity. These membranes feature

benign nanomaterials incorporated into the thin-film polyamide layer of a compos-

ite membrane. This innovative patent-pending technology significantly increases

membrane permeability and improves salt rejection.

• Industry-standard flux with highest salt rejection

• Standard 8-inch spiral wound element design

• Easy to retrofit existing RO plants

• NSF Standard 61 Certified

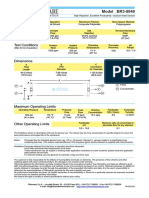

Product Specifications

Configuration: 8-inch spiral wound

Membrane Polymer: Thin-film nanocomposite (TFN) polyamide

Product Number Permeate flow Minimum Stabilized Active Membrane Feed Spacer Stabilized

rate NaCl NaCl Area mil Boron

m3/d (gpd) Rejection Rejection m2 (ft2) Rejection

% % %

LG SW 440 GR 31.2 (8,250) 99.7 99.85 41 (440) 28 93

Note: The above values are normalized to the following conditions: 32,000 ppm NaCl, 5 ppm boron, 5.5 MPa (800 psi), 25°C (77°F), pH 8, 8% recovery. Per-

meate flows for individual elements may vary +/- 15%.

A Part Number Length Element Perm Tube Weight

A O.D. I.D. kg (lbs.)

B C

B C LG SW 440 GR 1,016 mm 200 mm 28.6 mm 16.4

(40 in.) (7.9 in.) (1.125 in.) (36)

Operating Specifications For more information and operating guidelines, visit www.LGwatersolutions.com

Max. Applied Pressure: 8.27 MPa (1200 psig)

Max. Chlorine Concentration: < 0.1 ppm

Max. Operating Temperature: 45°C (113°F)

pH Range, Continuous (Cleaning): 2-11 (2-13)

Max. Feedwater Turbidity: 1.0 NTU

Max. Feedwater SDI (15 mins): 5.0

Max. Feed Flow: 17.0 m3/h (75 GPM)

Min. Ratio of Concentrate to Permeate Flow for any Element: 5:1

Max. Pressure Drop (ΔP) for Each Element: 1.0 bar (15 psi)

The information and data contained herein are deemed to be accurate and reliable and are offered in good faith, but without guarantee of performance. LG NanoH2O assumes no liability for

results obtained or damages incurred through the application of the information contained herein. Customer is responsible for determining whether the products and information presented

herein are appropriate for the customer’s use and for ensuring that customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments.

Specifications subject to change without notice. LG NanoH2O is a wholly owned company of LG Chem, Ltd. All rights reserved. © 2015 LG NanoH2O, Inc.

Lenntech Rev. E (08.15)

info@lenntech.com Tel. +31-152-610-900

www.lenntech.com Fax. +31-152-616-289

You might also like

- Intersubjectivity in Primary and Secondary Education A Review StudyDocument23 pagesIntersubjectivity in Primary and Secondary Education A Review StudyEDDY ALEXANDER VILLADA MARQUEZNo ratings yet

- Worldwide Engineering Standards: Neutral Salt Spray (NSS) TestDocument4 pagesWorldwide Engineering Standards: Neutral Salt Spray (NSS) Testjorgesalg100% (2)

- Carl Jung and The Visions of ZosimosDocument3 pagesCarl Jung and The Visions of ZosimosWolfMensch1216No ratings yet

- Cisco ASR 9922 Full Slot 8x100 Power CalculatorDocument6 pagesCisco ASR 9922 Full Slot 8x100 Power CalculatorMizhfar MuhammadNo ratings yet

- LG SW 440 SRDocument1 pageLG SW 440 SRkylealamangoNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- Lenntech: High RejectionDocument1 pageLenntech: High Rejectioncristian orihuelaNo ratings yet

- Data Sheet: LG BW 400 EsDocument1 pageData Sheet: LG BW 400 EsZi Wei LeongNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- LG Chem LG BW 4040 ES L PDFDocument1 pageLG Chem LG BW 4040 ES L PDFhonoviw115No ratings yet

