Professional Documents

Culture Documents

Air Dryer - Crx3100ae-E2 Orion

Air Dryer - Crx3100ae-E2 Orion

Uploaded by

garu2529Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Dryer - Crx3100ae-E2 Orion

Air Dryer - Crx3100ae-E2 Orion

Uploaded by

garu2529Copyright:

Available Formats

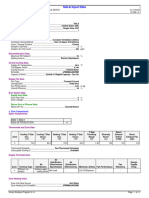

Spec. No.

CRX3100AE-E2

ORION AIR DRYER

Trade Name

Model CRX3100A-E

Date Apr .5.2012

APPD CKD DWN

T.Takeuchi T.Maruyama T.Maruyama

ORION MACHINERY CO.,LTD

SPECIFICATIONS

Specification Ref. No. CRX3100AE-E2

CRX3100A-E

Measurement conditions on air processing

Model

Air processing capacity m3/ min 31

Inlet air pressure (Gauge pressure) MPa 0.69

Inlet air temperature ℃ 50

Dewpoint of outlet air ℃ 10

+1

Ambient temperature ℃ 35

Allowable conditions

Medium Compressed air

Inlet air temperature ℃ 10 - 60

Ambient temperature ℃ 2 - 45

Applicable air pressure (Gauge pressure) MPa 0.29 - 0.98

External dimensions

Height x Depth x Width mm 1500X1500X802

Mass kg 385

Air pipe connection 3B (80A) Flange

Electric rating

Power source 3phase 380V+/-10% 50Hz

Power consumption kW 10

Electric current A 18

Equipment details

Refrigerant compressor Fully enclosed scroll type 3.0kwX2

Condenser Fin and tube, forced air cooling

Chiller Plate fin type, alminum shell

Refrigerant controller Capillary tube system

Refrig.comp. Controller Digita display, 100% and 50% load congtrol, Alarm display

Capacity controller Capacity control valve

Fan motor for condenser Φ / W (500 / 400)X2

Overload protection device Fluid injection

Refrigerant R -407C

Auto drain trap Disk type (AD-5)

Protection devices

Compressor Over current relay

Discharge pipe thermostat

Opposite phase relay

Fan motor for condenser Winding thermostat

Refrigerant circuit Fan control pressure switch

High pressure switch

Temperature detecting type antifreeze system

Control circuit Glass tube fuse

Drawings attached

External dimensions 4-DM334

Wiring diagram 4-DM335

System diagram 4-DM336

Foundation drawing 4-DM333

Detail of control panel 4-DN342

Paint color Munsell No. Right front panel :N3.0 , Others :7.5Y7.5/0.5

Pre. Filter DSF3500A-SUS (Option)

Remarks:

1.This air dryer is designed for indoor use.

2.The air processing capacity indicated above is converted to a value at atmospheric pressure , 32deg C, and 75% RH based on ANR.

3.Pressure dew point of outlet air is a converted value with outlet air pressure and may vary depending on the amount ofsupersaturated moisture.

4.Air filter (5μm) must be installed before this air dryer.

5.With companion flanges.

DM334 4

8-φ18

4-Φ20 1100 175

0

16 φ200 Air outlet

φ 80A(3B) Flange

Air inlet

879

839

80A(3B) Flange

Cooling air outtake port

Flange detail drawing

1500

(HG/T20592 PN16 fairly article) Auto drain trap

802 (200) 535.4 795.6

80A(3B)Companion Flange Filter for condenser

127.5

Cooling air exhaust Cooling air exhaust

O

OO

N

NN

ON

h

℃

O

OO

F

FF

OF

FF

FF

POWER SAVETEMP.

LOCAL COMP.1

DEW POINT ALARM

REMOTE HOUR METER COMP.2

SE

SS

E

ST

EET

TT ∨

∨

∨

∨ ∧

∧

∧

∧ M

MM

O

OO

MD

DD

OE

EE

DE

RR

RES

EE

RS

EE

EE

SST

TT

ET

A RA R M

A

A

A

AI

II

R

I

RR

RP

PP

R

P

RR

E

R

EE

S

E

SS

S

S

SS

U

S

UU

R

U

RR

E

R

EE

E

L

L

L

LO

OO

C

O

CC

A

C

AA

L

A

LL

L R

R

R

RE

EE

M

E

MM

O

M

OO

T

O

TT

E

T

EE

E

E

E

E

EV

VV

A

V

AA

P

A

PP

.

