Professional Documents

Culture Documents

Shell and Tube Multipass Heat Exchanger Design - Tubular Juice Heater

Shell and Tube Multipass Heat Exchanger Design - Tubular Juice Heater

Uploaded by

Govinda DeshmukhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell and Tube Multipass Heat Exchanger Design - Tubular Juice Heater

Shell and Tube Multipass Heat Exchanger Design - Tubular Juice Heater

Uploaded by

Govinda DeshmukhCopyright:

Available Formats

6/12/2021 Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater

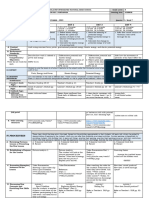

S.no Particulars Sign and formulas Values UOM

Data to be required for calculation

1 Crushing rate TCH 210 TCH

2 Juice % cane P 102 %

3 Velocity of Juice Vj 1.8 m/sec

4 Density of juice ρ 1.06 gm / ml3

5 Tube OD OD 45 mm

6 Tube Thickness Tk 1.2 mm

7 Tube ID ID 42.6 mm

8 Tube length L 4000 mm

9 Specific heat of juice Cp 0.9 Kcal/Kg/oC

10 Legment Lg 12 mm

11 Vapour inlet temperature Tv 85 oC

12 Juice inlet temperature ti 60 oC

13 Juice outlet temperature to 75 oC

14 Tube plate thickness Tb 25 mm

15 Velocity of vapour Vv 40 m/sec

16 Heater Heating Surface S 250 m2

17 Velocity of condensate Vc 1 m/sec

18 Proportional factor β = 0.7 to 0.8 0.7

19 Latent heat of vapour 548.24 kcal/Kg

20 Specific volume of vapour μ 2.83 M3/kg

Calculation part

1 Number of tubes per pass

Volume of the juice M = (TCH x P) / ( ρ x 3600) 0.0561 M3/sec

Area of the one tube A = 0.785 x ID2 0.0014 M2

M / ( A x Vj) 21.89 tubes/pass

i.e 22.00

2 Number of the tubes

Mean Dia Dm = OD – Tk 43.8

Effective tube length L m = L – 2 x Tb – 2 x 5 3940

Number of the tubes N t = S / ( π x Dm x Lm ) 461.36

i.e 462.00 no.s

3 Number of Passes n = Nt / tubes per pass 21.00

3 Number of passes should be always taken even number ( n ) 22

As Per Even number of passes Heater parameters to be calculated

4 No. of compartments Top side = n/2 +1 12

Bottom side = n/2 11

5 Actual number of tubes Nt = n x tubes per pass 484 no.s

6 Actual heating surface S = π x Dm x Lm x Nt 262 m2

7 Actual velocity Vj = M / Area of one pass 1.79 m/sec

8 pressure drop across the juice heater 0.0025 x n x Vj2 x ( L/ ID +3) 17.10 MWC

9 Tube plate dia

Pt = OD + Legment + Tube

Pitch Tolerance(0.5mm) + Hole 57.6

Tolerance(0.1mm)

Tube plate Area At = 0.866 x Pt 2 x Nt / β 1.99 m2

https://www.sugarprocesstech.com/tubular-juice-heater/ 1/3

6/12/2021 Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater

Take 10% extra 2.19 m2

Tube plate dia Dt = SQRT ( At / 0.785)

1668 mm

10 Dia of juice inlet pipe

Area Aj = M / Vj

0.031 m2

Dj = SQRT ( Aj / 0.785)

0.199 mtrs

i.e 200 NB

11 Vapour inlet Dia Qj x Cp x ΔT = W x λ mtrs

Qj = TCH x P x 1000 214200 Kg/hr

ΔT = to -ti 15 oC

W = weight of the vapour 5274.515 kg/hr

Qv = W x μ /3600 4.146 M3/ sec

Av = Qv / Vv 0.104 m2

Take 10% extra 0.114 m2

Dv = SQRT ( Av / 0.785) 0.381 mtrs

i.e 400 NB

12 Condensate pipe Dia

Qc = weight of the condensate =

0.00147 M3/sec

W

Ac = Qc/ Vc 0.00147 M2

Take 50% extra for free removal 0.00220 M2

Dc = SQRT ( Ac /0.785) 0.053 mtrs

i.e 75 mm

13 NCG pipe line dia

2

For every 10m Heating surface

Cross section area of pipe required 1 cm2 area to be 26.23 cm2

required ( An )

