Professional Documents

Culture Documents

Footing F2: Design of Isolated Footing

Footing F2: Design of Isolated Footing

Uploaded by

PraYush RajbhandariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Footing F2: Design of Isolated Footing

Footing F2: Design of Isolated Footing

Uploaded by

PraYush RajbhandariCopyright:

Available Formats

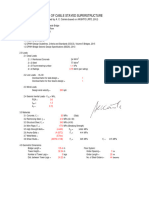

DESIGN OF ISOLATED FOOTING

Footing F2

Input Load Combination:

Width along x, a 500 mm x-direction

Width along y, b 500 mm y-direction

Grade of concrete,fck = 20 N/mm2 Pu (kN) Mux(kNm) Muy (kNm)

2

Grade of steel, fy = 500 N/mm 1337.5 7.244 17.3375

Clear cover 50 mm P (kN) Mx(kNm) My (kNm)

Safe bearing pressure 150 kN/m2 980.84 4.83 11.56

Loading condition Normal ey = 0.005 m

Safe bearing pressure for given loading 150 kN/m2 ex = 0.013 m

Quick Check

Calculated length 2.56 m Suggested Length 2.65 m (X-dimension)

Calculated width 2.56 m Suggested width 2.65 m (Y-dimension)

Pressure at corner points

at (-1.325,1.325) = 137.50 OK at (1.325,1.325) = 144.95 OK

at (-1.325,-1.325) = 134.39 OK at (1.325,-1.325) = 141.84 OK

Check for development length: OK Check for bearing pressure: SAFE

Check for X-direction Check for Y-direction

Required d for moment 216.57 mm Required d for moment 217

Provide D 500.00 mm Provide D 500.00

Diameter of bars 12 mm Diameter of bars 12

Calculated Spacing 164 mm Calculated Spacing 163

Provided spacing 125 mm Provided spacing 125

Check for two way shear SAFE Check for two way shear SAFE

Check for one way shear SAFE Check for one way shear SAFE

Calculations

2

Area of footing required, LB 6.54 m

a-b = 0 mm

𝐿^2−(𝑎−𝑏)𝐿−𝐿𝐵=0 Ref. S.N Sinha

L= 2.56 m Provide 2.65 m

B= 2.56 m Provide 2.65 m

Area provided = 7.0225 m2

Moment of Inertia about X axix, Ix = 4.11 m4

Moment of Inertia about Y axix, Iy = 4.11 m4

Stress at any point is given by, 𝑝=𝑃/𝐴+𝑀_𝑦/𝐼_𝑥 𝑥+𝑀

At x = -L/2 = -1.33 y = -B/2 = -1.325 p= 134.39 kN/m2 OK

x = L/2 = 1.325 y = -B/2 = -1.325 p= 141.84 kN/m2 OK

x = L/2 = 1.325 y = B/2 = 1.325 p= 144.95 kN/m2 OK

x = -L/2 = -1.325 y = B/2 = 1.325 p= 137.50 kN/m2 OK

Calculation for X-direction

206.25 (Factored upward pressure)

217.43 kN/m2

1.58 m 1.08 m

212.90

Bending moment at critical section 124.76 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 217 mm

Provide overall depth, D 500 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 432 mm

0.66851

Ast required 691.63 mm2

Ast minimum 518.4 mm2

Spacing 163.52 mm Provide 125 mm c/c

Area of steel provided 904.78 mm2 and pt = 0.21%

Provide 12 mm dia bars @ 125 mm c/c at bottom (Parallel to X)

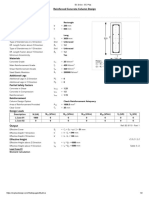

Check for two way shear:

Critical Section in two way shear

The critical section for the two way

2

shear occurs at a distance of d/2

from the face of the column 1.5

a+d = 932 mm 1

b+d = 932 mm 0.5

Punching area = 0.87 m2 0

Punching perimeter = 3.728 m -2.00 -1.00 0.00 1.00 2.00

-0.5

-1

Factored pressure at corners

2 -1.5

at (-0.466,-0.466) = 206.72 kN/m

2 -2

at (0.466,-0.466) = 210.65 kN/m

2

at (0.466,0.466) = 212.29 kN/m

2

at (-0.466,0.466) = 208.36 kN/m

2

Average factored upward pressure = 209.506 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

1155.52 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣 = 0.72 N/mm Ref. IS 456: 2000, Cl. 31.6.1

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.643 m from edge of the fooring

2

Factored upward stress at that point = 214.718 kN/m

2

Average upward stress 216.075 kN/m

Total shear force along the critical section = 368.18 kN

2

Nominal shear stress 0.32 N/mm

Percentage of steel, pt 0.21%

= 11.23

2

Design shear stress, = 0.33 N/mm

SAFE

Calculation for Y-direction

212.76 (Factored upward pressure)

217.43 kN/m2

1.58 m 1.08 m

215.54

Bending moment at critical section 125.27 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 217 mm

Provide overall depth, D 500 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 432 mm