P

..

P

.

PP

R

P

RR

RE

E

E

ES

SS

S

S

SS

U

S

UU

R

U

RR

E

R

EE

E C

COO

NN

DD

..

PPR

REE

SS

SS

UU

RR

EE

C

COO

NN

DD

..

PPR

REE

SS

SS

UU

RR

EE

Cooling air intake

1601

1500

ORI ON AIR

AIR

AIR DRYER

DRYER

ORION

(665)

861

Power cord hole

(φ26 X 2)

Scale APPROVED CHECKED CHECKED DRAWN DESIGNED

1 Y.Kuroiwa N.Takeuchi N.Kobayashi

25 Jan.27.2011 Jan.27.2011 Jan.24.2011

MODEL CRX3100A-E DRAWING No,

3rd

Angle

System

EXTERNAL DIMENSION 4 DM334

ORION MACHINERY CO. , LTD

No.B-G0020-13-02

DM335 4

3φ AC380V 50Hz R1

R1

E L1 L2 L3 13 14 22

K1 22 OPERATION

13 14 23

REMOTE CONTROL

K2 23 STOP

E R S T CN2 CN6

1 11

1 11 ON:ALARM 1 (Main alarm)

2 2

380V TR1 220V R1 12 OFF:NORMAL OPERATION

3 3 12 (No-Electric voltage)

380V 220V F1 4 4

S1 S2 13

5 5 13 ON:ALARM 2 (Preparatory alarm)

380V 220V 6 6 OFF:NORMAL OPERATION

T1 14

7 7 14

380V (No-Electric voltage)

TR2 220V

31 31 TR3 7 CN1 CN7 15

1 1 15 ON:RUNNING

MC1 MC2 MC3 MC1 MC2 2 2

8 16 OFF:MACHINE STOP

32 32 3 3 16

THR1 THR2 U3 V3 W3

12V 220V (No-Electric voltage)

4 4

24 S2 25 T1 9 5 5

U1 V1 W1 U2 V2 W2 10 6 6

7

THR1 TTH1 CN3

M M 95 96 26 1 1 E11

OL1 OL2 θ

CN8

3~ 3~ 2

THR295 TTH2 1

96 27 2 N.C.

3 E21 2

M1-1 M1-2 M2-1 M2-2 CH1 CH2 θ

4

ITH1 28 ITH2 31 CN9

5 E08 TH1

Symbol Name of parts θ θ 1

M1-1 Motor (Compressor motor 1) CN4 2

3 1 E10

M1-2 Motor (Compressor motor 2) CN10

2 TH2

1

M2-1,2 Motor (Fan motor) 3 2

MC1,2 Electromagnetic contactor(M1-1,2) 4

MC3 Electromagnetic contactor(M2) 5 CN11

1 COS

6

THR1,2 Over current relay(M1-1,2) 2

7 17

3

CH1,2 Crank case heater 18 1 P

CN5 4

HP High pressure switch HP A B 5

S2 3 MC1 1

CP Fan control pressure switch p 2 CN12 19

K1

A B 6 1

5

COS Change over switch Output of signal MC2 3 20 9

2

4 21

CN1to12 Connector ・Relay output : a contact CP 32 A B 34

5 3

MC3 5 9

4 K2

TR1,2 Transformer ・Contact rating : AC250V 5A(Resistance load) p CPU BOARD

TR3 Transformer DC30V 5A(Resistance load) TTH3 33

SV

K1.2 Auxiliary relay ・Maximum open/close voltage : AC250V θ

TH1.2 Thermistor DC150V

TTH1,2 Discharge thermostat ・Application minimum load : DC5V 100mA

TTH3 Bimetallic thermostat Scale CHECKED

APPROVED CHECKED DRAWN DESIGNED

OL1,2 Internal protector (M1) 1 Y.Kuroiwa N.Takeuchi N.Kobayashi

ITH1.2 Fan motor over temp. switch 1 Dec.6.2010 Dec.06.'10 Nov.05.2010

F1 Glass fuse φ6X30 3A MODEL CRX3100A-E DRAWING No,

3rd

SV Solenoid valve

Angle 4 DM335

□:Number indicated on terminal block. System

WIRING DIAGRAM

○:Nunber marked on electric wire.

