Professional Documents

Culture Documents

Footing F5: Design of Isolated Footing

Footing F5: Design of Isolated Footing

Uploaded by

PraYush RajbhandariCopyright:

Available Formats

You might also like

- Numerical MethodsDocument88 pagesNumerical MethodsJoshua MNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- ISMS-FORM-06-3 Scenario-Based RAT ToolDocument20 pagesISMS-FORM-06-3 Scenario-Based RAT ToolBayNo ratings yet

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Isolated Footing F1Document3 pagesDesign of Isolated Footing F1PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Pad Footing - F1: Project Structure Document TitleDocument1 pageDesign of Pad Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Footing Design Details-HASSAN HASSANIDocument354 pagesFooting Design Details-HASSAN HASSANIShaniha kkNo ratings yet

- Footing-Design PDFDocument10 pagesFooting-Design PDFAhmed MohammedNo ratings yet

- Sloped Isolated Tata-Steel-Ld3 PDFDocument12 pagesSloped Isolated Tata-Steel-Ld3 PDFArvind DoraiNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- F1 (NODE NO 279) : Design of FootingsDocument12 pagesF1 (NODE NO 279) : Design of FootingsPinapaSrikanthNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Design of Footing - F1: Project Structure Document TitleDocument1 pageDesign of Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Rectangular Footing - Concrete DesignDocument6 pagesRectangular Footing - Concrete DesignVincelord CabadduNo ratings yet

- Design of Combined Footing For Staircase Columns: Project Structure Document TitleDocument1 pageDesign of Combined Footing For Staircase Columns: Project Structure Document TitlerisrizNo ratings yet

- MM Ty Eccentrici 20 : DB F PDocument2 pagesMM Ty Eccentrici 20 : DB F PPraYush RajbhandariNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Raft FoundationDocument12 pagesRaft FoundationAasif ShaikNo ratings yet

- Design CalculationsDocument110 pagesDesign Calculationsfredcantos02.mc88No ratings yet

- G 3 EccDocument8 pagesG 3 EcckuttyNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- DPT 2 EkstrDocument62 pagesDPT 2 EkstrSeptiawan D4fNo ratings yet

- Footing Design F1Document16 pagesFooting Design F1Urmi PanchalNo ratings yet

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Staircase SKILL MUSEUMDocument2 pagesStaircase SKILL MUSEUMalok ranjanNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Col Design MenukaDocument3 pagesCol Design Menukaprakashchalise1993No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Isolated FootingDocument4 pagesIsolated FootingMark Brien Vincent YbañezNo ratings yet

- Design of Square Footing: F-1Document1 pageDesign of Square Footing: F-1Dorothy Leonardo ObriqueNo ratings yet

- Footing PDFDocument1 pageFooting PDFDorothy Leonardo ObriqueNo ratings yet

- Isolated Footing Design F2Document16 pagesIsolated Footing Design F2Saugat ThapaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CHAPTER 2 Part 2 PDFDocument55 pagesCHAPTER 2 Part 2 PDFAB20 012 Lee Yee XynnNo ratings yet

- Square Footing - Concrete DesignDocument5 pagesSquare Footing - Concrete DesignVincelord CabadduNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Miscellaneous DesignDocument5 pagesMiscellaneous DesignShaun PattersonNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignPraYush RajbhandariNo ratings yet

- Research Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesDocument17 pagesResearch Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesPraYush RajbhandariNo ratings yet

- All QntyDocument8 pagesAll QntyPraYush RajbhandariNo ratings yet

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Strap Foundation (3C-3D)Document5 pagesDesign of Strap Foundation (3C-3D)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- Design of Combined Footing (Cf1)Document3 pagesDesign of Combined Footing (Cf1)PraYush RajbhandariNo ratings yet

