Professional Documents

Culture Documents

Defects - Faults and Remedies of Warping - Textile Learner

Defects - Faults and Remedies of Warping - Textile Learner

Uploaded by

GOWTHAM CHANDRUCopyright:

Available Formats

You might also like

- 01-Operating Manual For 1200 MTPD Ammonia Plant PDFDocument315 pages01-Operating Manual For 1200 MTPD Ammonia Plant PDFAbdulla100% (4)

- Clothing Construction BookDocument172 pagesClothing Construction BookDebbie Bacalso95% (21)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Polymer-Plastics Additives PDFDocument643 pagesPolymer-Plastics Additives PDFwardolier67% (3)

- Learn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Document362 pagesLearn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Jeļena Krētaine100% (2)

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Assignment On Different Kinds of Knitting Faults Causes and Their RemediesDocument4 pagesAssignment On Different Kinds of Knitting Faults Causes and Their RemediesRaihan Moner Manush0% (2)

- Biocompatibility of Aluminium Alloys and Anodic Al2O3Document6 pagesBiocompatibility of Aluminium Alloys and Anodic Al2O3Nícolas LaraNo ratings yet

- Warping - Objects of Warping - Importance of Warping in Weaving - Textile LearneDocument4 pagesWarping - Objects of Warping - Importance of Warping in Weaving - Textile LearneGOWTHAM CHANDRUNo ratings yet

- Effect of Balloon Breaker in Winding - Textile LearnerDocument8 pagesEffect of Balloon Breaker in Winding - Textile Learnermasum_austNo ratings yet

- Stitch Diary Ebook Defects Part 2Document26 pagesStitch Diary Ebook Defects Part 2Rafael CuicapuzaNo ratings yet

- Sewing DeffectsDocument11 pagesSewing DeffectsVeverley CarupoNo ratings yet

- Creels - Warping Creels - Types of Creel - Mobile Creel - Magazine Creel - SwiveDocument4 pagesCreels - Warping Creels - Types of Creel - Mobile Creel - Magazine Creel - SwiveGOWTHAM CHANDRUNo ratings yet

- Uaq Assignment 2Document5 pagesUaq Assignment 2vaishnavi.chaudhariNo ratings yet

- Embroidery & Machine BasicsDocument57 pagesEmbroidery & Machine BasicsJuciêr AlcântaraNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- Fabric DefectsDocument5 pagesFabric Defectsalibaqar74100% (5)

- Surigao Del Sur State University-Main CampusDocument5 pagesSurigao Del Sur State University-Main Campusjemuel cinso0% (1)

- KTTM Yarn Quality and End Breakage ControlDocument22 pagesKTTM Yarn Quality and End Breakage ControlJigneshSaradava100% (1)

- Seminar 3Document40 pagesSeminar 3Solomon Solostar JacobNo ratings yet

- Understandi NG Apparel Quality: Fabric DefectsDocument32 pagesUnderstandi NG Apparel Quality: Fabric DefectsAnchal AryanNo ratings yet

- UNIT IV Fabric Defects & InspectionDocument62 pagesUNIT IV Fabric Defects & InspectionDeepthi channaNo ratings yet

- Textilelearner Blogspot Com 2012 07 Fabric Spreading Types of Fabric HTMLDocument6 pagesTextilelearner Blogspot Com 2012 07 Fabric Spreading Types of Fabric HTMLDeepthi SonuNo ratings yet

- Troubleshooting Knitting Machine Problems - Knitting ClosetDocument9 pagesTroubleshooting Knitting Machine Problems - Knitting ClosetAmira's ClothesNo ratings yet

- DFM - Ethernet CableDocument7 pagesDFM - Ethernet Cablelinh leNo ratings yet

- PillingDocument3 pagesPillingইসলামিক টিভিNo ratings yet

- Common Seam Quality DefectsDocument6 pagesCommon Seam Quality Defectskernchia100% (2)

- Melt Spinning Process - Feature of Melt Spinning - Advantages and Disadvantage of Melt Spinning - Textile LearnerDocument4 pagesMelt Spinning Process - Feature of Melt Spinning - Advantages and Disadvantage of Melt Spinning - Textile LearnerrajinderNo ratings yet

- Fields of Textiles: Tree DiagramDocument24 pagesFields of Textiles: Tree Diagramsarwat yaseenNo ratings yet

- Common Defects in Denim Jeans SewingDocument10 pagesCommon Defects in Denim Jeans SewingShaaban NoamanNo ratings yet

