Professional Documents

Culture Documents

Robust Performance of PID Controller by Using Artificial Intelligence

Robust Performance of PID Controller by Using Artificial Intelligence

Uploaded by

NARESHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Robust Performance of PID Controller by Using Artificial Intelligence

Robust Performance of PID Controller by Using Artificial Intelligence

Uploaded by

NARESHCopyright:

Available Formats

International Journal of Current Engineering and Technology E-ISSN 2277 – 4106, P-ISSN 2347 – 5161

©2021 INPRESSCO®, All Rights Reserved Available at http://inpressco.com/category/ijcet

National Conference on Recent Advances in Civil Engineering Infrastructure (rACEi-2021)

Robust Performance of PID Controller by using Artificial Intelligence

Shachi Tiwary#, Ashraf Jafri#, Kushal Tiwari^, Richa Tiwari# and Chaman Yadav^

#CSIT Durg, India

^CREDA Raipur, India

Received 05 Aug 2021, Accepted 10 Aug 2021, Available online 15 Aug June 2021, Special Issue-9 (Aug 2021)

Abstract

This document gives formatting instructions for authors preparing papers for publication in the International

Journal of Current Engineering and Technology. The authors must follow the instructions given in the document for

the papers to be published. You can use this document as both an instruction set and as a template into which you

can type your own text.

Keywords: The author can include 5-7 words like Thermal Analysis, Pre-conditioner, In-mold, Inoculant’s efficiency.

1. Introduction thermal analysis to determine the percentage of carbon

equivalent liquidus, carbon and silicon levels, it can

This document is a template. An electronic copy can be also be used to monitor metallurgical processes and

downloaded from the INPRESSCO website. For identify potential problems areas such as low nodule

questions on paper guidelines, please contact count, under-cooled graphite and carbide/chill

editor.ijcet @inpressco.com or the author can visit the propensity (Udroiu, 2002), (Corneli, et al, 2004),

website for the guidelines. (Seidu, 2008). It can be used to predict iron shrinkage

We use 10 point Cambria Font and the font size tendency and help the foundry to control scrap.

must not be changed. The authors are required to

format their article according to this. 2. Placing the figures

Please see the reference citing style i.e. how the

references are to be written as described below. All the figures must be placed in the column wise,

INPRESSCO uses the reference style as: (author’s however the authors can use single column to place big

name et al, Year of publication). An example is give figures provided that the template formatting must not

below. change. The title of the figure is to be placed below the

A cooling curve is a plot of temperature as a figures as shown.

function of time for a sample of an alloy poured into a

standardized mould with a thermocouple usually Note: Please note the figures must be placed in in line

positioned in the center (Warsinsk, 1975). Depending with text mode, not in any other Wrap mode. Also, the

on the sampling rate of the data, the cooling curve can figures must not be inserted into tables.

be represented and the first derivative can be

accurately calculated (Backerud, et al, 1975). Invention

and introduction of thermal analysis in casting

production has brought a comprehensive evaluation of

melt iron quality. Research has shown that the shape of

the cooling curve measured by thermal couple

mounted in the thermal analysis sample cup reflects

the solidification process of iron melt in the cup (Zhu

and Smith, 1995) .Measuring the shape of the cooling

curve will give comprehensive information about the

melting and treatments quality thereby the properties

and microstructure could be predicted (Labrecque and

Gagne, 1998), (Chisamera, et al, 2009) , (Riposan, et al Fig.1 Typical cooling curve and its first derivative

2003). 2.1 Placing the graphs

Thermal analysis can be used to determine inoculants

performance, apart from the traditional usage of

1| International Journal of Current Engineering and Technology, Special Issue-9 (Aug 2021)

[TYPE THE DOCUMENT TITLE] Ramesh et al

The graphs must be properly drawn in MS excel. Please undercooling of the liquidus and solidus

note that all the legends should be drawn in the MS temperature.

excel single file. They are not to be inserted in MS Word 2) Thermal analysis is a good technique to control

which will affect the formatting of the template. Care carbides, shrinkage and micro-shrinkage

should also be taken to keep the font as Cambria. As formation.

the default font in Excel is Calibri. So the graphs by 3) It is visibly shown that there is significant

default take it. The authors are required to keep the reduction in undercooling degree on the alloys and

font as Cambria. The graphs must be in line with text the value of inoculation index was increased.

and are not be placed in any other wrap mode Although the addition of Al,Ca,Zr-FeSi pre-

conditioners gives no significant influence .