- Staircase Design: Open Well Second FlightDocument3 pagesStaircase Design: Open Well Second FlightPraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Open Well Staircase First and Third FlightDocument2 pagesSTAIRCASE DESIGN: Open Well Staircase First and Third FlightPraYush RajbhandariNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Agreement For Residential Building Construction (Labor and Material)Document3 pagesAgreement For Residential Building Construction (Labor and Material)PraYush RajbhandariNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Document1 pagePlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariNo ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Final Arch Drawing-Layout2Document1 pageFinal Arch Drawing-Layout2PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Is 269 PDFDocument1 pageIs 269 PDFPraYush RajbhandariNo ratings yet

- Project SynopsisDocument16 pagesProject SynopsisPriyanshu MangalNo ratings yet

- 8I Heating and Cooling Multiple Choice TestDocument3 pages8I Heating and Cooling Multiple Choice Testapi-369814690% (10)

- R K PathakDocument5 pagesR K PathakBharatNo ratings yet

- Pricelist MiniBooster 2023.003 ENDocument2 pagesPricelist MiniBooster 2023.003 ENMilorad LazovicNo ratings yet

- Drawbar Pull vs. Rim Pull - MCM - Multi Construction MachinesDocument1 pageDrawbar Pull vs. Rim Pull - MCM - Multi Construction Machinesمهدي وجيه كمال100% (1)

- Roof Inspection ReportDocument13 pagesRoof Inspection ReportTroy HoveyNo ratings yet

- Media and Information LiteracyDocument15 pagesMedia and Information Literacyنجشو گحوشNo ratings yet

- Best CAD NotesDocument122 pagesBest CAD Noteswubie bayeNo ratings yet

- PLC C200HDocument3 pagesPLC C200HRidho AkbarNo ratings yet

- IOT, Sumaiya KhanDocument22 pagesIOT, Sumaiya Khanshashank kumarNo ratings yet

- RIPSTAR 103 Ev3Document3 pagesRIPSTAR 103 Ev3Ankita Baban GavadeNo ratings yet

- Analysis of Support Vector Machine-Based Intrusion Detection TechniquesDocument13 pagesAnalysis of Support Vector Machine-Based Intrusion Detection TechniquesInstaNo ratings yet

- Aerodynamic A350Document10 pagesAerodynamic A350HelloWorld100% (1)

- Power Optimization in 5G Networks: A Step Towards Green CommunicationDocument20 pagesPower Optimization in 5G Networks: A Step Towards Green CommunicationElmustafa Sayed Ali Ahmed100% (1)

- Collaboration GuidelinesDocument1 pageCollaboration GuidelinesKarisoNo ratings yet

- Ricardo Vargas Practice-Guide Flow Color En-A0Document1 pageRicardo Vargas Practice-Guide Flow Color En-A0CICERO JOSÉ SANTANANo ratings yet

- MK110 Project 4Document5 pagesMK110 Project 4harryNo ratings yet

- Resume - Andrew Nguyen 1Document3 pagesResume - Andrew Nguyen 1api-532461346No ratings yet

- Relative SizeDocument20 pagesRelative SizeMoh SaadNo ratings yet

- Q Mix Tmix 8-16-30 UsermanualDocument146 pagesQ Mix Tmix 8-16-30 UsermanualJonathan BayonaNo ratings yet

- Contoh Soal Materi Bab 2 BinggrisDocument5 pagesContoh Soal Materi Bab 2 Binggrisersa wahyu100% (1)

- Equipment RentalDocument1 pageEquipment RentalKate Perez50% (2)

- Bonus 3 - The White Hat Hacks PDFDocument14 pagesBonus 3 - The White Hat Hacks PDFSAranNo ratings yet

- IA PfeDocument2 pagesIA Pfeihssane hajjajNo ratings yet

- Berin Operator.Document7 pagesBerin Operator.Godwin GodwinNo ratings yet

- ESS1 Data Documentation Report E06 5Document178 pagesESS1 Data Documentation Report E06 5ajp11No ratings yet

- Pragnesh Black Book 18Document77 pagesPragnesh Black Book 18Pragnesh PawarNo ratings yet

- Glossary: Google UX Design CertificateDocument6 pagesGlossary: Google UX Design CertificateZin Mon ThetNo ratings yet