- Perform Basic MaintenanceDocument3 pagesPerform Basic MaintenancejessafesalazarNo ratings yet

- Characteristics of Defects of Different Fabrics and Their RemediesDocument4 pagesCharacteristics of Defects of Different Fabrics and Their RemediesSajad AliNo ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- Operating Instructions Cleaver A8Document2 pagesOperating Instructions Cleaver A8عبدالله الشهاريNo ratings yet

- Process Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerDocument3 pagesProcess Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerНурбек КасимовNo ratings yet

- DefectsDocument31 pagesDefectsKawsar HamidNo ratings yet

- Warp Way DefectsDocument11 pagesWarp Way Defectsharshal52855No ratings yet

- Minimizing Needle Cutting On Knits 2-3-101Document3 pagesMinimizing Needle Cutting On Knits 2-3-101BalaNo ratings yet

- Defects in The Knitted Fabrics (Project)Document23 pagesDefects in The Knitted Fabrics (Project)Rana AhmedNo ratings yet

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDNo ratings yet

- Sr. No Page NoDocument33 pagesSr. No Page NoAmor ELHAJAHMEDNo ratings yet

- 1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsDocument40 pages1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsshaifaliNo ratings yet

- Serviceability of FabricDocument64 pagesServiceability of FabricVasant Kothari100% (1)

- Individual Assignment II: Dheepan Ravichandran, Student Number: 8812248Document9 pagesIndividual Assignment II: Dheepan Ravichandran, Student Number: 8812248dheepan ravichandranNo ratings yet

- Sadia Mam... PPDocument11 pagesSadia Mam... PPsazzad alaminNo ratings yet

- Student NOTESDocument53 pagesStudent NOTESRohan YadavNo ratings yet

- Apparel Design and Production IDocument18 pagesApparel Design and Production IStacey MinNo ratings yet

- Embrdry Tutorials EbookDocument15 pagesEmbrdry Tutorials EbookMarittaKarmaNo ratings yet

- Fabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchDocument229 pagesFabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & Researchfuad ahmed100% (1)

- Will Be Covered:: Labels Requirement What Are The Safety Rules For Children'S Nightwear?Document5 pagesWill Be Covered:: Labels Requirement What Are The Safety Rules For Children'S Nightwear?SılaNo ratings yet

- Q2 PPT-1 (FABRIC FAULTS)Document28 pagesQ2 PPT-1 (FABRIC FAULTS)abhigupta9809No ratings yet

- S7220D CatalogDocument4 pagesS7220D Catalogluciano casteNo ratings yet

- WarpingDocument10 pagesWarpingNedian87No ratings yet

- Garment Defect AnalysisDocument21 pagesGarment Defect AnalysisIndranil Saha100% (10)

- Print & Emboidery SOPDocument1 pagePrint & Emboidery SOPAbdul AzizNo ratings yet

- Chapter 2 1Document22 pagesChapter 2 1Leslie AnasNo ratings yet

- Denim Seam Quality DefectsDocument6 pagesDenim Seam Quality Defectsapi-26494555No ratings yet

- Identifying Casting Defects - AFSDocument3 pagesIdentifying Casting Defects - AFSnddkNo ratings yet

- Internship JuryDocument24 pagesInternship JurySarthak JainNo ratings yet

- Stitch Types Contd... - Lec 3Document14 pagesStitch Types Contd... - Lec 3dewmikushani1994No ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- 101 Bladesmithing Mistakes: Knife Making Mistakes That Ruin Your Knives and How to Avoid ThemFrom Everand101 Bladesmithing Mistakes: Knife Making Mistakes That Ruin Your Knives and How to Avoid ThemRating: 5 out of 5 stars5/5 (1)

- KRYKARD CORPORATE CLIENTS LIST - StabiliserDocument4 pagesKRYKARD CORPORATE CLIENTS LIST - StabiliserGOWTHAM CHANDRUNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument4 pagesProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- KRYKARD 3phase Stabiliser BrochureDocument2 pagesKRYKARD 3phase Stabiliser BrochureGOWTHAM CHANDRUNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument1 pageProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- Quality Control:: Quality Control Garment Industry Quality Control Colour FastnessDocument2 pagesQuality Control:: Quality Control Garment Industry Quality Control Colour FastnessGOWTHAM CHANDRUNo ratings yet

