Professional Documents

Culture Documents

Footing F3: Design of Isolated Footing

Footing F3: Design of Isolated Footing

Uploaded by

PraYush RajbhandariCopyright:

Available Formats

You might also like

- Forces in Equilibrium LabDocument15 pagesForces in Equilibrium LabNabil IbrahimNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Isolated Footing F1Document3 pagesDesign of Isolated Footing F1PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Pad Footing - F1: Project Structure Document TitleDocument1 pageDesign of Pad Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Footing Design Details-HASSAN HASSANIDocument354 pagesFooting Design Details-HASSAN HASSANIShaniha kkNo ratings yet

- Footing-Design PDFDocument10 pagesFooting-Design PDFAhmed MohammedNo ratings yet

- Sloped Isolated Tata-Steel-Ld3 PDFDocument12 pagesSloped Isolated Tata-Steel-Ld3 PDFArvind DoraiNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- F1 (NODE NO 279) : Design of FootingsDocument12 pagesF1 (NODE NO 279) : Design of FootingsPinapaSrikanthNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Design of Footing - F1: Project Structure Document TitleDocument1 pageDesign of Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Rectangular Footing - Concrete DesignDocument6 pagesRectangular Footing - Concrete DesignVincelord CabadduNo ratings yet

- Design of Combined Footing For Staircase Columns: Project Structure Document TitleDocument1 pageDesign of Combined Footing For Staircase Columns: Project Structure Document TitlerisrizNo ratings yet

- MM Ty Eccentrici 20 : DB F PDocument2 pagesMM Ty Eccentrici 20 : DB F PPraYush RajbhandariNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Raft FoundationDocument12 pagesRaft FoundationAasif ShaikNo ratings yet

- Design CalculationsDocument110 pagesDesign Calculationsfredcantos02.mc88No ratings yet

- G 3 EccDocument8 pagesG 3 EcckuttyNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- DPT 2 EkstrDocument62 pagesDPT 2 EkstrSeptiawan D4fNo ratings yet

- Footing Design F1Document16 pagesFooting Design F1Urmi PanchalNo ratings yet

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Col Design MenukaDocument3 pagesCol Design Menukaprakashchalise1993No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Isolated FootingDocument4 pagesIsolated FootingMark Brien Vincent YbañezNo ratings yet

- Footing PDFDocument1 pageFooting PDFDorothy Leonardo ObriqueNo ratings yet

- Design of Square Footing: F-1Document1 pageDesign of Square Footing: F-1Dorothy Leonardo ObriqueNo ratings yet

- Isolated Footing Design F2Document16 pagesIsolated Footing Design F2Saugat ThapaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CHAPTER 2 Part 2 PDFDocument55 pagesCHAPTER 2 Part 2 PDFAB20 012 Lee Yee XynnNo ratings yet

- Square Footing - Concrete DesignDocument5 pagesSquare Footing - Concrete DesignVincelord CabadduNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Miscellaneous DesignDocument5 pagesMiscellaneous DesignShaun PattersonNo ratings yet

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignPraYush RajbhandariNo ratings yet

- All QntyDocument8 pagesAll QntyPraYush RajbhandariNo ratings yet

- Research Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesDocument17 pagesResearch Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesPraYush RajbhandariNo ratings yet

- Design of Strap Foundation (3C-3D)Document5 pagesDesign of Strap Foundation (3C-3D)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- Staircase Design: Open Well Second FlightDocument3 pagesStaircase Design: Open Well Second FlightPraYush RajbhandariNo ratings yet

- Design of Combined Footing (Cf1)Document3 pagesDesign of Combined Footing (Cf1)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Open Well Staircase First and Third FlightDocument2 pagesSTAIRCASE DESIGN: Open Well Staircase First and Third FlightPraYush RajbhandariNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Agreement For Residential Building Construction (Labor and Material)Document3 pagesAgreement For Residential Building Construction (Labor and Material)PraYush RajbhandariNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Document1 pagePlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Final Arch Drawing-Layout2Document1 pageFinal Arch Drawing-Layout2PraYush RajbhandariNo ratings yet

