Professional Documents

Culture Documents

Controles de La Lm57 (Traccion Control)

Controles de La Lm57 (Traccion Control)

Uploaded by

Roberto henry martinez abastoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controles de La Lm57 (Traccion Control)

Controles de La Lm57 (Traccion Control)

Uploaded by

Roberto henry martinez abastoCopyright:

Available Formats

Trident S.A Doc. No.

WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 1 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Purpose

The purpose of this work instruction is to describe the steps to be taken to

assemble the Traction Control for the LM70/71 air loader to ensure that the

performance of the machine meets both Trident S.A & the respective client’s

specification.

Who is responsible for performing this task?

- Fitter / Assembler.

What documentation will be required?

- Atlas Loader (LM70/71) Check List (Form Number T/FM/012/03);

Procedure – Steps to perform task:

Safety

PPE EQUIPMENT

Ensure PPE Equipment worn. Who is Responsible

What PPE is required? for Safety?

- Eye protection;

- Ear protection; You are!

- Safety Shoes.

Assembly of the Traction Control (LM70/71)

Assembly of

the Traction

Control

Spares required to assembly the

Traction Controller.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 2 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Traction Control

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 3 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

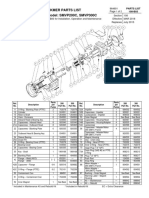

Spares Required to Assemble Traction Controller.

Ref. No. Part number QTY Description Standard Designation

1 5032 0155 01 1 Control Housing

2 0335 1146 00 2 Circlip 52

3 0657 5864 00 1 Gasket 61/71 x 2

4 5032 0164 00 15 Plug

5 0333 2125 00 15 Washer 8.2

6 0211 1322 00 **) 1 Screw M8 x 16-12.9

7 5031 0230 80 **) 1 Valve Housing Comp.

8 -*) 1 Valve Housing

9 -*) 1 Valve

13 0108 1292 00 1 Pin 5 x 12

14 5032 0152 00 1 Spacer

15 0335 2125 00 2 Circlip 23

16 5032 0154 00 1 Coil Spring

17 5032 0150 00 **) 1 Swivelling Link

18 5032 0151 00 **) 1 Felt Ring

19 0335 2146 00 1 Circlip 52

20 5032 0153 00 1 Pinion

21 0663 2136 00 2 O’Ring 44,2 x 5,7

22 5032 0165 00 1 Adapter

23 0663 2120 00 1 O’Ring 13.3 x 2,4

24 5032 0316 00 1 Safety Catch

25 5032 0279 00 1 Pin

26 0663 6135 00 1 O’Ring 54.5 x 3,1

27 5032 0146 80 **) 2 Liner with Valve

28 -*) **) 1 Liner

29 -*) **) 1 Valve

31 5032 0315 00 1 Lever

33 0108 1327 00 1 Pin 6 x 26

34 0113 2255 00 1 Pin 13 x 70

35 0111 1305 00 1 Pin 4 x 20

36 5032 0160 00 **) 1 Bushing

37 0295 3105 00 1 Nut 20

38 0108 1362 00 1 Pin 8 x 45

39 0337 2557 00 **) 4 Key 4x4x8

40 5032 0149 00 2 Bushing

41 5032 0148 00 Sleeve

42 9713 5358 00 Spring

43 5032 0161 00 Cover

44 5032 0156 00 Guard

45 0333 2136 00 **) 1 Washer 12.2

46 0147 1399 00 1 Screw M12 x 22-8.8

47 6001 2037 00 4 Spring

48 0517 1418 00 4 Ball

-*) Not delivered separately

**) Included in 9713 5501 94 Service Kit 255134474

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 4 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Assembly Process / Procedure

Place Control Housing (1) onto the work Insert O-Rings (26) into the four groves

bench. Working surface to be clean & machined inside the Control Housing.

tidy. Ensure that Control Housing has Ensure that O-Rings are properly seated

steam clean and free from any dirt. in the grooves.

Turn Control Housing

(1) onto its side as

shown on photograph.

Fit Liner (28) into the

bore of the Control

Housing.

Note: the “cut out

middle diameter”

must be facing

Apply grease or oil onto O-Rings towards the safety

assist with the fitting of the Liner catch ears – see

directional pointers.

(28).