- Tiruppur DatabaseDocument5 pagesTiruppur DatabaseGOWTHAM CHANDRUNo ratings yet

- Categories An Overview of Quality and Quality Control in Textile IndustryDocument14 pagesCategories An Overview of Quality and Quality Control in Textile IndustryGOWTHAM CHANDRUNo ratings yet

- Krykard Corporate Clients List - StabiliserDocument2 pagesKrykard Corporate Clients List - StabiliserGOWTHAM CHANDRUNo ratings yet

- 18 Types of FABRIC WEAVES (An Overview) - Sew GuideDocument36 pages18 Types of FABRIC WEAVES (An Overview) - Sew GuideGOWTHAM CHANDRUNo ratings yet

- Warping - Objects of Warping - Importance of Warping in Weaving - Textile LearneDocument4 pagesWarping - Objects of Warping - Importance of Warping in Weaving - Textile LearneGOWTHAM CHANDRUNo ratings yet

- Warping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1Document4 pagesWarping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1GOWTHAM CHANDRUNo ratings yet

- Weaving Machinery - Toyota Industries CorporationDocument2 pagesWeaving Machinery - Toyota Industries CorporationGOWTHAM CHANDRUNo ratings yet

- Types of Looms and WeavesDocument13 pagesTypes of Looms and WeavesGOWTHAM CHANDRUNo ratings yet

- Explaining TextilesDocument109 pagesExplaining TextilesGOWTHAM CHANDRUNo ratings yet

- Nozzle EfficiencyDocument32 pagesNozzle EfficiencyGOWTHAM CHANDRUNo ratings yet

- Chemical TableDocument16 pagesChemical TableGokul VenugopalNo ratings yet

- Statiflo Brochure - EN-GBDocument12 pagesStatiflo Brochure - EN-GBalfreddieick1No ratings yet

- PDS 100RTS864-469 BlancoDocument3 pagesPDS 100RTS864-469 Blancoandreisanchez32No ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Resin Coated Sand TechnologyDocument5 pagesResin Coated Sand TechnologyTarasree TechnocastNo ratings yet

- Presentation 1Document19 pagesPresentation 1Ika ChasaNo ratings yet

- Br09 Tds Bladerep Lep 9Document2 pagesBr09 Tds Bladerep Lep 9Swarf DwarfNo ratings yet

- Test Report GroutDocument2 pagesTest Report GroutKuldeep Chakerwarti100% (1)

- Elements Compounds and Mixtures WorksheetDocument2 pagesElements Compounds and Mixtures WorksheetLiam PriceNo ratings yet

- 0 Basics Facts About ClinkerDocument1 page0 Basics Facts About ClinkerAhmed Younis100% (1)

- Automatic Fire Extinguishing SystemDocument33 pagesAutomatic Fire Extinguishing Systemlmt76No ratings yet

- The Structure of Crystalline and Amorphous SolidsDocument3 pagesThe Structure of Crystalline and Amorphous SolidsFranzhean Balais CuachonNo ratings yet

- 2019 - CBM - 계면부착 실험간 비교 참고Document11 pages2019 - CBM - 계면부착 실험간 비교 참고이호진No ratings yet

- Comparison of Deformation Behavior of 316L Stainless Steel and Ti6Al4V Alloy Applied in TraumatologyDocument5 pagesComparison of Deformation Behavior of 316L Stainless Steel and Ti6Al4V Alloy Applied in TraumatologyAhmedNo ratings yet

- Pt. Puji Lestari Purnama: Iso Classification HFA HFB HFC HFD-R Hfd-U HLPDocument1 pagePt. Puji Lestari Purnama: Iso Classification HFA HFB HFC HFD-R Hfd-U HLPTommy KurniaNo ratings yet

- Welding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Document14 pagesWelding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Prisma RianNo ratings yet

- Thông Tin Sợi Thủy Tinh Bản t.anhDocument70 pagesThông Tin Sợi Thủy Tinh Bản t.anhhue558110No ratings yet

- ME6302-SCAD-MSM-by WWW - LearnEngineering.inDocument130 pagesME6302-SCAD-MSM-by WWW - LearnEngineering.inKKNo ratings yet

- Sl. No Description of Items Qty Unit Rate Amount 1 2 3 4 5 6 BOQ Quarter & Barrack Abstract of The EstimateDocument8 pagesSl. No Description of Items Qty Unit Rate Amount 1 2 3 4 5 6 BOQ Quarter & Barrack Abstract of The EstimateChandan DeyNo ratings yet

