Professional Documents

Culture Documents

PI1042PEPA00300 - Tracker - Wireless System - Assembly Details

PI1042PEPA00300 - Tracker - Wireless System - Assembly Details

Uploaded by

pedrodaflorestaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PI1042PEPA00300 - Tracker - Wireless System - Assembly Details

PI1042PEPA00300 - Tracker - Wireless System - Assembly Details

Uploaded by

pedrodaflorestaCopyright:

Available Formats

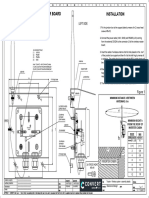

WIRELESS MASTER BOARD INSTALLATION

FRONT VIEW LEFT SIDE

1. Fix the junction box to the support plate by means of n.2 cross head

screws M5x16;

2. Connect the power cable (+24V, GND) and RS485 (A, B) coming

from the external SCADA to the connector J3 of the wireless master

board;

J3 connector Pinout:

(1) +24Vdc 3. Insert the cable of wireless antenna into the hole placed on the roof

(2) RS485- of the junction box support and then fix it to the half ring by menas of

(3) RS485+

(4) GND a cable tie. The cable should pass trhough the PG11 cable gland and

Antenna

be connected to the J2 connector on the wireless master board.

max 1.5 mm^2 - min 0.34 mm^2 cores

(1) and (4) are on the same twisted pair

(2) and (3) are on the same twisted pair Support plate 4. Place the master board on each inverter cabin, taking care that the

cable tie

height of the wireless antenna from the roof of the inverter cabin

Junction Box respects the indication of Figure 1.

159

n°4 fixing holes

79

5. The minimum distance between two master board is 6m

cable tie Figure 1

MINIMUM DISTANCE d BETWEEN

7

Ø7 Ø7

ANTENNAS: 6 m

2x CROSS HEAD

SCREW M5x16

d

J2 antenna

connector

cable tie (SMA female)

MINIMUM HEIGHT h

cable tie FROM THE ROOF OF

Schneider INVERTER CABIN

178

+24V 00925

143

Ø7 J3 connector +24V

RS485

(J3)

RS485 SMA

(J2)

(J3)

RF GW Board

+24V ROOF MIN

RS485

J2 antenna

(J3)

h DIMENSION HEIGHT

max(L1, L2) h

SMA

connector (J2)

(SMA female) [m] [m]

L1 2 0.6

n°4 fixing holes L2

4 0.9

6 1.1

INVERTER CABIN

2x CROSS HEAD 8 1.3

7

Ø7 Ø7

M5x16

10 1.5

12 1.6

109

material (weight) --------------------------------------

Tracker - Wireless system - assembly details PI1040PEPA00300

surface protection -------------------------------------- 30/07/2020 30/07/2020

tolerances -------------------------------------- R.BIAGI G.MORO Executive Design 1 1

A ® COMPANY

notes -------------------------------------- 1:2, 1:10 paper A4

You might also like

- T45i Spindle MoulderDocument19 pagesT45i Spindle MoulderFlorin Gabroveanu0% (1)

- Arnes Paccar mx13 2017Document10 pagesArnes Paccar mx13 2017Adderly Chinchero Torres100% (3)

- Jftot II Service RevcDocument94 pagesJftot II Service RevckevinNo ratings yet

- AP MK8 MK9 Installation ManualDocument48 pagesAP MK8 MK9 Installation ManualMorseunitedNo ratings yet

- PI1051PEPA00300 - Tracker - Wireless System - Assembly Details-LayoutDocument1 pagePI1051PEPA00300 - Tracker - Wireless System - Assembly Details-Layoutcaos99No ratings yet

- Quick Reference Guide For RTN510 AP Deployment (Web)Document7 pagesQuick Reference Guide For RTN510 AP Deployment (Web)Sinini MhlangaNo ratings yet

- Installation/Owner's Manual: 1838 PC ProgrammableDocument60 pagesInstallation/Owner's Manual: 1838 PC ProgrammablealejandraNo ratings yet

