Professional Documents

Culture Documents

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Uploaded by

Loan NguyênCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Piaggio Fly 50 2t (EN)Document153 pagesPiaggio Fly 50 2t (EN)ManuallesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bosch K-Jet (CIS)Document14 pagesBosch K-Jet (CIS)gjm126No ratings yet

- Hankinson Hhe SeriesDocument68 pagesHankinson Hhe SeriesWalter Simms JuniorNo ratings yet

- Pte20n BPT 005 enDocument33 pagesPte20n BPT 005 enЖеня СтецьNo ratings yet

- BA MARINER 320 Englisch 2010Document72 pagesBA MARINER 320 Englisch 2010Perc AleksandarNo ratings yet

- High Pressure Over Pressure Slam Shut Nominal Diameter " & 1"Document2 pagesHigh Pressure Over Pressure Slam Shut Nominal Diameter " & 1"hon choong chongNo ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- 4211-4, S 3Document8 pages4211-4, S 3arunachalakaniNo ratings yet

- Hydraulics by MakinoDocument112 pagesHydraulics by Makinopreetish123456100% (1)

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- FS Series Pneumatic Drive Bellows Pump Instruction ManualDocument42 pagesFS Series Pneumatic Drive Bellows Pump Instruction ManualIwaki AmericaNo ratings yet

- BM520Document2 pagesBM520semoyapaNo ratings yet

- Allison Transmission Troubleshooting Guide Rev 1 0 - 6927312 - 02Document7 pagesAllison Transmission Troubleshooting Guide Rev 1 0 - 6927312 - 02ahmed nour100% (1)

- Test2 21 22iiDocument15 pagesTest2 21 22iijocker's informationsNo ratings yet

- W10 HART ManualDocument182 pagesW10 HART ManualNahal FathirNo ratings yet

- DOC102 FM-200 Operation Design and Service Manual Revision FDocument131 pagesDOC102 FM-200 Operation Design and Service Manual Revision Fmax_powerNo ratings yet

- Weflo Swing Check Valve F0311-300-Data-SheetDocument1 pageWeflo Swing Check Valve F0311-300-Data-Sheetachmad.zs7827No ratings yet

- RD Circulating ValveDocument6 pagesRD Circulating ValvearslanadeelNo ratings yet

- Typical Well Control EquipmentDocument5 pagesTypical Well Control EquipmentJason AdamsNo ratings yet

- Digital Distributor Valves in Low Speed Motors - Practical ApproachDocument12 pagesDigital Distributor Valves in Low Speed Motors - Practical Approachhsrao77No ratings yet

- Hydro Series Wet Dispersion Units (MAN0479-05-En-00)Document116 pagesHydro Series Wet Dispersion Units (MAN0479-05-En-00)KREAL PELAYONo ratings yet

- Operation Manual (EngDocument78 pagesOperation Manual (EngAnonymous MxwCc4100% (1)

- ASTM F 1508 2021, Standard Specification For Angle Style, PressureDocument15 pagesASTM F 1508 2021, Standard Specification For Angle Style, PressurelaythNo ratings yet

- Single Packaged Air Conditioner: Service ManualDocument32 pagesSingle Packaged Air Conditioner: Service ManualIsrael Garfias LopezNo ratings yet

- Kontrol 50 For Pools and SpaDocument44 pagesKontrol 50 For Pools and SpaDaniela Téllez OrtegaNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- Brochure Ventiladores OeldeDocument6 pagesBrochure Ventiladores OeldeJorge CarignanoNo ratings yet

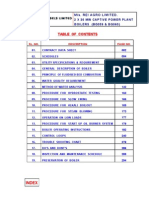

- NHPC Training ReportDocument85 pagesNHPC Training ReportShadab Khan100% (2)

- Appendix 7 - Wellsite Well Test Equipment Preparation ChecklistDocument6 pagesAppendix 7 - Wellsite Well Test Equipment Preparation Checklistsergiopuyo9184100% (3)

- Iom Forged GGC ValvesDocument12 pagesIom Forged GGC ValvesMohamadIbnuHassanNo ratings yet

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Uploaded by

Loan NguyênOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Capital Controls® Series 480: All Vacuum Gas Feeders Designed For Manual or Semi-Automatic Gas Regulation

Uploaded by

Loan NguyênCopyright:

Available Formats

CAPITAL CONTROLS®

SERIES 480

All vacuum gas feeders designed for

manual or semi-automatic gas regulation.

