Professional Documents

Culture Documents

RESISTORES DE FRENADO-for-sub-micro-and-smvector-series-drives

RESISTORES DE FRENADO-for-sub-micro-and-smvector-series-drives

Uploaded by

Kevin MorosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RESISTORES DE FRENADO-for-sub-micro-and-smvector-series-drives

RESISTORES DE FRENADO-for-sub-micro-and-smvector-series-drives

Uploaded by

Kevin MorosCopyright:

Available Formats

Application Note

Dynamic Brake Selection for Sub-Micro & SMV Series Drives

Dynamic braking is used when an overhauling load causes regeneration from the motor to occur, especially in

situations where the required deceleration time to stop the motor cannot be achieved due to High Voltage nuisance

tripping. Most Lenze-AC Tech DB circuits are rated for light-duty use only. The dynamic braking (DB) control circuit

is connected to and monitors the fixed DC bus line. When the DC bus reaches 114% of the maximum tolerance, it

triggers the chopper circuit in the dynamic brake. The DB circuit will be active whenever the voltage rises on the DC

bus. This can occur while the drive is running, while it accelerates or decelerates or even when it is stopped. Using

dynamic braking allows a faster deceleration time of a high inertia load. However, fast deceleration of a high inertia

load may sometimes cause regeneration and trip the drive into a High Voltage fault. To avoid this, a dynamic brake

chopping circuit is switched on when the voltage levels exceed the rated tolerance and brake resistors dissipate

the regenerated voltage as excess energy.

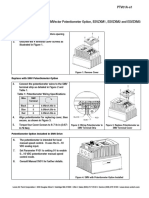

Thermal Protection from Overload for the DB Module

Lenze-AC Tech brake modules rated at 0.33 to 10 HP have resistors that are internally mounted. In these modules

there is a thermistor that monitors the resistor’s temperature and can be connected back to the drive to trigger a

drive fault. Refer to Table 1.

Table 1: Dynamic Braking Modules with Built-in Resistors

HP 240V 480V 590V

0.25-0.5 845-206 845-406 N/A

40 W / 250 Ω 40 W / 1000 Ω

1-1.5 845-209 845-409 845-509

80 W / 125 Ω 80 W / 500 Ω 80 W / 775 Ω

2-3 845-211 845-411 845-511

160 W / 63 Ω 160 W / 250 Ω 160 W / 388 Ω

5 845-213 845-413 845-513

240 W / 42 Ω 240 W / 167 Ω 240 W / 258 Ω

7.5 845-214 845-414 845-514

360 W / 28 Ω 360 W / 111 Ω 360 W / 172 Ω

10 845-215 845-415 845-515

480 W / 21 Ω 480 W / 83 Ω 480 W / 129 Ω

The larger modules (15 to 30 HP) use a brake chopper circuit plus a set of external resistors. These configurations

do not have a thermistor or any other means for monitoring resistor temperature. Refer to Tables 2 and 3.

Table 2: External Resistors for Sub-Micro Series DB Modules (15-30HP)

HP 240V 480V 590V

15-20 845-200 N/A N/A

15-30 N/A 845-400 845-500

Table 3: External Resistors for SMV Series DB Modules (15-30HP)

HP 240V 480V 590V

15-20 841-009 841-009 841-010

500W / 12W 510W / 47W 530W / 70W

25-30 N/A 841-011 841-012

770W / 31W 800W / 47W

1 AN 0039A April 2009

Copyright © 2009 by Lenze AC Tech Corporation www.lenze-actech.com 1-508-278-9100

For general information only. Content subject to change without notice.

Application Note

Both of these braking configurations are triggered and controlled by Lenze-AC Tech drive control software. This

means the control board is monitoring the DC bus level and triggers the brake when the voltage level exceeds

114%. The software is programmed to activate the chopper circuit for up to 5 seconds. If it doesn’t reduce the DC

Bus voltage to an acceptable level, then the module sends a fault trip (dF) to the drive. There is an algorithm in the

drive software that is designed to keep track of how long and how often the brake is triggered.

When smaller HP brake modules (0.33 - 10 HP) are applied, protection is provided by the thermistor and the soft-

ware algorithm. In the larger HP brake modules (15 - 30 HP) protection is provided by the software algorithm only.

For the SC series and SMV series1drives, the DB circuit is completely external to the drive inside a separate module.