- RO Membane - LG - 4040Document1 pageRO Membane - LG - 4040Muzakkir MohamadNo ratings yet

- LG-Chem SWRODocument2 pagesLG-Chem SWROblekhebonkNo ratings yet

- Data Sheet: LG SW 4040 RDocument1 pageData Sheet: LG SW 4040 RAcquetech AcquetechNo ratings yet

- Saving: EnergyDocument1 pageSaving: EnergyJavier Oyarzún CastroNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- Membrane LG BW 4040RDocument1 pageMembrane LG BW 4040RPT Deltapuro Indonesia100% (1)

- Data Sheet: LG BW 4040 EsDocument1 pageData Sheet: LG BW 4040 EsAcquetech AcquetechNo ratings yet

- Toray TML20D LDocument2 pagesToray TML20D LEber saidNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- Membrane RO SuezDocument2 pagesMembrane RO SuezSatria ArchilezNo ratings yet

- Ak-90le SuezDocument1 pageAk-90le Suezinversiones del peruNo ratings yet

- Filmtec BW30-400-IGDocument2 pagesFilmtec BW30-400-IGPT Deltapuro IndonesiaNo ratings yet

- DOW FILMTEC™ ECO Line RO Elements: Product DatasheetDocument2 pagesDOW FILMTEC™ ECO Line RO Elements: Product DatasheetakbarNo ratings yet

- GE Osmonics SWRO HR Series RO High Rejections Elements LDocument1 pageGE Osmonics SWRO HR Series RO High Rejections Elements LAlexis Jara VidalNo ratings yet

- Ion Labxt DS - 063023Document2 pagesIon Labxt DS - 063023nha vũNo ratings yet

- Swro TM800KDocument2 pagesSwro TM800KthanhhuyenNo ratings yet

- High Rejection Brackish Water RO Elements: DimensionsDocument2 pagesHigh Rejection Brackish Water RO Elements: Dimensionssunil patelNo ratings yet

- Hsro-390-Ff & Hsro-4040-FfDocument2 pagesHsro-390-Ff & Hsro-4040-FfYasser Mahmoud ZiadaNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- Toray TM820V 400 Sea Water RO Element LDocument2 pagesToray TM820V 400 Sea Water RO Element LLuzmaNo ratings yet

- Sea Water RO Elements: DimensionsDocument2 pagesSea Water RO Elements: DimensionsAlexis Jara VidalNo ratings yet

- TW 1812 100Document1 pageTW 1812 100Sergio Franco HernandezNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- ALPHA EF-6100P Liquid Flux EN 24jan20 TBDocument6 pagesALPHA EF-6100P Liquid Flux EN 24jan20 TBfernandoNo ratings yet

- LGWS Brochure 230620Document8 pagesLGWS Brochure 230620Mohamed MotaweaNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- Outside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyDocument2 pagesOutside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyParvinder KaurNo ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- PH76Document4 pagesPH76dannyNo ratings yet

- Toray TM820M 440 - Spec - SheetDocument2 pagesToray TM820M 440 - Spec - SheetJoselito CortesNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- AX080E002B IPSAlphaDocument29 pagesAX080E002B IPSAlphaRobert MalancaNo ratings yet

- Cartucho Ósmosis inversa-Dow-Filmtec-RO4040-FF-LDocument2 pagesCartucho Ósmosis inversa-Dow-Filmtec-RO4040-FF-LDiego RossoNo ratings yet

- Re8040-Be - 190312Document2 pagesRe8040-Be - 190312Willy ChandraNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Suez Ae 1Document1 pageSuez Ae 1Luis Alberto Castillo MaurtuaNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- Filmtec Hsro 390 FF Pds 45 d01701 enDocument3 pagesFilmtec Hsro 390 FF Pds 45 d01701 enGunwant VarmaNo ratings yet

- HM 4040 - BWE: High Performance Brackish Water RO ElementDocument2 pagesHM 4040 - BWE: High Performance Brackish Water RO Elementmaksudur4100% (1)

- Ejc Enerjet Combination BurnerDocument20 pagesEjc Enerjet Combination Burner鄭元豪No ratings yet