:Wiring at user end. ORION MACHINERY CO. , LTD

No.B-G0020-13-02

DM336 4

TH1

HX1 HX2

AIR IN Symbol Name of parts

HX1,2 Chiller

TH2 AIR OUT M1 Compressor motor

EPG M2 Fan motor

CON Condenser

APG DR Refrigerant dryer

EXV Capillary tube

CCV Capacity control valve

BV

HP High pressure switch

AD EXV

CJL CP Fan control pressure switch

SV

EPG Evaporating pressure gauge

CCV CPG Condensing pressure gauge

CPG APG Air pressure gauge

HP CP CJ(H,L) High/Low pressure check joint

BV Ball valve

TTH1 AD Auto drain trap

DR

SV Solenoid valve for fluid injection

TH1,2 Thermistor

M1-1 CJ1 TTH1,2 Discharge thermostat

CJH

TTH3 Thermistor for fluid injection

TTH3

OILS Oil separetor

M2-1 M2-2 ACCM Accumlator

CJ Check valve

TTH2 ST Refrigerant strainer

CJ2 OILS

ACCM

CON OILP Oil return pipe

ST EJP Fluid injection pipe

M1-2

FI Fillter for condenser

FI

OILP

EJP

Scale APPROVEDCHECKED CHECKED DRAWN DESIGNED

1 Y.Kuroiwa N.Takeuchi N.Kobayashi

1 Dec.6.2010 Dec.06.'10 Nov.18.2010

MODEL CRX3100A-E DRAWING No,

3rd

Angle 4 DM336

System

SYSTEM DIAGRAM

ORION MACHINERY CO. , LTD

No.B-G0020-13-02

DM333 4

620 839 620

600

M16X200L (L type)

Anchor bolt X 4

175

Anchor bolt X 4 (JIS B1178)

Rear panel Air dryer

30

FL

1400

1100

Air dryer

Concrete floor

concrete foundation

Front panel View from front side

125

600

600 879 600 Scale APPROVED CHECKED CHECKED DRAWN DESIGNED

1 Y.Kuroiwa N.Takeuchi N.Kobayashi

2079 20 Dec.6.2010 Dec.06.'10 Nov.18.2010

MODEL CRX2300A,3100A-E DRAWING No,

3rd

Angle 4 DM333

System

FOUNDATION DRAWING

ORION MACHINERY CO. , LTD

No.B-G0020-13-02

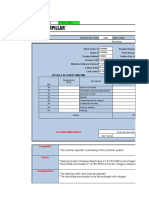

DN342 4

(It lights when compressor No.1 is operating.) Lamp Digital indicator

(It lights when compressor No.2 is operating.) Lamp RUN lamp (It lights when the machine is operating.)

(It lights or flashes while setting.) Lamp ON switch

(It lights when time is displayed.) Lamp OFF switch

ALARM lamp

(It lights when high pressure switch is activated.)

(It lights when local control is set..) Lamp

ALARM lamp

(It lights when remote control is set..) Lamp (It lights when thermal relay or discharge thermostat

of compressor No.1 is activated.)

ALARM lamp

(It lights when thermal relay or discharge thermostat

of compressor No.1 is activated.)

Alarm Alarm details

CAUTION lamp

C00 Time to clean condenser filter. (It lights when it comes to the time to replace filter element(s).)

CAUTION lamp

C05 Abnormal rise of dew point

(It lights when dew point at the air outlet goes up.)

C16 Time to replace filter element(s) of air filter(s). LOCAL/REMOTE select switch

E01 Malfunction of controller CPU

E02 The power was detected as open phase.

Air pressure gauge

E03 The power was detected as negative phase.

E04 The power was detected as interrupted. Evaporating pressure gauge

E06 Dew point sensor is disconnected or short-circuited. Condensing pressure gauge

E07 Sensor of suction temperature of refrigeration compressor is disconnected or short-circuited.

E08 Thermal relay for fan motor is activated.

E10 High pressure switch for refrigeration compressor is activated.

Refrigeration compressor No.1

E11

Thermal relay or discharge thermostat is activated.

Refrigeration compressor No.2

E21

Thermal relay or discharge thermostat is activated.

E30 Suction temperature of refrigeration compressor is abnormally low. Scale APPROVED CHECKED CHECKED DRAWN DESIGNED

Err The remote input signal is not of the "Momentary" type.