The Capital Controls® Series 480 all-vacuum gas feeder is

designed for direct mounting to a 150 pound gas cylinder or

ton container. It is a basic alternative for those applications

requiring a chlorine feed rate of 250 PPD (5 kg/h) or less.

The gas feed rate is controlled under sonic flow conditions

eliminating the need for an auxiliary differential pressure

regulators.

Multiple feed points can be fed using one feeder by utilizing

additional remote meters and corresponding ejectors.

A variety of different ejectors are available to meet specific

hydraulic requirements.

– Safe and reliable all-vacuum operation

– Superior materials of construction for wet or dry

gas service

– Safe integral venting system

– Six capacities up to 250 PPD (5 kg/h)

– Solid silver rate and inlet valves

– Direct cylinder mounted

– Replaceable inlet capsule

– Remote metering available

– Optional switchover capability with automatic reset for

uninterrupted service

For more information on Capital Controls® gas feeders

visit www.denora.com

We Understand

Gas Feed Systems

Capital Controls® Series 480 Design Features

Easy to install, for indoor or outdoor installation, each Series – Sonic Flow: Gas flows at sonic velocity maintaining constant

480 chlorinator is factory tested and needs no field adjustment gas flow; additional pressure regulation is not required

prior to start-up. Five different flowmeter capacities provide – Automatic Switchover: A separate, independent device that

versatility in meeting gas flow requirements. Chlorinators does not require manual reset. Flow indication is available

mount directly on the gas valve of a cylinder or ton container, at both vacuum regulators. Each vacuum regulator has a

utilizing a lead gasketed positive yoke clamp. Diaphragm separate independent vent and an integral pressure relief

ejectors are standard with a choice of diffuser outlets. check valve

A Series 480 chlorinator consists of a vacuum regulator,

– Reliable: Over 35 years of experience with all-vacuum

ejector or chemical induction unit and vacuum and vent

operation, loss of chlorine supply indicator, integral venting

tubing to make a complete system. If multiple feed points

system, main regulating diaphragm, integral gas flow

are required, remote meter panels and additional ejectors

indicator

are provided. A variety of ejectors are available to meet your

application needs. A switchover module is offered to provide – Ease of maintenance: Simplicity of design and modularized

for uninterrupted service. components; such as the replaceable inlet capsule for

minimized maintenance

– Superior materials of construction: Solid silver rate valve,

corrosion resistant yoke assembly, tantalum springs

Applications

For process water, waste treatment and water treatment in the

municipal or industrial marketplace:

– Potable water disinfection, well water, surface water

treatment facilities

– Slime and algae control: irrigation systems, cooling towers,

rechlorination points, remote systems

– Wastewater disinfection: packaged plants, lagoons, industrial

effluents

– Process water: chemical and pharmaceutical

manufacture, food (washdown, canning, bleaching, taste and

odor control)

– Cyanide, chromium removal: metal finishing wastes

– Recreation water: swimming pools, fountains, spray ponds

2 De Nora Water Technologies

Operation Technical Data

Water flowing through the ejector venturi, creates a vacuum Quality Standard: ISO 9001

which opens the check valve in the ejector. The vacuum is

carried through the vacuum line to the vacuum regulator Capacities: Standard dual-rate indicating flowmeters are

where the pressure differential created causes the inlet valve available with the following capacities: 4, 10, 25, 50, 100, 250

at the vacuum regulator to open, initiating gas flow. A spring PPD (75, 200 g/h, 0.5, 1, 2, 5 kg/h) of chlorine gas.

opposed diaphragm in the vacuum regulator, regulates the

vacuum. The gas passes under vacuum through the flowmeter, Flowmeter: The minimum feed capacity is 1/20th of the

the rate control valve, the vacuum line and to the ejector. Here maximum capacity. Accuracy is within ±4% of maximum

the gas is thoroughly mixed with the motive water and applied flowmeter capacity.

as a solution.

The system is completely under vacuum from the ejector to

the vacuum regulator inlet safety valve. If the water supply

to any ejector stops or vacuum is lost for any other reason,

Series 480 Vacuum Gas Feeder

the spring loaded inlet valve immediately closes and isolates

the gas supply. If the gas source is depleted, the unit seals to Model 4 8 ___ C ___ FEATURE

prevent moisture from being drawn back into the gas source.

When more than one feed point is desired multiple flowmeters A B C POSITION

and ejectors can be supplied.