- Is 269 PDFDocument1 pageIs 269 PDFPraYush RajbhandariNo ratings yet

- Brochure SchedulefmfpDocument22 pagesBrochure SchedulefmfpAaradhya MishraNo ratings yet

- Boundary Layed - NoteDocument3 pagesBoundary Layed - NoteMohammed AlshangitiNo ratings yet

- Is800 2007 PDFDocument150 pagesIs800 2007 PDFAnonymous dSFbLxc9100% (3)

- (Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27Document8 pages(Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27AlinaBogoiNo ratings yet

- 132 TOP Strength of Materials Multiple Choice Questions and Answers PDF MCQs Preparation For Engineering Competitive Exams PDFDocument12 pages132 TOP Strength of Materials Multiple Choice Questions and Answers PDF MCQs Preparation For Engineering Competitive Exams PDFDivakar singhNo ratings yet

- Elasticity, Calorimetry & Thermal Expansion (Teaching Notes)Document21 pagesElasticity, Calorimetry & Thermal Expansion (Teaching Notes)Sankar KumarasamyNo ratings yet

- Human Perception of Wind Farm Vibration: Duc-Phuc Nguyen, Kristy Hansen and Branko ZajamsekDocument11 pagesHuman Perception of Wind Farm Vibration: Duc-Phuc Nguyen, Kristy Hansen and Branko ZajamsekgpromoNo ratings yet

- Solutions To I E Irodov Problems in General PhysicsDocument3 pagesSolutions To I E Irodov Problems in General Physicsakshit14nov1996No ratings yet

- 2.1 MotionDocument18 pages2.1 MotioncetinNo ratings yet

- WTC2005 63324 PDFDocument2 pagesWTC2005 63324 PDFMarcelo VeronezNo ratings yet

- Prs w01d1 QonlyDocument9 pagesPrs w01d1 Qonlyakirank1No ratings yet

- Fluid Mech. ExperimentDocument12 pagesFluid Mech. Experimentsimple-CE-studNo ratings yet

- CH 13Document15 pagesCH 13xperia30100% (1)

- Simulation Analysis of Hydraulic Lifting Mechanism of A ForkliftDocument4 pagesSimulation Analysis of Hydraulic Lifting Mechanism of A ForkliftPacy MugishoNo ratings yet

- CalorimeterDocument3 pagesCalorimeterSagarika ManmohanNo ratings yet

- Selection and Design of An Axial Flow FanDocument4 pagesSelection and Design of An Axial Flow Fanashwin vijayNo ratings yet

- The Great Blunders - in Modern - PhysicsDocument128 pagesThe Great Blunders - in Modern - Physicsrennie1957No ratings yet

- Thin and Thick Cylindrical Shells UNIT-5Document15 pagesThin and Thick Cylindrical Shells UNIT-5Parikshit YadavNo ratings yet

- Physics L.O: Matter, Form and FunctionDocument7 pagesPhysics L.O: Matter, Form and FunctionAbo Alphotoh GamingNo ratings yet

- The Added Mass Coefficient Computation of Sphere, Ellipsoid and Marine Propellers Using Boundary Element MethodDocument10 pagesThe Added Mass Coefficient Computation of Sphere, Ellipsoid and Marine Propellers Using Boundary Element MethodsantoshNo ratings yet

- Report - AirfoilDocument14 pagesReport - Airfoilvivek bhatiNo ratings yet

- 04 LAJPE 782 ChudinovDocument5 pages04 LAJPE 782 Chudinovbenitogaldos19gmail.comNo ratings yet

- Natural Convection Heat Transfer in A Baffled TriangularDocument15 pagesNatural Convection Heat Transfer in A Baffled Triangularbooklover1950No ratings yet

- Physics A: Unit 2: Approved Specimen Mark SchemeDocument9 pagesPhysics A: Unit 2: Approved Specimen Mark SchemeSam LankaNo ratings yet

