Professional Documents

Culture Documents

Impressions in Implant Dentistry - A Review: April 2015

Impressions in Implant Dentistry - A Review: April 2015

Uploaded by

Riya KvCopyright:

Available Formats

You might also like

- Creating Cross Platform C Applications With Uno 1801078491 9781801078498 CompressDocument258 pagesCreating Cross Platform C Applications With Uno 1801078491 9781801078498 Compresscan ipek100% (1)

- Wpa PaperDocument12 pagesWpa Paperkhairul ezwan100% (1)

- Dental Implant Impression Techniques: Revisited: European Journal Pharmaceutical and Medical Research February 2021Document7 pagesDental Implant Impression Techniques: Revisited: European Journal Pharmaceutical and Medical Research February 2021Elizabeth Vicencio AstudilloNo ratings yet

- Oral Implantology: ImplantsDocument52 pagesOral Implantology: ImplantsDabala Harish Reddy100% (6)

- Indirect Orthodontic Bonding - A Modified Technique For Improved Efficiency and PrecisionDocument10 pagesIndirect Orthodontic Bonding - A Modified Technique For Improved Efficiency and PrecisionSimon SitumorangNo ratings yet

- Implant Prosthetic DentistryDocument86 pagesImplant Prosthetic DentistryAnirban MallikNo ratings yet

- EJMCM - Volume 7 - Issue 4 - Pages 1689-1693Document5 pagesEJMCM - Volume 7 - Issue 4 - Pages 1689-1693Tanushree JainNo ratings yet

- 5 Implant ProstheticsDocument3 pages5 Implant ProstheticsFifth Year Dentistry ZUNo ratings yet

- Dental Implants and Dentures: Open Access: Computer Guided Implantology: For Optimal Implant PlanningDocument4 pagesDental Implants and Dentures: Open Access: Computer Guided Implantology: For Optimal Implant PlanningFiru LgsNo ratings yet

- Micro-Implants For Orthodontic Anchorage: A Review: July 2013Document6 pagesMicro-Implants For Orthodontic Anchorage: A Review: July 2013Vijay ChinthaNo ratings yet

- Implant ImpressionsDocument7 pagesImplant ImpressionsAnjana ThomasNo ratings yet

- Specops Jiacd 20090708Document88 pagesSpecops Jiacd 20090708Mario AdánNo ratings yet

- Various Treatment Modalities For Retrieval of Broken Abutment Screw in Implant ProsthodonticsDocument6 pagesVarious Treatment Modalities For Retrieval of Broken Abutment Screw in Implant Prosthodonticsrood_kNo ratings yet

- March 2019 1551512385 344Document4 pagesMarch 2019 1551512385 344Faisal hayatNo ratings yet

- Article-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330Document3 pagesArticle-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330saia windaNo ratings yet

- 2176 9451 Dpjo 25 04 85Document16 pages2176 9451 Dpjo 25 04 85prodontiaslpNo ratings yet

- Author's Accepted ManuscriptDocument22 pagesAuthor's Accepted Manuscriptlingual courseNo ratings yet

- Radiographic Stents and Surgical Stents in ImplantDocument6 pagesRadiographic Stents and Surgical Stents in Implantkavya ravuriNo ratings yet

- Clear Aligner Therapy - New Vistas in OrthodonticsDocument5 pagesClear Aligner Therapy - New Vistas in OrthodonticsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Litreture Review 5Document6 pagesLitreture Review 5Daniel AtiehNo ratings yet

- Implant Impression TechniquesDocument54 pagesImplant Impression TechniquesSupriya ShuklaNo ratings yet

- Author's Accepted Manuscript: Seminars inDocument77 pagesAuthor's Accepted Manuscript: Seminars innhasuonlineNo ratings yet

- 1 - Best - Immediate - Implant - PlacementDocument13 pages1 - Best - Immediate - Implant - PlacementMostafa El GendyNo ratings yet

- Thesis On Zygomatic ImplantsDocument4 pagesThesis On Zygomatic Implantskimberlypattersoncoloradosprings100% (2)

- Decision Making ImplantDocument2 pagesDecision Making Implant김문규No ratings yet

- Windowimpressiontechnique 2018Document5 pagesWindowimpressiontechnique 2018Winda KhosasiNo ratings yet

- Immediate Implant Placement in MaxillarDocument7 pagesImmediate Implant Placement in MaxillarrtyNo ratings yet

- Impression Techniques in Implant Dentistry: Susanna S Brainerd, Dr. Bindu R NayarDocument12 pagesImpression Techniques in Implant Dentistry: Susanna S Brainerd, Dr. Bindu R NayarMaqbul AlamNo ratings yet

- Endodontology 3: RootsDocument44 pagesEndodontology 3: RootsCarlos San MartinNo ratings yet

- Preoperative View of A DiastemaDocument6 pagesPreoperative View of A Diastemaulfa rizalniNo ratings yet

- The Notion of Platform-Switching in Implants A RevDocument8 pagesThe Notion of Platform-Switching in Implants A RevChifa MusrataNo ratings yet

- Dental Implant Site Preparation - A Review: C.J.Venkatakrishnan, S.Bhuminathan and Chitraa.R.ChandranDocument4 pagesDental Implant Site Preparation - A Review: C.J.Venkatakrishnan, S.Bhuminathan and Chitraa.R.ChandranLouis HutahaeanNo ratings yet

- History of AlignersDocument8 pagesHistory of AlignersAssem GamalNo ratings yet

- Thesis Topics On Dental ImplantsDocument4 pagesThesis Topics On Dental Implantsgbwwdfq5100% (2)

- Implant Supported OverdentureDocument5 pagesImplant Supported OverdentureFadil ObiNo ratings yet

- Prosthetic Management of Implants Placed With The Socket-Shield TechniqueDocument6 pagesProsthetic Management of Implants Placed With The Socket-Shield TechniqueSofia LondoñoNo ratings yet

- ThesisDocument13 pagesThesisvadianonymousNo ratings yet

- Inconsiderate Try in of Complete Denture ProsthesiDocument5 pagesInconsiderate Try in of Complete Denture Prosthesitaqia zulfaNo ratings yet

- Implant PPT Phase 2 Aseptico ImplantDocument63 pagesImplant PPT Phase 2 Aseptico Implantapi-152953067No ratings yet

- Entrevista IngDocument3 pagesEntrevista IngmedicalcenterNo ratings yet

- ReviewDocument4 pagesReviewSonali KinikarNo ratings yet

- Review PDFDocument4 pagesReview PDFSonali KinikarNo ratings yet

- Clear Aligners, A Milestone in Invisible Orthodontics - A Literature ReviewDocument4 pagesClear Aligners, A Milestone in Invisible Orthodontics - A Literature ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Stage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresDocument5 pagesStage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresasclepiuspdfsNo ratings yet

- Introduction To Dental Implants 2017 PDFDocument61 pagesIntroduction To Dental Implants 2017 PDFChong Weng Wah100% (2)

- Published Immediate ImplantDocument6 pagesPublished Immediate Implantshayma rafatNo ratings yet

- 01.2023 ECD IV IMPLANT PortfolioDocument24 pages01.2023 ECD IV IMPLANT Portfolioksan040114No ratings yet