- LMDQDocument601 pagesLMDQMohd Azamuddin Mohd SaifullizanNo ratings yet

- BSR 2016-Renovation PDFDocument141 pagesBSR 2016-Renovation PDFthareendaNo ratings yet

- 6403 en Speedi-SleevesDocument44 pages6403 en Speedi-Sleevesdestro3000No ratings yet

- 3m (Data Sheet) - Scotchkote Fbe-6233Document3 pages3m (Data Sheet) - Scotchkote Fbe-6233PubcrawlNo ratings yet

- JSS 2 Basic TechnologyDocument3 pagesJSS 2 Basic TechnologyTriplejayartNo ratings yet

- CP26 PDFDocument47 pagesCP26 PDFrafik1995No ratings yet

Defects - Faults and Remedies of Warping - Textile Learner

Defects - Faults and Remedies of Warping - Textile Learner

Uploaded by

GOWTHAM CHANDRUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Defects - Faults and Remedies of Warping - Textile Learner

Defects - Faults and Remedies of Warping - Textile Learner

Uploaded by

GOWTHAM CHANDRUCopyright:

Available Formats

SPONSORED SEARCHES

welding and fabrication

inspection testing

wire size calculator

production machine

manufacturing and production

Search... Search

Categories

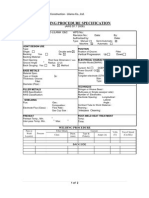

Defects/Faults and Remedies of Warping

Warping means, winding of warp yarns onto a beam usually in preparation for slashing, weaving, or Select a Category to View

warp knitting. It is also called Beaming. When warping operation is done some defects occur as well as

other operations. Now we will discuss faults and it’s remedies of warping. Find Us @

Defects & Remedies of Warping

Join Us:

Explore our ecstatic

bathroom collection,

bathroom designs to…

Premium Lunchboxes from Vaya Premium Lunchboxes from Vaya

New-age stainless steel

New-age stainless steel

lunchboxes keep food fresh lunchboxes keep food fresh and

and warm up to 6 hours warm up to 6 hours

1. Lapped end

Cause:

The broken end of yarn is not tied to the end on the warp beam & overlaps the adjoining yarn. The

beam is not properly brake & the signal hook fails to operate.

Remedies:

Tying the broken end to the end on the warp beam.

Proper signal hook. Bombay Shirt Company

2. Piecing Classic white shirt,

monogrammed for you.

Designed by you, crafted by us.

Cause:

One broken end is pieced to another yarn end on the warping beam.

Remedies:

Get Article in Email

By proper joining.

Enter Email Address Here

3. Soft ends on the warping beam Subscribe

http://textilelearner.blogspot.com/2012/03/defectsfaults-and-remedies-of-warping.html?m=1 22/02/19, 00B12

Page 1 of 4

Cause: Sponsored

Breakage of a group of ends & piecing them in bundle or by lapping. This defect is caused by the

careless of the operator.

Remedies:

Careful operation.

Broken end should be piece up properly.

4. Incorrect form of build

Cause:

Caused by non uniform spreading of ends in the guide reed & its improper setting & conical winding in

case of non uniform pressure of the warping beam.

Remedies: Popular Posts

Uniform spreading of ends. Burn Out Printing | Printing Process of

Burn out Print 1

Appropriate setting.

Different Types of Dyes with Chemical

5. Slacks & irregular yarn tension

Structure 2

Cause: Interview Questions and Answers for

It happens due to any one of these reasons- improper threading of the yarn into the tension devices, Garments Job (Part-1) 3

ejection of yarn from under the disc of the yarn tensioning device, or yarn tension devices of poor

quality. Major Formula on Garments for Beginners 4

Different Parts of Modern Cotton Ginning

Remedies:

Machine 5

Proper threading of tension device.

Textile Calculation | Different Formula of

Good quality of tension device. Textile Calculation 6

6. Broken ends on the beam Dyeing Process | Different Types of Dyes |

Classification of Dyes 7

Cause:

Textile Manufacturing Process | Process

A group of ends is broken & tied as a brunch or worked-in with overlapping.

Flow Chart of Textile Manufacturing 8

Remedies:

SPONSORED SEARCHES

Broken ends should be removed.

welding and fabrication

7. Conical winding on the beam

flow measurement

Cause:

It occurs due to incorrect load applied by the pressure roller. production machine

Remedies: inspection testing

Correct load applied.

dyeing textile

8. Improper length of warping

Important Categories

Cause:

It is due to malfunction of the counter & the brakes of the measuring device & warp beams.