0.671

Ast required 694.572 mm2

Ast minimum 518.4 mm2

Spacing 162.83 mm Provide 125 mm c/c

Area of steel provided 904.78 mm2 and pt = 0.21%

Provide 12 mm dia bars @ 125 mm c/c at bottom (Parallel to X)

Check for two way shear:

The critical section for the two way Critical Section in two way shear

shear occurs at a distance of d/2 2

from the face of the column 1.5

a+d = 932 mm

1

b+d = 932 mm

0.5

Punching area = 0.87 m2

Punching perimeter = 3.728 m 0

-2.00 -1.00 0.00 1.00 2.00

-0.5

Factored pressure at corners

-1

2

at (-0.466,-0.466) = 206.72 kN/m

2 -1.5

at (0.466,-0.466) = 210.65 kN/m

2 -2

at (0.466,0.466) = 212.29 kN/m

2

at (-0.466,0.466) = 208.36 kN/m

2

Average factored upward pressure = 209.506 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

1155.52 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣= 0.72 N/mm

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE Ref. IS 456: 2000, Cl. 31.6.1

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.643 m from edge of the fooring

2

Factored upward stress at that point = 216.298 kN/m

2

Average upward stress 216.864 kN/m

Total shear force along the critical section = 369.526 kN

2

Nominal shear stress 0.32 N/mm

Percentage of steel, pt 0.21%

= 11.23

2

Design shear stress, = 0.33 N/mm

SAFE

Check for development Length

Sufficient development length should be available for the reinforcement from the critical section.

2 2

𝜏_𝑏𝑑= 1.92 N/mm 𝜎_𝑠= 434.783 N/mm

Ld = 679 mm

The total length available from the critical section = 0.5(L - a)- Cover 1025 mm

OK

Check for bearing stress

2

A1 = 7.0225 m 2

2 2

A2 = 0.25 m = 18 N/mm

2

5.35 N/mm SAFE

You might also like

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Martin's Physical Pharmacy - Chapters 2 - 12 (High Yeild!)Document14 pagesMartin's Physical Pharmacy - Chapters 2 - 12 (High Yeild!)Lloyd Selorio ArboledaNo ratings yet

- The Fundamental StructureDocument3 pagesThe Fundamental StructureDhrubajyoti debNo ratings yet

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Isolated Footing F1Document3 pagesDesign of Isolated Footing F1PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Pad Footing - F1: Project Structure Document TitleDocument1 pageDesign of Pad Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Footing Design Details-HASSAN HASSANIDocument354 pagesFooting Design Details-HASSAN HASSANIShaniha kkNo ratings yet

- Footing-Design PDFDocument10 pagesFooting-Design PDFAhmed MohammedNo ratings yet

- Sloped Isolated Tata-Steel-Ld3 PDFDocument12 pagesSloped Isolated Tata-Steel-Ld3 PDFArvind DoraiNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- F1 (NODE NO 279) : Design of FootingsDocument12 pagesF1 (NODE NO 279) : Design of FootingsPinapaSrikanthNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Design of Footing - F1: Project Structure Document TitleDocument1 pageDesign of Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Rectangular Footing - Concrete DesignDocument6 pagesRectangular Footing - Concrete DesignVincelord CabadduNo ratings yet

- Design of Combined Footing For Staircase Columns: Project Structure Document TitleDocument1 pageDesign of Combined Footing For Staircase Columns: Project Structure Document TitlerisrizNo ratings yet

- MM Ty Eccentrici 20 : DB F PDocument2 pagesMM Ty Eccentrici 20 : DB F PPraYush RajbhandariNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Raft FoundationDocument12 pagesRaft FoundationAasif ShaikNo ratings yet

- Design CalculationsDocument110 pagesDesign Calculationsfredcantos02.mc88No ratings yet

- G 3 EccDocument8 pagesG 3 EcckuttyNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- DPT 2 EkstrDocument62 pagesDPT 2 EkstrSeptiawan D4fNo ratings yet

- Footing Design F1Document16 pagesFooting Design F1Urmi PanchalNo ratings yet

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Col Design MenukaDocument3 pagesCol Design Menukaprakashchalise1993No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Isolated FootingDocument4 pagesIsolated FootingMark Brien Vincent YbañezNo ratings yet

- Footing PDFDocument1 pageFooting PDFDorothy Leonardo ObriqueNo ratings yet

- Design of Square Footing: F-1Document1 pageDesign of Square Footing: F-1Dorothy Leonardo ObriqueNo ratings yet

- Isolated Footing Design F2Document16 pagesIsolated Footing Design F2Saugat ThapaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CHAPTER 2 Part 2 PDFDocument55 pagesCHAPTER 2 Part 2 PDFAB20 012 Lee Yee XynnNo ratings yet

- Square Footing - Concrete DesignDocument5 pagesSquare Footing - Concrete DesignVincelord CabadduNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Miscellaneous DesignDocument5 pagesMiscellaneous DesignShaun PattersonNo ratings yet

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignPraYush RajbhandariNo ratings yet

- All QntyDocument8 pagesAll QntyPraYush RajbhandariNo ratings yet

- Research Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesDocument17 pagesResearch Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesPraYush RajbhandariNo ratings yet

- Design of Strap Foundation (3C-3D)Document5 pagesDesign of Strap Foundation (3C-3D)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- Staircase Design: Open Well Second FlightDocument3 pagesStaircase Design: Open Well Second FlightPraYush RajbhandariNo ratings yet

- Design of Combined Footing (Cf1)Document3 pagesDesign of Combined Footing (Cf1)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Open Well Staircase First and Third FlightDocument2 pagesSTAIRCASE DESIGN: Open Well Staircase First and Third FlightPraYush RajbhandariNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Agreement For Residential Building Construction (Labor and Material)Document3 pagesAgreement For Residential Building Construction (Labor and Material)PraYush RajbhandariNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Document1 pagePlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Final Arch Drawing-Layout2Document1 pageFinal Arch Drawing-Layout2PraYush RajbhandariNo ratings yet

- Is 269 PDFDocument1 pageIs 269 PDFPraYush RajbhandariNo ratings yet

- LMA 2014 12 036 ContainersDocument3 pagesLMA 2014 12 036 ContainersJuan Andrés Díaz RiveroNo ratings yet

- Design and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-MarathonDocument76 pagesDesign and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-Marathonanhelllo100% (1)

- Experimental Investigation On Swash Plate Axial Piston Pumps With Conical Cylinder Blocks Using Fuzzy Logic ControlDocument9 pagesExperimental Investigation On Swash Plate Axial Piston Pumps With Conical Cylinder Blocks Using Fuzzy Logic ControlpiopollastriNo ratings yet

- Visit: Civildatas - Blogspot.inDocument9 pagesVisit: Civildatas - Blogspot.insankaran sNo ratings yet

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- Rock Mechanics - Unit - 3 PDFDocument11 pagesRock Mechanics - Unit - 3 PDFAkshay MehtaNo ratings yet

- Example Beam ProblemDocument2 pagesExample Beam ProblemxicaodocetNo ratings yet

- Es 13 PS 1Document5 pagesEs 13 PS 1Reynald DaluzNo ratings yet

- Searl DiscDocument13 pagesSearl DiscSteve Zettler100% (4)

- SBK TDocument1 pageSBK Tralish12No ratings yet

- Analysis of Flange Transverse Bending of Corrugated Web I-Girders Under In-Plane LoadsDocument9 pagesAnalysis of Flange Transverse Bending of Corrugated Web I-Girders Under In-Plane LoadsAsr FlowerNo ratings yet

- CM 2010 Fasc 4A EnglezaDocument41 pagesCM 2010 Fasc 4A EnglezaAlina Mirela0% (1)

- 020 - Automatic Transmission - 6T70 (M7U M7W) - SpecificationsDocument8 pages020 - Automatic Transmission - 6T70 (M7U M7W) - SpecificationsGedas GvildysNo ratings yet

- Shear CalculationDocument12 pagesShear CalculationJohn Patric Ranjo SiaNo ratings yet

- PC2 - Practice Exam WorkedDocument12 pagesPC2 - Practice Exam WorkednomsyNo ratings yet

- Methods of Analysis For Earthquake Resistant Design123Document41 pagesMethods of Analysis For Earthquake Resistant Design123Sudip PathakNo ratings yet

- Hydrogen Balmer Series and Rydberg ConstantDocument4 pagesHydrogen Balmer Series and Rydberg Constantflawson0078970100% (2)

- Cavitation NotesDocument12 pagesCavitation NotesrajeevNo ratings yet

- 2016 Specimen Paper 4 Mark SchemeDocument6 pages2016 Specimen Paper 4 Mark SchemeMaheerNo ratings yet

- Mems 1 Ktunotes - inDocument36 pagesMems 1 Ktunotes - inAlfin TomNo ratings yet

- Modeling and Adaptive Control of An Omni-Mecanum-Wheeled RobotDocument14 pagesModeling and Adaptive Control of An Omni-Mecanum-Wheeled RobotTelmoNo ratings yet

- QUESTION BANK COMPOSITE Unit1Document2 pagesQUESTION BANK COMPOSITE Unit1Ganesh Natarajan SNo ratings yet

- Implementation of Interactive Control of A Crane Ship Model in MATLAB/Simulink EnvironmentDocument9 pagesImplementation of Interactive Control of A Crane Ship Model in MATLAB/Simulink EnvironmenthathamphanNo ratings yet

- Relativistic Mechanics-Complete Notes (Unedited)Document98 pagesRelativistic Mechanics-Complete Notes (Unedited)Mehul GuptaNo ratings yet

- Vibration Analysis of GearsDocument21 pagesVibration Analysis of GearsAnil_Nambiaruveetil100% (6)

- 3 Reciprocating Pump Air Vessel and Indicator Diag - 231127 - 162720Document41 pages3 Reciprocating Pump Air Vessel and Indicator Diag - 231127 - 162720Muhammad MubashirNo ratings yet

- Acoustics PPTDocument22 pagesAcoustics PPTankiw89100% (1)