Position Feature Description

A Maximum Capacity 1 100 PPD (2 kg/h)

2 250 PPD (5 kg/h)

B Gas Handled C Chlorine

Vacuum Regulator Cylinder or manifold

C 1

Mounting mounted with rate valve

Container mounted with

2

drip leg and rate valve

Cylinder or manifold

3 mounted with remote

meter(s) and rate valve

Container mounted with

4 drip leg with remote

meter(s) and rate valve

De Nora Water Technologies 3

We Understand

Gas Feed Systems

Automatic Switchover Chemical Induction Units

For uninterrupted gas feeding on a round-the-clock basis, an De Nora Water Technologies CHLOR-A-VAC® Series 1420

automatic switchover system is required. Each system consists chemical induction units offer improved chlorination and

of two vacuum regulators, one vacuum type automatic dechlorination through the high-efficiency mixing of gaseous

switchover module, one ejector and one remote meter panel. chemical with process water. This translates into operating and

An automatic switchover module allows gas to flow under chemical cost savings.

vacuum from the regulator in service through the switchover

module to the remote meter panel and the ejector, until that CHLOR-A-VAC® units produce a vacuum when process water

source is depleted. The vacuum sealing valve on the regulator passes through water inlet ports and through a venturi. The

then closes and the vacuum level in the system increases, high vacuum and recessed impeller create great turbulence to

initiating the spring-loaded toggle assembly in the switchover insure complete chemical mixing.

module. (See figure below)

A chemical induction unit in lieu of an ejector should be

The open valve on the depleted source closes while the valve considered for the following applications: contact basins,

on the standby source opens to permit gas flow. When a fresh headwater, return sludge processes, clarifier inlets, collection

gas supply replaces the depleted source it will automatically basins, equalization tanks and clear wells. (Refer to Bulletin

be placed in standby. The fresh supply will not be accessed 130.0001)

until the in-service supply is exhausted.

Automatic Switchover Flow Diagram

TO REMOTE CHLORINE O-RING SEAT

FLOWMETER

DIAPHRAGM

FROM FROM

VACUUM VACUUM

REGULATOR REGULATOR

NO. 1 NO. 2

TOGGLE ASSEMBLY

4 De Nora Water Technologies

Cylinder Mounted Chlorinator Flow Diagram

LEAD VACUUM SEAL

GASKET O-RING TO

INLET SAFETY VENT

CHLORINE VALVE RATE

CYLINDER VALVE VALVE OUTLET

STEM

CONNECTION

CHLORINE

CYLINDER VALVE

PACKING UNIT

VENT VALVE

VACUUM

YOKE LINE

X X

CLAMP

RATE INDICATOR

INLET FILTER

EJECTOR AND

REGULATING CHECK VALVE

DIAPHRAGM ASSEMBLY

CHLORINE

GAS ASSEMBLY

WATER SUPPLY EJECTOR

TO EJECTOR DISCHARGE

CHLORINE CHLORINE

LIQUID CYLINDER

OR

CHECK VALVE VACUUM LINE

POWER

CHLOR-A-VAC

CHEMICAL

INDUCTION UNIT

CONTACT TANK

De Nora Water Technologies 5

We Understand

Gas Feed Systems

Brief Specification Warranty

The chlorinator design shall be of the vacuum operated, De Nora Water Technologies offers a limited three (3) year

solution feed type. The chlorinator shall be constructed of warranty on the Series 480 chlorinator and a limited lifetime

materials suitable for wet or dry gas service. All springs used in warranty on the springs and Halar diaphragm.

the vacuum regulator shall be of tantalum alloy. The rate valve

and seat shall be solid silver. A diaphragm shall be provided De Nora Water Technologies is ISO 9001 certified to provide

for vacuum regulation. The rate of gas feed shall be set quality and precision materials.

manually and shall remain constant until manually changed.

The gas shall flow at sonic velocity is eliminating the need for a

differential pressure regulator.

The vacuum regulator shall mount directly on the container

valve by means of a corrosion resistant yoke assembly. A

spring-opposed inlet valve shall close tight upon loss of

vacuum. Each vacuum regulator shall be equipped with a

loss-of-gas indicator, and a gas flowmeter. A spring-loaded

diaphragm actuated pressure relief valve integral to the

vacuum regulator shall be provided to relieve gas pressure.

The inlet capsule shall be a complete module, installed

without the use of any tools.

The vacuum producing device shall be an ejector with a

spring-loaded check valve to prevent flooding of the vacuum

regulator or a CHLOR-A-VAC® chemical induction unit, Series

1420.

An automatic switchover module shall be provided with

automatic reset.

The chlorinator shall be De Nora Water Technologies Capital

Controls® Series 480C.

