Professional Documents

Culture Documents

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Uploaded by

Sameer JogasCopyright:

Available Formats

You might also like

- European Heavy-Duty Vehicle Market Development Quarterly: January - September 2023 (Final v2)Document11 pagesEuropean Heavy-Duty Vehicle Market Development Quarterly: January - September 2023 (Final v2)The International Council on Clean TransportationNo ratings yet

- Project On TATA MOTORSDocument54 pagesProject On TATA MOTORSpreeyankagupta82% (87)

- SM498S CGC, CGP, CDP 20-30 Shop Manual: Main Table of ContentsDocument961 pagesSM498S CGC, CGP, CDP 20-30 Shop Manual: Main Table of ContentsMarioNo ratings yet

- Isuzu 4fb1 Engine ManualDocument3 pagesIsuzu 4fb1 Engine ManualGermán40% (10)

- Sae J287 1988 PDFDocument50 pagesSae J287 1988 PDFJason Rogers100% (2)

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 pagesHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Catalogo de Aplicacoes PoliDocument23 pagesCatalogo de Aplicacoes PoliÁlvaro Ricardo Lopatiuk0% (1)

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRaju100% (1)

- 001 SWMS - Piling WorkDocument20 pages001 SWMS - Piling Worksasi kumar0% (1)

- Jsa For Grinding WorkDocument113 pagesJsa For Grinding WorkAmit BhattNo ratings yet

- BackfillingDocument2 pagesBackfillingGyanendra Narayan NayakNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Scaffolding Risk AssessmentDocument4 pagesScaffolding Risk AssessmentDARENo ratings yet

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- RISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing WorksDocument9 pagesRISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing Worksmohsin.meizaNo ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- RA0019 General Lifting Operation v1Document6 pagesRA0019 General Lifting Operation v1dsadasNo ratings yet

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Curing Compound ApplicationDocument12 pagesCuring Compound ApplicationyashNo ratings yet

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliNo ratings yet

- Rig - 1 - Safety Observation Report#75Document1 pageRig - 1 - Safety Observation Report#75Jennifer WangNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (2)

- MEIL Rigging Plan For Unloading LoaderDocument4 pagesMEIL Rigging Plan For Unloading LoaderGyanendra Narayan NayakNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- JSA For Formwork (Shuttering)Document1 pageJSA For Formwork (Shuttering)HSE fahadNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- JSP For Over Head Crane (JSP-HHI-Comm-07)Document4 pagesJSP For Over Head Crane (JSP-HHI-Comm-07)Farooq MohammadNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- EEEPL - JSA Unloading MaterialsDocument3 pagesEEEPL - JSA Unloading MaterialsnishanthNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- HIRAC B224 Najarul On ConcreteDocument9 pagesHIRAC B224 Najarul On ConcreteSurendra JangidNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- All HiraDocument34 pagesAll HiraSuryavenkat RaghavanNo ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- Job Hazards AnalysisDocument3 pagesJob Hazards AnalysismohamedNo ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792100% (1)

- CCM HIRA Register (CCM)Document13 pagesCCM HIRA Register (CCM)mool rajNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- VO Summery For JAC 20210201 (R1)Document5 pagesVO Summery For JAC 20210201 (R1)Dinith ChathurangaNo ratings yet

- List Invoice Dan FP 3CDocument4 pagesList Invoice Dan FP 3CHagai STI TestNo ratings yet

- Heli Heftruck - All Kind of Oil Capacity ListDocument1 pageHeli Heftruck - All Kind of Oil Capacity ListFolkwin LapNo ratings yet

- Ad at 380T44 WH PDFDocument2 pagesAd at 380T44 WH PDFHani SweetieNo ratings yet

- Quebec Super Cheese Company QSC Produces Many Varieties of Cheese PDFDocument1 pageQuebec Super Cheese Company QSC Produces Many Varieties of Cheese PDFTaimour HassanNo ratings yet

- Sumber: Said Firman Furqan (Environment Departement)Document11 pagesSumber: Said Firman Furqan (Environment Departement)sri ramadhaniNo ratings yet

