Professional Documents

Culture Documents

GT Nexus Retail and Seasonal Demand WP

GT Nexus Retail and Seasonal Demand WP

Uploaded by

MageshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GT Nexus Retail and Seasonal Demand WP

GT Nexus Retail and Seasonal Demand WP

Uploaded by

MageshCopyright:

Available Formats

The Retailer’s Challenge

Responding Effectively to Seasonal Demand In a Global Sourcing Environment

A GT Nexus White Paper

Executive Summary

Retailers of seasonal merchandise source and manufacture most of their goods overseas. Reducing cost of

goods sold (COGS) is the primary motivation to source globally. However, a key disadvantage of global sourcing

is increased lead time and resulting lack of responsiveness to demand.

Many retailers are finding that available savings opportunities from moving to low cost sources are nearing

exhaustion. As a result, retailers are examining the demand chain, looking for ways to compress the order-to-

delivery cycle and to accelerate goods in transit to protect margins and avoid markdowns.

If the supply chain were responsive enough to allow postponing the order, manufacture, and shipment of some

goods until after the start of the selling season, a retailer could use actual market demand data to determine

store inventory and thus prevent markdowns.

Some leading retailers are working on a model that breaks the season into two segments, the “initial buy,”

based on forecasts, and the “responsive buy,” which is based on actual store sales. Success in this approach is

contingent on superior global supply chain intelligence and control, which can be achieved through a series of

key building blocks, including:

• Postponement Strategies

• Margin vs. supply chain cost analysis

• Segmentation and initial buy

• POS data analysis

• Vendor visibility

• PO to store delivery monitoring

• World-class partners

To develop the metrics and achieve the goals that drive a highly fluid, seasonal-demand-driven global sourcing

and logistics operation, an organization must adopt technologies that support a collaborative, “extra-enterprise”

solution. This integrated solution must provide visibility and tools for decision-making that can be used by all

constituents across the extended supply chain.

This white paper explores the challenges and solutions associated with creating a nimble, demand-driven

supply chain for retailers who must deal with the challenges of seasonal merchandise.

©2007 GT Nexus Inc.

2

The challenge: Betting for margin

Demand for retail products has always been seasonal. For example,

the closer you get to inherently seasonal, high-end fashion goods, the

more “perishable” those goods become in the context of market tim-

ing and ability to sell at maximum margins. This is true for other prod-

uct categories, such as outdoor goods, sports and recreation, home

improvement, and toys. All are subject to season-specific demand.

Over the past two decades, retailers of such merchandise have

gradually shifted the sourcing and manufacturing of these goods

from domestic to global factories, predominantly in Asia. The prime

motivation for this shift is substantially lower labor costs in those

regions and resulting reductions in sourcing cost (or, Cost Of Goods Sold — COGS). A well-known, but tolerated,

disadvantage of global sourcing is the increased lead-time or length of the supply chain and a resulting lack of

responsiveness to market demand.

A few high-end retailers have instituted strategies and business models that explicitly run counter to this

trend; for example, Adidas Taylor-Made is making premium golf clubs to customer order in the US, differentiat-

ing itself from the market not by price, but by rapid delivery of exclusive, custom-made merchandise. Never-

theless, the broader market is continuing the trend towards sourcing from remote, low wage countries.

For retailers in seasonal segments, this trend has gradually led to the following business practices and

challenges:

Sourcing and Product Development

Selecting vendors, working on materials and product design are activities that take a surprisingly long

time. Many retailers work with overseas partners to make these kinds of decisions between six and

twelve months before the start of the sales season. Considering that the world’s leading car manufac-

turers take just over 24 months to design and launch production of a new automobile, it is astounding

that typical apparel retailers take almost half of that time to design, source and deliver to stores the

latest cashmere sweater.

The lack of reliable demand data this early in the process creates an obvious challenge in production

planning. Much effort has been spent on improving demand forecast accuracy; yet, forecasts will inevi-

tably be substantially off this far out before actual market demand materializes.

Considering that the world’s leading car manufacturers take just over 24

months to design and launch production of a new automobile, it is astounding

that typical apparel retailers take almost half of that time to design, source and

deliver to stores the latest cashmere sweater.