Fitting of the Liner (28) may

necessitate making use of a

Fit Circlip (2) into both sides of the

nylon mallet and a wooden

rod to locate it. Control Housing after Liner (28) in

position. Ensure Circlip (2) seated

correctly.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 5 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

After fitting the Note: When inserting

circlips (2) insert the

the teeth of the

Valve (29). Valve can

Oil Valve (29) must face

be fitted from any one

of the two sides of the the same direction

Control Housing. as that of large hole

Before fitting apply

in the Liner (28).

oil to the Valve.

By making use of a vernier ensure that Apply grease to the Pinion (20) before

Valve (29) is center of the Liner (28). inserting it into the rear part of the

This can be achieved by measuring from Control Housing.

each side of the Control Housing (1).

When inserting the shaft ensure that the

shaft keyway is facing the top. – The

fitting of the shaft Key will be made Insert the Sleeve (25) onto the Pinion (22)

simpler by inserting the shaft that the shaft. By making use of the pin and the

shaft key slot is facing upwards. Once the hammer gently tap the sleeve until it

shaft inserted fit the circlip (19) to the seats into place on the shaft.

back of the Control Housing (1)

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 6 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Fit split pin (38) into the hole situated Fitting of the Split Pin (38) may

inside the Control Housing (1). necessitate the use of a hammer (Tool

No.XX) to locate it into position.

Fit the Shaft Key (39) to the Shaft (20). Slide the Sleeve (41) over the Bushing

(40).

Fit the Spring (42) by sliding it over Locating the bottom end of the Spring

the Bushing (41). (42) against the Pin (38) as shown in

above photograph.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 7 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

By making use of a side cutters / Photograph of Spring (42) in place.

Pliers pull the top end of the Spring

(42) over and past the Pin (38) and

release.

Apply grease to the Spring / Sleeve / Fit split pin (38) into the hole situated

Bushing configuration. inside the Cover (43).

Fitting the Pin

(38) to the correct

depth is crucial. If

not the correct

length the Pin

could catch on the

inside of the

cover causing the

Lever (31) to

Fitting of the Split Pin (38) may move from side to

side with

necessitate the use of a hammer to

difficulty.

locate it into position.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 8 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Split Pin should protrude ± 10mm. if Fit the Cover (3) to the Control Housing

once assembled the lever is found to (1). Ensure that the Pin (38) (attached to

be catching on the casing of the the cover) slots in-between the two ends

Control Housing the necessary of the spring ends. This allows the unit

adjustments to be made. to have the spring action both to the left

& to the right.

Check that the Pins (38) – both pins – one from the cover as well as the one from the

Control Housing does not catch / rub against the opposite component i.e. Control

Housing & End Cover. As you swing the cover from side to side also check that the unit

has a spring back action. Additionally, check for any play in the movement of the lever

relative to the spring tension. If ant movement found remove the Cover (43) and make

the necessary adjustments to the Spring (16) Ends.

Apply Loctite to the thread of the Shaft Screw on the Nut (37) and tighten.

(22) before fitting of the lock Nut (37).

Ensure that the Shaft thread is clean and

free of any grease & oil.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 9 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Slide Felt Ring (18) onto the Swivelling

1

Link (17) from the side of the large lug;

Slide the Spacer (14) onto the Swivelling

Link (17) from the side of the smaller lug

2

(Notice: direction spacer to allow Coil

Spring to be fitted);

Slide Coil Spring (16) onto Swivelling Link

3

(17);

Slide the Spacer (14) onto the Swivelling

Link (17) from the side of the smaller lug

4

(Notice: direction spacer to allow Coil

Spring to be fitted);

Once second Spacer (14) fitted compress

5 the two Spacers together compressing the

Coil Spring and clamp in vice grip;

The lug (smaller of the two ends) should

be sticking out of the Spring section.

6

Now slide the Valve (12) (female side)

onto the lug;

Secure Valve (12) section to the Lug of

7

the Swivelling Link (17);

8 View of Pin (13) inserted;

Apply grease to the Spring of the now

9 assembled section before inserting

the unit into the Control Housing (1).

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 10 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Apply grease to the Spring section of Insert the Sub Assembled unit, with

Sub Assembled unit. the lug side into the Control

Housing (1)

Photograph of the Sub Assembled unit Sub Assembled unit in place.

being inserted into the back section of

the Control Housing.