- Ionpurecedilxzptech 8344Document2 pagesIonpurecedilxzptech 8344Hoanh Hai NguyenNo ratings yet

- catalogue-BW SeriesDocument2 pagescatalogue-BW SeriessugiantoNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- ALPHA OM 338 PT Solder Paste EN 22oct21 TBDocument7 pagesALPHA OM 338 PT Solder Paste EN 22oct21 TBEdison SpolaorNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Dow UF IntegraPac IP 77 LDocument2 pagesDow UF IntegraPac IP 77 LPatricio AcuñaNo ratings yet

- FilmTec Hypershell Dairy Membranes PDS 45 D00720 enDocument4 pagesFilmTec Hypershell Dairy Membranes PDS 45 D00720 enMauricio ChiNo ratings yet

- DOW™ Electrodeionization Modules: Product InformationDocument2 pagesDOW™ Electrodeionization Modules: Product InformationjonnelNo ratings yet

- Odalog L2 1407995247 LDocument2 pagesOdalog L2 1407995247 LAmeenudeenNo ratings yet

- Hand Truck Sop - CleanedDocument1 pageHand Truck Sop - CleanedkylealamangoNo ratings yet

- IOM Pneumatic ActuatorsDocument15 pagesIOM Pneumatic Actuatorskylealamango100% (1)

- Hammerita Paint - 2021Document15 pagesHammerita Paint - 2021kylealamangoNo ratings yet

- Tangit ProcedureDocument5 pagesTangit ProcedurekylealamangoNo ratings yet

- Socket Welding: InstructionsDocument3 pagesSocket Welding: InstructionskylealamangoNo ratings yet

- Metal Chop Saw SopDocument2 pagesMetal Chop Saw SopkylealamangoNo ratings yet

- Angle Grinder SopDocument2 pagesAngle Grinder SopkylealamangoNo ratings yet

- Tunnel Fire SafetyDocument13 pagesTunnel Fire SafetykylealamangoNo ratings yet

- TM National Cycling StrategyDocument106 pagesTM National Cycling StrategykylealamangoNo ratings yet

- Study On The Heat Load Characteristics of Underground StructuresDocument9 pagesStudy On The Heat Load Characteristics of Underground StructureskylealamangoNo ratings yet

- Design of Modern Subway Ventilation SystemDocument5 pagesDesign of Modern Subway Ventilation SystemkylealamangoNo ratings yet

- E3sconf Clima2019 01039Document5 pagesE3sconf Clima2019 01039kylealamangoNo ratings yet

- Converting Railway Tunnels Into Walking and Cycling RoutesDocument60 pagesConverting Railway Tunnels Into Walking and Cycling RouteskylealamangoNo ratings yet

- 5 - Zhou Xu Wang and Sheng Estimating Capacity of Bicycle Path On Urban Roads in Hangzhou China - 2014Document18 pages5 - Zhou Xu Wang and Sheng Estimating Capacity of Bicycle Path On Urban Roads in Hangzhou China - 2014kylealamangoNo ratings yet

- Assessment of The Type of Cycling Infrastructure Required To Attract New Cyclists October 2011Document154 pagesAssessment of The Type of Cycling Infrastructure Required To Attract New Cyclists October 2011kylealamangoNo ratings yet

- Performance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomDocument9 pagesPerformance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomkylealamangoNo ratings yet

- Systems Approach To Underground Safety: SciencedirectDocument9 pagesSystems Approach To Underground Safety: SciencedirectkylealamangoNo ratings yet

- Gülyüz Et Al. Multiphase Deformation, Fluid Flow and Mineralization in Epithermal Systems Inferences From Structures, Vein Textures and Breccias of The Kestanelik Epithermal Au-ADocument22 pagesGülyüz Et Al. Multiphase Deformation, Fluid Flow and Mineralization in Epithermal Systems Inferences From Structures, Vein Textures and Breccias of The Kestanelik Epithermal Au-Ahüseyin burak göktaşNo ratings yet