- Physics: Physics EUEE 2007 E.C Grade 11 Unit OneDocument34 pagesPhysics: Physics EUEE 2007 E.C Grade 11 Unit OneFuad AminNo ratings yet

- BUET04 UDocument31 pagesBUET04 Uমোঃ ইনজামুল হক মেহেদীNo ratings yet

- Chapter 3 Fluid Flow - Question SetDocument2 pagesChapter 3 Fluid Flow - Question SetAbhijit KuchbhilikhtaNo ratings yet

- Differential ManometersDocument3 pagesDifferential ManometersAnonymous QM0NLqZO100% (1)

Footing F3: Design of Isolated Footing

Footing F3: Design of Isolated Footing

Uploaded by

PraYush RajbhandariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Footing F3: Design of Isolated Footing

Footing F3: Design of Isolated Footing

Uploaded by

PraYush RajbhandariCopyright:

Available Formats

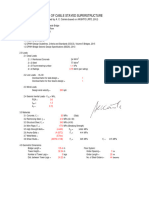

DESIGN OF ISOLATED FOOTING

Footing F3

Input Load Combination:

Width along x, a 500 mm x-direction

Width along y, b 500 mm y-direction

Grade of concrete,fck = 20 N/mm2 Pu (kN) Mux(kNm) Muy (kNm)

2

Grade of steel, fy = 500 N/mm 945.607 12.673 21.893

Clear cover 50 mm P (kN) Mx(kNm) My (kNm)

Safe bearing pressure 150 kN/m2 693.45 8.45 14.60

Loading condition Normal ey = 0.013 m

Safe bearing pressure for given loading 150 kN/m2 ex = 0.023 m

Quick Check

Calculated length 2.15 m Suggested Length 2.3 m (X-dimension)

Calculated width 2.15 m Suggested width 2.3 m (Y-dimension)

Pressure at corner points

at (-1.15,1.15) = 128.05 OK at (1.15,1.15) = 142.45 OK

at (-1.15,-1.15) = 119.72 OK at (1.15,-1.15) = 134.12 OK

Check for development length: OK Check for bearing pressure: SAFE

Check for X-direction Check for Y-direction

Required d for moment 179.18 mm Required d for moment 180

Provide D 450.00 mm Provide D 450.00

Diameter of bars 12 mm Diameter of bars 12

Calculated Spacing 212 mm Calculated Spacing 211

Provided spacing 150 mm Provided spacing 150

Check for two way shear SAFE Check for two way shear SAFE

Check for one way shear SAFE Check for one way shear SAFE

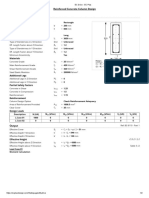

Calculations

2

Area of footing required, LB 4.62 m

a-b = 0 mm

𝐿^2−(𝑎−𝑏)𝐿−𝐿𝐵=0 Ref. S.N Sinha

L= 2.15 m Provide 2.3 m

B= 2.15 m Provide 2.3 m

Area provided = 5.29 m2

Moment of Inertia about X axix, Ix = 2.33 m4

Moment of Inertia about Y axix, Iy = 2.33 m4

Stress at any point is given by, 𝑝=𝑃/𝐴+𝑀_𝑦/𝐼_𝑥 𝑥+𝑀

At x = -L/2 = -1.15 y = -B/2 = -1.15 p= 119.72 kN/m2 OK

x = L/2 = 1.15 y = -B/2 = -1.15 p= 134.12 kN/m2 OK

x = L/2 = 1.15 y = B/2 = 1.15 p= 142.45 kN/m2 OK

x = -L/2 = -1.15 y = B/2 = 1.15 p= 128.05 kN/m2 OK

Calculation for X-direction

192.08 (Factored upward pressure)

213.67 kN/m2

1.40 m 0.90 m

205.23

Bending moment at critical section 85.40 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 179 mm

Provide overall depth, D 450 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 382 mm