- Delivery OrderTai Tung-14Document4 pagesDelivery OrderTai Tung-14Malik FaisalNo ratings yet

- FATHDocument9 pagesFATHيوسف خزانيNo ratings yet

- SP2010Document2 pagesSP2010Ernesto Capdepon CarvajalNo ratings yet

- Battery Electric: Master Cylinder Master Cylinder Master CylinderDocument5 pagesBattery Electric: Master Cylinder Master Cylinder Master CylinderВиктор МушкинNo ratings yet

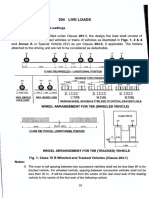

- 70R Track Live LoadDocument1 page70R Track Live LoadSrinivasulu Reddy KoduruNo ratings yet

- IGC 2 Element 2 New Syllabus PDFDocument10 pagesIGC 2 Element 2 New Syllabus PDFnaveed awanNo ratings yet

- Meet The: The New Standard in Terminal TractorsDocument5 pagesMeet The: The New Standard in Terminal TractorsEstefahnia CabezasNo ratings yet

- At 2352 - Automotive Chassis Components Design Question BankDocument13 pagesAt 2352 - Automotive Chassis Components Design Question Bankram sunNo ratings yet

- Tires InformationDocument2 pagesTires Informationمارتن بولسNo ratings yet

- American-Europe Catalogs 2010Document110 pagesAmerican-Europe Catalogs 2010Rodrigo Siqueira CalliariNo ratings yet

- Nippon Piston Ring Co.,Ltd.: Fit for SUZUKI /スズキ Fit for SUZUKI /スズキDocument3 pagesNippon Piston Ring Co.,Ltd.: Fit for SUZUKI /スズキ Fit for SUZUKI /スズキEdixo ReyesNo ratings yet

- As 210e Englisch 3 2015 PDFDocument8 pagesAs 210e Englisch 3 2015 PDFVandersonOrtolaniNo ratings yet

- Merritt Morning Market 3425 - May 27Document2 pagesMerritt Morning Market 3425 - May 27Kim LeclairNo ratings yet

- Self-Propelled Modular Trailers: For More Information, Please Have A LookDocument2 pagesSelf-Propelled Modular Trailers: For More Information, Please Have A LookAdnanNo ratings yet

- Engine Oil CapacitiesDocument2 pagesEngine Oil CapacitiessughieantoNo ratings yet

- 5 Performance Evaluation Criteria For The Analysis of Class-4Document6 pages5 Performance Evaluation Criteria For The Analysis of Class-4birdview champlainNo ratings yet

- Straightening I PressDocument6 pagesStraightening I PresssahayaNo ratings yet

- Catalogue TrailerbrakekitsDocument60 pagesCatalogue TrailerbrakekitsAaron GilmourNo ratings yet

- Europa Operators Handbook English (Olympus Euro 6)Document80 pagesEuropa Operators Handbook English (Olympus Euro 6)Przemysław PastuchaNo ratings yet

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Uploaded by

Sameer JogasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Index of OP Project HIRA Activities ID No. Activities Remarks Format No

Uploaded by

Sameer JogasCopyright:

Available Formats

Project Management, India

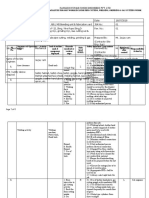

Index of OP Project HIRA Activities

ID No. Activities Remarks Format No.

Transportation of materials by vehicles (trailer, truck, tractor, camper, pickup, etc.) and equipment's K001B-OHS-OP Prj-

1 (forklift, farana, pick and carry etc.) HIRA-Tp006B/OP-ID-

Note: It is recommended not to use Hydra for shifting activity as this has inherent problem of toppling. 01/Rev06/Feb2020

Loading and Un loading of Materials by Mechanical Equipment (farana, pick and carry, tower crane, K001B-OHS-OP Prj-

2 mobile crane, pulleys, Monkey Lifts, etc.) HIRA-Tp006B/OP-ID-

Note: It is recommended not to use Hydra for shifting activity as this has inherent problem of toppling. 02/Rev06/Feb2020