©2007 GT Nexus Inc.

3

100% Make-to-Forecast

The selling “window” for seasonal items is very short. The US holidays of Halloween, Thanksgiving and

Christmas are good examples, with peak selling periods of as little as three to at most eight weeks.

The regular spring and summer apparel seasons also are measured in weeks, typically 12-15 weeks per

season, with 50-80% of the merchandise being season-specific. At the same time, lead times to order,

manufacture, ship, and distribute that same merchandise to stores can range from six to twelve weeks

for the key supplier regions of China, the Philippines, Singapore, and South America.

The common business practice resulting from supplier lead times that meet or exceed the length of the

sales window is that retailers order and ship close to, if not all, of an entire season’s merchandise well

before the beginning of the selling period. For instance, a retailer like The Gap receives 100% of its

seasonal wares into its US distribution centers at least two to three weeks before start of the season.

The challenge here is that all of this buying, down to the specific configuration of the merchandise, is

based on forecasted demand. If the buyers do not have the right instincts or short-term fashion waves

change the demand profile, there is nothing, for the entire season, that can be done to respond to new

market signals. The retailer is stuck with the product on hand.

Margin vs. Markdown

As consumers we are all familiar with — and actually

quite like — the result of this inflexibility: Sales, mark-

downs, and clearances. From the retailer’s point of

view, however, these events are very costly. Since the

supply side of the equation is fixed, the only option

the retailer has is to give up margin on slow-selling

merchandise by cutting prices. The high margin on

hot selling items becomes the source of income that

subsidizes losing items. It is not unusual to see as

little as 20-30% of merchandise sold at full margin.

The remaining goods are “pushed” into the market in

three phases: First, sales, with prices discounted to

a lower margin, then markdowns priced at cost, and The demand chain presents opportunities to compress the or-

finally clearances at a loss, simply to recover some of der to delivery cycle to protect margins and avoid markdowns.

the COGS investment and to make room for the new

season’s goods. This scenario is repeated every sea-

son, every 12-15 weeks, four to five times a year.

Today, many retailers are finding further improvements in COGS increasingly hard to realize. Price optimization,

category management and other improvements in corporate sourcing activities may hold further potential. Yet,

the available savings opportunities from moving to low cost sources are nearing exhaustion. As a result, retail-

ers are examining the demand chain, looking for ways to compress the order to delivery cycle and to accelerate

goods in transit to protect margins and avoid markdowns.

©2007 GT Nexus Inc.

4

Can global supply chains be made nimble enough for more profitable

seasonal merchandising responses?

The concept is simple. If the supply chain were responsive enough to allow postponing the order, manufacture,

and shipment of some goods, a retailer could use actual market demand data to determine store inventory

and thus prevent markdowns. A handful of retailers have successfully accomplished this feat, including Adidas

Taylor-Made, mentioned above. Another example is the European fashion retailer ZARA. However, both of these

companies market higher-end products, at higher prices. Thus, they have big enough margins to be able to

locate production close to demand. Large retailers with narrow margins, who compete for mainstream demand

and are compelled to source globally, face the greater challenge: Can they find ways to make their supply

chains nimble enough both to achieve low COGS and to preserve their margins?

The “responsive buy”allows retailers to rapidly adjust supplies based on actual demand.

Some of the leading retailers believe that they can master this art. The model they are working on breaks the

season into two segments. The first four to six weeks, the “initial buy, ” will be forecast driven as is the case

today. The second segment, the rest of the 12-15 week season, is the “responsive buy ” period, which will be

informed by actual store sales, i.e. market demand. In this period, retailers adjust the supply of merchandise to

the extent possible and sensible, considering the profit margin. This model requires the following capabilities:

Postponement

Fundamentally, overseas vendors must be able to support retailer needs to postpone the ordering

of merchandise until the latest possible moment. Sourcing decisions, design, and material selection

should be mostly unaffected, although exploring ideas popular in other industries, such as modular

design, may positively support postponement. Similarly, contracts may have to be adjusted to reflect

the additional flexibility demanded by the capability, for instance by committing buyers and vendors

to volumes at the product family, rather than the style/size/color, level. The largest challenges lie in

developing the vendor’s ability to offer short manufacturing lead times, possibly by pre-fabricating

semi-finished products that can be produced in large volumes within hours, once replenishment orders

with exact specifications come in.