- QSD Tapered Implant Manual Art939BDocument24 pagesQSD Tapered Implant Manual Art939BkhashmiraNo ratings yet

- Factors Affecting The Clinical Success of Screw Mplants Used As Orthodontic AnchorageDocument8 pagesFactors Affecting The Clinical Success of Screw Mplants Used As Orthodontic AnchorageDraganita AdnanaNo ratings yet

- Free Hand Vs Guided Implant SurgeryDocument5 pagesFree Hand Vs Guided Implant SurgeryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Roots 2009Document52 pagesRoots 2009betoweb1No ratings yet

- Mini Implantes en Ortodoncia .Document9 pagesMini Implantes en Ortodoncia .erika de andradeNo ratings yet

- Good Occlusal Practice in The Provision of Implant Borne ProsthesesDocument10 pagesGood Occlusal Practice in The Provision of Implant Borne ProsthesesNoland NaidooNo ratings yet

- The Orthodontic Mini-Implants Failures Based On Patient Outcomes: Systematic ReviewDocument13 pagesThe Orthodontic Mini-Implants Failures Based On Patient Outcomes: Systematic ReviewKristin HalimNo ratings yet

- Invisible Aligners - Is It The Future of OrthodonticsDocument4 pagesInvisible Aligners - Is It The Future of OrthodonticsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Article: © The Author(s), Under Exclusive Licence To British Dental Association 2023Document9 pagesArticle: © The Author(s), Under Exclusive Licence To British Dental Association 2023DANTE DELEGUERYNo ratings yet

- Rcs 2115Document21 pagesRcs 2115Kim Chi NguyễnNo ratings yet

- Prosthodontic Perspective To All-On-4 Concept For Dental ImplantsDocument4 pagesProsthodontic Perspective To All-On-4 Concept For Dental Implantsprostho booksNo ratings yet

- JOHCD-Maintenance of Implant SupportedDocument3 pagesJOHCD-Maintenance of Implant SupportedManoj HumagainNo ratings yet

- 1 s2.0 S0889540616001955 MainDocument9 pages1 s2.0 S0889540616001955 MainPanaite TinelaNo ratings yet

- Partial Extraction Therapy in Implant DentistryFrom EverandPartial Extraction Therapy in Implant DentistryUdatta KherNo ratings yet

- Dental Implant Treatment Planning for New Dentists Starting Implant TherapyFrom EverandDental Implant Treatment Planning for New Dentists Starting Implant TherapyRating: 4 out of 5 stars4/5 (1)

- Impression TraysDocument2 pagesImpression TraysRiya KvNo ratings yet

- Gypsum ProductsDocument23 pagesGypsum ProductsRiya KvNo ratings yet

- Anatomical LandmarksDocument6 pagesAnatomical LandmarksRiya KvNo ratings yet

- Desigining Crown Contour in Fixed Prosthodontics: A Neglected ArenaDocument7 pagesDesigining Crown Contour in Fixed Prosthodontics: A Neglected ArenaRiya KvNo ratings yet

- Chronology of Human DentitionDocument1 pageChronology of Human DentitionRiya KvNo ratings yet

- Ag-Ab Reactions Tests For Ag-Ab ReactionsDocument36 pagesAg-Ab Reactions Tests For Ag-Ab ReactionsRiya KvNo ratings yet

- Gingival Crevicular Fluid: S.Lakshmi Ajithan 3 BDS Roll No:44Document57 pagesGingival Crevicular Fluid: S.Lakshmi Ajithan 3 BDS Roll No:44Riya KvNo ratings yet

- Screw Versus Cemented Implant Supported RestoratioDocument8 pagesScrew Versus Cemented Implant Supported RestoratioRiya KvNo ratings yet

- Study of Surface Hardness of Gypsum Casts Made With Slurry Water: An in Vitro StudyDocument4 pagesStudy of Surface Hardness of Gypsum Casts Made With Slurry Water: An in Vitro StudyRiya KvNo ratings yet

- ProsthokrantiDocument8 pagesProsthokrantiRiya KvNo ratings yet

- A Review On The Human Oral MicrofloraDocument5 pagesA Review On The Human Oral MicrofloraRiya KvNo ratings yet

- Management of Flabby Ridge Cases: A Challenge in Clinical PracticeDocument6 pagesManagement of Flabby Ridge Cases: A Challenge in Clinical PracticeRiya KvNo ratings yet

- Dental Impant MaterialsDocument6 pagesDental Impant MaterialsRiya KvNo ratings yet

- Prosthetic Management of Implants Placed With The Socket-Shield TechniqueDocument5 pagesProsthetic Management of Implants Placed With The Socket-Shield TechniqueRiya KvNo ratings yet

- Occlusal Splint Therapy-Review Article: March 2013Document12 pagesOcclusal Splint Therapy-Review Article: March 2013Riya KvNo ratings yet

- Development of JawDocument47 pagesDevelopment of JawRiya KvNo ratings yet

- Biomimetic Materials: A ReviewDocument11 pagesBiomimetic Materials: A ReviewRiya KvNo ratings yet

- Paper 1Document7 pagesPaper 1Riya KvNo ratings yet

- Sleep Apnoea and ManagementDocument1 pageSleep Apnoea and ManagementRiya KvNo ratings yet

- 3D Printing in Prosthodontics: Additive Manufacturing TechnologyDocument6 pages3D Printing in Prosthodontics: Additive Manufacturing TechnologyRiya KvNo ratings yet

- A New Peripheral Tracing Material For Mandibular Complete Denture ImpressionDocument5 pagesA New Peripheral Tracing Material For Mandibular Complete Denture ImpressionRiya KvNo ratings yet

- NutritionDocument6 pagesNutritionRiya KvNo ratings yet

- Ethics in Esthetics PDFDocument3 pagesEthics in Esthetics PDFRiya KvNo ratings yet

- Short Clinical CrownsDocument7 pagesShort Clinical CrownsRiya KvNo ratings yet

- JC Article 1Document5 pagesJC Article 1Riya KvNo ratings yet

- Anterior Dental Aesthetics: Dental Perspective: British Dental Journal September 2005Document7 pagesAnterior Dental Aesthetics: Dental Perspective: British Dental Journal September 2005Riya KvNo ratings yet

- Camera ConfidenceDocument13 pagesCamera ConfidenceCont ReadNo ratings yet

- BT08 PDFDocument4 pagesBT08 PDFAfdhalNo ratings yet

- CVPDocument20 pagesCVPThomas K. AddaiNo ratings yet

- Learning & Development Activity Enrollment Form: Employee-Applicant DataDocument17 pagesLearning & Development Activity Enrollment Form: Employee-Applicant DataEvelyn dela CruzNo ratings yet

- Catalogo Vidrio Mobicell DistribuidorDocument3 pagesCatalogo Vidrio Mobicell DistribuidorANTHONY SANCHEZNo ratings yet

- Plaintiffs' Motion For Entry of JudgmentDocument14 pagesPlaintiffs' Motion For Entry of JudgmentBen SheffnerNo ratings yet

- Sample Assignment 1-1Document20 pagesSample Assignment 1-1Nir IslamNo ratings yet

- Data Compression (RCS 087)Document51 pagesData Compression (RCS 087)sakshi mishraNo ratings yet