Y.Kuroiwa N.Takeuchi N.Kobayashi

Dec.6.2010 Dec.06.'10 Nov.19.2010

MODEL CRX3100A DRAWING No,

3rd

Angle

System

DETAIL OF OPERATION PLATE 4 DN342

ORION MACHINERY CO. , LTD

No.B-G0020-13-02

You might also like

- Service Manual: Inverter Split System Air ConditionerDocument41 pagesService Manual: Inverter Split System Air Conditionerplumber1900No ratings yet

- Introduction To The Loxone SystemDocument43 pagesIntroduction To The Loxone Systemmbyaray75 Byaray100% (1)

- NPM SimulationDocument405 pagesNPM SimulationĐàm Duân100% (1)

- A - Gray: C - Red B - GreenDocument4 pagesA - Gray: C - Red B - Greentigre1677100% (1)

- Specification ARX120HK EnglishDocument5 pagesSpecification ARX120HK Englishheruono sitorusNo ratings yet

- Operating Manual: FOR Commpressed Air SystemDocument11 pagesOperating Manual: FOR Commpressed Air Systemthach pha thienNo ratings yet

- CR780 SpecificationDocument1 pageCR780 SpecificationBeatriz RibeiroNo ratings yet

- Spec en 4L40Z02307P1-06Document27 pagesSpec en 4L40Z02307P1-06Ageng A. PooNo ratings yet

- Spec. No. E) CRX75C: Orion Machinery Co., LTDDocument5 pagesSpec. No. E) CRX75C: Orion Machinery Co., LTDHa CongNo ratings yet

- Exp 12Document7 pagesExp 12Dhanush kumarNo ratings yet

- Manufacture Reserves The Right To Discontinue, or Change at Any Time, Specifications or Designs Without Notices and Without Incurring ObligationsDocument57 pagesManufacture Reserves The Right To Discontinue, or Change at Any Time, Specifications or Designs Without Notices and Without Incurring ObligationsRomano VallettaNo ratings yet

- Data Sheet For Air Cooled Scroll Chillers: 2 Nosas Per BoqDocument3 pagesData Sheet For Air Cooled Scroll Chillers: 2 Nosas Per BoqHemanti SharmaNo ratings yet

- ChicagoPneumatic CPF 200 CPVS 250 Instruction Book EN 6230579965Document32 pagesChicagoPneumatic CPF 200 CPVS 250 Instruction Book EN 6230579965osmanyildirim85No ratings yet

- Gta Series 2022Document4 pagesGta Series 2022yohanesNo ratings yet

- Spec en 4K40Z02306P1-06Document23 pagesSpec en 4K40Z02306P1-06Ageng A. PooNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Specifications: DaikinDocument17 pagesSpecifications: DaikinyoyokNo ratings yet

- Power Supplies - MLK004100 PDFDocument3 pagesPower Supplies - MLK004100 PDFadel haghiNo ratings yet

- Daikin JT160L P8Y1 Teknik DokumanDocument18 pagesDaikin JT160L P8Y1 Teknik DokumanShuanglai LiuNo ratings yet

- Esd144 enDocument1 pageEsd144 enMahmoud MagdyNo ratings yet

- 30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramDocument13 pages30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramBJNE01No ratings yet

- 08.47.300Document15 pages08.47.300kuatifansyahNo ratings yet

- 24 11 15 Engineering Data Gardnerdenver GDD76HS GDD1800HS 50HZ Iso PDFDocument29 pages24 11 15 Engineering Data Gardnerdenver GDD76HS GDD1800HS 50HZ Iso PDFNhân NgọcNo ratings yet

- Datos Tecnico SRL 200 6000Document30 pagesDatos Tecnico SRL 200 6000Raimundo GuevaraNo ratings yet

- Spesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryDocument1 pageSpesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryBaelish PeterNo ratings yet

- Air System InputsDocument8 pagesAir System InputsahmedNo ratings yet

- Systems Input DataDocument8 pagesSystems Input Datacomekib310No ratings yet

- Ewadc14Tzxrc2: Technical Data SheetDocument4 pagesEwadc14Tzxrc2: Technical Data SheetstomakosNo ratings yet

- Daikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALDocument4 pagesDaikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALBibin VijayakumarNo ratings yet

- Enclosure Cooling Unit Model User's GuideDocument24 pagesEnclosure Cooling Unit Model User's GuideAgus CahyonoNo ratings yet

- LAARS - Mighty Therm II - SpecificationsDocument2 pagesLAARS - Mighty Therm II - SpecificationsJonalou ArominNo ratings yet