Footing F5: Design of Isolated Footing

Footing F5: Design of Isolated Footing

Uploaded by

PraYush RajbhandariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Footing F5: Design of Isolated Footing

Footing F5: Design of Isolated Footing

Uploaded by

PraYush RajbhandariCopyright:

Available Formats

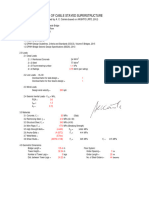

DESIGN OF ISOLATED FOOTING

Footing F5

Input Load Combination:

Width along x, a 500 mm x-direction

Width along y, b 500 mm y-direction

Grade of concrete,fck = 20 N/mm2 Pu (kN) Mux(kNm) Muy (kNm)

2

Grade of steel, fy = 500 N/mm 1098.56 6.8319 18.8696

Clear cover 50 mm P (kN) Mx(kNm) My (kNm)

Safe bearing pressure 200 kN/m2 805.61 4.55 12.58

Loading condition Normal ey = 0.006 m

Safe bearing pressure for given loading 200 kN/m2 ex = 0.017 m

Quick Check

Calculated length 2.01 m Suggested Length 2.1 m (X-dimension)

Calculated width 2.01 m Suggested width 2.1 m (Y-dimension)

Pressure at corner points

at (-1.05,1.05) = 177.48 OK at (1.05,1.05) = 193.78 OK

at (-1.05,-1.05) = 171.58 OK at (1.05,-1.05) = 187.88 OK

Check for development length: OK Check for bearing pressure: SAFE

Check for X-direction Check for Y-direction

Required d for moment 186.00 mm Required d for moment 187

Provide D 450.00 mm Provide D 450.00

Diameter of bars 12 mm Diameter of bars 12

Calculated Spacing 197 mm Calculated Spacing 195

Provided spacing 150 mm Provided spacing 150

Check for two way shear SAFE Check for two way shear SAFE

Check for one way shear SAFE Check for one way shear SAFE

Calculations

2

Area of footing required, LB 4.03 m

a-b = 0 mm

𝐿^2−(𝑎−𝑏)𝐿−𝐿𝐵=0 Ref. S.N Sinha

L= 2.01 m Provide 2.1 m

B= 2.01 m Provide 2.1 m

Area provided = 4.41 m2

Moment of Inertia about X axix, Ix = 1.62 m4

Moment of Inertia about Y axix, Iy = 1.62 m4

Stress at any point is given by, 𝑝=𝑃/𝐴+𝑀_𝑦/𝐼_𝑥 𝑥+𝑀

At x = -L/2 = -1.05 y = -B/2 = -1.05 p= 171.58 kN/m2 OK

x = L/2 = 1.05 y = -B/2 = -1.05 p= 187.88 kN/m2 OK

x = L/2 = 1.05 y = B/2 = 1.05 p= 193.78 kN/m2 OK

x = -L/2 = -1.05 y = B/2 = 1.05 p= 177.48 kN/m2 OK

Calculation for X-direction

266.22 (Factored upward pressure)

290.67 kN/m2

1.30 m 0.80 m

281.36

Bending moment at critical section 92.02 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 186 mm

Provide overall depth, D 450 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 382 mm

0.63061

Ast required 575.485 mm2

Ast minimum 458.4 mm2

Spacing 196.53 mm Provide 150 mm c/c

Area of steel provided 753.98 mm2 and pt = 0.20%

Provide 12 mm dia bars @ 150 mm c/c at bottom (Parallel to X)

Check for two way shear:

Critical Section in two way shear

The critical section for the two way

1.5

shear occurs at a distance of d/2

from the face of the column 1

a+d = 882 mm

b+d = 882 mm 0.5

Punching area = 0.78 m2 0

Punching perimeter = 3.528 m -2.00 -1.00 0.00 1.00 2.00

-0.5

Factored pressure at corners

2

-1

at (-0.441,-0.441) = 267.02 kN/m

2 -1.5

at (0.441,-0.441) = 277.29 kN/m

2

at (0.441,0.441) = 281.01 kN/m

2

at (-0.441,0.441) = 270.74 kN/m

2

Average factored upward pressure = 274.018 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