6 De Nora Water Technologies

Option: VEGA - Vent Exhaust Gas Arrestor

Refer to product bulletin 141.0001

Typical Arrangement

For those instances where occasional operational venting

cannot be tolerated, a VEGA can be used to eliminate any

errant gas emissions. The VEGA will last for a year under

normal operating condition.

De Nora Water Technologies 7

De Nora Water Technologies

3000 Advance Lane

Colmar, PA 18915

United States

T: +1 215 997 4000

F: +1 215 997 4062 SEP 2015

E: info.dnwt@denora.com

100.0001.17

www.denora.com

® Registered Trademark. © 2015. All Rights Reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Piaggio Fly 50 2t (EN)Document153 pagesPiaggio Fly 50 2t (EN)ManuallesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bosch K-Jet (CIS)Document14 pagesBosch K-Jet (CIS)gjm126No ratings yet

- Hankinson Hhe SeriesDocument68 pagesHankinson Hhe SeriesWalter Simms JuniorNo ratings yet

- Pte20n BPT 005 enDocument33 pagesPte20n BPT 005 enЖеня СтецьNo ratings yet

- BA MARINER 320 Englisch 2010Document72 pagesBA MARINER 320 Englisch 2010Perc AleksandarNo ratings yet

- High Pressure Over Pressure Slam Shut Nominal Diameter " & 1"Document2 pagesHigh Pressure Over Pressure Slam Shut Nominal Diameter " & 1"hon choong chongNo ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- 4211-4, S 3Document8 pages4211-4, S 3arunachalakaniNo ratings yet

- Hydraulics by MakinoDocument112 pagesHydraulics by Makinopreetish123456100% (1)

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- FS Series Pneumatic Drive Bellows Pump Instruction ManualDocument42 pagesFS Series Pneumatic Drive Bellows Pump Instruction ManualIwaki AmericaNo ratings yet

- BM520Document2 pagesBM520semoyapaNo ratings yet

- Allison Transmission Troubleshooting Guide Rev 1 0 - 6927312 - 02Document7 pagesAllison Transmission Troubleshooting Guide Rev 1 0 - 6927312 - 02ahmed nour100% (1)

- Test2 21 22iiDocument15 pagesTest2 21 22iijocker's informationsNo ratings yet

- W10 HART ManualDocument182 pagesW10 HART ManualNahal FathirNo ratings yet

- DOC102 FM-200 Operation Design and Service Manual Revision FDocument131 pagesDOC102 FM-200 Operation Design and Service Manual Revision Fmax_powerNo ratings yet

- Weflo Swing Check Valve F0311-300-Data-SheetDocument1 pageWeflo Swing Check Valve F0311-300-Data-Sheetachmad.zs7827No ratings yet

- RD Circulating ValveDocument6 pagesRD Circulating ValvearslanadeelNo ratings yet

- Typical Well Control EquipmentDocument5 pagesTypical Well Control EquipmentJason AdamsNo ratings yet

- Digital Distributor Valves in Low Speed Motors - Practical ApproachDocument12 pagesDigital Distributor Valves in Low Speed Motors - Practical Approachhsrao77No ratings yet

- Hydro Series Wet Dispersion Units (MAN0479-05-En-00)Document116 pagesHydro Series Wet Dispersion Units (MAN0479-05-En-00)KREAL PELAYONo ratings yet

- Operation Manual (EngDocument78 pagesOperation Manual (EngAnonymous MxwCc4100% (1)

- ASTM F 1508 2021, Standard Specification For Angle Style, PressureDocument15 pagesASTM F 1508 2021, Standard Specification For Angle Style, PressurelaythNo ratings yet

- Single Packaged Air Conditioner: Service ManualDocument32 pagesSingle Packaged Air Conditioner: Service ManualIsrael Garfias LopezNo ratings yet

- Kontrol 50 For Pools and SpaDocument44 pagesKontrol 50 For Pools and SpaDaniela Téllez OrtegaNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- Brochure Ventiladores OeldeDocument6 pagesBrochure Ventiladores OeldeJorge CarignanoNo ratings yet

- NHPC Training ReportDocument85 pagesNHPC Training ReportShadab Khan100% (2)

- Appendix 7 - Wellsite Well Test Equipment Preparation ChecklistDocument6 pagesAppendix 7 - Wellsite Well Test Equipment Preparation Checklistsergiopuyo9184100% (3)

- Iom Forged GGC ValvesDocument12 pagesIom Forged GGC ValvesMohamadIbnuHassanNo ratings yet