©2007 GT Nexus Inc.

5

Market demand assessment

Forecast accuracy increases closer to the start of the season. Two weeks prior to season-start, forecasts

will be more accurate than they were six or even two months before. However, even two weeks out,

retailers can only forecast general levels of demand. For apparel, predicting demand at the level of color,

size, and style is error-prone even then. The ultimate postponement strategy, however, will allow the

retailer to delay re-ordering merchandise for the second segment until the season has begun and actual

store sales data is available for analysis. That data, aggregated across hundreds of stores, will allow

vastly more accurate demand prediction at the detailed specification level.

Expedited transportation

Major retailers predominantly use containerized ocean freight to import merchandise from overseas.

The much more expedient air cargo transportation mode is, on average, seven to eight times more

expensive. In effect, the retailer finds itself in a “loss-loss” situation: Using slower ocean transport saves

freight dollars, but results in margin loss due to supply-demand mismatches (product late to stores).

Using fast air transport allows postponement and thus improves the supply-demand match and pre-

serves margin, yet consumes higher freight charges and reduces the overall profitability of the goods.

The challenge for retailers is to optimize the mix between air and ocean freight; they must know which

method is costliest, depending on season, product, and region. If retailers can compare the margin

upside of reduced lead-time with the freight cost downside, they can make globally profitable post-

ponement decisions. Clearly, these decisions will vary by product, source and season.

Zero dead-time logistics

Once the retailer makes a calculated investment in expedited transportation, it becomes impera-

tive also to shrink the overall vendor-to-store lead-time. Consolidated transportation practices are

optimized for low freight cost, but not for minimal lead-time. Typically, over half of the total time goods

spend en route globally from vendor to store is spent waiting: Waiting for pickup at the vendor, waiting

for consolidation into containers, waiting for loading into airplanes or onto ships, waiting at the des-

tination airport or port, waiting for customs clearance, waiting for pickup for inland drayage to the DC,

waiting in the DC yard for receiving, waiting in the DC for allocation to a store order, for pick and pack,

and, finally, waiting for pickup by the LTL carrier for shipping to the store. A door-to-door air shipment

from a China-based vendor to a US store via DC cross docking may take 25 days, out of which 15-20 days

are non-travel time. Retailers aiming to capture extra margin through postponement and expedited

transportation must track, measure, and eliminate as much of this dead time as possible.

Cross-dock direct-to-store

The classic transportation model of retailers sourcing from overseas is via containerized ocean freight,

then by truck or rail to inland DCs. From there, goods are distributed to regional warehouses and finally

to individual stores. Again, this model has been optimized for cost efficiency, not for speed.

Retailers looking to improve their responsiveness have to carefully trade off cost efficiency against potential

margin gains. One of the more popular network design choices is to avoid inventorying goods for the late-

season. Instead, retailers task 3PLs with cross-docking incoming ocean/air freight goods directly at port of

entry and redistributing the products as smaller shipments to regional warehouses or even directly to stores.

Similarly, retailers are seeking to consolidate at origin according to final destination (not DC), to improve

logistics flows and minimize dead time.

©2007 GT Nexus Inc.

6

Nimbleness through global supply chain intelligence and control

Retailers working on implementing responsive global supply chains are reinventing many areas of their busi-

ness. Many processes cry out for adjustments, some minor and some more involved. The most critical changes

or new capabilities are the ones listed below. Clearly, hitting every point on this list does not guarantee suc-

cess, but these are some of the key building blocks:

Postponement Strategies

The critical prerequisite for an organization to engage

“Postponement, especially across a

in any form of postponement strategy is the ability to

global supply chain, requires high lev-

produce standardized products and to delay product cus-

els of data accuracy, as well as near-real

tomization to the optimal point in the supply chain. Once

time information sharing. Fundamen-

an organization’s products accommodate manufacturing

tal to successful implementation of

standardization and deferred customization, it is essen-

postponement is supply chain visibility,

tial to modify business processes to encourage adoption

thought of as “an up-to-the-event

of postponement strategies. Such modifications include

view” of each node in the continuum

instituting goals, metrics, and targets that support

bridging orders and delivery. Critical

increasingly necessary and complex product collaboration

to visibility is the physical logistics

from order design, raw materials sourcing and manufac-

network, technology deployed for

turing processing. To this end, executive support is vital to

product identification and tracking, and

successful postponement implementations.

systems that manage resource alloca-

Additionally, to make effective use of the new goals,

tion and material flow.”

metrics, and targets, an organization must adopt tech-

nologies that support an extra-enterprise, integrated, Manufacturing Systems Magazine, 4/04

web-based solution capable of facilitating collaboration

and real-time visibility across the extended supply chain.

Margin vs. supply chain cost analysis

Perhaps the most difficult piece of the postponement strategy puzzle is obtaining the reliable infor-

mation needed to help retailers segment their product portfolio and decide where and when to use

demand-driven replenishment. Careful analysis of historical forecast and sales actuals, price points,

discounts, and margins will be required in order to determine which products offer sufficient margin

upside. Likewise, developing the cost vs. margin-loss trade-off requires an analysis of freight cost,

landed cost and delivered-at-store cost by product, depending on mode of transport and routing.

Segmentation and initial buy

Retailers can select products for demand-driven replenishment based on the segmentation and margin

analysis. Sizing the initial buy by product and setting the time windows and lot sizes for demand-driven

replenishment are other crucial parts of creating an optimal solution.

©2007 GT Nexus Inc.

7

POS data analysis

Once the season has begun, retailers require detailed POS (point of sale) data across their various

stores and wholesale channels in order to determine actual market demand. Retailers who own their

own stores are typically in a better position to gather this data than are those who sell through chan-

nels (e.g. department stores). These channel-focused retailers traditionally find it harder to obtain

the same data as store owners, at the same level of detail, within a timeframe that allows re-ordering.

Having the right tool to analyze the vast quantity of POS data is the other key ingredient needed to

determine actual demand. Typically, the sheer volume of this data far exceeds the capacity of the

world’s most popular planning tool, Microsoft Excel.

Vendor visibility

The vendor plays a very important role in the success of the model; the chance for failure is probably

highest at the vendor. Yet this responsibility is new and is complicated by the fact that the vendor is an

ocean or a continent, at least one language, and many time zones away. Hence, retailers will have to

put in place processes, metrics, and systems to gain visibility into vendor performance and to provide

advanced warning of exceptions. For instance, on-line visibility into the inventory of semi-finished

products at vendors, into daily production actuals, and into booking and shipment volumes by product

are among the many data points retailers must monitor closely in order to guarantee success.

PO-to-Store delivery monitoring

Once goods have left the vendor’s factory, the fight against “dead-time” begins. As every day that

passes erodes profit margin, retailers cannot afford to rely on their transportation and 3PL partners to

deliver minimal dead-time. Visibility from vendor pickup to store delivery — across many carriers, 3PLs,

and internal warehouse locations — becomes the single source of truth and metric of success for the

retailer and all of its partners. Beyond tracking shipments against anticipated cycle times, the visibility

platform also gathers the logistics cost data elements required for the landed cost analysis described

earlier in this paper.

World-class partners

Finally, the goal of “zero dead-time” can only be accomplished by involving world-class partners.

The retailer must utilize the value-added services provided by both carrier and 3PL partners with this

overall goal in mind. Express service by carriers, in-transit customs clearance, cross-docking at port of

entry, and multi-stop TL service from cross-dock to store are just a few of the options available. Gaining

visibility across the performance of partners and the costs of their service offerings is essential to drive

continuous improvement along a set of well-defined, shared metrics.

©2007 GT Nexus Inc.