- Air Cooled Chiller Noise Control - Case StudyDocument2 pagesAir Cooled Chiller Noise Control - Case StudyProingmeca CANo ratings yet

- WrittingDocument13 pagesWrittingDuy Nguyễn CôngNo ratings yet

- Anushka Jain - MDC003 - BBADocument5 pagesAnushka Jain - MDC003 - BBAAnushka JainNo ratings yet

- Managerial Economics: Production FunctionDocument17 pagesManagerial Economics: Production FunctionAnshu MishraNo ratings yet

- Module 2 Gen. Physics 1Document8 pagesModule 2 Gen. Physics 1KapelsuNo ratings yet

- Online Supplementary MaterialsDocument4 pagesOnline Supplementary MaterialsCyrus Mozart Magno BritanicoNo ratings yet

- Algorithms For Diophantine Equations - B.M.M. de WegerDocument220 pagesAlgorithms For Diophantine Equations - B.M.M. de Wegermontesdoc.trabajo Mont&DocNo ratings yet

- 24 PCM EncodingDocument4 pages24 PCM EncodingAli Mohammed Quasim MofasselNo ratings yet

- Commercial Cooking NC Iii Rostering Staff: Company Agreements andDocument14 pagesCommercial Cooking NC Iii Rostering Staff: Company Agreements andCaracciolo CulinaryNo ratings yet

- El Support Lesson Cause and Effect StructureDocument16 pagesEl Support Lesson Cause and Effect Structureapi-335012938100% (1)

- Tanzania Water Quality Old Report PDFDocument88 pagesTanzania Water Quality Old Report PDFElite Cleaning ProductsNo ratings yet

- Unit 8 Rate of Reaction: Summary QuestionsDocument2 pagesUnit 8 Rate of Reaction: Summary QuestionsLei YinNo ratings yet

- Cultural Anthropology 16th Edition Conrad Test BankDocument20 pagesCultural Anthropology 16th Edition Conrad Test Bankjonathanwelchjrcizmsdty100% (29)

- Book Part 9781789907193 8Document8 pagesBook Part 9781789907193 8Abbas Al hemeryNo ratings yet

- What Is The Format of A Memo?Document3 pagesWhat Is The Format of A Memo?Syeda Ghazia BatoolNo ratings yet

- Seal of Good Local GovernanceDocument46 pagesSeal of Good Local GovernanceKyza Mae AlcontinNo ratings yet

- GLP Lecture 8Document45 pagesGLP Lecture 8BABAR ZAFARULLAH MINHASNo ratings yet

- TECHNICAL CATALOGUE - VSF - IEC - ATEX - EN - Rev1 - 2017 PDFDocument172 pagesTECHNICAL CATALOGUE - VSF - IEC - ATEX - EN - Rev1 - 2017 PDFLASCARZAMFIRESCUNo ratings yet

- Teacher I-Iii: Cot-RpmsDocument2 pagesTeacher I-Iii: Cot-RpmsMary Belle DerracoNo ratings yet

- David Ellen - The Scientific Examination of Documents - Methods and Techniques - Methods and Techniques-Taylor & Francis (2014)Document189 pagesDavid Ellen - The Scientific Examination of Documents - Methods and Techniques - Methods and Techniques-Taylor & Francis (2014)Daniel BolivarNo ratings yet

- 1 s2.0 S0016236118304976 MainextDocument19 pages1 s2.0 S0016236118304976 MainextPriyam NayakNo ratings yet

- Bishop Cotton Women's Christian College: Rathus Assertiveness ScaleDocument14 pagesBishop Cotton Women's Christian College: Rathus Assertiveness ScaleKarthik BharadwajNo ratings yet

- Biology Report (Experiment 2)Document2 pagesBiology Report (Experiment 2)djash92100% (1)

- CFAR Radar Constant False Alarm Rate CalculatorDocument5 pagesCFAR Radar Constant False Alarm Rate CalculatorIvanNo ratings yet

- ISWM Practice ProblemsDocument4 pagesISWM Practice ProblemsApoorv DixitNo ratings yet