- Aa - Moneyback20 - 29-10-2023 8.59.34Document6 pagesAa - Moneyback20 - 29-10-2023 8.59.34do.yogeshaNo ratings yet

- Week1 CombineDocument91 pagesWeek1 CombineraleyNo ratings yet

- EN Quick Reference Guide Fabian HFOi-V4.0Document30 pagesEN Quick Reference Guide Fabian HFOi-V4.0Tanzimul IslamNo ratings yet

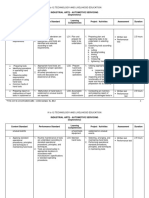

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- CURVESDocument30 pagesCURVESPHULARAM PEGUNo ratings yet

- Happy Ladies and GentlemanDocument2 pagesHappy Ladies and GentlemanLalufathirNo ratings yet

- A Guide To The Management of Tuberculosis in Patients With Chronic Liver DiseaseDocument12 pagesA Guide To The Management of Tuberculosis in Patients With Chronic Liver DiseaseMeldaNo ratings yet

- Structural Developments: Inland Waterway Towboats and BargesDocument8 pagesStructural Developments: Inland Waterway Towboats and BargesEd UrquizaNo ratings yet

- Sony Hcd-Bx6av Dx6avDocument64 pagesSony Hcd-Bx6av Dx6avFrancisco ParedesNo ratings yet

- MA 231 MATHEMATICS III 2006 Question PaperDocument3 pagesMA 231 MATHEMATICS III 2006 Question Paperyasin muhamedNo ratings yet

- Class 9 Science Worksheet - Matter in Our Surroundings - 1Document2 pagesClass 9 Science Worksheet - Matter in Our Surroundings - 1Sumedha Thakur100% (1)

- Alternative Disposal of Polystyrene Fish BoxesDocument2 pagesAlternative Disposal of Polystyrene Fish Boxesهزاع الفارسNo ratings yet

- Chapter 3Document10 pagesChapter 3Adrian LohNo ratings yet

- Introduction To Spread Spectrum CommunicationDocument7 pagesIntroduction To Spread Spectrum CommunicationAli KashiNo ratings yet

- National War Memorial - Urban DesignDocument15 pagesNational War Memorial - Urban DesignRoopendraKumarNo ratings yet

- Acmepacket4500 InstallationDocument112 pagesAcmepacket4500 InstallationfujiNo ratings yet

- G9 Brand StoryDocument34 pagesG9 Brand StoryBaghiuNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingIshwarNo ratings yet

- Guide: Daily ReferenceDocument8 pagesGuide: Daily ReferenceGalina TodorovaNo ratings yet

- Waterstop Catalog 0411Document12 pagesWaterstop Catalog 0411hks1209No ratings yet

Impressions in Implant Dentistry - A Review: April 2015

Impressions in Implant Dentistry - A Review: April 2015

Uploaded by

Riya KvOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impressions in Implant Dentistry - A Review: April 2015

Impressions in Implant Dentistry - A Review: April 2015

Uploaded by

Riya KvCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/277306370

IMPRESSIONS IN IMPLANT DENTISTRY – A REVIEW

Article · April 2015

CITATION READS

1 2,493

1 author:

Suryakant C Deogade

Government Dental College And Hospital Nagpur

80 PUBLICATIONS 296 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

prosthetic status and need View project

Dental prosthesis View project

All content following this page was uploaded by Suryakant C Deogade on 11 August 2015.

The user has requested enhancement of the downloaded file.

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

Available online at www.ordoneardentistrylibrary.org ISSN 2249-488X

Review – report

INTERNATIONAL JOURNAL OF RESEARCH IN DENTISTRY

IMPRESSIONS IN IMPLANT DENTISTRY – A REVIEW.

Dr Sumathi K*1 Dr Sneha S Mantri , Dr Suryakant C Deogade

Hitkarini Dental College & Hospital, Jabalpur.

Received: 7 Feb 2015; Revised: 5 Mar. 2015; Accepted: 2 Apr 2015; Available online: 5 May 2015

ABSTRACT

Dental implants have provided an alternative treatment option after the popularity of the concept of osseointegration. There

are numerous options available to the implantologist in relation to different impression techniques and materials available for

impression making. Implant impression accuracy is one area of ongoing research and development to improve the success of

the implant prosthesis. The various impression techniques and parameters affecting the accuracy of implant impression is

reviewed in this article

Key words

Direct technique, indirect technique, Snap fit, Mira tray, G-Cuff TM, digital impression

INTRODUCTION

Modern implantology has lit up the lives of million individuals across the world. The objective of impression

making in implant dentistry is to relate the coronal portion of the implant to other structures of oral cavity.

Achieving passive adaptation is one of the most important biomechanical purposes in prosthetic treatment based

on implant.1,2,3 Misfiting of the prosthesis may lead to mechanical and biological complications, mechanical

complication includes loosening , bending or fracture of implant or prosthetic components and biological

complication may affect the osseointegration by loading above the physiologic tolerance level. Recording the

three dimensional orientation of the implant as in the oral cavity is the critical aspect than reproducing the

surface detail in impression making.4 This article outlines the various impression techniques in implant

dentistry.

Precautions before impression making

A radiograph is made to confirm the level of seating of impression coping/abutment to the implant fixture.

Using vinyl glove instead of latex glove which retards the setting of the poly vinyl siloxane impression

material.2

22 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

Implant impression are classified as

Implant impression

Conventional Digital

Chair side Laboratory Centralized

Production production production

At the time of surgical After the fixture placement

placement of fixture

Bone indexing

WithTray With Jig Based on level of impression Based on coping

Implant level Abutment level

Transfer Pick-up Splinting

Conventional method to record the implant position includes either at the time of surgical placement of fixture

or after osseointegration is achieved.

Implant Indexing

Implant Indexing is a method in which impression is made at the time of surgical placement. This allows for the

preparation of an abutment and provisional crown placement for one stage procedure or the provisional crown is

inserted instead of healing abutment at the time of exposure in two stage implant procedure. It is of two types:

tray technique and jig technique.5

Tray technique

The pick- up coping is recommended to minimize the amount of force loaded onto the newly placed implant

using a traditional tray.

23 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

Jig technique

Prior to surgery a jig is fabricated to avoid using the impression material while the surgical flap is opened. An

acrylic splint including 3-4 adjacent teeth should be fabricated on a diagnostic cast. Space is created in the jig

for the future impression coping. After surgical placement of implant fixture, place the pick- up coping. A cold

sterilized jig is positioned in the mouth. Relate the coping to the jig using liquid acrylic or Triad gel. Make sure

that the coping screw rotates freely and the undercut is not blocked. The acrylic or gel can be cured now.

Release the coping screw and free the splint with the abutment in it. Release space in the stone cast to

accommodate the implant analog. Position the jig and attached analog. Pour the stone and remove the jig once

the stone is set. The implant is indexed onto the model.