2.2 Using and placing the equations 4) The use of relative performance makes a clear

distinction of the alloys efficiency and could be

Please not that all the equations must be written in in concluded that Ca,RE,S,O-FeSi inoculated iron gave

Microsoft equation 3.0 or above versions. Click Insert the most influence.

and under Object you will find the Microsoft equation 5) From the result obtained, it could be deduced

3.0. Type all your equations here. Do not paste comparatively that Ca,RE,S,O-FeSi inoculant give

equations from any other file. Equations appearing as the best efficiency followed by Ca,Zr-FeSi and

images will not be considered .Such equations are not Ca,Ba-FeSi inoculants respectively.

clear when the paper is converted in pdf. An example

of Microsoft equation 3.0 is given as under. References

available Time The authors are required to follow the following

Takt Time= reference style i.e. Authors names (Year of

production Time

(1) publication), Title of the Article, Name of the journal in

Please note that the properties of the equations must Italics, Vol. No. Page No. The examples is given as

not be locked under

3. Placing the tables J.B.Humphreys,(1961), Effect of composition on the liquidus

and eutectic temperature and on the eutectic point of cast

irons, BCRIAJ,19,609-621.

It should be noted that all the tables must be firstly R.G.Warsinsk, (1975) Ford develops CE cooling curve

drawn in Excel and after that they should be placed in computer, Foundry M&T,3,104-107

your article. The heading of the table should be above L.Backerud, K.Nilsson, N.Steen,(1975) The metallurgy of cast

the table. An example is given as under. iron,St.Saphorin,SwiitzerlandGenrgi publishing

company,pp.625-637.

Note: Please note the tables must be placed in in line P.Zhu, R.W.Smith, (1995) Thermal analysis of nodular

with text mode, not in any other Wrap mode. Also, the graphite cast iron, AFS Transaction, 103,601-609

C.Labrecque, M.Gagne,(1998), Interpretation of cooling

figures must not be inserted into tables

curves of cast iron: A literature review, AFS

Transaction,106,pp.83-90

Table 1 Experimental procedure parameters M. Chisamera, I.Riposan, S. Stan, D. White, (2009), Influence

of Residual Aluminum on Solidification Pattern of Ductile

S. No Parameters Values iron, International Journal of Cast metals research, vol.22,no.6,

1 Melting Acid lining coreless induction pp. 401-410.

Changes furnace,100kg, 2400Hz I.Riposan, M.Chisamera, S. Stan, C. Gadarautanu, T. Skaland,

(2003), Analysis of Cooling and Contraction Curves to

2 Charges 3.6%C, 1.22%Si, 0.02%P, 0.016%S,

Identify the Influence of Inoculants on Shrinkage behavior of

0.04%Cr, 0.47%Mn, 0.005%As,

Ductile Irons, Keith Millis Symposium on Ductile Cast Iron,

0.001%V, 0.001%Pb, 0.002%Ti.

pp.125-135.

3 Base Metal 3.56%C, 2.78%Si, 0.47%Mn,

A.Udroiu,(2002), The use of Thermal Analysis for Process

0.020%P, 0.008%S, 0.0384%Cr,

Control of Ductile Iron, Seminarium Nova cast, Italy.

0.0384%Cr, 0.042%Mo, 0.023%Ni,

J. corneli, V.Ettinger, W. Baumgart, (2004), Thermal

analysis ,an Unique Fingerprint of a melt ,66th World Foundry

Conclusions Congress 6-9 , pp. 743-756.