Once Sub Assembled unit in place fit the Before fitting the Valve Housing

circlip (15) Compl. (7) apply a generous layer of

oil into the opening of the Control

Housing (1).

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 11 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Insert the Valve Housing (8) into the Once Valve Housing (8) in place line-up

Control Housing (1) as shown in above the holes to insert the

photograph. Screws (6) & Washers (7).

Insert the Screws (6) and the Washers (5) By making use of an Allen Key tigthen the

to secure Valve Housing to the Control three screws.

Housing (1).

Fit Gasket (3) onto Plug (4). Screw the Plug (4) & Gasket (3) into the

Control Housing (1).

Note: Viewing the Control Housing from

the front with the Cover in full view

insert the Plug (4) into the left side of

the Control Housing.`

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 12 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

By making use of a fastening wrench Fit the Gasket (3) to the Adapter (22)

tighten the Plug (4). and screw it into the Control Housing

(1). This is fitted to the opposite side

to that of the Plug (4) and when

looking at the lever from the front

view its fitted on the right side.

By making use of the fastening wrench Fit the O-Ring (21) into the

tigthen the Adapter (22). Adapter (22).

Adapter (22 ) in place with O-Ring Insert the two Bushings (36) into the

(21) seated in Adapter. Cover (43) as shown above.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 13 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Bushing (36) in place Slide the Lever (31) into position as

shown above.

Insert the pin (34) through the Bushing Once Pin (34) through both Bushings (36)

(36) and Lever (31) secured insert Split Pin

(35) and bend one side of thepin open to

lock & prevent the Pin (34) from coming

loose.

Insert Pin (33) into back part of the By making use of a Pin Punch knock the

Lever (31). The Pin (33) must go Pin (33) in deep enough to secure the lug

through the eye of the Swivelling of the Swivelling Link (17) and prevent

Link’s lug (17). the Pin (36) from catching the sides of

the Cover.

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 14 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

Ensure that the Lever (31) moves up an

down and also ensure that the

Swivelling Link (17) attached to the

lever (31) via the Split Pin (33) also Insert the Safety Catch (24) between

moves freely up & down. the safety lugs on top of the Control

Housing (1).

By making use of a hammer (Tool No.XX) Safety Catch (24) securely in position.

knock the Pin (25) through the Safety

Catch Lug – through the Safety Catch –

and through the Safety Catch Lug.

Fit the Guard (44) by lining up the Once holes lined up fit the Guard (44)

holes in the Guard’s Mounting Bracket by screwing in the Bolts (46) and

with the drilled & tapped holes in the Washers (45)

Control Housing (1).

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

Trident S.A Doc. No. WI/750/008/03

ISO 9001:2008 - Work Instructions Rev. 02

Assembly of Traction Control Page Page 15 of 15

Loader Div. Compiled: W. Tribelhorn Approved: M. Calvert Date April 2009

TAKE PRIDE IN WHAT YOU DO!

PURSUE EXCELLENCE!

By making use of a ring spanner

QUALITY - A WAY OF LIFE

tigthen the Bolts (46).

END OF WORK INSTRUCTION

Date : Compiled By: Signature : Date : Approved By : Signature :

April 2009 W. Tribelhorn April 2009 M. Calvert

This document and its contents are the property of Trident SA. They are furnished to you on the following conditions: No right or license is given

or waived in supplying the document or its contents are not to be treated in any manner inconsistent with rights of Trident SA or to its detriment

and are not to be copied, reproduced to others, or disposed of except with prior consent of the undersigned.