K001B-OHS-OP Prj-

3 Scaffold Erection & Dismantling HIRA-Tp006B/OP-ID-

03/Rev06/Feb2020

K001B-OHS-OP Prj-

4 Fabrication works (Welding, Gas cutting, Grinding, Brazing, etc.) HIRA-Tp006B/OP-ID-

04/Rev06/Feb2020

K001B-OHS-OP Prj-

Temporary Electrical Supply, Installation Activities (Panels, DB's, Cable Management, Diesel Generator, HIRA-Tp006B/OP-ID-

5 Earthing, etc.)

05/Rev06/Feb2020

K001B-OHS-OP Prj-

6 Demolition, Chipping (by equipment, power tools, hand tools, etc.) HIRA-Tp006B/OP-ID-

06/Rev06/Feb2020

K001B-OHS-OP Prj-

7 Hoist (passenger / material) Operation & maintenance HIRA-Tp006B/OP-ID-

07/Rev06/Feb2020

K001B-OHS-OP Prj-

Loading, Unloading & Shifting of Materials from Store to work location (Manual and by using wheel

8 HIRA-Tp006B/OP-ID-

barrow, pallet trolley / truck, etc. )

08/Rev06/Feb2020

K001B-OHS-OP Prj-

9 Water proofing work (bitumen, adhesives, sealants, synthetic chemicals etc.) HIRA-Tp006B/OP-ID-

09/Rev06/Feb2020

K001B-OHS-OP Prj-

10 Masonry work in internal floors (block / brick work & plastering) HIRA-Tp006B/OP-ID-

10/Rev06/Feb2020

K001B-OHS-OP Prj-

11 Floor Cutting with floor cutting machine, chipping machine HIRA-Tp006B/OP-ID-

11/Rev06/Feb2020

K001B-OHS-OP Prj-

Supports fixing - Tie rod (Hi-tech), cable tray, conduit, angles, raceway, pipe fixing work (fire fighting, HIRA-Tp006B/OP-ID-

12 electrical, HVAC, FAPA, Access & Device Control Systems)

12/Rev06/Feb2020

Cable laying/ pulling works (Electrical, Fire Alarm & Public Addressing systems 'FAPA', Access Control & K001B-OHS-OP Prj-

13 HIRA-Tp006B/OP-ID-

Devices, Net working Cables)