SQRT (( An/4) / 0.785) 2.89 cm

4 no.s NCG points and each

NCG pipe line dia 32 mm

having

14 Calendria shell thickness (P* Di / (2*F*J – P) ) + C

Maximum allowable pressure P (Hydraulic test pressure) 3 kg/cm2

ID of the Juice heater Di 1668 mm

Allowable stress F 1400 kg/cm2

Welding Joint efficiency J 0.75

Corrosion allowance C = 1.5 for calendria shell 1.5 mm

Calendria shell thickness 3.89 mm

Say 4 mm

But as per standard specification 12mm for longitude of equipment

15 Tube plate thickness f x G x SQRT((0.25 x P)/F) + C

Corrosion allowance C = 3.0mm for tube plate 3 mm

Allowable stress F 1400 kg/cm2

Maximum allowable pressure P 3 kg/cm2

Modulus factor for MS sheet Es 2100000 kg/cm2

Modulus factor for SS sheet Et 1900000 kg/cm2

ID of the shell G 1668 mm

Thickness of the shell ts 12 mm

Thickness of tube tt 1.22 mm

OD of the tube do 45 mm

Do = OD of the calendria sheet Do = ID + 2 x shell thickness 1692 mm

Number of tubes Nt 484 no.s

K =( Es x ts x (Do -ts)) /(Nt x Et

K 0.862174

x tt x(do -tt))

f = safety factor f = SQRT ( K / (2 + 3K)) 0.433567

Tube plate thickness 19.74 mm

But as per standard specification 25mm for tube plate

https://www.sugarprocesstech.com/tubular-juice-heater/ 2/3

6/12/2021 Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater

16 Thickness of the cover plate tc = Gc x SQRT ( K x P /f ) + C.A

ID of the shell Gc 1668 mm

For flat joint K = 0.3 0.3

Design Pressure P 3 kg/cm2

Allowable stress f 1400 kg/cm2

Corrosion allowance C = 1.5mm for cover plate 1.5 mm

Thickness of the cover plate 43.79 mm

But as per the Indian practice to given 32mm cover plate with adequate stiffening is sufficient

https://www.sugarprocesstech.com/tubular-juice-heater/ 3/3

You might also like

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- Detroit Diesel - 2ngines V-71 Operators Manual: Downloaded From Manuals Search EngineDocument174 pagesDetroit Diesel - 2ngines V-71 Operators Manual: Downloaded From Manuals Search EngineAlexNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- PED (Design of Shell and Tube Heat Exchanger) 63Document5 pagesPED (Design of Shell and Tube Heat Exchanger) 63Dinesh0% (1)

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Heat Exchanger DesihnDocument4 pagesHeat Exchanger DesihnayatbimaNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document4 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- 3... 80x65 FS JA (22 KW)Document5 pages3... 80x65 FS JA (22 KW)tinhNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatinggabrieltravassosNo ratings yet

- Tube Rating: Properties of Fluid Inside TubeDocument4 pagesTube Rating: Properties of Fluid Inside Tubesiti_zubaidah_37No ratings yet

- Shell and Tube Heat ExchangerDocument19 pagesShell and Tube Heat ExchangerMangesh MandgeNo ratings yet

- Data Sheet 3D 65-160 156Document6 pagesData Sheet 3D 65-160 156Cristopher Jimenez JaramilloNo ratings yet

- New Heat Exchaner Design - 5mwDocument20 pagesNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Book 1Document1 pageBook 1Manju NaikNo ratings yet

- B41OA Datasheet 2017-2018Document7 pagesB41OA Datasheet 2017-2018Turkan AliyevaNo ratings yet