Seidu, S.O (2008). Influence of Inoculant’s type on thermal

The authors can write the conclusion as a whole in a analysis parameters of ductile irons, 4thinternaltion

paragraph or by making points. An example is given as conference, Galati, Romania, pp. 237-241.

under. M. Chisamera, S. Stan, I. Riposan, E. Stefan, G. Costache,

1) Derivatives of the cooling curve can be used to (2007), Thermal analysis of Inoculated Grey Cast Irons,

UGALMAT,Galati,TechnologiisiMaterialeAvansate,University

understand the small changes in the

press,Vol.1, pp.17-23.

HP | Error! No text of specified style in document. 2

[TYPE THE DOCUMENT TITLE] Ramesh et al

HP | Error! No text of specified style in document. 3

You might also like

- Checkpoint Science Past Papers April 2023Document20 pagesCheckpoint Science Past Papers April 2023Harini Bharani89% (85)

- Template On Sample IEEE Paper For A4 Page SizeDocument2 pagesTemplate On Sample IEEE Paper For A4 Page SizeAman A True FriendNo ratings yet

- WELDING RESEARCH S 111 WELDING JOURNALDocument6 pagesWELDING RESEARCH S 111 WELDING JOURNALfazakas barnaNo ratings yet

- Simulation of Heat Transfer in Steel Billets During Continuous CastingDocument14 pagesSimulation of Heat Transfer in Steel Billets During Continuous CastingFahrgerusteNo ratings yet

- 7968 PDFDocument81 pages7968 PDFAdeline MargaretNo ratings yet

- Thermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleDocument15 pagesThermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleMonish KumarNo ratings yet

- Camera-Ready Articles Preparation Instructions For International Conference "Industrial Engineering 2020"Document5 pagesCamera-Ready Articles Preparation Instructions For International Conference "Industrial Engineering 2020"oiiiNo ratings yet

- Predicting Delta Ferrite Content in Stainless Steel CastingsDocument12 pagesPredicting Delta Ferrite Content in Stainless Steel CastingsYlich SchmittNo ratings yet

- Soldagem InoxDocument10 pagesSoldagem InoxEdenilson BotelhoNo ratings yet

- 3d Heat Transfer Analysis and Numerical Modeling of LENSTM Process For One End Stepped Cylindrical Wall by Using Stainless Steel 304Document5 pages3d Heat Transfer Analysis and Numerical Modeling of LENSTM Process For One End Stepped Cylindrical Wall by Using Stainless Steel 304IJMERNo ratings yet

- Heat Transfer Modeling of Metal Deposition Employing Welding Heat SourceDocument9 pagesHeat Transfer Modeling of Metal Deposition Employing Welding Heat SourcefelavinNo ratings yet

- Pid 4607223Document6 pagesPid 4607223porisok617No ratings yet

- Development of An Austenitization Kinetics Model For 22MnB5 SteelDocument11 pagesDevelopment of An Austenitization Kinetics Model For 22MnB5 SteelAndress SsalomonnNo ratings yet

- Finite Element Modeling of Hot Stamping: Metal FormingDocument7 pagesFinite Element Modeling of Hot Stamping: Metal FormingsharenterNo ratings yet

- Ijdmt: ©iaemeDocument7 pagesIjdmt: ©iaemeIAEME PublicationNo ratings yet

- Quantitative Analysis of Pitting Corrosion Behavior of Thixoformed A356alloy in Chloride Medium Using Electrochemical TechniquesDocument7 pagesQuantitative Analysis of Pitting Corrosion Behavior of Thixoformed A356alloy in Chloride Medium Using Electrochemical TechniquesMostafa Mahmoud ShehataNo ratings yet

- Demarque 2018Document9 pagesDemarque 2018Jose G. Cueva CardeñaNo ratings yet

- Taguchi Optimization of Process Parameters in Friction Stir Welding of 6061 Aluminum Alloy: A Review and Case StudyDocument12 pagesTaguchi Optimization of Process Parameters in Friction Stir Welding of 6061 Aluminum Alloy: A Review and Case StudyVijay GadakhNo ratings yet