The DB module is independent of the drive’s normal function and ratings. Current sharing or connecting the DC

bus terminals between multiple drives is not allowed. Use larger DB kits or connect modules in parallel to keep the

same drive size. Lenze-AC Tech offers modules based on HP and voltage rating. This means even a 15HP Dynamic

Brake module could be used on a 5HP drive.

Correctly Sizing the Dynamic Brake to Stop a Large Inertial Load

A very common question from customers is how to properly size dynamic braking for a large inertial load. In order

to do this, gather all the (drive) system mechanical and electrical characteristics to properly calculate the DB value.

Whether or not the DB resistor bank will meet these requirements can only be determined by analyzing the entire

mechanical system of the driven equipment.

Troubleshooting Dynamic Brake Faults

Drive Display shows “EF” when using a DB kit

The "EF" display means either noise is coming onto the 13A or 13B terminals, or the dynamic braking circuit is

sending a faulty signal to the drive. Disconnect the 13A or 13B wire feed to TB 47 on the braking module. If the

fault doesn't return, the problem is noise on that line or the DB module is bad. If a dF alarm occurs, the regenerated

energy is overheating the braking resistors. In this case, a higher resistor value is necessary.

Insufficient Energy from the Dynamic Braking Circuit

Sometimes the amount of energy that must be dissipated using dynamic braking is too much for the DB circuit.

Lenze-AC Tech Dynamic Braking circuits are primarily light-duty and not intended for long on-times. In this case,

using a separate line regeneration module is recommended. The line regeneration module is tied between the

3-phase input side of the drive and the DC bus terminals. It is used for regeneration control of any AC drive system

that uses a fixed DC bus system. This unit provides for regulation of the bus and prevents the drive from tripping

on overvoltage. Regeneration modules are available from companies like Bonitron.

Using a Lenze-AC Tech DB with Another Manufacturer's Drive

Applications Suipport is often asked if the Lenze-AC Tech DB module can be used with a non-Lenze AC Tech drive.

This is not possible. The Lenze-AC Tech sub-micro drives have specific inputs that are set to trigger the Lenze-AC

Tech DB modules. Other VFD manufacturers may encounter problems trying to trigger the DB chopper properly.

1 For the SMVector drives, the dynamic braking module includes a small connector that plugs onto the drive's DC

Bus Board for the B+ and B- connections. A set of mounting instructions is included.

2 AN 0039A April 2009

Copyright © 2009 by Lenze AC Tech Corporation www.lenze-actech.com 1-508-278-9100

For general information only. Content subject to change without notice.

You might also like

- COROLLA VERSO (EWD570E) Electrical and MoreDocument545 pagesCOROLLA VERSO (EWD570E) Electrical and MoresantiagoNo ratings yet

- Micro Controller Washing Machine TimerDocument40 pagesMicro Controller Washing Machine TimerArjun Pratap Singh85% (20)

- Robin AR4000 Series Data SheetDocument4 pagesRobin AR4000 Series Data SheetPaulo DiasNo ratings yet

- 01 Engine and PeripheralsDocument1,014 pages01 Engine and PeripheralsKorisnik195660% (5)

- Signa 400V/480V TWIN Catalog M3088TM / E4505CG Main Disconnect Panel Service ManualDocument44 pagesSigna 400V/480V TWIN Catalog M3088TM / E4505CG Main Disconnect Panel Service ManualJongchan Jason MoonNo ratings yet

- BL2 & BL4 DriverDocument68 pagesBL2 & BL4 DriverVasuPatelNo ratings yet

- LV Alternator (730kVA)Document12 pagesLV Alternator (730kVA)AfiqNo ratings yet

- Instructions - Sun 12 16k sg01lp1 Eu - 240203 - enDocument48 pagesInstructions - Sun 12 16k sg01lp1 Eu - 240203 - enf789sgacanonNo ratings yet

- Acme Main Buck Boost TransformersDocument16 pagesAcme Main Buck Boost TransformerssjcgraceNo ratings yet

- PS Technical Specifications 2014Document11 pagesPS Technical Specifications 2014Nihat KahvecioNo ratings yet

- Datasheet Inverter VE - Direct 250VA 1200VA enDocument2 pagesDatasheet Inverter VE - Direct 250VA 1200VA enErnesto Espinoza ArayaNo ratings yet