Transfer or Indirect technique

The copings are connected to the implants, and an impression is made and separated from the mouth, leaving

the copings intraorally. The copings are removed and connected to the implant analogs, and then the coping-

analog assemblies are reinserted in the impression before fabricating the definitive cast. A tapered coping

facilitates the use of a closed tray or indirect technique.3,4,6,7,8

Pick-up or Direct technique

In Pick up impression technique, impression coping is removed from the mouth together with the set

impression. A conventional alginate impression is made and rigid custom tray is fabricated with a window cut

through over the implant region to gain access to the retaining screw to allow release of the screw prior to

removal of the impression coping — impression assembly, the analogues are attached to the impression copings

while they are embedded in the impression tray. After removing the healing abutment, the selected impression

coping is fitted and the tray is tried in. A square coping is required for open tray to allow the coronal ends of the

impression coping screw to be exposed and the technique is therefore the direct technique.3,4,6,7,8

Snap-fit (press fit) plastic impression coping

This technique does not require an open tray, but instead uses a closed tray. The press-fit impression coping is

connected to the implant by pressing instead of screwing and the plastic impression copings are picked up in the

impression.

Advantages

1. Helps to overcome the movement of impression coping inside the impression material

2. Time saving

3. used in both the open and closed tray implant impression techniques

4. more comfortable for both the clinician and the patient

The snap-fit technique may be a reliable impression making technique but regarding accuracy of this technique

none of the study is available for investigation.9

24 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

Splint Technique

The underlying principle of splinting was to connect all the impression copings together using a rigid material

to prevent individual coping movement during the impression making. 10 Assif et al and Naconey et al showed

that splinting technique was significantly more accurate than unsplinting technique.11,12 Other studies showed

that splinting may provide stabilization of transfer coping against torque from analogue tightening and reduce

rotational freedom within resilient impression material. The materials used to splint copings are auto

polymerizing acrylic resin, dual polymerizing acrylic resin and impression plaster.13

Even though auto polymerizing acrylic has been reported to be the material of choice, it has some

disadvantages like distortion of splint materials , fracture of connection between splint material and impression

copings 14, bulk shrinkage caused by long splinting might cause considerable distortion.15 Light cured acrylic

resin is less accurate as compared to auto polymerizing acrylic resin and impression plaster. Assif et al has

stated that the reason for this could be shrinkage during polymerization of the light cured acrylic resin creates

stresses at the impression coping / acrylic resin interface. The intensity and direction of the light source may

have a negative influence on the adaptation of the resin to the coping.16

The advantages of impression plaster includes rapid setting, quite accurate ,rigid, easy to manipulate, less time

consuming ,economical and exothermic reaction is negligible.17 Disadvantages of impression plaster is that it

can be used only in completely edentulous patients in whom there are no anatomic limits like undercuts.16

Implant-level technique

Implant level impression involves placing an implant analog that mimics the implant on the stone model. It is

designed to transfer the soft tissue profile as well as the implant's position and hex orientation. This can be done

by using both open and closed tray.

Abutment level technique

Abutment level impression involves placing an abutment analog that mimics the abutment.

Recent advance in impression tray

The Mira tray developed by Hager is the recent advance to overcome the difficulties in an open tray

technique.18 The tray comes with unique design and available in three sizes. The transparent foil in the occlusal

surface helps in identifying the head of the pins intra orally. The loaded impression tray is inserted and pressed

apically; the pins pierce the film and capture the impression more easily. Once the material is set, the pins are

rotated counter clock wise to remove the tray intra orally. This tray can be used in all situations whether the

arch is partially or completely edentulous.

Gingival retraction

The aim of gingival retraction is to allow the impression material to create space for the impression material in

order to provide sufficient thickness of impression material to withstand the tearing force while retrieving the

impression.19 Bennani discussed various gingival retraction methods in teeth and implant and concluded that

25 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

there is no existing device or method to retract gingiva that can be used for direct impression of the implant

abutment.20

The support provided by the peri- implant fiber is not the same as the peridental structure; therefore it may not

be able to prevent the collapse of retracted tissues as compared to peridental tissues. Hence it is difficult to

make accurate impression in implant dentistry.21

To overcome this a Canadian company, Stomatotech, came up with a simple idea to retract the gingival tissue

using a disposable plastic collar The main purpose of the G-CuffTM system is to support the soft tissue that

surrounds the dental implant abutments allowing the impression means (conventional or digital) to access to the

surface of the abutment. It is inserted on the apical end of the abutment before the abutment is engaged to the

implant.22 Following the abutment’s engagement to the implant, the plastic collar is found between the apical

part of the abutment and the gingival soft tissue. Shortly after the removal of the impression from the mouth, the

plastic collar is pulled out and removed permanently. The plastic collar creates a perfect gingival retraction with

a valve factor preventing the liquids from contaminating the area of the finish line of the abutment.

Benefits of G-CuffTM

1. simple, more reliable, economical

2. compatible with most of the existing dental implant brands

3 .impression can be made with either “open tray” or “close tray”

4. Due to the significant shortening of the lab procedure the risk of impression distortion is dramatically

lowered.

5. Eliminates the need of the materials such as: Impression Copings, Implant Analogs, Temporary Abutments

and Custom Impression Trays.

Factors determining the accuracy of impression

1. Number of implants

Impression making of multiple implants are complicated than single implant. The positional errors in restorative

stage are less likely to affect the passive fit in single implant. Daoydi MF et al found that a positional error in

the restorative stage is unlikely to affect the passive fit with the implant. But rotational or dimensional

discrepancy in the impression is likely to affect the appearance, contact points and occlusal requirements.23

2. Position of implants

The amount of distortion is limited in parallel abutments. In case of non parallel abutments, the direct transfer

method provides the accurate working cast when compared to the indirect method.24

3. Impression material

The appropriate selection of impression material and tray bring the accuracy of the cast. The choice of material

varies according to the complexity of work, impression technique, tray, implant system and prosthetic

components to be used. 25 Elastomeric impression material seems to be logical, since they prevent impression

26 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

displacement due to the rigidity. They are stable in diameters, resistant in deformation, have low strain when

under pressure, and they also have high initial shear strength. The unpleasant smell and polymerization

reactions of poly sulfide make it difficult to use. Condensation silicones are dimensionally less stable. Mostly

poly ether and addition cured silicones are used. The amount of expansion of polyether makes the transfer loose

and mobile in impression. Therefore not suitable for techniques using impression transfer.21 Polyether and

addition silicone are preferred in presence of undercuts and multiple implants. A study by S Reddy et al

concluded that polyvinyl or polyether impression materials have similar dimensional accuracy for transfer

procedures in parallel or angled implants.26

4. Type of Impression Tray

Selection of a tray is an effective factor on accuracy of impression. Impression trays can be either custom made

or stock trays. Generally custom made trays are preferred since it permits a uniform thickness of impression

material.27 It has been determined that applying special hard trays is better than polycarbonate trays because

rigid stainless steel trays limits the distortion of the impression.28 Masri et al concluded in his study that plastic

stock trays can increase the possibility of deformation due to lack of rigidity. 29Carotte et al found that metal

and rigid plastic trays gave greater accuracy than flexible trays. Though the study was directed to conventional

fixed partial dentures, the principle of implant dentistry remains the same.27

5. Design of the coping

Shortened length connection screw eases the removal of the coping from the implant in open tray technique.

Roberto Sorrentino et al stated that shortened connection length compensated the higher removal stress in

angulated implants.30 The coping length extended inside the impression material plays an important role in

retention and resistance against displacement.31New modifications like acrylic resin transfer caps, gold

machined castable abutments have been introduced to improve the accuracy of impression.