8

Conclusion

Implementing responsive global supply chains that can successfully deliver high-revenue, high-margin per-

formance for time sensitive seasonal products is one of the most difficult management tasks facing retailers

today. This hurdle is not insurmountable, but does require that fundamental elements of the organization

adapt to new capabilities and new realities. Needed changes include:

Employee culture management: Operating as a business that responds rapidly to changing demand

and short fulfillment cycles requires that employees learn to work in a highly collaborative, efficient,

time-compressed environment. The silo-based mentality (I work for purchasing; I work for merchandis-

ing; I work for logistics; I work for finance) that pervades many retail organizations today needs to be

re-oriented to team-based performance, where information is shared, decisions are made and executed

quickly, and responsibility is placed as close to the work as possible. To incent proper behavior and

motivate individual action toward team goals, compensation systems must reward individuals based on

achieving stated team goals for supply chain performance, revenue and profit. This is the way to build a

culture of collaboration and responsibility for shared goals across the organization.

Business process change management: As outlined throughout this paper, there are many opportu-

nities for retailers to adopt strategies to successfully manage seasonal demand while sourcing globally.

These business initiatives can be adopted incrementally in the sequence that best fits the retailer’s

needs. Yet organizations run the risk of failure unless process change is managed aggressively, with

commitment. Without strong leadership, the workforce will fall back on past practices that won’t rise

to meet the new challenges of demand-driven seasonal global sourcing and logistics. New business

processes must be founded on an understanding of the new global market in which the company now

operates. In order for them to be successfully implemented, employees must be trained to develop an

understanding of how these processes influence and guide their everyday jobs.

Technology change management: Technology enables an organization to accomplish business goals

more effectively and to operate more efficiently. However, the choice of technology, how it is applied, and

how pervasively it becomes institutionalized will be the true determinant of success. To support the goals

and metrics that drive a highly fluid, seasonal-demand-driven global sourcing and logistics operation,

an organization must adopt technologies that support a collaborative, “extra-enterprise” integrated

solution capable of providing visibility and decision-making tools across the extended supply chain.

On-demand, web-based systems are emerging as the technology of choice to meet these requirements.

These systems are integration-centric; by design they receive and send information from a multitude

of partner platforms. They provide a central data repository with an “up to the event” view of products

as they proceed through the demand chain, from order placement at the factory, to tendering with the

carrier, through cross-border transportation, to delivery. This new class of technologies is built first and

foremost with the user in mind and is designed for rapid training and ease of use. This visibility system,

appearing at first glance to be tactical, is the foundation of a strategic technology platform. This platform

becomes the single source of truth and the basis for a common workflow system on which all partners in

the demand-driven seasonal supply chain perform their tasks with powerful applications.

With world class partners, an effective Web-based collaborative global visibility and control system, and a

workforce motivated and trained for the rigors of the global market, organizations can prosper in this ever-

more-competitive world of globally-sourced seasonal products.

©2007 GT Nexus Inc.

9

GT Nexus, Inc.

Alameda, CA 94501

ph: 510.747.3200

email: information@gtnexus.com

www.gtnexus.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Business Plan: Silver Bear LodgeDocument28 pagesBusiness Plan: Silver Bear LodgeVaibhav AgarwalNo ratings yet

- Chapter 5 Statement of Changes in EquityDocument4 pagesChapter 5 Statement of Changes in Equityellyzamae quiraoNo ratings yet

- IJCRT2306544Document7 pagesIJCRT2306544shahidafzalsyedNo ratings yet

- 2021 - PJM - L - 2 - 1627735738763-Project ManagementDocument67 pages2021 - PJM - L - 2 - 1627735738763-Project ManagementKumar AbhishekNo ratings yet

- Apk ReportDocument31 pagesApk ReportRed0123100% (3)

- Assignment 7Document25 pagesAssignment 7asif2022coursesNo ratings yet

- PitchdeckDocument25 pagesPitchdeckm_vamshikrishna22No ratings yet

- Strategic and Marketing PlanningDocument5 pagesStrategic and Marketing PlanningMuhammad FaizanNo ratings yet

- Quiz 03 Name: - Score: - Rating: - Problem 01Document3 pagesQuiz 03 Name: - Score: - Rating: - Problem 01Jom BuddyNo ratings yet