885.399 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣 = 0.66 N/mm Ref. IS 456: 2000, Cl. 31.6.1

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.418 m from edge of the fooring

2

Factored upward stress at that point = 285.803 kN/m

2

Average upward stress 288.236 kN/m

Total shear force along the critical section = 253.014 kN

2

Nominal shear stress 0.32 N/mm

Percentage of steel, pt 0.20%

= 11.92

2

Design shear stress, = 0.32 N/mm

SAFE

Calculation for Y-direction

281.82 (Factored upward pressure)

290.67 kN/m2

1.30 m 0.80 m

287.30

Bending moment at critical section 92.65 kN-m/m at face of the column

Reinforcement index 0.133

Minimum depth, d 187 mm

Provide overall depth, D 450 mm approx three times calculated value

Assume diameter of bar 12 mm

Effective depth d 382 mm

0.635

Ast required 579.612 mm2

Ast minimum 458.4 mm2

Spacing 195.13 mm Provide 150 mm c/c

Area of steel provided 753.98 mm2 and pt = 0.20%

Provide 12 mm dia bars @ 150 mm c/c at bottom (Parallel to X)

Check for two way shear:

The critical section for the two way Critical Section in two way shear

shear occurs at a distance of d/2 1.5

from the face of the column

1

a+d = 882 mm

b+d = 882 mm 0.5

Punching area = 0.78 m2

Punching perimeter = 3.528 m 0

-2.00 -1.00 0.00 1.00 2.00

-0.5

Factored pressure at corners

2

at (-0.441,-0.441) = 267.02 kN/m -1

2

at (0.441,-0.441) = 277.29 kN/m

2 -1.5

at (0.441,0.441) = 281.01 kN/m

2

at (-0.441,0.441) = 270.74 kN/m

2

Average factored upward pressure = 274.018 kN/m

Punching shear force = Factored load - factored upward pressure x punching area

885.399 kN

2

Therefore, Nominal punching shear stress, 𝜏_𝑣= 0.66 N/mm

2

Allowable shear stress = 〖𝑘_𝑠𝜏 1.12 N/mm SAFE Ref. IS 456: 2000, Cl. 31.6.1

Where, ks = 1

𝜏_𝑐= 2

1.12 N/mm

Check for one way shear:

The critical section for one way shear occurs at a distance "d" from the face of the column.

= 0.418 m from edge of the fooring

2

Factored upward stress at that point = 288.908 kN/m

2

Average upward stress 289.789 kN/m

Total shear force along the critical section = 254.376 kN

2

Nominal shear stress 0.32 N/mm

Percentage of steel, pt 0.20%

= 11.92

2

Design shear stress, = 0.32 N/mm

SAFE

Check for development Length

Sufficient development length should be available for the reinforcement from the critical section.

2 2

𝜏_𝑏𝑑= 1.92 N/mm 𝜎_𝑠= 434.783 N/mm

Ld = 679 mm

The total length available from the critical section = 0.5(L - a)- Cover 750 mm

OK

Check for bearing stress

2

A1 = 4.41 m 2

2 2

A2 = 0.25 m = 18 N/mm

2

4.39 N/mm SAFE

You might also like

- Numerical MethodsDocument88 pagesNumerical MethodsJoshua MNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- ISMS-FORM-06-3 Scenario-Based RAT ToolDocument20 pagesISMS-FORM-06-3 Scenario-Based RAT ToolBayNo ratings yet

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Isolated Footing F1Document3 pagesDesign of Isolated Footing F1PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Pad Footing - F1: Project Structure Document TitleDocument1 pageDesign of Pad Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Footing Design Details-HASSAN HASSANIDocument354 pagesFooting Design Details-HASSAN HASSANIShaniha kkNo ratings yet

- Footing-Design PDFDocument10 pagesFooting-Design PDFAhmed MohammedNo ratings yet