6. Splinting transfer coping

Inaccuracies in the impression during clinical and lab phase may occur due to the movement of the copings in

multiple implants. To obtain maximum accuracy, splinting of transfer copings plays an important role in case of

multiple implants.

7. Surface treatment of coping

To enhance the accuracy, the coping can be treated with air-borne particle abrasion and impression adhesive.32

But a study conducted by Vigolo P, FonziF disprove this.33

Digital impression technique

Dental restorations produced with computer assistance have become more in recent years.34 The current trend

in digital technology is to achieve a total digital workflow from implant planning to definitive restoration.

Benefits of the digital impression for implant rehabilitation

1 .eliminates tray selection

2. eliminates dispensing and setting of impression material

3. disinfection and shipping of impression to the laboratory not required

27 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

4. patient comfort and education

5. virtual assessment for implant prosthetic space, depth of restorative interface, emergence profile

configuration before proceeding with lab steps.35,36

6. digital scanning data base can be stored in computer hard drives which are not subjected to physical damage.

7. more efficient, more predictable

8.allows additional re-scans without repeating entirely the impression technique and save chair time for

patients.37,38

9. Other application of CAD/CAM is to produce implant abutments and frame work from metal or ceramic

materials.

10. Digital impression allows for day-of-surgery impressions and indexing for creating custom abutments to

place the final restoration earlier in the healing period after implant integration.

The three main components required for the CAD/CAM are the (1) the digital scanner to which transforms the

geometry into the digital data which can be processed by the computer (2) software that processes the data (3) a

production technology that transforms the data set into the desired product.

There are three different concepts in CAD/CAM production in dentistry.

1. Chair Side production

All the components are available at the chair side and thus dental restoration fabrication takes place without a

laboratory procedure. The intra oral digital scanner registers the clinical situation and offers the patient

indirectly fabricated restoration in a single visit. Cerec system (Sirona) offers this facility. Variety of materials

can be processed from glass-ceramic to high performance oxide ceramic, since Cerec system functions with

water cooling.

2. Laboratory production

The first step is similar to the traditional FPD impression. The dentist sends the impression to the laboratory and

the master cast is scanned to obtain the 3-dimensional data. The CAD process data will be sent to a special

milling devices and that produces the real geometry in the dental laboratory.

3. Centralized production

In this, the prosthesis is fabricated in a milling centre. The satellite scanner in the laboratory is connected with a

production centre via the internet. Data collected in the laboratory are sent to the production centre for the

fabrication of prosthesis with a CAD/CAM device. The benefit of this system is only small investment needed

for the CAD system and high quality production obtained from the centre.

Conclusion

Designing and making prosthesis in implant dentistry needs time and attention to obtain adaption, accuracy and

efficiency of the prosthesis. Various techniques had been introduced to get accurate impression. There is no

evidence supporting that one impression technique or material is better than the other. Impression forms the

28 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

back bone for the success of the prosthesis therefore appropriate technique has to be selected for greater

accuracy. Digital impressions have made the dental practitioners to say no to impression copings and laboratory

procedures related to it. The computerized engineering technology provides high precision fit, durability,

simpler fabrication protocol and minimal human intervention. The development in CAD/CAM technology will

most likely lead to an exponential growth in implant dentistry.

Table :1 Comparison of Indirect and Direct impression technique

Indirect technique Direct technique

Tray No tray preparation Window should be created at the

preparation implant region of the tray

Type of the Round/conical coping used Square coping are preferred

coping used

Interarch space Used in patients with limited mouth More space needed for the instrument

opening placed in implant to unscrew the implant

abutment connection

Precision of Chances of distortion because of the re- 1. Less distortion because coping

impression insertion of coping back in impression remains in the impression.

before fabrication of master cast 2. Splinted copings add more

precision.

Splinting Not possible Possible

multiple coping

Gaggers Used for gaggers May induce gagging

Angulated Easy to make Difficult to make

implants

Deeply placed Not Indicated Indicated

implants

Advantage Easy to perform Reduce the effect of implant angulations

and deformation of impression material

upon recovery from mouth

Disadvantage Possibility of rotational movement of Need to fabricate custom tray

coping when securing implant analog

resulting in inaccuracies

29 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

Table:2 Difference in Implant and Abutment level impression techniques

Implant level Abutment level

Coping location Requires sub gingival Supra gingival margins, hence

placement of copings easier

Abutment selection and On a model in the laboratory Can be done in the mouth

preparation

Abutment modification Not needed May be needed in the mouth

Custom Abutment Available Not available

REFERENCES

1. Leonardo Moreira Cabral, Carlos Gramani Guedes. Comparative Analysis of 4 Impression Techniques for

Implants. Implant dentistry2007; 16: 1-9.

2. W.Chee, S.Jivraj. Impression techniques for implant dentistry. Br Dent J 2006;201:429-432.

3. S Bhakta, J Vere, I Calder, RPatel. Impressions in Implant dentistry: Br Dent J 2011;211:361-367.

4. AnilSharma, Anuj Chhabra, Neeraj Madan, Natasha Madan. Contemporary impression techniques in implant

prosthontics. Indian Journal of Dental Sciences2010;2:61- 62.

5. Manual of Dental Implants. David P Sarment, MS Beth Peshman RDH.Edition Pg 46

6. D.R.Prithviraj, MaleshL.Pujari, PoojaGarg, D.P.Shruthi. Accuracy of the implant impression obtained from

different impression materials and techniques: review. J Clin Exp Dent 2011;3(2):e106-11.

7. Heeje Lee, JosephS, JLHochstedler,Carlo Ercoli.The accuracy of implant impressions: A systematic review.

J Prosthet Dent 2008;100:285-291.

8. Heather J Conrad,Igor J. Pesun,Ralph DeLong,James S. Hodges. Accuracy of two impression techniques

with angulated implants. J Prosthet Dent 2007;97:349-356.

9. Nissan J, Ghelfan O. The press fit implant impression coping technique. J Prosthet Dent 2009; 101:413-4.

10. Mahesh Lahori, Mahesh Lanka, Rahul Nagrath, Shweta Singh. An evaluation of the accuracy of multiple

implant impression technique: An in vitro study. The Journal of implants and Advanced Clinical Dentistry

2012; 4: 57-69.

11. Assif D, Marshak B, Schmidt A. Accuracy of implant impression techniques. Int J Oral Maxillofac Implants

1996;11:216-22.

12. Naconecy MM, Teixeira ER, Shinkai RS, Frasca LC, Cervieri A. Evaluation of the accuracy of 3 transfer

techniques for implant-supported prostheses with multiple abutments. Int J Oral Maxillofac Implants 2004;

19:192-8.

30 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

13. N.A.Tarib, T W Seong, KM Chuen,MS Khan. Evaluation of Splinting implant impression Techniques: Two

Dimensional Analyses: Eur J Prosthodont Rest Dent 2012; 20:35-39.

14. Richard Blustein, Richard Jackson, Kenneth Rotskoff, Richard E. Coy, Dennis Godar. Use of Splint

Material in the Placement of Implants. Int J Oral Maxillofac Implants on CD-ROM, 1986 Jan 47-49.