You might also like

- Technical Manual MEP-006aDocument325 pagesTechnical Manual MEP-006amilhouse68100% (2)

- TMVW Orbital Motor Repair InstructionDocument28 pagesTMVW Orbital Motor Repair InstructionServicio TLMNo ratings yet

- ZOOMLION 櫓젬路옰Document376 pagesZOOMLION 櫓젬路옰Jamyansuren Tseveendorj100% (2)

- Towimor C30B-PK114Document246 pagesTowimor C30B-PK114john smithNo ratings yet

- 9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryDocument2 pages9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryGarcia CruzNo ratings yet

- Shantui SF50 SF60 SF70 Parts BookDocument162 pagesShantui SF50 SF60 SF70 Parts BookVontext100% (3)

- Vibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Document2 pagesVibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Control ExcavatorDocument20 pagesControl ExcavatorGarcia CruzNo ratings yet

- Brake Assembly (15 - 20 - 25 - 30 - 40) (05.3-04.2-002)Document2 pagesBrake Assembly (15 - 20 - 25 - 30 - 40) (05.3-04.2-002)Guillermo Cruz ValenciaNo ratings yet

- Flygt Basic Repair Kit. Kit CatalogueDocument44 pagesFlygt Basic Repair Kit. Kit Cataloguebezabih tegegnNo ratings yet

- Part Catalog Es22d5 Es28d5 X3engineDocument96 pagesPart Catalog Es22d5 Es28d5 X3engineSugeng Ariyadi100% (1)

- Suspension: 02-10 General ProceduresDocument1 pageSuspension: 02-10 General ProceduresSebastian SirventNo ratings yet

- QA103 (CC23) MC 481914Document1 pageQA103 (CC23) MC 481914م.حسين العامريNo ratings yet

- 4.0 Control ExcavatorDocument2 pages4.0 Control ExcavatorGarcia CruzNo ratings yet

- QA103 (CC04) MC 481892Document1 pageQA103 (CC04) MC 481892م.حسين العامريNo ratings yet

- QA103 (CC19) MC 481909Document1 pageQA103 (CC19) MC 481909م.حسين العامريNo ratings yet

- 245DI Parts Catg PDFDocument35 pages245DI Parts Catg PDFRahul PatelNo ratings yet

- Engine Mechanical: IVG30EDocument54 pagesEngine Mechanical: IVG30EWSMengine WSMengineNo ratings yet

- SV-09-039 - ZF Ecosplit Gearbox Valve Block Test Step List PDFDocument34 pagesSV-09-039 - ZF Ecosplit Gearbox Valve Block Test Step List PDFDavid Ross100% (3)

- 5 Engine Timing, Unimog 435 Workshop ManualDocument28 pages5 Engine Timing, Unimog 435 Workshop ManualJuan Jap100% (2)

- 33 Crankshaft Rear Seal - RemoveDocument2 pages33 Crankshaft Rear Seal - RemovegwahyudinnNo ratings yet

- Parts Manual ECL10MDocument57 pagesParts Manual ECL10MAdriana martinezNo ratings yet

- CTR Tubing Rotators Operating InstructionsDocument15 pagesCTR Tubing Rotators Operating InstructionsEvolution Oil ToolsNo ratings yet

- Globe Angle Valve Series - 5000Document25 pagesGlobe Angle Valve Series - 5000demblavalvesltd1989No ratings yet

- Oil ValveDocument4 pagesOil ValveGolbert GolbiNo ratings yet

- Armado de Transmision 924G - 101803Document30 pagesArmado de Transmision 924G - 101803linko estradaNo ratings yet

- 7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitDocument52 pages7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitFernando ChavesNo ratings yet

- 3.20 On-Off - 27000Document13 pages3.20 On-Off - 27000Cuong TranNo ratings yet

- (10 29 18 99) Regulator - 20200928 - 132443Document1 page(10 29 18 99) Regulator - 20200928 - 132443sam techgNo ratings yet

- 4 CxspaDocument848 pages4 CxspaJulian Andres ZancajoNo ratings yet

- Brake Assembly (15 - 20 - 25 - 30 - 40) (05.3-04.2-001)Document2 pagesBrake Assembly (15 - 20 - 25 - 30 - 40) (05.3-04.2-001)Guillermo Cruz ValenciaNo ratings yet

- Globe 3 Way Valve Series-3000Document25 pagesGlobe 3 Way Valve Series-3000demblavalvesltd1989No ratings yet

- Double Offset Butterfly Valve (Flanged Type) Series-7400Document25 pagesDouble Offset Butterfly Valve (Flanged Type) Series-7400demblavalvesltd1989No ratings yet

- 0370-AGA-0005 - I&MM Rev. Agosto 99Document44 pages0370-AGA-0005 - I&MM Rev. Agosto 99Carlos Rafael Uriarte VasquezNo ratings yet