- Motion Coordinator Motion Coordinator: Quick Connection GuideDocument8 pagesMotion Coordinator Motion Coordinator: Quick Connection Guidespotlight studiosNo ratings yet

- Assembly and Use RFLink V1.1.4 EN NLDocument18 pagesAssembly and Use RFLink V1.1.4 EN NLpierrepauljacquesNo ratings yet

- tr808 Snare Diy Project PDFDocument12 pagestr808 Snare Diy Project PDFdse666No ratings yet

- Rs485 Click Manual v100Document2 pagesRs485 Click Manual v100Francisco Gutierrez Mojarro100% (1)

- 3.5 CN2 Connector: The Terminal Block of The Connector and Pin Number Are As FollowsDocument3 pages3.5 CN2 Connector: The Terminal Block of The Connector and Pin Number Are As FollowsuthmaansNo ratings yet

- BackupBox - (B0, B1) Quick GuideDocument16 pagesBackupBox - (B0, B1) Quick GuideAdrian OLNo ratings yet

- FR EpnDocument56 pagesFR EpnmazehNo ratings yet

- MIN 7000-10000TL-X Quick GuideDocument2 pagesMIN 7000-10000TL-X Quick Guidewhoru320No ratings yet

- User Manual I Part 6 4341691Document17 pagesUser Manual I Part 6 4341691chinhdt83No ratings yet

- HMS-2000-4T Quick Installation Guide: 1. AccessoriesDocument2 pagesHMS-2000-4T Quick Installation Guide: 1. AccessoriesOscar Fernando Roque PardoNo ratings yet

- G4HFQ Software - LinksDocument1 pageG4HFQ Software - LinksANSELMO LIMANo ratings yet

- 03 05 Analog Gauge Installation With Additional Notes For 06 07 With PerfectPassDocument14 pages03 05 Analog Gauge Installation With Additional Notes For 06 07 With PerfectPassGustavo Flores MorenoNo ratings yet

- Vision Instruments LTD: 1:1 NaturalDocument1 pageVision Instruments LTD: 1:1 NaturalNguyễnVănLượngNo ratings yet

- ASSY Wi-Fi Kit 2.0: Model Name: MIM-H04E MIM-H04 MIM-H04UDocument17 pagesASSY Wi-Fi Kit 2.0: Model Name: MIM-H04E MIM-H04 MIM-H04Ulazzarini cesareNo ratings yet

- Dynapar s428Document16 pagesDynapar s428Leopoldo FloresNo ratings yet

- MIC 750-3300TL-X Quick Guide EN202201Document2 pagesMIC 750-3300TL-X Quick Guide EN202201zatkbgfebnjolcvruvNo ratings yet

- MID 17-40KTL3-X Quick Guide EN 202305Document2 pagesMID 17-40KTL3-X Quick Guide EN 202305whoru320No ratings yet

- Components: Aurora 2400 Installation GuideDocument4 pagesComponents: Aurora 2400 Installation GuideavoldNo ratings yet

- General Information About Connecting The Remote Bus Cable: Creation of A Cable PlanDocument5 pagesGeneral Information About Connecting The Remote Bus Cable: Creation of A Cable PlanGilbert H. Quiroga G.No ratings yet

- SUN2000 - (2KTL-6KTL) - L1 Quick GuideDocument22 pagesSUN2000 - (2KTL-6KTL) - L1 Quick GuideNicolae ChirilaNo ratings yet

- F18 Quick Start GuideDocument4 pagesF18 Quick Start GuideLionel SaudinNo ratings yet

- Half-Bridge Driver (S) & (PBF) : Features PackagesDocument22 pagesHalf-Bridge Driver (S) & (PBF) : Features Packageskhawar mukhtarNo ratings yet

- OptimDocument16 pagesOptimCh Ll. Q.No ratings yet

- PRSB 15kW, 48VDC: Installation GuideDocument6 pagesPRSB 15kW, 48VDC: Installation GuideVictor Rodrigo Cruz DelgadoNo ratings yet