15. Gamal Burawi, Frank Houston, Declan Byrne, Noel Claffey. A comparison of the dimensional accuracy of

the splinted and unsplinted impression techniques for the Bone-Lock implant system .J Prosthet Dent 1997;

77:68-75.

16. Assif D, Nissan J, Varsano I, Singer A. Accuracy of implant impression splinted techniques, effect of

splinting material. Int J Oral Maxillofac Implants1999; 14:885-888.

17.Craig RG Restorative Dental material Ed 8. Toronto:Mosby 1989:328-329.

18. Gregori M Kurtzman, Lanka Mahesh. Advances in dental implant impression. Famdent Practical Dentistry

Handbook, Apr-June2012; 12:78-81.

19.KrishnaD Prasad,Chettan Hegde, Gaurav Agrawal, Manoj Shetty. Gingival displacement in

prosthodontics:A critical review of existing methods. J Interdiscip Dentistry 2011:2:80-86.

20. Bennani V Schwass D,Chandler N. Gingival retraction technique for implant versus teeth:Current status. J

Am Dent Assoc 2008:139:1354-63.

21. Ericson I, Lindhe J Probing depth at implants and teeth: experimental study in the dog. J Periodontol

1993:20; 623-7.

22. Zvi Fudim. Implant impression techniques comparative review: Transfer impression versus direct abutment

level. Dental Tribune U.S. Edition | August 2012; A10.

23.Daoudi MF, Setchell DJ, Searson LJ. An evaluation of three implant level impression techniques for single

tooth implant. Eur J Prosthodont Rest Dent 2004; 12:9-14.

24. Carr AB. A Comparison of Impression Techniques for a Five- Implant Mandibular Model. Int J Oral

Maxillofac Implants 1991;6:448-455.

25.Júlio César Brigolini de Faria(a) Laís Regiane Silva-Concílio(a) Ana Christina Claro Neves(a) Milton Edson

Miranda(b) Marcelo Lucchesi Teixeira. Evaluation of the accuracy of different transfer impression techniques

for multiple implants. Braz Oral Res2011;25;163-7.

26. S Reddy, K Prasad, H Vakil, A Jain, R Chowdhary. Accuracy of impressions with different impression

materials in angulated implants .Nig J Clin Pract 2013; 16:279-284.

27. Carrotte PV, Johnson A, Winstanley R B. The influence of the impression tray on the accuracy of

impression for crown and bridge work-an investigation and review. Br Dent J 1998;18:580-585.

28. Burns J, Palmer R, Howe L, Wilson R. Accuracy of open tray implant impressions: an in vitro comparison

of stock versus custom. J Prosthet Dent 2003; 89:250-255.

31 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar-Apr. 2015

29.Masri R, Driscoll CF, Burkhardt J, Von Fraunhofer A, Romberg E. Pressure generated on a simulated oral

analogue by impression materials in custom trays of different designs. J Prosthodont 2002;11:155-160.

30.Roberto Sorrentino, Enrico Felice Gherlone, Gaetano Calesini, Fernando Zarone. Effect of Implant

Angulation, Connection Length, and Impression Material on the Dimensional Accuracy of Implant Impressions:

An In Vitro Comparative Study. Clin Imp Dent & Rel Res 2009;1-14.

31. Paolo Vigolo, Zeina Majzoub, Giampiero Cordioli. Evaluation of the accuracy of three techniques used for

multiple implant abutment impressions. J Prosthet Dent 2003;89:186-192.

32. Herbst, JC Nel, CH Driessen, PJBecker. Evaluation of impression accuracy for osseointegrated implant

supported superstructures. J Prosthet Dent 2000; 83:555-61.

33. Paolo Vigolo, Fulvio Fonzi, Zeina Majzoub et al An evaluation of impression techniques for multiple

internal connection implant prostheses. J Prosthet Dent 2004; 92:470-6.

34. Jaufar Abudo, Karl Lyons. Rationale for the use of CAD/CAM technology in Implant prosthodonics . Int J

Dent 2013;Article ID-768121.

35. Patel N. Intergrating three dimensional digital technologies for comprehensive implant dentistry. J Am Dent

Assoc 2010;141 (suppl 2) 20s-24s

36.Panos Papaspyridakos,Chun-Jung Chen,German O.Gallucci, Asterios Doukoudakis, Hans-Peter

Weber,Vasilios Chronopoulos. Accuracy of Implant Impressions for Partially and Completely Edentulous

Patients: A Systematic Review. Int J OralMaxillofac Implants 2014; 29:836–845.

37. F Buer, J Schweiger, D Edelhoff. Digital dentistry: an overview of recent developments for CAD/CAM

generated restorations.Br Dent J 2008; 204:505-511.

38. Sang J Lee,German O Gallucci. Digital Vs conventional implant impression: efficiency outcomes. Clin

Oral Imp & Res2013; 24:111-115.

32 Dr Sumathi K et al. / IJRID Volume 5 Issue 2 Mar.-Apr. 2015

View publication stats

You might also like

- Creating Cross Platform C Applications With Uno 1801078491 9781801078498 CompressDocument258 pagesCreating Cross Platform C Applications With Uno 1801078491 9781801078498 Compresscan ipek100% (1)

- Wpa PaperDocument12 pagesWpa Paperkhairul ezwan100% (1)

- Dental Implant Impression Techniques: Revisited: European Journal Pharmaceutical and Medical Research February 2021Document7 pagesDental Implant Impression Techniques: Revisited: European Journal Pharmaceutical and Medical Research February 2021Elizabeth Vicencio AstudilloNo ratings yet

- Oral Implantology: ImplantsDocument52 pagesOral Implantology: ImplantsDabala Harish Reddy100% (6)

- Indirect Orthodontic Bonding - A Modified Technique For Improved Efficiency and PrecisionDocument10 pagesIndirect Orthodontic Bonding - A Modified Technique For Improved Efficiency and PrecisionSimon SitumorangNo ratings yet

- Implant Prosthetic DentistryDocument86 pagesImplant Prosthetic DentistryAnirban MallikNo ratings yet

- EJMCM - Volume 7 - Issue 4 - Pages 1689-1693Document5 pagesEJMCM - Volume 7 - Issue 4 - Pages 1689-1693Tanushree JainNo ratings yet

- 5 Implant ProstheticsDocument3 pages5 Implant ProstheticsFifth Year Dentistry ZUNo ratings yet

- Dental Implants and Dentures: Open Access: Computer Guided Implantology: For Optimal Implant PlanningDocument4 pagesDental Implants and Dentures: Open Access: Computer Guided Implantology: For Optimal Implant PlanningFiru LgsNo ratings yet

- Micro-Implants For Orthodontic Anchorage: A Review: July 2013Document6 pagesMicro-Implants For Orthodontic Anchorage: A Review: July 2013Vijay ChinthaNo ratings yet

- Implant ImpressionsDocument7 pagesImplant ImpressionsAnjana ThomasNo ratings yet

- Specops Jiacd 20090708Document88 pagesSpecops Jiacd 20090708Mario AdánNo ratings yet

- Various Treatment Modalities For Retrieval of Broken Abutment Screw in Implant ProsthodonticsDocument6 pagesVarious Treatment Modalities For Retrieval of Broken Abutment Screw in Implant Prosthodonticsrood_kNo ratings yet