- Air System InputsDocument36 pagesAir System InputsARUL SANKARANNo ratings yet

- BIOGAS DRYER Technical ENrev5Document4 pagesBIOGAS DRYER Technical ENrev5Manikandan SWMSNo ratings yet

- TFV - 750 Manual OriginalDocument35 pagesTFV - 750 Manual OriginalJohn SafeerNo ratings yet

- XG110 160kWWDocument29 pagesXG110 160kWWAgeng A. PooNo ratings yet

- SLPA-75E-385 - Specification SheetDocument1 pageSLPA-75E-385 - Specification Sheetsomsak SontedNo ratings yet

- II 3 Technical Data - HVACDocument206 pagesII 3 Technical Data - HVACAnh Vân Trần100% (1)

- Manual PAC606FCDocument41 pagesManual PAC606FCluischiribogaNo ratings yet

- Spec en 4H40Z02304P1-07Document23 pagesSpec en 4H40Z02304P1-07Ageng A. PooNo ratings yet

- SSD3000WNaA-M 选型报告1126Document3 pagesSSD3000WNaA-M 选型报告1126saad rehmanNo ratings yet

- Screw Compressors: Model: VE22-10BDocument30 pagesScrew Compressors: Model: VE22-10BVoştinar IoanNo ratings yet

- SRK HDDocument14 pagesSRK HDАнастасия ДоморацкаяNo ratings yet

- XG200 250kWWDocument28 pagesXG200 250kWWAgeng A. PooNo ratings yet

- Data Sheet For Mag Bearing Centrifugal ChillersDocument4 pagesData Sheet For Mag Bearing Centrifugal ChillersHemanti SharmaNo ratings yet

- C - E20-II - Projects - HAP51 - Air System InputsDocument2 pagesC - E20-II - Projects - HAP51 - Air System InputspxpingenieriaNo ratings yet

- Ewad820mzssb2Document4 pagesEwad820mzssb2RakeshNo ratings yet

- 英文 - Finished Docu.-fin. (Part One)Document107 pages英文 - Finished Docu.-fin. (Part One)joseflores888No ratings yet

- General Specifications:: Packaged Air Cooled ChillerDocument3 pagesGeneral Specifications:: Packaged Air Cooled ChillerLuis Enrique Barreto GarciaNo ratings yet

- 0-WD110-EZ300-B2002 - Rev - 0 - Calculations For Safety Relief Valves and Silencers0Document10 pages0-WD110-EZ300-B2002 - Rev - 0 - Calculations For Safety Relief Valves and Silencers0carlos tapia bozzoNo ratings yet

- Specification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021Document3 pagesSpecification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021claverNo ratings yet

- Ace G225LHDocument17 pagesAce G225LHAntonioMurteiraNo ratings yet

- XG110 160kWADocument27 pagesXG110 160kWAAgeng A. PooNo ratings yet

- Option-2 Tech Sheet-EWAD820MZSSB2 - NominalDocument4 pagesOption-2 Tech Sheet-EWAD820MZSSB2 - NominalMohammed EmamNo ratings yet

- DaikinAppliedEu 20220719Document4 pagesDaikinAppliedEu 20220719ahmed ragabNo ratings yet

- Corridor 3@ 18degcDocument5 pagesCorridor 3@ 18degcMARIVEL BASANo ratings yet

- 2367 Transmitter Cooling UnitTCUDocument2 pages2367 Transmitter Cooling UnitTCUGIlbert StefhenNo ratings yet

- Fresh-air duct unit SMMSu - 33,50 kW - R410A - VRF MMD-UP1121HFP-E enDocument2 pagesFresh-air duct unit SMMSu - 33,50 kW - R410A - VRF MMD-UP1121HFP-E enAnass GarnaoutNo ratings yet

- Selection SheetDocument6 pagesSelection Sheethussam_98No ratings yet

- AHU Elultimo 20240124 1555Document34 pagesAHU Elultimo 20240124 1555Abraham Sierra MartinezNo ratings yet

- Spec en 4G40Z02312P1-05Document23 pagesSpec en 4G40Z02312P1-05Ageng A. PooNo ratings yet

- XG110 160kWWVDocument28 pagesXG110 160kWWVAgeng A. PooNo ratings yet

- Cummins - 50 kVA SpecsDocument5 pagesCummins - 50 kVA SpecsJose Emmanuel A NavarroNo ratings yet