- F2 Manual Transmission/Manual Transaxle: To IndexDocument21 pagesF2 Manual Transmission/Manual Transaxle: To IndexKwun Hok ChongNo ratings yet

- 2002 JCB JZ70 Fan Belt, Pulleys & TensionersDocument6 pages2002 JCB JZ70 Fan Belt, Pulleys & Tensionerscj002No ratings yet

- VM479Document8 pagesVM479Benydictus Ari SetiabudiNo ratings yet

- C15 T&A Engine Valve Lash - Inspect - AdjustDocument4 pagesC15 T&A Engine Valve Lash - Inspect - AdjustREYNALDO CARLONo ratings yet

- 31 Crankshaft Front Seal - Remove and InstallDocument4 pages31 Crankshaft Front Seal - Remove and InstallgwahyudinnNo ratings yet

- 8103-128 - SWE90U (SWE85-90) Parts BookDocument194 pages8103-128 - SWE90U (SWE85-90) Parts BookatakanNo ratings yet

- Turbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Document4 pagesTurbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Valve c4Document5 pagesValve c4lilikNo ratings yet

- Valve Tappet With Guide Block - WBD-IEL-5C0201Document1 pageValve Tappet With Guide Block - WBD-IEL-5C0201tomi100% (1)

- Engine Valve Lash - InspectAdjust (UENR4524-24)Document5 pagesEngine Valve Lash - InspectAdjust (UENR4524-24)Guido Emanuel SteinbachNo ratings yet

- RTH2610B - RT3210HV Carrier Catalogue PDFDocument16 pagesRTH2610B - RT3210HV Carrier Catalogue PDFasdNo ratings yet

- Flywheel Housing - Remove and Install - Standard Housing (KENR6081-15)Document8 pagesFlywheel Housing - Remove and Install - Standard Housing (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Technical Service Bulletin: 6MMT DTC P0900 Clutch Actuator Circuit MalfunctionDocument4 pagesTechnical Service Bulletin: 6MMT DTC P0900 Clutch Actuator Circuit MalfunctionNv TháiNo ratings yet

- Replace Valve Stem Seals With Cylinder Head InstalledDocument4 pagesReplace Valve Stem Seals With Cylinder Head InstalledRendy MechanicNo ratings yet

- (57 17 543 08) Driving Gear - 20200928 - 132503Document1 page(57 17 543 08) Driving Gear - 20200928 - 132503sam techgNo ratings yet

- B Ackmer PompaDocument2 pagesB Ackmer PompaGrzegorzNo ratings yet

- 03) Mazda-Allegro Manual de Taller Tren DelanteroDocument35 pages03) Mazda-Allegro Manual de Taller Tren DelanteroJohn Jairo MontoyaNo ratings yet

- Service PartsDocument6 pagesService Partsbundajoseph148No ratings yet

- DTC Trans AltimaDocument209 pagesDTC Trans AltimaAlberto AcostaNo ratings yet

- Service PartsDocument6 pagesService PartsESRANo ratings yet

- Parts JCB Js160lcDocument2,073 pagesParts JCB Js160lcAdriano SilvaNo ratings yet

- V-Ball Valve Series-8200FVDocument27 pagesV-Ball Valve Series-8200FVdemblavalvesltd1989No ratings yet

- Front Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersDocument30 pagesFront Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersCarlos SolisNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- martillo HLX 5 OMS80 (2) jumbo dsandvik dd321Document202 pagesmartillo HLX 5 OMS80 (2) jumbo dsandvik dd321Roberto henry martinez abastoNo ratings yet

- ELECTRICALDocument30 pagesELECTRICALRoberto henry martinez abastoNo ratings yet

- FRAME RELATEDDocument44 pagesFRAME RELATEDRoberto henry martinez abastoNo ratings yet

- st2gDocument643 pagesst2gRoberto henry martinez abastoNo ratings yet

- Asme Section Ix InterpretationDocument70 pagesAsme Section Ix InterpretationShubham ShuklaNo ratings yet

- MHC Checklist04Document13 pagesMHC Checklist04Tawfiq ZidanNo ratings yet

- Project Report On APPLICATION OF NEWTON'S FIRST LAWDocument10 pagesProject Report On APPLICATION OF NEWTON'S FIRST LAWALFIA KHANNo ratings yet