- Sloped Isolated Tata-Steel-Ld3 PDFDocument12 pagesSloped Isolated Tata-Steel-Ld3 PDFArvind DoraiNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- F1 (NODE NO 279) : Design of FootingsDocument12 pagesF1 (NODE NO 279) : Design of FootingsPinapaSrikanthNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Design of Footing - F1: Project Structure Document TitleDocument1 pageDesign of Footing - F1: Project Structure Document TitlerisrizNo ratings yet

- Rectangular Footing - Concrete DesignDocument6 pagesRectangular Footing - Concrete DesignVincelord CabadduNo ratings yet

- Design of Combined Footing For Staircase Columns: Project Structure Document TitleDocument1 pageDesign of Combined Footing For Staircase Columns: Project Structure Document TitlerisrizNo ratings yet

- MM Ty Eccentrici 20 : DB F PDocument2 pagesMM Ty Eccentrici 20 : DB F PPraYush RajbhandariNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Raft FoundationDocument12 pagesRaft FoundationAasif ShaikNo ratings yet

- Design CalculationsDocument110 pagesDesign Calculationsfredcantos02.mc88No ratings yet

- G 3 EccDocument8 pagesG 3 EcckuttyNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- DPT 2 EkstrDocument62 pagesDPT 2 EkstrSeptiawan D4fNo ratings yet

- Footing Design F1Document16 pagesFooting Design F1Urmi PanchalNo ratings yet

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Staircase SKILL MUSEUMDocument2 pagesStaircase SKILL MUSEUMalok ranjanNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Col Design MenukaDocument3 pagesCol Design Menukaprakashchalise1993No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Isolated FootingDocument4 pagesIsolated FootingMark Brien Vincent YbañezNo ratings yet

- Design of Square Footing: F-1Document1 pageDesign of Square Footing: F-1Dorothy Leonardo ObriqueNo ratings yet

- Footing PDFDocument1 pageFooting PDFDorothy Leonardo ObriqueNo ratings yet

- Isolated Footing Design F2Document16 pagesIsolated Footing Design F2Saugat ThapaNo ratings yet

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CHAPTER 2 Part 2 PDFDocument55 pagesCHAPTER 2 Part 2 PDFAB20 012 Lee Yee XynnNo ratings yet

- Square Footing - Concrete DesignDocument5 pagesSquare Footing - Concrete DesignVincelord CabadduNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Miscellaneous DesignDocument5 pagesMiscellaneous DesignShaun PattersonNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Preliminary DesignDocument3 pagesPreliminary DesignPraYush RajbhandariNo ratings yet

- Research Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesDocument17 pagesResearch Review: Post-Earthquake Fire Assessment of Steel Buildings in The United StatesPraYush RajbhandariNo ratings yet

- All QntyDocument8 pagesAll QntyPraYush RajbhandariNo ratings yet

- Footing F5: Design of Isolated FootingDocument4 pagesFooting F5: Design of Isolated FootingPraYush RajbhandariNo ratings yet

- Design of Strap Foundation (3C-3D)Document5 pagesDesign of Strap Foundation (3C-3D)PraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- Design of Combined Footing (Cf1)Document3 pagesDesign of Combined Footing (Cf1)PraYush RajbhandariNo ratings yet

- Staircase Design: Open Well Second FlightDocument3 pagesStaircase Design: Open Well Second FlightPraYush RajbhandariNo ratings yet

- STAIRCASE DESIGN: Open Well Staircase First and Third FlightDocument2 pagesSTAIRCASE DESIGN: Open Well Staircase First and Third FlightPraYush RajbhandariNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Agreement For Residential Building Construction (Labor and Material)Document3 pagesAgreement For Residential Building Construction (Labor and Material)PraYush RajbhandariNo ratings yet

- Footing 4CDocument4 pagesFooting 4CPraYush RajbhandariNo ratings yet

- MM Ty Eccentrici: Design of Square ColumnDocument3 pagesMM Ty Eccentrici: Design of Square ColumnPraYush RajbhandariNo ratings yet