Accessories Advanced Dyeing

Remedies:

Automation

Bleaching Bra Calculation

Good measuring device.

Campus Carding

Career

Circular Knitting Clothing Color

Color Fastness Combing Computer

Costing

http://textilelearner.blogspot.com/2012/03/defectsfaults-and-remedies-of-warping.html?m=1 22/02/19, 00B12

Page 2 of 4

Cotton Count Cutting Defects

Denim Disperse Dye Drafting Dye

Dyeing Dyeing Auxiliaries

Dyeing M/C Ebooks Enzyme ETP

Experiment Fabric

Fabric Manufacturing

Fabric Stracture and Design

Fabric Test Factory Fashion

Fashion and Design Fiber

Finishing Finishing M/C

PREVIOUS NEXT

Flow Chart

Beam Warping Machine | Working Principle of Types of Singeing Machines | Plate Singeing

Beam Warping Machine Machine | Rotary-Cylinder Singeing Machine | Garment Wash Garments M/C

Gas Singeing Machine

Garments Manufacturing IE

Inspection Jute Fiber Jute Spinning

Knitting Knitting M/C Loom

Related Post:

Machines Maintenance

Warping | Objects of Warping | Importance of Warping in Weaving Manmade Fiber Marker

Identification of End (Warp) & Pick (Weft) Medical Textile Mercerizing

Beam Warping Machine | Working Principle of Beam Warping Machine Microfiber

Merchandising

Warping Calculation | Calculation for Direct Warping and Sectional Warping Nanotechnology

Creels | Warping Creels | Types of Creel | Mobile Creel | Magazine Creel | Swivel

Needle Nonwoven Pattern Pigment

Frame Creel | V-shaped Creel

Plasma Technology Polyester

Pretreatment Printing

Printing and Finishing Properties

Questions Reactive Dye Recycling

Report

Research Ring Frame Rotor Spinning

Safety Textile

Sample Scouring Seam Sewing

Sewing M/C Silk Simplex Singeing

Sizing

Smart Textile Software Special Dye

Special Fabric

Special Fiber Special Finishing

Spinning Spinning M/C Stitch

Sulpher Dye Technical textile

Testing M/C Textile News

Textile Terms

Thesis Thread

TTQC Twist

Undergarment Uster M/C Vat Dye

Warp Knitting

Warping Washing Wastage Water

Weaving

http://textilelearner.blogspot.com/2012/03/defectsfaults-and-remedies-of-warping.html?m=1 22/02/19, 00B12

Page 3 of 4

Wet process Winding Wool Yarn

Our App @ Play Store

Ad

1. Design Fabric Print

2. Fabric Manufacturing

3. Cotton Knitting Yarn

Copyright © 2019 : Textile Learner

http://textilelearner.blogspot.com/2012/03/defectsfaults-and-remedies-of-warping.html?m=1 22/02/19, 00B12

Page 4 of 4

You might also like

- 01-Operating Manual For 1200 MTPD Ammonia Plant PDFDocument315 pages01-Operating Manual For 1200 MTPD Ammonia Plant PDFAbdulla100% (4)

- Clothing Construction BookDocument172 pagesClothing Construction BookDebbie Bacalso95% (21)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Polymer-Plastics Additives PDFDocument643 pagesPolymer-Plastics Additives PDFwardolier67% (3)

- Learn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Document362 pagesLearn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Jeļena Krētaine100% (2)

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Assignment On Different Kinds of Knitting Faults Causes and Their RemediesDocument4 pagesAssignment On Different Kinds of Knitting Faults Causes and Their RemediesRaihan Moner Manush0% (2)

- Biocompatibility of Aluminium Alloys and Anodic Al2O3Document6 pagesBiocompatibility of Aluminium Alloys and Anodic Al2O3Nícolas LaraNo ratings yet

- Warping - Objects of Warping - Importance of Warping in Weaving - Textile LearneDocument4 pagesWarping - Objects of Warping - Importance of Warping in Weaving - Textile LearneGOWTHAM CHANDRUNo ratings yet

- Effect of Balloon Breaker in Winding - Textile LearnerDocument8 pagesEffect of Balloon Breaker in Winding - Textile Learnermasum_austNo ratings yet