- Weight Metallic Materials II, Eds. C. M. Ward-Close, F. H. Froes, S. S. Cho, and D. JDocument3 pagesWeight Metallic Materials II, Eds. C. M. Ward-Close, F. H. Froes, S. S. Cho, and D. JDavico MartinezNo ratings yet

- 2nd PaperDocument11 pages2nd PaperGaurav PandeyNo ratings yet

- V Manojlovic,+5 673 PPDocument15 pagesV Manojlovic,+5 673 PPMonish Kumar V RNo ratings yet

- Microstructural Evolution in Friction Stir Welded API 5L-X52 SteelDocument7 pagesMicrostructural Evolution in Friction Stir Welded API 5L-X52 SteelSameer MDNo ratings yet

- COB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileDocument9 pagesCOB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileAlbert AlmeidaNo ratings yet

- Optmzn of HT - AMSDocument4 pagesOptmzn of HT - AMSsushmaxNo ratings yet

- Predicting Delta Ferrite Content in Stainless Steel CastingsDocument12 pagesPredicting Delta Ferrite Content in Stainless Steel CastingsShubham sahuNo ratings yet

- S.K. Mohammad Shareef PDFDocument5 pagesS.K. Mohammad Shareef PDFasdfNo ratings yet

- Musonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162Document7 pagesMusonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162JUANNo ratings yet

- Materials and Design: A. Kermanpur, M. Eskandari, H. Purmohamad, M.A. Soltani, R. ShateriDocument9 pagesMaterials and Design: A. Kermanpur, M. Eskandari, H. Purmohamad, M.A. Soltani, R. ShaterircarpiooNo ratings yet

- L-4rr-1/MME Date: 07/12/2014Document14 pagesL-4rr-1/MME Date: 07/12/2014Utsho DasNo ratings yet

- The Simulation of Magnesium Wheel Low Pressure Die Casting Based On PAM-CASTDocument7 pagesThe Simulation of Magnesium Wheel Low Pressure Die Casting Based On PAM-CASTMar'i MuchammadNo ratings yet

- Gao 2019 IOP Conf. Ser. - Mater. Sci. Eng. 592 012086Document8 pagesGao 2019 IOP Conf. Ser. - Mater. Sci. Eng. 592 012086Mar'i MuchammadNo ratings yet

- Metals: Ni-And Co-Based Superalloys and Their CoatingsDocument3 pagesMetals: Ni-And Co-Based Superalloys and Their Coatingsmuhammad azwanNo ratings yet

- Effect of Tempering Pass On HSLA-80 Steel HAZ MicrostructuresDocument8 pagesEffect of Tempering Pass On HSLA-80 Steel HAZ MicrostructuresElias KapaNo ratings yet

- Transf Fases Na SoldagemDocument36 pagesTransf Fases Na SoldagemengetarcioNo ratings yet

- 6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysDocument12 pages6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysMuhammad Umer Farooq AwanNo ratings yet

- Finite Element Modelling of Concurrent Deformation and Transformation in Metastable SteelsDocument13 pagesFinite Element Modelling of Concurrent Deformation and Transformation in Metastable Steelsklomps_jrNo ratings yet

- Taheri2020 - Article - CharacterizationsOfDissimilar DSS-316LDocument9 pagesTaheri2020 - Article - CharacterizationsOfDissimilar DSS-316Lkamal touilebNo ratings yet

- Thermal StressesDocument3 pagesThermal StressesRajeshNo ratings yet

- Failure Case Studies of SA213 T22 SteelDocument8 pagesFailure Case Studies of SA213 T22 SteelBasim Al-bhadleNo ratings yet

- A FEM Model To Study The Fiber Laser Welding of Ti6Al4V - Casalino & Mortello 2016Document8 pagesA FEM Model To Study The Fiber Laser Welding of Ti6Al4V - Casalino & Mortello 2016615513No ratings yet

- Ipc2012 90337Document6 pagesIpc2012 90337Marcelo Varejão CasarinNo ratings yet

- Application of 3-D Numerical Simulation Software SRIFCAST To Produce Ductile Iron CastingsDocument8 pagesApplication of 3-D Numerical Simulation Software SRIFCAST To Produce Ductile Iron CastingsTalha Nibras AliNo ratings yet