- Chapter 1Document4 pagesChapter 1Aiman HazimNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaNo ratings yet

- Heat Exchanger Calculation SheetDocument6 pagesHeat Exchanger Calculation SheetPrakashNo ratings yet

- PretraitementDocument5 pagesPretraitementAhmed WagihNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Data Sheet 80x65 FS2JA 5 22Document5 pagesData Sheet 80x65 FS2JA 5 22Cường NguyễnNo ratings yet

- 16 - Blending and AgitationDocument27 pages16 - Blending and AgitationSimon Tin Hann PyngNo ratings yet

- 4.... 65 DVS53.7....Document4 pages4.... 65 DVS53.7....tinhNo ratings yet

- Data Sheet 3D 40-160 4.0Document6 pagesData Sheet 3D 40-160 4.0Gokula Krishnan CNo ratings yet

- MC Fe-88115spiDocument1 pageMC Fe-88115spigallegos70No ratings yet

- Salt Day Tank Design With 50mm Dip - 01-03-2017Document8 pagesSalt Day Tank Design With 50mm Dip - 01-03-2017Dhamotharan ChinnaduraiNo ratings yet

- 6.... 100x80 FS HCA (37 KW)Document5 pages6.... 100x80 FS HCA (37 KW)tinhNo ratings yet

- 1.... Evmsg 515N5 Q1 Bege-3.0Document7 pages1.... Evmsg 515N5 Q1 Bege-3.0tinhNo ratings yet

- Design and Calculation AgitationDocument25 pagesDesign and Calculation Agitationibson045001256No ratings yet

- Fire Tank Recirculation Pump SizingDocument1 pageFire Tank Recirculation Pump SizingAkhil VijaiNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Data Sheet DWO 2006Document6 pagesData Sheet DWO 2006Josue UrgilésNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Oil Cooler DS FormDocument5 pagesOil Cooler DS Formmkfe2005No ratings yet

- Data Sheet GS4 80-400-438 B 37Document4 pagesData Sheet GS4 80-400-438 B 37arshin wildanNo ratings yet

- 30 TR IG Tube PDFDocument1 page30 TR IG Tube PDFshree awateNo ratings yet

- Che0405 Ped Lecture 1Document25 pagesChe0405 Ped Lecture 1miraNo ratings yet

- Charcoal Tower Pressure Drop CalculationDocument5 pagesCharcoal Tower Pressure Drop CalculationNalin GujaratiNo ratings yet

- Centrifugal Pump SizingDocument1 pageCentrifugal Pump SizingVIVEKZI0100% (1)

- Data Is Taken From Fluid PropDocument8 pagesData Is Taken From Fluid PropJofanny Ferdian Rahmansyah100% (1)

- bp3d CimmDocument17 pagesbp3d Cimmkuntasee.duckNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- Data Sheet 3M 40-200 9.26 IE3Document6 pagesData Sheet 3M 40-200 9.26 IE3Gokula Krishnan CNo ratings yet

- Data Sheet 3D 40-125 4.06Document6 pagesData Sheet 3D 40-125 4.06Cristopher Jimenez JaramilloNo ratings yet

- Heat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesDocument2 pagesHeat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesMohammad Mehdi JafariNo ratings yet

- Ebara 3PF 32-160 PDFDocument6 pagesEbara 3PF 32-160 PDFEddie GuillénNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- Data Sheet 3D 40-200 9.26Document6 pagesData Sheet 3D 40-200 9.26Josue UrgilésNo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Science 8 DLL Q1 Week 7Document5 pagesScience 8 DLL Q1 Week 7Jun De FontanozaNo ratings yet

- QTT Spare Part Deutz TCD Dan BF6MDocument2 pagesQTT Spare Part Deutz TCD Dan BF6MvirtualakunifnuNo ratings yet

- Listening 7Document4 pagesListening 7Vy PhạmNo ratings yet

- ML Ai in Gas Hydrate Exploration and Production ASSIGNMENT PDFDocument30 pagesML Ai in Gas Hydrate Exploration and Production ASSIGNMENT PDFAnurag TopnoNo ratings yet