- Ascon KM3Document40 pagesAscon KM3Juan Carlos Abarca SereñoNo ratings yet

- Installation Guide - TLG7921M Series V1.2Document12 pagesInstallation Guide - TLG7921M Series V1.2Marthin KingNo ratings yet

- 2.0 VISION 2020i: 2.1 PrecautionsDocument3 pages2.0 VISION 2020i: 2.1 PrecautionsTran Van TienNo ratings yet

- Half-Bridge Driver (S) & (PBF) : Features PackagesDocument22 pagesHalf-Bridge Driver (S) & (PBF) : Features PackagesTeles SilvaNo ratings yet

- Symphony II To RNS-E RetrofitDocument26 pagesSymphony II To RNS-E Retrofitgeorge murphyNo ratings yet

- Release 1.0-4.1 Interconnect InformationDocument23 pagesRelease 1.0-4.1 Interconnect Informationandriy nbookNo ratings yet

- English - EnerSolis Interface Cards User's Manual - 192321462004000Document4 pagesEnglish - EnerSolis Interface Cards User's Manual - 192321462004000Abdelwhab ElsaftyNo ratings yet

- Camino 108 BrochureDocument2 pagesCamino 108 BrochureIdwan IskandarNo ratings yet

- CP3/CP3N 3-Series® Control SystemDocument2 pagesCP3/CP3N 3-Series® Control SystemCan FightstarterNo ratings yet

- M7635C - 7608 - 7612 QigDocument2 pagesM7635C - 7608 - 7612 QigVictor BitarNo ratings yet

- $R3S8X82Document8 pages$R3S8X82Yılmaz BaranNo ratings yet

- Stop!: On The GatewayDocument2 pagesStop!: On The GatewayFilip MilicNo ratings yet

- 1734 In510 - en P PDFDocument12 pages1734 In510 - en P PDFAraik AmbartsumyanNo ratings yet

- JPX321-BM2-128D Installation GuideDocument1 pageJPX321-BM2-128D Installation GuideSamuelNo ratings yet

- R03 SA-ETH Ethernet Interface Card Installation SheetDocument4 pagesR03 SA-ETH Ethernet Interface Card Installation SheetDiegoNo ratings yet

- Octopre Le Optional Codec Installation Guide: Top Cover RemovalDocument1 pageOctopre Le Optional Codec Installation Guide: Top Cover RemovaltaatuNo ratings yet

- 433Mhz Uhf Ask Data Transmitter and Receiver: Egrf-433A1Document12 pages433Mhz Uhf Ask Data Transmitter and Receiver: Egrf-433A1SIVARAMANJAGANATHANNo ratings yet

- Icefree To Hybrid™ XT Sensor Retrofit For Ge 1.5 Sle TurbineDocument7 pagesIcefree To Hybrid™ XT Sensor Retrofit For Ge 1.5 Sle Turbinetzy_007No ratings yet

- Digital Panel Meter: Model A2100 Series Operation ManualDocument2 pagesDigital Panel Meter: Model A2100 Series Operation ManualAung MhNo ratings yet

- 21 ModuloDocument2 pages21 ModulosuryaNo ratings yet

- 21modulo Smart OneDocument2 pages21modulo Smart OnePedroNo ratings yet

- 01F Addressable Input Module AcidDocument2 pages01F Addressable Input Module AcidmotaNo ratings yet

- Instructions For Bypassing The Control 26-DT's Transformer: ObjectivesDocument3 pagesInstructions For Bypassing The Control 26-DT's Transformer: ObjectivesCalvin DeSarioNo ratings yet

- 433Mhz Receiver Logic Board Antenna Extension Kit: InstallationDocument1 page433Mhz Receiver Logic Board Antenna Extension Kit: Installationabe saulNo ratings yet

- EPC Installation and Wiring Guide 836262aDocument2 pagesEPC Installation and Wiring Guide 836262adylan_dearing@hotmail.comNo ratings yet

- 9XR Telemetry Mods With Max232 PDFDocument9 pages9XR Telemetry Mods With Max232 PDFYimmeeeNo ratings yet

- Picaxe Experimenter Board Axe090Document5 pagesPicaxe Experimenter Board Axe090Adrian CamilleriNo ratings yet