0.58522

Ast required 532.509 mm2

Ast minimum 458.4 mm2

Spacing 212.39 mm Provide 150 mm c/c

Area of steel provided 753.98 mm2 and pt = 0.20%

Provide 12 mm dia bars @ 150 mm c/c at bottom (Parallel to X)

Check for two way shear:

Critical Section in two way shear

The critical section for the two way

2

shear occurs at a distance of d/2

from the face of the column 1.5

a+d = 882 mm 1

b+d = 882 mm 0.5

Punching area = 0.78 m2 0

Punching perimeter = 3.528 m -2.00 -1.00 0.00 1.00 2.00

-0.5

-1

Factored pressure at corners

2 -1.5

at (-0.441,-0.441) = 190.09 kN/m

2 -2

at (0.441,-0.441) = 198.37 kN/m

2

at (0.441,0.441) = 203.17 kN/m

2

at (-0.441,0.441) = 194.89 kN/m

2

Average factored upward pressure = 196.629 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

792.645 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣 = 0.59 N/mm Ref. IS 456: 2000, Cl. 31.6.1

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.518 m from edge of the fooring

2

Factored upward stress at that point = 208.812 kN/m

2

Average upward stress 211.243 kN/m

Total shear force along the critical section = 251.675 kN

2

Nominal shear stress 0.29 N/mm

Percentage of steel, pt 0.20%

= 11.92

2

Design shear stress, = 0.32 N/mm

SAFE

Calculation for Y-direction

201.18 (Factored upward pressure)

213.67 kN/m2

1.40 m 0.90 m

208.78

Bending moment at critical section 85.88 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 180 mm

Provide overall depth, D 450 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 382 mm

0.589

Ast required 535.617 mm2

Ast minimum 458.4 mm2

Spacing 211.15 mm Provide 150 mm c/c

Area of steel provided 753.98 mm2 and pt = 0.20%

Provide 12 mm dia bars @ 150 mm c/c at bottom (Parallel to X)

Check for two way shear:

The critical section for the two way Critical Section in two way shear

shear occurs at a distance of d/2 2

from the face of the column 1.5

a+d = 882 mm

1

b+d = 882 mm

0.5

Punching area = 0.78 m2

Punching perimeter = 3.528 m 0

-2.00 -1.00 0.00 1.00 2.00

-0.5

Factored pressure at corners

-1

2

at (-0.441,-0.441) = 190.09 kN/m

2 -1.5

at (0.441,-0.441) = 198.37 kN/m

2 -2

at (0.441,0.441) = 203.17 kN/m

2

at (-0.441,0.441) = 194.89 kN/m

2

Average factored upward pressure = 196.629 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

792.645 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣= 0.59 N/mm

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE Ref. IS 456: 2000, Cl. 31.6.1

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.518 m from edge of the fooring

2

Factored upward stress at that point = 210.86 kN/m

2

Average upward stress 212.267 kN/m

Total shear force along the critical section = 252.895 kN

2

Nominal shear stress 0.29 N/mm

Percentage of steel, pt 0.20%

= 11.92

2

Design shear stress, = 0.32 N/mm

SAFE

Check for development Length

Sufficient development length should be available for the reinforcement from the critical section.

2 2

𝜏_𝑏𝑑= 1.92 N/mm 𝜎_𝑠= 434.783 N/mm

Ld = 679 mm

The total length available from the critical section = 0.5(L - a)- Cover 850 mm

OK

Check for bearing stress

2

A1 = 5.29 m 2

2 2

A2 = 0.25 m = 18 N/mm

2

3.78 N/mm SAFE

You might also like

- Forces in Equilibrium LabDocument15 pagesForces in Equilibrium LabNabil IbrahimNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Isolated Footing F1Document3 pagesDesign of Isolated Footing F1PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Pad Footing - F1: Project Structure Document TitleDocument1 pageDesign of Pad Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Footing Design Details-HASSAN HASSANIDocument354 pagesFooting Design Details-HASSAN HASSANIShaniha kkNo ratings yet