- March 2019 1551512385 344Document4 pagesMarch 2019 1551512385 344Faisal hayatNo ratings yet

- Article-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330Document3 pagesArticle-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330saia windaNo ratings yet

- 2176 9451 Dpjo 25 04 85Document16 pages2176 9451 Dpjo 25 04 85prodontiaslpNo ratings yet

- Author's Accepted ManuscriptDocument22 pagesAuthor's Accepted Manuscriptlingual courseNo ratings yet

- Radiographic Stents and Surgical Stents in ImplantDocument6 pagesRadiographic Stents and Surgical Stents in Implantkavya ravuriNo ratings yet

- Clear Aligner Therapy - New Vistas in OrthodonticsDocument5 pagesClear Aligner Therapy - New Vistas in OrthodonticsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Litreture Review 5Document6 pagesLitreture Review 5Daniel AtiehNo ratings yet

- Implant Impression TechniquesDocument54 pagesImplant Impression TechniquesSupriya ShuklaNo ratings yet

- Author's Accepted Manuscript: Seminars inDocument77 pagesAuthor's Accepted Manuscript: Seminars innhasuonlineNo ratings yet

- 1 - Best - Immediate - Implant - PlacementDocument13 pages1 - Best - Immediate - Implant - PlacementMostafa El GendyNo ratings yet

- Thesis On Zygomatic ImplantsDocument4 pagesThesis On Zygomatic Implantskimberlypattersoncoloradosprings100% (2)

- Decision Making ImplantDocument2 pagesDecision Making Implant김문규No ratings yet

- Windowimpressiontechnique 2018Document5 pagesWindowimpressiontechnique 2018Winda KhosasiNo ratings yet

- Immediate Implant Placement in MaxillarDocument7 pagesImmediate Implant Placement in MaxillarrtyNo ratings yet

- Impression Techniques in Implant Dentistry: Susanna S Brainerd, Dr. Bindu R NayarDocument12 pagesImpression Techniques in Implant Dentistry: Susanna S Brainerd, Dr. Bindu R NayarMaqbul AlamNo ratings yet

- Endodontology 3: RootsDocument44 pagesEndodontology 3: RootsCarlos San MartinNo ratings yet

- Preoperative View of A DiastemaDocument6 pagesPreoperative View of A Diastemaulfa rizalniNo ratings yet

- The Notion of Platform-Switching in Implants A RevDocument8 pagesThe Notion of Platform-Switching in Implants A RevChifa MusrataNo ratings yet

- Dental Implant Site Preparation - A Review: C.J.Venkatakrishnan, S.Bhuminathan and Chitraa.R.ChandranDocument4 pagesDental Implant Site Preparation - A Review: C.J.Venkatakrishnan, S.Bhuminathan and Chitraa.R.ChandranLouis HutahaeanNo ratings yet

- History of AlignersDocument8 pagesHistory of AlignersAssem GamalNo ratings yet

- Thesis Topics On Dental ImplantsDocument4 pagesThesis Topics On Dental Implantsgbwwdfq5100% (2)

- Implant Supported OverdentureDocument5 pagesImplant Supported OverdentureFadil ObiNo ratings yet

- Prosthetic Management of Implants Placed With The Socket-Shield TechniqueDocument6 pagesProsthetic Management of Implants Placed With The Socket-Shield TechniqueSofia LondoñoNo ratings yet

- ThesisDocument13 pagesThesisvadianonymousNo ratings yet

- Inconsiderate Try in of Complete Denture ProsthesiDocument5 pagesInconsiderate Try in of Complete Denture Prosthesitaqia zulfaNo ratings yet

- Implant PPT Phase 2 Aseptico ImplantDocument63 pagesImplant PPT Phase 2 Aseptico Implantapi-152953067No ratings yet

- Entrevista IngDocument3 pagesEntrevista IngmedicalcenterNo ratings yet

- ReviewDocument4 pagesReviewSonali KinikarNo ratings yet

- Review PDFDocument4 pagesReview PDFSonali KinikarNo ratings yet

- Clear Aligners, A Milestone in Invisible Orthodontics - A Literature ReviewDocument4 pagesClear Aligners, A Milestone in Invisible Orthodontics - A Literature ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Stage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresDocument5 pagesStage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresasclepiuspdfsNo ratings yet

- Introduction To Dental Implants 2017 PDFDocument61 pagesIntroduction To Dental Implants 2017 PDFChong Weng Wah100% (2)

- Published Immediate ImplantDocument6 pagesPublished Immediate Implantshayma rafatNo ratings yet

- 01.2023 ECD IV IMPLANT PortfolioDocument24 pages01.2023 ECD IV IMPLANT Portfolioksan040114No ratings yet

- QSD Tapered Implant Manual Art939BDocument24 pagesQSD Tapered Implant Manual Art939BkhashmiraNo ratings yet

- Factors Affecting The Clinical Success of Screw Mplants Used As Orthodontic AnchorageDocument8 pagesFactors Affecting The Clinical Success of Screw Mplants Used As Orthodontic AnchorageDraganita AdnanaNo ratings yet

- Free Hand Vs Guided Implant SurgeryDocument5 pagesFree Hand Vs Guided Implant SurgeryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Roots 2009Document52 pagesRoots 2009betoweb1No ratings yet

- Mini Implantes en Ortodoncia .Document9 pagesMini Implantes en Ortodoncia .erika de andradeNo ratings yet

- Good Occlusal Practice in The Provision of Implant Borne ProsthesesDocument10 pagesGood Occlusal Practice in The Provision of Implant Borne ProsthesesNoland NaidooNo ratings yet

- The Orthodontic Mini-Implants Failures Based On Patient Outcomes: Systematic ReviewDocument13 pagesThe Orthodontic Mini-Implants Failures Based On Patient Outcomes: Systematic ReviewKristin HalimNo ratings yet

- Invisible Aligners - Is It The Future of OrthodonticsDocument4 pagesInvisible Aligners - Is It The Future of OrthodonticsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Article: © The Author(s), Under Exclusive Licence To British Dental Association 2023Document9 pagesArticle: © The Author(s), Under Exclusive Licence To British Dental Association 2023DANTE DELEGUERYNo ratings yet

- Rcs 2115Document21 pagesRcs 2115Kim Chi NguyễnNo ratings yet

- Prosthodontic Perspective To All-On-4 Concept For Dental ImplantsDocument4 pagesProsthodontic Perspective To All-On-4 Concept For Dental Implantsprostho booksNo ratings yet

- JOHCD-Maintenance of Implant SupportedDocument3 pagesJOHCD-Maintenance of Implant SupportedManoj HumagainNo ratings yet

- 1 s2.0 S0889540616001955 MainDocument9 pages1 s2.0 S0889540616001955 MainPanaite TinelaNo ratings yet

- Partial Extraction Therapy in Implant DentistryFrom EverandPartial Extraction Therapy in Implant DentistryUdatta KherNo ratings yet

- Dental Implant Treatment Planning for New Dentists Starting Implant TherapyFrom EverandDental Implant Treatment Planning for New Dentists Starting Implant TherapyRating: 4 out of 5 stars4/5 (1)