- Fatigue Limit Prediction of A356-T6 Cast Aluminum Alloys With Different Defect Sizes Sampled From An Actual Large-Scale ComponentDocument15 pagesFatigue Limit Prediction of A356-T6 Cast Aluminum Alloys With Different Defect Sizes Sampled From An Actual Large-Scale ComponentFrancesco MontagnoliNo ratings yet

- ACMFMS2022 Template Full Paper2Document4 pagesACMFMS2022 Template Full Paper2Zeeshan AbbasNo ratings yet

- Effect of Geometry, Material and Thickness of Fin On Engine Cylinder FinsDocument6 pagesEffect of Geometry, Material and Thickness of Fin On Engine Cylinder FinsAnonymous kw8Yrp0R5rNo ratings yet

- Numerical Simulation of Low Pressure Die-Casting Aluminum WheelDocument5 pagesNumerical Simulation of Low Pressure Die-Casting Aluminum WheelMostafaNo ratings yet

- Scale Development On Steel During Hot Strip RollingDocument7 pagesScale Development On Steel During Hot Strip RollingMochamad Kamal IhsanNo ratings yet

- Numerical Analysis of Steel Circular Structure With ButtweldDocument10 pagesNumerical Analysis of Steel Circular Structure With ButtweldAjithNo ratings yet

- 59 - Isijint 2018 432Document10 pages59 - Isijint 2018 432harishNo ratings yet

- IEI Journal PaperDocument7 pagesIEI Journal PaperPearl IPNo ratings yet

- Author's Accepted Manuscript: Case Studies in Thermal EngineeringDocument41 pagesAuthor's Accepted Manuscript: Case Studies in Thermal EngineeringInce OnderNo ratings yet

- E03ST29Document21 pagesE03ST29José Luis PárragaNo ratings yet

- Numerical Modeling of Temperature Distribution in Laser Beam Welding of 304 Stainless SteelDocument12 pagesNumerical Modeling of Temperature Distribution in Laser Beam Welding of 304 Stainless SteelTJPRC PublicationsNo ratings yet

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNo ratings yet

- 90 Years of Thermal Analysis As A Control Tool in The Melting of Cast IronDocument16 pages90 Years of Thermal Analysis As A Control Tool in The Melting of Cast IronDouglas RodriguesNo ratings yet

- Comparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014Document8 pagesComparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014DonatasNo ratings yet

- Modelling and Optimization of Aging Parameters For Thermal Properties of Al 6082 Alloy Using Response Surface MethodologyDocument12 pagesModelling and Optimization of Aging Parameters For Thermal Properties of Al 6082 Alloy Using Response Surface MethodologyDevendra kumar VishwakarmaNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- LPDC Flow SimulationDocument5 pagesLPDC Flow SimulationDavid JendraNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Disaster Preparedness & Planning: Iii Year B.Tech Ii Sem Computer Secience EngineeringDocument26 pagesDisaster Preparedness & Planning: Iii Year B.Tech Ii Sem Computer Secience EngineeringNARESHNo ratings yet

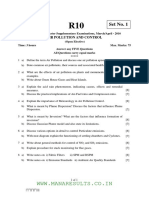

- WWW - Manaresults.Co - In: Set No. 1Document1 pageWWW - Manaresults.Co - In: Set No. 1NARESHNo ratings yet

- APC Lecture NotesDocument107 pagesAPC Lecture NotesNARESHNo ratings yet

- WWW - Manaresults.Co - In: Set No. 1Document1 pageWWW - Manaresults.Co - In: Set No. 1NARESHNo ratings yet

- Analysis of CombustionDocument14 pagesAnalysis of CombustionNARESHNo ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- MSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)Document15 pagesMSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)rakeshpatkar332No ratings yet

- Afghanistan's Mineral Resource Potential A Boon or BaneDocument24 pagesAfghanistan's Mineral Resource Potential A Boon or BaneKinza ZebNo ratings yet