- Braking Unit For Frequency Inverter Serie 3CV 380 - 480V 18,5 Bis 55kWDocument14 pagesBraking Unit For Frequency Inverter Serie 3CV 380 - 480V 18,5 Bis 55kWany3000No ratings yet

- Braking Unit: (Product Profile)Document4 pagesBraking Unit: (Product Profile)ArtyomNo ratings yet

- TSG7000-Unipower 48V 10A Rectifier ModuleDocument3 pagesTSG7000-Unipower 48V 10A Rectifier ModuleAmelia GoordeenNo ratings yet

- Ups PDFDocument29 pagesUps PDFFeredNo ratings yet

- Safety Guide Smart-UPS® SU and SURT Under 5000 VA Uninterruptible Power Supply 220/230/240 VacDocument29 pagesSafety Guide Smart-UPS® SU and SURT Under 5000 VA Uninterruptible Power Supply 220/230/240 VacFeredNo ratings yet

- Manual Revolution87Document40 pagesManual Revolution87PruebaNo ratings yet

- Enermax - Platimax - Epm500awt Power SupplyDocument40 pagesEnermax - Platimax - Epm500awt Power Supplyuzdi_512034557No ratings yet

- Aj Power Ats Panels Handbook-En-rev3Document44 pagesAj Power Ats Panels Handbook-En-rev3Fernando QuisberthNo ratings yet

- ABB DatasheetDocument9 pagesABB DatasheetIsaac TellezNo ratings yet

- Reflected WaveDocument2 pagesReflected WaveMat MaxNo ratings yet

- f412daa6f827300577fc378a490b9e0dDocument40 pagesf412daa6f827300577fc378a490b9e0dRoma AbdoNo ratings yet

- On Grid Solar Power PlantDocument6 pagesOn Grid Solar Power PlantELANGOVAN VNo ratings yet

- Datasheet Phoenix Inverter VE - Direct 250VA 1200VA enDocument2 pagesDatasheet Phoenix Inverter VE - Direct 250VA 1200VA enMaxi I. Céspedes GonzalesNo ratings yet

- SMA Core1Document2 pagesSMA Core1Syed Umair AliNo ratings yet

- Bonfiglioli RPS InverterDocument16 pagesBonfiglioli RPS Inverterwesley maxmilianoNo ratings yet

- WEG MSW Switch Disconnectors 50038864 enDocument36 pagesWEG MSW Switch Disconnectors 50038864 enRODRIGO_RALONo ratings yet

- DAFL6775321853807447Document14 pagesDAFL6775321853807447HeinrichErnst1No ratings yet

- MultiPlus Generator FAQ (Victron Energy)Document6 pagesMultiPlus Generator FAQ (Victron Energy)georgesNo ratings yet

- M2FQ 7Document2 pagesM2FQ 7Cbdtxd PcbtrNo ratings yet

- Solar Datasheet CCTVDocument16 pagesSolar Datasheet CCTVAla' MuhannaNo ratings yet

- 510 Braking ManualDocument29 pages510 Braking Manualiveth oliverNo ratings yet

- Servo Training Rev2.2Document152 pagesServo Training Rev2.2Javier QuinchimbaNo ratings yet

- Catálogo Técnico Transferencias OTMDocument116 pagesCatálogo Técnico Transferencias OTMCarolina Alicia Bravo VillegasNo ratings yet

- AF75-30-00 48-130V 50Hz / 48-130V 60Hz / 48-130V DCDocument5 pagesAF75-30-00 48-130V 50Hz / 48-130V 60Hz / 48-130V DCpo truongNo ratings yet

- User Manual: Revo-Ii 3-5kva InverterDocument18 pagesUser Manual: Revo-Ii 3-5kva InverterAymanNo ratings yet

- Eaton Dilm750Document12 pagesEaton Dilm750tecnicohugogarciaNo ratings yet

- Outupt Reactor For AC Drive, Frequency InverterDocument2 pagesOutupt Reactor For AC Drive, Frequency InverterManikanta SwamyNo ratings yet

- Brake Chopper IM 09-08Document18 pagesBrake Chopper IM 09-08earespNo ratings yet

- Line Protection: 12.1 Classifications of Lines and FeedersDocument8 pagesLine Protection: 12.1 Classifications of Lines and FeedersSebastian MezaNo ratings yet

- SMA HIghpower Peak3 Product Datasheet EN 100 20Document2 pagesSMA HIghpower Peak3 Product Datasheet EN 100 20Michel GuerreroNo ratings yet