- Impression TraysDocument2 pagesImpression TraysRiya KvNo ratings yet

- Gypsum ProductsDocument23 pagesGypsum ProductsRiya KvNo ratings yet

- Anatomical LandmarksDocument6 pagesAnatomical LandmarksRiya KvNo ratings yet

- Desigining Crown Contour in Fixed Prosthodontics: A Neglected ArenaDocument7 pagesDesigining Crown Contour in Fixed Prosthodontics: A Neglected ArenaRiya KvNo ratings yet

- Chronology of Human DentitionDocument1 pageChronology of Human DentitionRiya KvNo ratings yet

- Ag-Ab Reactions Tests For Ag-Ab ReactionsDocument36 pagesAg-Ab Reactions Tests For Ag-Ab ReactionsRiya KvNo ratings yet

- Gingival Crevicular Fluid: S.Lakshmi Ajithan 3 BDS Roll No:44Document57 pagesGingival Crevicular Fluid: S.Lakshmi Ajithan 3 BDS Roll No:44Riya KvNo ratings yet

- Screw Versus Cemented Implant Supported RestoratioDocument8 pagesScrew Versus Cemented Implant Supported RestoratioRiya KvNo ratings yet

- Study of Surface Hardness of Gypsum Casts Made With Slurry Water: An in Vitro StudyDocument4 pagesStudy of Surface Hardness of Gypsum Casts Made With Slurry Water: An in Vitro StudyRiya KvNo ratings yet

- ProsthokrantiDocument8 pagesProsthokrantiRiya KvNo ratings yet

- A Review On The Human Oral MicrofloraDocument5 pagesA Review On The Human Oral MicrofloraRiya KvNo ratings yet

- Management of Flabby Ridge Cases: A Challenge in Clinical PracticeDocument6 pagesManagement of Flabby Ridge Cases: A Challenge in Clinical PracticeRiya KvNo ratings yet

- Dental Impant MaterialsDocument6 pagesDental Impant MaterialsRiya KvNo ratings yet

- Prosthetic Management of Implants Placed With The Socket-Shield TechniqueDocument5 pagesProsthetic Management of Implants Placed With The Socket-Shield TechniqueRiya KvNo ratings yet

- Occlusal Splint Therapy-Review Article: March 2013Document12 pagesOcclusal Splint Therapy-Review Article: March 2013Riya KvNo ratings yet

- Development of JawDocument47 pagesDevelopment of JawRiya KvNo ratings yet

- Biomimetic Materials: A ReviewDocument11 pagesBiomimetic Materials: A ReviewRiya KvNo ratings yet

- Paper 1Document7 pagesPaper 1Riya KvNo ratings yet

- Sleep Apnoea and ManagementDocument1 pageSleep Apnoea and ManagementRiya KvNo ratings yet

- 3D Printing in Prosthodontics: Additive Manufacturing TechnologyDocument6 pages3D Printing in Prosthodontics: Additive Manufacturing TechnologyRiya KvNo ratings yet

- A New Peripheral Tracing Material For Mandibular Complete Denture ImpressionDocument5 pagesA New Peripheral Tracing Material For Mandibular Complete Denture ImpressionRiya KvNo ratings yet

- NutritionDocument6 pagesNutritionRiya KvNo ratings yet

- Ethics in Esthetics PDFDocument3 pagesEthics in Esthetics PDFRiya KvNo ratings yet

- Short Clinical CrownsDocument7 pagesShort Clinical CrownsRiya KvNo ratings yet

- JC Article 1Document5 pagesJC Article 1Riya KvNo ratings yet

- Anterior Dental Aesthetics: Dental Perspective: British Dental Journal September 2005Document7 pagesAnterior Dental Aesthetics: Dental Perspective: British Dental Journal September 2005Riya KvNo ratings yet

- Camera ConfidenceDocument13 pagesCamera ConfidenceCont ReadNo ratings yet

- BT08 PDFDocument4 pagesBT08 PDFAfdhalNo ratings yet

- CVPDocument20 pagesCVPThomas K. AddaiNo ratings yet

- Learning & Development Activity Enrollment Form: Employee-Applicant DataDocument17 pagesLearning & Development Activity Enrollment Form: Employee-Applicant DataEvelyn dela CruzNo ratings yet

- Catalogo Vidrio Mobicell DistribuidorDocument3 pagesCatalogo Vidrio Mobicell DistribuidorANTHONY SANCHEZNo ratings yet

- Plaintiffs' Motion For Entry of JudgmentDocument14 pagesPlaintiffs' Motion For Entry of JudgmentBen SheffnerNo ratings yet

- Sample Assignment 1-1Document20 pagesSample Assignment 1-1Nir IslamNo ratings yet

- Data Compression (RCS 087)Document51 pagesData Compression (RCS 087)sakshi mishraNo ratings yet

- Aa - Moneyback20 - 29-10-2023 8.59.34Document6 pagesAa - Moneyback20 - 29-10-2023 8.59.34do.yogeshaNo ratings yet

- Week1 CombineDocument91 pagesWeek1 CombineraleyNo ratings yet

- EN Quick Reference Guide Fabian HFOi-V4.0Document30 pagesEN Quick Reference Guide Fabian HFOi-V4.0Tanzimul IslamNo ratings yet

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- CURVESDocument30 pagesCURVESPHULARAM PEGUNo ratings yet

- Happy Ladies and GentlemanDocument2 pagesHappy Ladies and GentlemanLalufathirNo ratings yet

- A Guide To The Management of Tuberculosis in Patients With Chronic Liver DiseaseDocument12 pagesA Guide To The Management of Tuberculosis in Patients With Chronic Liver DiseaseMeldaNo ratings yet

- Structural Developments: Inland Waterway Towboats and BargesDocument8 pagesStructural Developments: Inland Waterway Towboats and BargesEd UrquizaNo ratings yet

- Sony Hcd-Bx6av Dx6avDocument64 pagesSony Hcd-Bx6av Dx6avFrancisco ParedesNo ratings yet

- MA 231 MATHEMATICS III 2006 Question PaperDocument3 pagesMA 231 MATHEMATICS III 2006 Question Paperyasin muhamedNo ratings yet

- Class 9 Science Worksheet - Matter in Our Surroundings - 1Document2 pagesClass 9 Science Worksheet - Matter in Our Surroundings - 1Sumedha Thakur100% (1)

- Alternative Disposal of Polystyrene Fish BoxesDocument2 pagesAlternative Disposal of Polystyrene Fish Boxesهزاع الفارسNo ratings yet

- Chapter 3Document10 pagesChapter 3Adrian LohNo ratings yet

- Introduction To Spread Spectrum CommunicationDocument7 pagesIntroduction To Spread Spectrum CommunicationAli KashiNo ratings yet

- National War Memorial - Urban DesignDocument15 pagesNational War Memorial - Urban DesignRoopendraKumarNo ratings yet

- Acmepacket4500 InstallationDocument112 pagesAcmepacket4500 InstallationfujiNo ratings yet

- G9 Brand StoryDocument34 pagesG9 Brand StoryBaghiuNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingIshwarNo ratings yet

- Guide: Daily ReferenceDocument8 pagesGuide: Daily ReferenceGalina TodorovaNo ratings yet

- Waterstop Catalog 0411Document12 pagesWaterstop Catalog 0411hks1209No ratings yet