- Footing-Design PDFDocument10 pagesFooting-Design PDFAhmed MohammedNo ratings yet

- Sloped Isolated Tata-Steel-Ld3 PDFDocument12 pagesSloped Isolated Tata-Steel-Ld3 PDFArvind DoraiNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- F1 (NODE NO 279) : Design of FootingsDocument12 pagesF1 (NODE NO 279) : Design of FootingsPinapaSrikanthNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Design of Footing - F1: Project Structure Document TitleDocument1 pageDesign of Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Rectangular Footing - Concrete DesignDocument6 pagesRectangular Footing - Concrete DesignVincelord CabadduNo ratings yet

- Design of Combined Footing For Staircase Columns: Project Structure Document TitleDocument1 pageDesign of Combined Footing For Staircase Columns: Project Structure Document TitlerisrizNo ratings yet

- MM Ty Eccentrici 20 : DB F PDocument2 pagesMM Ty Eccentrici 20 : DB F PPraYush RajbhandariNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Raft FoundationDocument12 pagesRaft FoundationAasif ShaikNo ratings yet

- Design CalculationsDocument110 pagesDesign Calculationsfredcantos02.mc88No ratings yet

- G 3 EccDocument8 pagesG 3 EcckuttyNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- DPT 2 EkstrDocument62 pagesDPT 2 EkstrSeptiawan D4fNo ratings yet

- Footing Design F1Document16 pagesFooting Design F1Urmi PanchalNo ratings yet

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Col Design MenukaDocument3 pagesCol Design Menukaprakashchalise1993No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Isolated FootingDocument4 pagesIsolated FootingMark Brien Vincent YbañezNo ratings yet

- Footing PDFDocument1 pageFooting PDFDorothy Leonardo ObriqueNo ratings yet

- Design of Square Footing: F-1Document1 pageDesign of Square Footing: F-1Dorothy Leonardo ObriqueNo ratings yet

- Isolated Footing Design F2Document16 pagesIsolated Footing Design F2Saugat ThapaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CHAPTER 2 Part 2 PDFDocument55 pagesCHAPTER 2 Part 2 PDFAB20 012 Lee Yee XynnNo ratings yet

- Square Footing - Concrete DesignDocument5 pagesSquare Footing - Concrete DesignVincelord CabadduNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Miscellaneous DesignDocument5 pagesMiscellaneous DesignShaun PattersonNo ratings yet

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignPraYush RajbhandariNo ratings yet

- All QntyDocument8 pagesAll QntyPraYush RajbhandariNo ratings yet

- Research Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesDocument17 pagesResearch Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesPraYush RajbhandariNo ratings yet

- Design of Strap Foundation (3C-3D)Document5 pagesDesign of Strap Foundation (3C-3D)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- Staircase Design: Open Well Second FlightDocument3 pagesStaircase Design: Open Well Second FlightPraYush RajbhandariNo ratings yet

- Design of Combined Footing (Cf1)Document3 pagesDesign of Combined Footing (Cf1)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Open Well Staircase First and Third FlightDocument2 pagesSTAIRCASE DESIGN: Open Well Staircase First and Third FlightPraYush RajbhandariNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Agreement For Residential Building Construction (Labor and Material)Document3 pagesAgreement For Residential Building Construction (Labor and Material)PraYush RajbhandariNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Document1 pagePlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Final Arch Drawing-Layout2Document1 pageFinal Arch Drawing-Layout2PraYush RajbhandariNo ratings yet

- Is 269 PDFDocument1 pageIs 269 PDFPraYush RajbhandariNo ratings yet

- Brochure SchedulefmfpDocument22 pagesBrochure SchedulefmfpAaradhya MishraNo ratings yet

- Boundary Layed - NoteDocument3 pagesBoundary Layed - NoteMohammed AlshangitiNo ratings yet

- Is800 2007 PDFDocument150 pagesIs800 2007 PDFAnonymous dSFbLxc9100% (3)

- (Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27Document8 pages(Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27AlinaBogoiNo ratings yet