- 1SFA897110R7000 Pse142 600 70Document4 pages1SFA897110R7000 Pse142 600 70LUIS CARLOS SANDOVALNo ratings yet

- Functional Specification For Single Phase Pad Mounted Type Distribution Transformers 5 167 Kva Ps201002enDocument9 pagesFunctional Specification For Single Phase Pad Mounted Type Distribution Transformers 5 167 Kva Ps201002enRetsel WanNo ratings yet

- 208V Single Phase Power, MBB Bypass Switches, and Isolation Transformers: What You Need To KnowDocument3 pages208V Single Phase Power, MBB Bypass Switches, and Isolation Transformers: What You Need To KnowSteven MarksNo ratings yet

- Power-S - Datasheet - 20230515 V3.3Document8 pagesPower-S - Datasheet - 20230515 V3.3nwosuvictor31No ratings yet

- Manual Arrancador Suave Abb 210-600-70Document5 pagesManual Arrancador Suave Abb 210-600-70L.Miguel-6No ratings yet

- SudhirDocument24 pagesSudhirKomal MathurNo ratings yet

- M31e e ManualDocument23 pagesM31e e ManualВалсаNo ratings yet

- V Series Rectifier 102407 PDFDocument6 pagesV Series Rectifier 102407 PDFchiquilin2No ratings yet

- Onsemi Linear & Switching Voltage SMPS BookletDocument6 pagesOnsemi Linear & Switching Voltage SMPS BookletdonsterthemonsterNo ratings yet

- #3 MV1000 Micro Technology Presentation - Sept 2018 VSADocument46 pages#3 MV1000 Micro Technology Presentation - Sept 2018 VSAadolfoNo ratings yet

- Growatt 2500MTL-S/3000MTL-S/3600MTL-S/ 4200 MTL-S/5500MTL-S: Leading - Edge TechnologyDocument2 pagesGrowatt 2500MTL-S/3000MTL-S/3600MTL-S/ 4200 MTL-S/5500MTL-S: Leading - Edge TechnologyanhxcoNo ratings yet

- AF580-30-11 100-250V 50/60Hz / 100-250V DC Contactor: Product-DetailsDocument5 pagesAF580-30-11 100-250V 50/60Hz / 100-250V DC Contactor: Product-DetailsLê Xuân ĐịnhNo ratings yet

- 500 Watt Inverter Circuit With Battery Charger - Homemade Circuit ProjectsDocument38 pages500 Watt Inverter Circuit With Battery Charger - Homemade Circuit ProjectskaleemullaNo ratings yet

- Linkcv Family DatasheetDocument18 pagesLinkcv Family DatasheetaisanasNo ratings yet

- Item 1 y 2Document4 pagesItem 1 y 2MULTISERVICIOS FRESIA DEL SUR CANo ratings yet

- U35000 Motor BrakesDocument12 pagesU35000 Motor Brakesahmedalllam1993No ratings yet

- Generac Svp5000 97193 User ManualDocument16 pagesGenerac Svp5000 97193 User ManualJonathan smithNo ratings yet

- EP3000 PRO SERIES (1KW-6KW) : Low Frequency Power Inverter/ChargerDocument4 pagesEP3000 PRO SERIES (1KW-6KW) : Low Frequency Power Inverter/Chargeraqwa2No ratings yet

- SUMMER TRAINING REPORT - Astha - FinalDocument35 pagesSUMMER TRAINING REPORT - Astha - FinalAstha AroraNo ratings yet

- Small Size, Light Weight, Great Features, Best Value!: Blueplanet 2.0 TL1 - 3.0 TL1 4.0 TL1 - 5.0 TL1 Data SheetDocument3 pagesSmall Size, Light Weight, Great Features, Best Value!: Blueplanet 2.0 TL1 - 3.0 TL1 4.0 TL1 - 5.0 TL1 Data SheetYongki Adi Pratama PutraNo ratings yet

- Is Now Part ofDocument13 pagesIs Now Part ofRizkiWiraPratamaNo ratings yet

- LC1D25M7Document6 pagesLC1D25M7Dimaz IrawanNo ratings yet

- Smvector Esvzar0 Rs-485 Modbus Communication Module: Communications Interface Reference GuideDocument35 pagesSmvector Esvzar0 Rs-485 Modbus Communication Module: Communications Interface Reference GuideKevin MorosNo ratings yet