- Handrail StandardDocument2 pagesHandrail Standardgaru2529No ratings yet

- ToleranceDocument1 pageTolerancegaru2529No ratings yet

- Technical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required ActualDocument6 pagesTechnical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required Actualgaru2529No ratings yet

- Technical Data - Fan Model AP0634AA530Document5 pagesTechnical Data - Fan Model AP0634AA530garu2529No ratings yet

- Compressed Air Vacuum CleanerDocument3 pagesCompressed Air Vacuum Cleanergaru2529No ratings yet

- Paddle Feeder Lifting ProcedureDocument1 pagePaddle Feeder Lifting ProcedureIndermohan MehtaNo ratings yet

- Differences Related To Computer MaintenanceDocument5 pagesDifferences Related To Computer MaintenanceAlpesh ThesiyaNo ratings yet

- Request Form KH08588Document4 pagesRequest Form KH08588nelsonNo ratings yet

- Manual de Peças YAMAHA F 90 AET 2013Document69 pagesManual de Peças YAMAHA F 90 AET 2013cezar frasaoNo ratings yet

- Abalioglu - Kullanım - Klavuzu - ING PDFDocument251 pagesAbalioglu - Kullanım - Klavuzu - ING PDFCan YEŞİLNo ratings yet

- ABB Junction BoxDocument10 pagesABB Junction Boxjason chongNo ratings yet

- LC1D25M7: Product Data SheetDocument4 pagesLC1D25M7: Product Data SheetMathías Huillca CameronNo ratings yet

- Fleck 3150 Downflow: Service ManualDocument40 pagesFleck 3150 Downflow: Service ManualLund2016No ratings yet

- 550 Series Tanque de 5 GalonesDocument1 page550 Series Tanque de 5 GalonesamiguitoNo ratings yet

- Wiring Diagram Hand BookDocument168 pagesWiring Diagram Hand Bookyohan qonyta100% (1)

- GHC Katalog HadiahDocument7 pagesGHC Katalog HadiahIntanNo ratings yet

- B C E F D G A H: Bridgemaster and Standard Mixer PartsDocument1 pageB C E F D G A H: Bridgemaster and Standard Mixer PartsWladimir CheerNo ratings yet

- Optical Time Domain ReflectometerDocument4 pagesOptical Time Domain ReflectometerBinod Kumar BhagatNo ratings yet

- IC - 72330 MV KUI: Panel Note QTY 1 Unit Substation Power House 7 20Kv FG Plant DM1-A 1 Unit Power House 2 AssemblyDocument7 pagesIC - 72330 MV KUI: Panel Note QTY 1 Unit Substation Power House 7 20Kv FG Plant DM1-A 1 Unit Power House 2 AssemblyNur rohmanNo ratings yet

- LT-3300 Series Installation Guide: CautionDocument16 pagesLT-3300 Series Installation Guide: CautionJuan Jose Mamani RoqueNo ratings yet

- Digital Performance Series: Auto-Darkening Welding HelmetsDocument2 pagesDigital Performance Series: Auto-Darkening Welding HelmetsGesi KafexhiNo ratings yet

- Opti LED TubeDocument2 pagesOpti LED TubeZeeshan_Akram01No ratings yet

- Proper Tool SelectionDocument21 pagesProper Tool SelectionTheoSebastianNo ratings yet

- Webasto Air Top Evo 55 Heater Fault Codes Troubleshooting ManualDocument6 pagesWebasto Air Top Evo 55 Heater Fault Codes Troubleshooting Manualbmv toursNo ratings yet

- 3NA3022 Datasheet enDocument5 pages3NA3022 Datasheet enArthur BastosNo ratings yet

- Guard Locking Switches: Product SelectionDocument3 pagesGuard Locking Switches: Product SelectionConstantin MoldoNo ratings yet

- SPSP Certification Request Form - 20221003Document1 pageSPSP Certification Request Form - 20221003ali othmanNo ratings yet

- Functions: Digital Camera Finepix S3000Document3 pagesFunctions: Digital Camera Finepix S3000Andi GeraNo ratings yet

- Cizma Motorul Meu Evinrude 737Document2 pagesCizma Motorul Meu Evinrude 737CristianNo ratings yet

- Service Manual: Microwave Oven AVM 562Document8 pagesService Manual: Microwave Oven AVM 562Csaba KohegyiNo ratings yet

- CrushersDocument24 pagesCrushersThibaut LeconteNo ratings yet

- Mapro BlowersDocument24 pagesMapro BlowersNishanth GabrielNo ratings yet