13/Rev06/Feb2020

K001B-OHS-OP Prj-

14 Marking works at ceiling (HVAC, Electrical, FAPA, Access control, Fire fighting, C & I works) HIRA-Tp006B/OP-ID-

14/Rev06/Feb2020

K001B-OHS-OP Prj-

15 Duct fabrication, assembling and erection (GI, Pre-insulated ducts) HIRA-Tp006B/OP-ID-

15/Rev06/Feb2020

K001B-OHS-OP Prj-

16 Duct insulation (adhesives) HIRA-Tp006B/OP-ID-

16/Rev06/Feb2020

CBRE South Asia Pvt Ltd Page 1 of 7

Project Management, India

K001B-OHS-OP Prj-

17 Copper pipe fixing laying and jointing work (Brazing work) HIRA-Tp006B/OP-ID-

17/Rev06/Feb2020

K001B-OHS-OP Prj-

18 House Keeping on floors manual and mechanical HIRA-Tp006B/OP-ID-

18/Rev06/Feb2020

K001B-OHS-OP Prj-

19 Storage and use of Chemicals and materials / spares (in store/basement, etc.) HIRA-Tp006B/OP-ID-

19/Rev06/Feb2020

K001B-OHS-OP Prj-

20 Waste Management - segregation, storage, handling & disposal HIRA-Tp006B/OP-ID-

20/Rev06/Feb2020

K001B-OHS-OP Prj-

21 Work station installation & loose furniture installation HIRA-Tp006B/OP-ID-

21/Rev06/Feb2020

K001B-OHS-OP Prj-

22 Core cutting works HIRA-Tp006B/OP-ID-

22/Rev06/Feb2020

K001B-OHS-OP Prj-

23 Night Works HIRA-Tp006B/OP-ID-

23/Rev06/Feb2020

K001B-OHS-OP Prj-

24 Flooring Works (Tile/ marble/ granite Cutting and fixing work) HIRA-Tp006B/OP-ID-

24/Rev06/Feb2020

K001B-OHS-OP Prj-

25 False flooring work installation work HIRA-Tp006B/OP-ID-

25/Rev06/Feb2020

K001B-OHS-OP Prj-

26 POP Punning (application) for wall and ceiling work HIRA-Tp006B/OP-ID-

26/Rev06/Feb2020

K001B-OHS-OP Prj-

27 Gypsum partition / ceiling & MS / GI frame fixing HIRA-Tp006B/OP-ID-

27/Rev06/Feb2020

K001B-OHS-OP Prj-

28 Glass wool / rockwool fixing work HIRA-Tp006B/OP-ID-

28/Rev06/Feb2020

K001B-OHS-OP Prj-

29 Carpentry Work / Wood works , Corian Works (Shelf, tables, racks, doors, etc.) HIRA-Tp006B/OP-ID-

29/Rev06/Feb2020

K001B-OHS-OP Prj-

30 Wall chasing in wash rooms (chisel & hammer, cutting machine) HIRA-Tp006B/OP-ID-

30/Rev06/Feb2020

K001B-OHS-OP Prj-

31 Cutting Of PVC or CPVC pipes and joining as per requirement (by hacksaw & solvents) HIRA-Tp006B/OP-ID-

31/Rev06/Feb2020

K001B-OHS-OP Prj-

32 Shaft Work (Pipes laying, duct erection, fire fighting lines, electrical cable trays, gas lines, etc.) HIRA-Tp006B/OP-ID-

32/Rev06/Feb2020

CBRE South Asia Pvt Ltd Page 2 of 7

Project Management, India

K001B-OHS-OP Prj-

33 Installation of UPS and Batteries HIRA-Tp006B/OP-ID-

33/Rev06/Feb2020

K001B-OHS-OP Prj-

Below ceiling Internal works - Height Work (with the erection, use and dismantling of mobile or fixed HIRA-Tp006B/OP-ID-

34 scaffold and ladder) - 1.8 meters height work platform / level from floor

34/Rev06/Feb2020

K001B-OHS-OP Prj-

35 Commissioning & energizing of new electrical, mechanical, hydraulic or pneumatic equipment HIRA-Tp006B/OP-ID-

35/Rev06/Feb2020

K001B-OHS-OP Prj-

Coating of liquid on any surface for corrosion protection/anti- termite/insulation/aesthetics/paint etc.

36 HIRA-Tp006B/OP-ID-

(with brush or spray gun)

36/Rev06/Feb2020

K001B-OHS-OP Prj-

37 Partition Glass Installation (storage, shifting, handling, cutting, & fixing, sealant usage) HIRA-Tp006B/OP-ID-

37/Rev06/Feb2020

K001B-OHS-OP Prj-

38 Carpet laying in floors HIRA-Tp006B/OP-ID-

38/Rev06/Feb2020

Format No. K001B-OHS-OP Prj-HIRA-Tp006B/Rev06/Feb2020

CBRE South Asia Pvt Ltd Page 3 of 7

Project Management, India

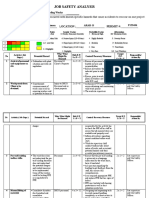

MASTER DOCUMENT Revised OP- PROJECT RISK INDEX FOR HIRA

Note: Master document shall be revised in every 6 months based on the analysis of OHSE dashboard analysis & key learnings of various incidents both internal & external issues

AUDITOR COMMENTS: Auditor Comments:BSI,REI,NST, /NT

CATEGORY OF COMPLIANCE WITH LEGISLATION AND

SEVERITY LEVEL EXPOSOURE PROBABLITY REGULATIONS

SR NO.