- LB3-46 ForkliftsDocument10 pagesLB3-46 ForkliftsWalidbenrhoumaNo ratings yet

- Brakes Clutches PDFDocument6 pagesBrakes Clutches PDFMarvinNo ratings yet

- Higher Order DerivativesDocument31 pagesHigher Order DerivativesNaitsirc UluputipanNo ratings yet

- Valvulas SMCDocument45 pagesValvulas SMCNacho PuenteNo ratings yet

- Buzwair - Rawdat Al-Khail Street (330) - Office No.03,5th Floor - Zone No. 25 - AL-Muntazah - Building No.57 DOHA-Tel: 44884667/9 - Mob.:55508140Document5 pagesBuzwair - Rawdat Al-Khail Street (330) - Office No.03,5th Floor - Zone No. 25 - AL-Muntazah - Building No.57 DOHA-Tel: 44884667/9 - Mob.:55508140NAHEEMA KPNo ratings yet

- Module 2 Approx Analysis of Rectangular Building FrameDocument16 pagesModule 2 Approx Analysis of Rectangular Building Frameshekaila.camisoNo ratings yet

- Apd 2006 07Document63 pagesApd 2006 07Soumen DasNo ratings yet

- Flat Springs, Torsion SpringsDocument1 pageFlat Springs, Torsion SpringsNenad MilanovicNo ratings yet

- LEPBP208M2 - PC200-8M0 J60001 and Up PDFDocument577 pagesLEPBP208M2 - PC200-8M0 J60001 and Up PDFteguh budiartoNo ratings yet

- CTS Welder 2017 SyllabusDocument55 pagesCTS Welder 2017 Syllabusgiti kalpi100% (1)

- Examples Work EnergiDocument108 pagesExamples Work EnergiMuhammad DaffaNo ratings yet

- ST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe LinesDocument10 pagesST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe LinesMaksim.em001No ratings yet

- Problem Set No. 5Document10 pagesProblem Set No. 5Carl Malone TolentinoNo ratings yet

- 1983, Holst T. L., Numerical Computation of Transonic Flow Governed by The Full-Potential Equation, NASA TM 84310 PDFDocument113 pages1983, Holst T. L., Numerical Computation of Transonic Flow Governed by The Full-Potential Equation, NASA TM 84310 PDFAnatoli KrasilnikovNo ratings yet

- Kaplan TurbineDocument7 pagesKaplan TurbineAaditya Aadi100% (1)

- Chapter 9 - Suggested ProblemsDocument10 pagesChapter 9 - Suggested Problemschanmyae toeyeeNo ratings yet

- PM 4 (2000 Hour Interval)Document9 pagesPM 4 (2000 Hour Interval)Ibrahim AwadNo ratings yet

- Reusabilidad de Bombas HidraulicasDocument134 pagesReusabilidad de Bombas HidraulicasAngelJavierCruzTorresNo ratings yet

- Air Conditioning Lab Unit A660Document155 pagesAir Conditioning Lab Unit A660Luyao ZHANG0% (1)

- Penggunaan High Damping Rubber Bearing System Pada Struktur Bangunan Gedung Dengan Analisis Time HistoryDocument10 pagesPenggunaan High Damping Rubber Bearing System Pada Struktur Bangunan Gedung Dengan Analisis Time HistoryC O L H O F V C KNo ratings yet

- Kathmandu Engineering College: Tutorial On Strain EnergyDocument2 pagesKathmandu Engineering College: Tutorial On Strain EnergyAlbie DahalNo ratings yet

- DR Apurba Talukdar Associate ProfessorDocument15 pagesDR Apurba Talukdar Associate ProfessorApurba TalukdarNo ratings yet

- TORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogDocument1 pageTORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogBluish FlameNo ratings yet

- Hermetic Type CAM CAMR EN 12 2019Document28 pagesHermetic Type CAM CAMR EN 12 2019SamanNo ratings yet

- IT Room Ground Floor - 12 KGDocument8 pagesIT Room Ground Floor - 12 KGhimajcpNo ratings yet

- Me 360 Armature DC Motor Transfer FunctionDocument2 pagesMe 360 Armature DC Motor Transfer FunctionArun SukumarNo ratings yet