- Exp-7 111Document4 pagesExp-7 111Dave Pooja DilipkumarNo ratings yet

- Source of Energy in The BiosphereDocument94 pagesSource of Energy in The BiosphereSamuel YangNo ratings yet

- Infra Audit Checklist Zone 4Document9 pagesInfra Audit Checklist Zone 4John Leo RosasNo ratings yet

- Oti Dali 10/220 240/700 NFC: Product DatasheetDocument5 pagesOti Dali 10/220 240/700 NFC: Product DatasheetKanakaraj PunchepadyNo ratings yet

- Civil Engineering Licensure ExaminationsDocument7 pagesCivil Engineering Licensure ExaminationsleryNo ratings yet

- Tetraethyllead: Jump To Navigation Jump To SearchDocument16 pagesTetraethyllead: Jump To Navigation Jump To SearchKenczar RomanoNo ratings yet

- Organic Chemistry 9Th Edition Carey Test Bank Full Chapter PDFDocument38 pagesOrganic Chemistry 9Th Edition Carey Test Bank Full Chapter PDFmisstepmonocarp1b69100% (9)

- Engineering Physics (PHY 1051)Document11 pagesEngineering Physics (PHY 1051)Harshita GauravNo ratings yet

- Fdocuments - in - Okida Electronics Internship ReportDocument22 pagesFdocuments - in - Okida Electronics Internship ReportSYNDICATE GamerNo ratings yet

- Grade 12 Set ADocument6 pagesGrade 12 Set Abalisimacmac095No ratings yet

- Alpha Laval Heat Exchangers DatasheetDocument18 pagesAlpha Laval Heat Exchangers Datasheetjosimarj272No ratings yet

- Channel Flow Behind CasingDocument2 pagesChannel Flow Behind Casingحسين رامي كريم A 12No ratings yet

- Renewable Energy in The Service of Mankind - Energy Efficiency Building Codes PDFDocument8 pagesRenewable Energy in The Service of Mankind - Energy Efficiency Building Codes PDFsatpal20253788No ratings yet

- Machine Lab 1Document7 pagesMachine Lab 1Taha Al-sprieNo ratings yet

- Eaton SWBD Quick Conn Design Guide Dg015007enDocument15 pagesEaton SWBD Quick Conn Design Guide Dg015007entammamshNo ratings yet

- Operating Manual: Continuous Band Sealer (Horizontal Orientation) Model No: FR-900SDocument5 pagesOperating Manual: Continuous Band Sealer (Horizontal Orientation) Model No: FR-900SVishal PorwalNo ratings yet

- LG Chem Residential Energy Storage 6.4ex Battery Pack ManualDocument42 pagesLG Chem Residential Energy Storage 6.4ex Battery Pack ManualCurariuDanielNo ratings yet

- Raal - Hidrolik SoğutucuDocument79 pagesRaal - Hidrolik SoğutucuRıfat BingülNo ratings yet

- Q4 Module 4 CompressedDocument2 pagesQ4 Module 4 CompressedFELIX ROBERT VALENZUELANo ratings yet

- PREPARE A Report Port of Various Pneumatic Hand Tools and Its AttachmentsDocument9 pagesPREPARE A Report Port of Various Pneumatic Hand Tools and Its AttachmentsMe Samarth BadsalNo ratings yet

- Instruction Manual: General-Purpose InverterDocument74 pagesInstruction Manual: General-Purpose InverterP100 Abdallah Ibrahem abdallah mohammed100% (1)

- ASTM D7547 For AVGAS UL91Document7 pagesASTM D7547 For AVGAS UL91tan kevinNo ratings yet

- Issct - Ijt PRSNTN June08Document21 pagesIssct - Ijt PRSNTN June08nagtummala100% (1)

- Rotor SailsDocument8 pagesRotor SailsVibha SharmaNo ratings yet

- Calculating Module VoltagesDocument2 pagesCalculating Module VoltagesTiu RonnelNo ratings yet