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Document1 pagePlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariNo ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Final Arch Drawing-Layout2Document1 pageFinal Arch Drawing-Layout2PraYush RajbhandariNo ratings yet

- Design of Isolated FootingDocument4 pagesDesign of Isolated FootingPraYush RajbhandariNo ratings yet

- Is 269 PDFDocument1 pageIs 269 PDFPraYush RajbhandariNo ratings yet

- Project SynopsisDocument16 pagesProject SynopsisPriyanshu MangalNo ratings yet

- 8I Heating and Cooling Multiple Choice TestDocument3 pages8I Heating and Cooling Multiple Choice Testapi-369814690% (10)

- R K PathakDocument5 pagesR K PathakBharatNo ratings yet

- Pricelist MiniBooster 2023.003 ENDocument2 pagesPricelist MiniBooster 2023.003 ENMilorad LazovicNo ratings yet

- Drawbar Pull vs. Rim Pull - MCM - Multi Construction MachinesDocument1 pageDrawbar Pull vs. Rim Pull - MCM - Multi Construction Machinesمهدي وجيه كمال100% (1)

- Roof Inspection ReportDocument13 pagesRoof Inspection ReportTroy HoveyNo ratings yet

- Media and Information LiteracyDocument15 pagesMedia and Information Literacyنجشو گحوشNo ratings yet

- Best CAD NotesDocument122 pagesBest CAD Noteswubie bayeNo ratings yet

- PLC C200HDocument3 pagesPLC C200HRidho AkbarNo ratings yet

- IOT, Sumaiya KhanDocument22 pagesIOT, Sumaiya Khanshashank kumarNo ratings yet

- RIPSTAR 103 Ev3Document3 pagesRIPSTAR 103 Ev3Ankita Baban GavadeNo ratings yet

- Analysis of Support Vector Machine-Based Intrusion Detection TechniquesDocument13 pagesAnalysis of Support Vector Machine-Based Intrusion Detection TechniquesInstaNo ratings yet

- Aerodynamic A350Document10 pagesAerodynamic A350HelloWorld100% (1)

- Power Optimization in 5G Networks: A Step Towards Green CommunicationDocument20 pagesPower Optimization in 5G Networks: A Step Towards Green CommunicationElmustafa Sayed Ali Ahmed100% (1)

- Collaboration GuidelinesDocument1 pageCollaboration GuidelinesKarisoNo ratings yet

- Ricardo Vargas Practice-Guide Flow Color En-A0Document1 pageRicardo Vargas Practice-Guide Flow Color En-A0CICERO JOSÉ SANTANANo ratings yet

- MK110 Project 4Document5 pagesMK110 Project 4harryNo ratings yet

- Resume - Andrew Nguyen 1Document3 pagesResume - Andrew Nguyen 1api-532461346No ratings yet

- Relative SizeDocument20 pagesRelative SizeMoh SaadNo ratings yet

- Q Mix Tmix 8-16-30 UsermanualDocument146 pagesQ Mix Tmix 8-16-30 UsermanualJonathan BayonaNo ratings yet

- Contoh Soal Materi Bab 2 BinggrisDocument5 pagesContoh Soal Materi Bab 2 Binggrisersa wahyu100% (1)

- Equipment RentalDocument1 pageEquipment RentalKate Perez50% (2)

- Bonus 3 - The White Hat Hacks PDFDocument14 pagesBonus 3 - The White Hat Hacks PDFSAranNo ratings yet

- IA PfeDocument2 pagesIA Pfeihssane hajjajNo ratings yet

- Berin Operator.Document7 pagesBerin Operator.Godwin GodwinNo ratings yet

- ESS1 Data Documentation Report E06 5Document178 pagesESS1 Data Documentation Report E06 5ajp11No ratings yet

- Pragnesh Black Book 18Document77 pagesPragnesh Black Book 18Pragnesh PawarNo ratings yet

- Glossary: Google UX Design CertificateDocument6 pagesGlossary: Google UX Design CertificateZin Mon ThetNo ratings yet