- Solent Capabilities DeckDocument21 pagesSolent Capabilities DecksiddhmayekarNo ratings yet

- 1 s2.0 S0967070X23003049 MainDocument17 pages1 s2.0 S0967070X23003049 MainAmin AminiNo ratings yet

- Filipino Style Sushi: The Business Concept and The Business ModelDocument5 pagesFilipino Style Sushi: The Business Concept and The Business ModelkathleenNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument17 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePrasanta BarmanNo ratings yet

- (Drnancyli - Com) Top 50 Real-Life FAANG PM Interview QuestionsDocument5 pages(Drnancyli - Com) Top 50 Real-Life FAANG PM Interview QuestionsMilanaNo ratings yet

- Valencia CF Business Plan and Financial Valuation: Facultad de Ciencias EconomicasDocument45 pagesValencia CF Business Plan and Financial Valuation: Facultad de Ciencias EconomicasHarsh BhatNo ratings yet

- 2022 - 09 - Strategy Making in Turbulent TimesDocument11 pages2022 - 09 - Strategy Making in Turbulent TimesEduardo Garza GarzaNo ratings yet

- Mind The Gap: Deloitte Digital Maturity Survey Insights For The Belgian Retail Banking MarketDocument16 pagesMind The Gap: Deloitte Digital Maturity Survey Insights For The Belgian Retail Banking MarketAytaç DemirNo ratings yet

- C11 - C12 - C13 - MEE2014 - Engineering Design and ModellingDocument1 pageC11 - C12 - C13 - MEE2014 - Engineering Design and Modellingtrash emailNo ratings yet

- Adfactor PR BrochureDocument1 pageAdfactor PR BrochureMohammed HaveliwalaNo ratings yet

- A Study On Consumer Buying Behaviour of Dairy Product With Special Reference To Chikhli TalukaDocument7 pagesA Study On Consumer Buying Behaviour of Dairy Product With Special Reference To Chikhli TalukaSimran GuptaNo ratings yet

- Cash Conversion Cycle and Its Impact On Profitability of Auto Mobile SectorDocument124 pagesCash Conversion Cycle and Its Impact On Profitability of Auto Mobile SectorAli HamzaNo ratings yet

- Class Notes Capital Rationing Sir Saud Tariq ST AcademyDocument13 pagesClass Notes Capital Rationing Sir Saud Tariq ST AcademyAhmed NisarNo ratings yet

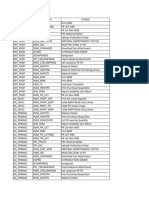

- User Tcode ZDocument108 pagesUser Tcode ZSetiady Perwira JatiNo ratings yet

- AA AQB - Slattery Co - QuestionDocument2 pagesAA AQB - Slattery Co - Question21073141No ratings yet

- Event Planning ChecklistDocument4 pagesEvent Planning ChecklistJuno LeeNo ratings yet

- LL IFAD Inclusive Rural and Agricultural Finance Experiments in West and Central Africa During The Last Decade 2009 2020 1Document56 pagesLL IFAD Inclusive Rural and Agricultural Finance Experiments in West and Central Africa During The Last Decade 2009 2020 1amir mahmudNo ratings yet

- Socio-Ecological Problems: Green Marketing Management DMA 557Document24 pagesSocio-Ecological Problems: Green Marketing Management DMA 557eklwgnnwlgNo ratings yet

- BASTRCSX Module 1 Self-Test Managerial Accounting and Business EnvironmentDocument3 pagesBASTRCSX Module 1 Self-Test Managerial Accounting and Business EnvironmentlcNo ratings yet

- MamataPATHAK M2MIB IAENice InternshipReportofBusinessDevelopmentinEducationConsultancyforAbroadStudyDocument71 pagesMamataPATHAK M2MIB IAENice InternshipReportofBusinessDevelopmentinEducationConsultancyforAbroadStudysrstychaliseNo ratings yet

- Lecture 08 Self-Assessment Exercise - AdditionalDocument3 pagesLecture 08 Self-Assessment Exercise - Additionalasfasf sfaNo ratings yet