DISCRIPTION FREQUENCY DISCRIPTION

(S) RATING (E) RATING (P) RATING LEGISLATION RATING

All aspects to which

No health effect /injury

1 /No damage. 1 (Very Low) Rarely 1 (Very Low) Never heard in Projects / Office 1 (Very Low) legislation/regulations YES - Significance

applies

First Aid Injury / Slight The existence of

2 health effect / little 2 (Low) Once in month 2 (Low) Heard in Projects / Offices outside 2 (Low) legislation/regulations has NO - No Significance

damage to property no influence on significance

REVISION REGISTER:

Incident happened in Projects of our

Minor Injury / health effect organization / company 2-3 times in a 3 (Moderate) R1- 06.11.2020

3

/ illness 3 (Moderate) Once in a week 3 (Moderate)

year.

Major injury / health effect

/ illness (fractures, Happened in Projects of our

4 breaking of organs, injury 4 (High) Once/twice a day 4 (High) organization / company 5-6 times in a 4 (High)

year

to body parts).

Fatal / Permanent loss of

organs / functions (eyes, Happened several times in a year in

5

legs, hands.) / Dangerous 5 (Very High) Continuous 5 (Very High) our Projects / Offices 5 (Very High)

Occurrences.

Risk Evaluation REMARKS:

LOW: MODERATE: HIGH:

IMPACT RISK UPTO 30 IMPACT RISK 31 TO 60 IMPACT RISK 61 & ABOVE

1 In the event Severity is 5 or the legislation is "NO"- irrespective of overall score, Risk is always high.

Note:

1. Revision details to be recorded in the given column & revision number and date to be updated in the document.

2. Speed limit of 10-15 KMPH for the vehicle movement inside the project site.

3. Tool Box talks for all the workforce involved in the activity to be conducted daily.

4. Contractor's supervisor shall ensure close monitoring the activity & ensure the control measures & workers adhere to safe working practices all the time.

5. All electrical cables to be routed overhead & electrical equipment to be routed through 30 mA ELCB / RCCB with earth connectivity.

6. Usage of mobile phones to be avoided while working in the site

7. Maintenance of construction machinery not to be carried out in the project site, if the maintenance is inevitable, contractor must take the client approval & submit a copy to CBRE for information & records.

8. In addition to the checklist defined in this document, PM can also use the OHSE checklist which are available in Wrench & update the details in the document

9. All internal audits shall be carried out based on this document in line with the mandatory requirement of applicable ISO 9001 standards.

10. All work permits to be checked in site by package in charge & SME mandatorily, comments to be written on the document with signature & time or site note with Permit number as reference.

PROJECT SPECIFIC HIRA DOCUMENTS FROM SIDDHIVINAYAK ENTERPRISES - Revised on: 26/06/2021

REGION : PUNE

Prepared & Reviewed By: Shubham Jogas

Project Name : IBM Project ETZ & TPO Name & Signature

Date : 26/06/2021

SEVERITY EXPOSOURE PROBABLITY

S FREQUENCY P LEGISLATION EXISTING ACTION MEASURE FOR RISK CONTROL OPERATIONAL CONTROL

ID No. ACTIVITY HAZARDS ASSOCIATED RISK (Relates to E IMPACT RISK CONTROL IN RISK LEVEL DOCUMENTS & Reference

Associated (Relates to (Relates to L PLACE ( please provide the second level document title and number from OHSE master list of documents for each activity ) no

Risk) Hazard) Incidents)

Offloading 1. fall of material

or damaged 1. injury to

1.Unload on level solid / non slippery ground with sufficient space.

2. Proper supervision while unloading so that other people in the area are aware of the

1 the material material body 3 1 2 N 1 ongoing activity.

from truck / 3. Use of hand gloves, safety shoes, helmets.

tempo

Shifting of 1. fall of material 1. injury to 1. Use of pallet to shift the material from 1 point to another point.

the material or damaged body 2. place the material as per the capacity of the pallet

from material 3. Use of hand gloves, safety shoes, helmets

2 unloading 2 2 2 N 1

area to

store area.

working on 1.Fall from 1.Erect scffold on on level surface

height height 2.wear all necesssary p.p.e. s

2.Fall of

3 material 2 2 1 N 2

drilling work 1.Fall from 1.wear mask and goggle while drilling 2.use

height wire with no joints

2.Fall of

4 material 2 2 2 N 2

copper pipe Fall from 1. use goofles and dust mask while deilling. 2.use

installation height drill machine without joints. 3. do

2.Fall of drill not horse play while working.

machine on

5 body 2 2 2 N 1

3.electric

shock

Brazing 1. Fire. 1. Use cylinders with N.R.V.

work 2.fall of 2.Use goggle while doing breezing 3.

cylinders Always place cylinder in tralley with chaning arrangmant.