- 2 YDK 669.1:622.267 O. P Baidin, V. I. Rostovsky, D.E EsezoborDocument11 pages2 YDK 669.1:622.267 O. P Baidin, V. I. Rostovsky, D.E EsezoborROWHEITNo ratings yet

- Tantalum and Niobium Deposits - A Primer For GeoscientistsDocument14 pagesTantalum and Niobium Deposits - A Primer For GeoscientistsCarlos BallestasNo ratings yet

- Electrical Properties of Materials: Chap 1Document21 pagesElectrical Properties of Materials: Chap 1Nur Mohammad AkramNo ratings yet

- Additive Manufacturing: H.R. Kotadia, Associate Professor, G. Gibbons, A. Das, P.D. HowesDocument23 pagesAdditive Manufacturing: H.R. Kotadia, Associate Professor, G. Gibbons, A. Das, P.D. HowesÁlvaro Nieto CastroNo ratings yet

- Bohler Uddeholm Brochure PDFDocument4 pagesBohler Uddeholm Brochure PDFMilos StoisavljevicNo ratings yet

- Itmk3 RDocument4 pagesItmk3 RVc ShekharNo ratings yet

- High Strength Low Alloy Steel: 1. AISI 9254Document4 pagesHigh Strength Low Alloy Steel: 1. AISI 9254Himanshu PawarNo ratings yet

- 21054-409-10.0.1 Especificacion Montaje Tuberias NEMDocument27 pages21054-409-10.0.1 Especificacion Montaje Tuberias NEMAriel MoralesNo ratings yet

- How Thick Is Gold Finger PCB Plating and Its CostDocument15 pagesHow Thick Is Gold Finger PCB Plating and Its CostjackNo ratings yet

- Chapter - 3: Metals and Non MetalsDocument25 pagesChapter - 3: Metals and Non MetalsKiran PatilNo ratings yet

- Niobium: Niobium, Also Known As Columbium, Is A Chemical Element With TheDocument15 pagesNiobium: Niobium, Also Known As Columbium, Is A Chemical Element With TheVysakh VasudevanNo ratings yet

- HQ182EN Metal FormingDocument6 pagesHQ182EN Metal FormingLuis MartinezNo ratings yet

- ( (Manufacturing) ) : Powder Metallurgy (PM)Document12 pages( (Manufacturing) ) : Powder Metallurgy (PM)MECHANICAL ENGINEERINGNo ratings yet

- Ductile IronDocument2 pagesDuctile Ironpraval84No ratings yet

- Umar, 04 Isyatun RodliyahDocument8 pagesUmar, 04 Isyatun Rodliyahrizky dwi anandaNo ratings yet

- Sa 739Document3 pagesSa 739Elgen IgloriaNo ratings yet

- Blueshield La 23 SawDocument1 pageBlueshield La 23 SawSungJun ParkNo ratings yet

- Ratio and Proportion Part 2Document3 pagesRatio and Proportion Part 2Lynn-MarieNo ratings yet

- Gould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Document2 pagesGould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Gourav SharmaNo ratings yet

- CREEP Corrosion Presentation MS2007Document4 pagesCREEP Corrosion Presentation MS2007anwarhas05No ratings yet

- 4-API RP-571 - Chapter 4-5 Environmental DamagesDocument74 pages4-API RP-571 - Chapter 4-5 Environmental DamagesLily & Ameer لى لى و أمير100% (2)

- Steel Castings, Surface Acceptance Standards, Visual ExaminationDocument3 pagesSteel Castings, Surface Acceptance Standards, Visual ExaminationRamzi BEN AHMEDNo ratings yet

- Jungo 4500Document2 pagesJungo 4500Ercan YilmazNo ratings yet

- ASTM A 494 Nickel AlloysDocument7 pagesASTM A 494 Nickel AlloysalirezaattariNo ratings yet

- 2018 Catalog Kti PDFDocument244 pages2018 Catalog Kti PDFJuan Carlos CandelarioNo ratings yet

- ISL G.I SheetDocument3 pagesISL G.I Sheetmalik hafeez0% (1)