- Smvector Potentiometer Option Instalation01 12 12 2152Document1 pageSmvector Potentiometer Option Instalation01 12 12 2152Kevin MorosNo ratings yet

- Dynamic Braking Resistor: Installation InstructionsDocument2 pagesDynamic Braking Resistor: Installation InstructionsKevin MorosNo ratings yet

- SMV Series Wiring Lab: 3-Wire Start / StopDocument49 pagesSMV Series Wiring Lab: 3-Wire Start / StopKevin MorosNo ratings yet

- PNP Epitaxial Silicon Darlington Transistor: Monolithic Construction With Built in Base-Emitter Shunt ResistorsDocument4 pagesPNP Epitaxial Silicon Darlington Transistor: Monolithic Construction With Built in Base-Emitter Shunt ResistorsMiguel GuzmanNo ratings yet

- Annual EV Report Card IndiaDocument14 pagesAnnual EV Report Card Indiasankalp.prasaddas22hNo ratings yet

- IsolaterDocument4 pagesIsolatermorning star0% (1)

- Assignment 3: 2.6 Single-Phase Half-Wave Controlled RectifierDocument9 pagesAssignment 3: 2.6 Single-Phase Half-Wave Controlled RectifierNedaa AltawalbehNo ratings yet

- Engine Control System: SectionDocument612 pagesEngine Control System: SectionRuhu royNo ratings yet

- SEERS Si500 Vs HeatPump - Case Study Centralized Hotel 30 RoomsDocument2 pagesSEERS Si500 Vs HeatPump - Case Study Centralized Hotel 30 RoomsAdvantron CorporationNo ratings yet

- Pinwriter p2000p2xDocument64 pagesPinwriter p2000p2xИгорь ЛяхNo ratings yet

- RAB Kamar Jenazah 2023Document18 pagesRAB Kamar Jenazah 2023Erna watiNo ratings yet

- Dme-II Question BankDocument7 pagesDme-II Question BankenggsantuNo ratings yet

- Engine Control 6.2 Flex Fuel F350 2012Document8 pagesEngine Control 6.2 Flex Fuel F350 2012autoclinic33No ratings yet

- SB DatasheetDocument4 pagesSB DatasheetMohammad AnwarNo ratings yet

- CITEL 2CP 202105en DS50PV-1000 51Document1 pageCITEL 2CP 202105en DS50PV-1000 51ilhamNo ratings yet

- Metalux ResidentialDocument16 pagesMetalux ResidentialRAUL354No ratings yet

- Table - 68: A.C. Resistance and Reactance Values For Xlpe Insulated CablesDocument1 pageTable - 68: A.C. Resistance and Reactance Values For Xlpe Insulated CablesarshadbayaNo ratings yet

- Siemens Power Engineering Guide 7E 131Document1 pageSiemens Power Engineering Guide 7E 131mydearteacherNo ratings yet

- M03 Test ComponentsDocument131 pagesM03 Test ComponentsbilisummaaNo ratings yet

- PRTSCRDocument6 pagesPRTSCRneldiNo ratings yet

- Unit-1 - Analog Electronics CBDocument47 pagesUnit-1 - Analog Electronics CBNagesh BhaviNo ratings yet

- Piping Symbols Library Version 1Document7 pagesPiping Symbols Library Version 1swap dNo ratings yet

- Why Starting Current of Induction Motor Is High - Engineering TutorialDocument3 pagesWhy Starting Current of Induction Motor Is High - Engineering TutorialPabitra Kumar Patra100% (1)

- Answers To Question-2Document350 pagesAnswers To Question-2Dev KumarNo ratings yet

- Maintenance Practices - IIDocument27 pagesMaintenance Practices - IIrashmiameNo ratings yet

- Simple MachinesDocument13 pagesSimple Machinespetunia1008554No ratings yet

- TIP35/35A/35B/35C: Silicon NPN Power TransistorsDocument4 pagesTIP35/35A/35B/35C: Silicon NPN Power TransistorsJose David Perez ParadaNo ratings yet

- Active and Passive Components: Kunal WakodeDocument3 pagesActive and Passive Components: Kunal WakodeKunal WakodeNo ratings yet

- 2007 Model Year Yaris VehiclesDocument4 pages2007 Model Year Yaris VehiclesSajjad HussainNo ratings yet