- Din Rail Install A6V10334278Document2 pagesDin Rail Install A6V10334278Daniel Astudillo GarcíaNo ratings yet

- RfrbkitDocument2 pagesRfrbkitpotoculNo ratings yet

- R&Mfreenet U/Utp Cat.6 250 MHZ: Cable ReferenceDocument2 pagesR&Mfreenet U/Utp Cat.6 250 MHZ: Cable ReferenceAndré HitoshiNo ratings yet

- 2Xx-Eip: Ethernet/Ip Interface CardDocument20 pages2Xx-Eip: Ethernet/Ip Interface Cardbalanzas pesajeNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Sabb-Gray Water WsfuDocument22 pagesSabb-Gray Water Wsfuabdullah amanullahNo ratings yet

- Tire Size CalculatorDocument2 pagesTire Size Calculatorjjcsr74No ratings yet

- Catalog Caterpillar 740b Articulated Truck SpecificationsDocument20 pagesCatalog Caterpillar 740b Articulated Truck Specificationssuwarjitechnic0% (1)

- SRV02 Rotary Pendulum User ManualDocument11 pagesSRV02 Rotary Pendulum User ManualRoby NicaNo ratings yet

- List of Approved ManufacturesDocument48 pagesList of Approved Manufacturesnadeem UddinNo ratings yet

- Proline Promag 50WDocument47 pagesProline Promag 50W112233No ratings yet

- Canon 4412 MFPDocument3 pagesCanon 4412 MFPseahateNo ratings yet

- 2650 1079 PDFDocument2 pages2650 1079 PDFZane HafizNo ratings yet

- Multistage Split Case Pumps: 420 SeriesDocument12 pagesMultistage Split Case Pumps: 420 SeriesJcube SysTechNo ratings yet

- BRAUN E16x356-Manual ENDocument89 pagesBRAUN E16x356-Manual ENMohamed AmiraNo ratings yet

- SeeSnake SelectionDocument18 pagesSeeSnake SelectionMohdHuzairiRusliNo ratings yet

- Datasheet Seimens ROD 320 005Document2 pagesDatasheet Seimens ROD 320 005Adilson BorgesNo ratings yet

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileDocument2 pagesHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94No ratings yet

- AX-TFR ManualDocument12 pagesAX-TFR ManualАндрей МаксименкоNo ratings yet

- Technical Specification For Safety Stairways: 1.1 General DetailsDocument4 pagesTechnical Specification For Safety Stairways: 1.1 General DetailsNithinNo ratings yet

- DET-838C Resi Electronic Circuit InterruptersDocument8 pagesDET-838C Resi Electronic Circuit InterruptersLemark R.No ratings yet

- Processor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSDocument26 pagesProcessor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSalejandro100% (1)

- 1 9 77 KW Tdi PD EngineDocument397 pages1 9 77 KW Tdi PD Engine19crystiNo ratings yet

- Sony Broadcast Monitor LMD-A Serires PDFDocument4 pagesSony Broadcast Monitor LMD-A Serires PDFShwe ThweNo ratings yet

- GME871P30 MT8072iP Installation 221019Document2 pagesGME871P30 MT8072iP Installation 221019where moneyNo ratings yet

- Alternate GuagingDocument5 pagesAlternate GuagingAusi RobloxNo ratings yet

- Simatic Et 200SPDocument10 pagesSimatic Et 200SPmax2007No ratings yet

- Bert Rowe's-AT-BlogDocument32 pagesBert Rowe's-AT-Blogerion cuniNo ratings yet

- GC 2014enDocument318 pagesGC 2014enkarups69No ratings yet

- Nord Clincher CatalogDocument356 pagesNord Clincher CatalogPaulo HenriqueNo ratings yet

- DKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CDocument82 pagesDKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CNoah MusundiNo ratings yet

- Auto Chassis and Trnasmission System by Srinath GhodkeDocument246 pagesAuto Chassis and Trnasmission System by Srinath Ghodkesrinath ghodkeNo ratings yet