6 3 2 3 N 3 4. Fire extinguisher should be kept near workplace.

Duct 1.fall of duct 1. adpot good posture while hanging duct 2.

hanging on body use helmet and hand gloves.

7 1 2 2 N 1

Casseette 1. Use lifter to lift casseete machine. 2.

installation 1.fall of use necessary P.P.Es

8 machine on 1 2 2 N 2

body

Refrigrant 1.cylinder should be placed in tralley. 2.

filling M.S.D.S. should be available ar workplace.

1.fall of

9 cylinder 2 1 2 N 1

2.burn to

hand

CBRE South Asia Pvt Ltd Page 4 of 7

Project Management, India

CBRE South Asia Pvt Ltd Page 5 of 7

Project Management, India

Format No. K001B-OHS-Prj-HIRA-Tp006B/Rev06/Feb2020

CBRE South Asia Pvt Ltd Page 6 of 7

HIRA Revision register

Project Name: IBM (ETZ & TPO)

Revision No : 00

Date of Revision :

SR.NO Date Revised Point Point No

You might also like

- European Heavy-Duty Vehicle Market Development Quarterly: January - September 2023 (Final v2)Document11 pagesEuropean Heavy-Duty Vehicle Market Development Quarterly: January - September 2023 (Final v2)The International Council on Clean TransportationNo ratings yet

- Project On TATA MOTORSDocument54 pagesProject On TATA MOTORSpreeyankagupta82% (87)

- SM498S CGC, CGP, CDP 20-30 Shop Manual: Main Table of ContentsDocument961 pagesSM498S CGC, CGP, CDP 20-30 Shop Manual: Main Table of ContentsMarioNo ratings yet

- Isuzu 4fb1 Engine ManualDocument3 pagesIsuzu 4fb1 Engine ManualGermán40% (10)

- Sae J287 1988 PDFDocument50 pagesSae J287 1988 PDFJason Rogers100% (2)

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 pagesHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Catalogo de Aplicacoes PoliDocument23 pagesCatalogo de Aplicacoes PoliÁlvaro Ricardo Lopatiuk0% (1)

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRaju100% (1)

- 001 SWMS - Piling WorkDocument20 pages001 SWMS - Piling Worksasi kumar0% (1)

- Jsa For Grinding WorkDocument113 pagesJsa For Grinding WorkAmit BhattNo ratings yet

- BackfillingDocument2 pagesBackfillingGyanendra Narayan NayakNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Scaffolding Risk AssessmentDocument4 pagesScaffolding Risk AssessmentDARENo ratings yet

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- RISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing WorksDocument9 pagesRISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing Worksmohsin.meizaNo ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- RA0019 General Lifting Operation v1Document6 pagesRA0019 General Lifting Operation v1dsadasNo ratings yet

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Curing Compound ApplicationDocument12 pagesCuring Compound ApplicationyashNo ratings yet

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliNo ratings yet

- Rig - 1 - Safety Observation Report#75Document1 pageRig - 1 - Safety Observation Report#75Jennifer WangNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (2)

- MEIL Rigging Plan For Unloading LoaderDocument4 pagesMEIL Rigging Plan For Unloading LoaderGyanendra Narayan NayakNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- JSA For Formwork (Shuttering)Document1 pageJSA For Formwork (Shuttering)HSE fahadNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- JSP For Over Head Crane (JSP-HHI-Comm-07)Document4 pagesJSP For Over Head Crane (JSP-HHI-Comm-07)Farooq MohammadNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- EEEPL - JSA Unloading MaterialsDocument3 pagesEEEPL - JSA Unloading MaterialsnishanthNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- HIRAC B224 Najarul On ConcreteDocument9 pagesHIRAC B224 Najarul On ConcreteSurendra JangidNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- All HiraDocument34 pagesAll HiraSuryavenkat RaghavanNo ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- Job Hazards AnalysisDocument3 pagesJob Hazards AnalysismohamedNo ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792100% (1)