- 132 TOP Strength of Materials Multiple Choice Questions and Answers PDF MCQs Preparation For Engineering Competitive Exams PDFDocument12 pages132 TOP Strength of Materials Multiple Choice Questions and Answers PDF MCQs Preparation For Engineering Competitive Exams PDFDivakar singhNo ratings yet

- Elasticity, Calorimetry & Thermal Expansion (Teaching Notes)Document21 pagesElasticity, Calorimetry & Thermal Expansion (Teaching Notes)Sankar KumarasamyNo ratings yet

- Human Perception of Wind Farm Vibration: Duc-Phuc Nguyen, Kristy Hansen and Branko ZajamsekDocument11 pagesHuman Perception of Wind Farm Vibration: Duc-Phuc Nguyen, Kristy Hansen and Branko ZajamsekgpromoNo ratings yet

- Solutions To I E Irodov Problems in General PhysicsDocument3 pagesSolutions To I E Irodov Problems in General Physicsakshit14nov1996No ratings yet

- 2.1 MotionDocument18 pages2.1 MotioncetinNo ratings yet

- WTC2005 63324 PDFDocument2 pagesWTC2005 63324 PDFMarcelo VeronezNo ratings yet

- Prs w01d1 QonlyDocument9 pagesPrs w01d1 Qonlyakirank1No ratings yet

- Fluid Mech. ExperimentDocument12 pagesFluid Mech. Experimentsimple-CE-studNo ratings yet

- CH 13Document15 pagesCH 13xperia30100% (1)

- Simulation Analysis of Hydraulic Lifting Mechanism of A ForkliftDocument4 pagesSimulation Analysis of Hydraulic Lifting Mechanism of A ForkliftPacy MugishoNo ratings yet

- CalorimeterDocument3 pagesCalorimeterSagarika ManmohanNo ratings yet

- Selection and Design of An Axial Flow FanDocument4 pagesSelection and Design of An Axial Flow Fanashwin vijayNo ratings yet

- The Great Blunders - in Modern - PhysicsDocument128 pagesThe Great Blunders - in Modern - Physicsrennie1957No ratings yet

- Thin and Thick Cylindrical Shells UNIT-5Document15 pagesThin and Thick Cylindrical Shells UNIT-5Parikshit YadavNo ratings yet

- Physics L.O: Matter, Form and FunctionDocument7 pagesPhysics L.O: Matter, Form and FunctionAbo Alphotoh GamingNo ratings yet

- The Added Mass Coefficient Computation of Sphere, Ellipsoid and Marine Propellers Using Boundary Element MethodDocument10 pagesThe Added Mass Coefficient Computation of Sphere, Ellipsoid and Marine Propellers Using Boundary Element MethodsantoshNo ratings yet

- Report - AirfoilDocument14 pagesReport - Airfoilvivek bhatiNo ratings yet

- 04 LAJPE 782 ChudinovDocument5 pages04 LAJPE 782 Chudinovbenitogaldos19gmail.comNo ratings yet

- Natural Convection Heat Transfer in A Baffled TriangularDocument15 pagesNatural Convection Heat Transfer in A Baffled Triangularbooklover1950No ratings yet

- Physics A: Unit 2: Approved Specimen Mark SchemeDocument9 pagesPhysics A: Unit 2: Approved Specimen Mark SchemeSam LankaNo ratings yet

- Physics: Physics EUEE 2007 E.C Grade 11 Unit OneDocument34 pagesPhysics: Physics EUEE 2007 E.C Grade 11 Unit OneFuad AminNo ratings yet

- BUET04 UDocument31 pagesBUET04 Uমোঃ ইনজামুল হক মেহেদীNo ratings yet

- Chapter 3 Fluid Flow - Question SetDocument2 pagesChapter 3 Fluid Flow - Question SetAbhijit KuchbhilikhtaNo ratings yet

- Differential ManometersDocument3 pagesDifferential ManometersAnonymous QM0NLqZO100% (1)