- CCM HIRA Register (CCM)Document13 pagesCCM HIRA Register (CCM)mool rajNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- VO Summery For JAC 20210201 (R1)Document5 pagesVO Summery For JAC 20210201 (R1)Dinith ChathurangaNo ratings yet

- List Invoice Dan FP 3CDocument4 pagesList Invoice Dan FP 3CHagai STI TestNo ratings yet

- Heli Heftruck - All Kind of Oil Capacity ListDocument1 pageHeli Heftruck - All Kind of Oil Capacity ListFolkwin LapNo ratings yet

- Ad at 380T44 WH PDFDocument2 pagesAd at 380T44 WH PDFHani SweetieNo ratings yet

- Quebec Super Cheese Company QSC Produces Many Varieties of Cheese PDFDocument1 pageQuebec Super Cheese Company QSC Produces Many Varieties of Cheese PDFTaimour HassanNo ratings yet

- Sumber: Said Firman Furqan (Environment Departement)Document11 pagesSumber: Said Firman Furqan (Environment Departement)sri ramadhaniNo ratings yet

- Delivery OrderTai Tung-14Document4 pagesDelivery OrderTai Tung-14Malik FaisalNo ratings yet

- FATHDocument9 pagesFATHيوسف خزانيNo ratings yet

- SP2010Document2 pagesSP2010Ernesto Capdepon CarvajalNo ratings yet

- Battery Electric: Master Cylinder Master Cylinder Master CylinderDocument5 pagesBattery Electric: Master Cylinder Master Cylinder Master CylinderВиктор МушкинNo ratings yet

- 70R Track Live LoadDocument1 page70R Track Live LoadSrinivasulu Reddy KoduruNo ratings yet

- IGC 2 Element 2 New Syllabus PDFDocument10 pagesIGC 2 Element 2 New Syllabus PDFnaveed awanNo ratings yet

- Meet The: The New Standard in Terminal TractorsDocument5 pagesMeet The: The New Standard in Terminal TractorsEstefahnia CabezasNo ratings yet

- At 2352 - Automotive Chassis Components Design Question BankDocument13 pagesAt 2352 - Automotive Chassis Components Design Question Bankram sunNo ratings yet

- Tires InformationDocument2 pagesTires Informationمارتن بولسNo ratings yet

- American-Europe Catalogs 2010Document110 pagesAmerican-Europe Catalogs 2010Rodrigo Siqueira CalliariNo ratings yet

- Nippon Piston Ring Co.,Ltd.: Fit for SUZUKI /スズキ Fit for SUZUKI /スズキDocument3 pagesNippon Piston Ring Co.,Ltd.: Fit for SUZUKI /スズキ Fit for SUZUKI /スズキEdixo ReyesNo ratings yet

- As 210e Englisch 3 2015 PDFDocument8 pagesAs 210e Englisch 3 2015 PDFVandersonOrtolaniNo ratings yet

- Merritt Morning Market 3425 - May 27Document2 pagesMerritt Morning Market 3425 - May 27Kim LeclairNo ratings yet

- Self-Propelled Modular Trailers: For More Information, Please Have A LookDocument2 pagesSelf-Propelled Modular Trailers: For More Information, Please Have A LookAdnanNo ratings yet

- Engine Oil CapacitiesDocument2 pagesEngine Oil CapacitiessughieantoNo ratings yet

- 5 Performance Evaluation Criteria For The Analysis of Class-4Document6 pages5 Performance Evaluation Criteria For The Analysis of Class-4birdview champlainNo ratings yet

- Straightening I PressDocument6 pagesStraightening I PresssahayaNo ratings yet

- Catalogue TrailerbrakekitsDocument60 pagesCatalogue TrailerbrakekitsAaron GilmourNo ratings yet

- Europa Operators Handbook English (Olympus Euro 6)Document80 pagesEuropa Operators Handbook English (Olympus Euro 6)Przemysław PastuchaNo ratings yet