- Stitch Diary Ebook Defects Part 2Document26 pagesStitch Diary Ebook Defects Part 2Rafael CuicapuzaNo ratings yet

- Sewing DeffectsDocument11 pagesSewing DeffectsVeverley CarupoNo ratings yet

- Creels - Warping Creels - Types of Creel - Mobile Creel - Magazine Creel - SwiveDocument4 pagesCreels - Warping Creels - Types of Creel - Mobile Creel - Magazine Creel - SwiveGOWTHAM CHANDRUNo ratings yet

- Uaq Assignment 2Document5 pagesUaq Assignment 2vaishnavi.chaudhariNo ratings yet

- Embroidery & Machine BasicsDocument57 pagesEmbroidery & Machine BasicsJuciêr AlcântaraNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- Fabric DefectsDocument5 pagesFabric Defectsalibaqar74100% (5)

- Surigao Del Sur State University-Main CampusDocument5 pagesSurigao Del Sur State University-Main Campusjemuel cinso0% (1)

- KTTM Yarn Quality and End Breakage ControlDocument22 pagesKTTM Yarn Quality and End Breakage ControlJigneshSaradava100% (1)

- Seminar 3Document40 pagesSeminar 3Solomon Solostar JacobNo ratings yet

- Understandi NG Apparel Quality: Fabric DefectsDocument32 pagesUnderstandi NG Apparel Quality: Fabric DefectsAnchal AryanNo ratings yet

- UNIT IV Fabric Defects & InspectionDocument62 pagesUNIT IV Fabric Defects & InspectionDeepthi channaNo ratings yet

- Textilelearner Blogspot Com 2012 07 Fabric Spreading Types of Fabric HTMLDocument6 pagesTextilelearner Blogspot Com 2012 07 Fabric Spreading Types of Fabric HTMLDeepthi SonuNo ratings yet

- Troubleshooting Knitting Machine Problems - Knitting ClosetDocument9 pagesTroubleshooting Knitting Machine Problems - Knitting ClosetAmira's ClothesNo ratings yet

- DFM - Ethernet CableDocument7 pagesDFM - Ethernet Cablelinh leNo ratings yet

- PillingDocument3 pagesPillingইসলামিক টিভিNo ratings yet

- Common Seam Quality DefectsDocument6 pagesCommon Seam Quality Defectskernchia100% (2)

- Melt Spinning Process - Feature of Melt Spinning - Advantages and Disadvantage of Melt Spinning - Textile LearnerDocument4 pagesMelt Spinning Process - Feature of Melt Spinning - Advantages and Disadvantage of Melt Spinning - Textile LearnerrajinderNo ratings yet

- Fields of Textiles: Tree DiagramDocument24 pagesFields of Textiles: Tree Diagramsarwat yaseenNo ratings yet

- Common Defects in Denim Jeans SewingDocument10 pagesCommon Defects in Denim Jeans SewingShaaban NoamanNo ratings yet

- Perform Basic MaintenanceDocument3 pagesPerform Basic MaintenancejessafesalazarNo ratings yet

- Characteristics of Defects of Different Fabrics and Their RemediesDocument4 pagesCharacteristics of Defects of Different Fabrics and Their RemediesSajad AliNo ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- Operating Instructions Cleaver A8Document2 pagesOperating Instructions Cleaver A8عبدالله الشهاريNo ratings yet

- Process Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerDocument3 pagesProcess Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerНурбек КасимовNo ratings yet

- DefectsDocument31 pagesDefectsKawsar HamidNo ratings yet

- Warp Way DefectsDocument11 pagesWarp Way Defectsharshal52855No ratings yet

- Minimizing Needle Cutting On Knits 2-3-101Document3 pagesMinimizing Needle Cutting On Knits 2-3-101BalaNo ratings yet

- Defects in The Knitted Fabrics (Project)Document23 pagesDefects in The Knitted Fabrics (Project)Rana AhmedNo ratings yet

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDNo ratings yet

- Sr. No Page NoDocument33 pagesSr. No Page NoAmor ELHAJAHMEDNo ratings yet

- 1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsDocument40 pages1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsshaifaliNo ratings yet

- Serviceability of FabricDocument64 pagesServiceability of FabricVasant Kothari100% (1)

- Individual Assignment II: Dheepan Ravichandran, Student Number: 8812248Document9 pagesIndividual Assignment II: Dheepan Ravichandran, Student Number: 8812248dheepan ravichandranNo ratings yet

- Sadia Mam... PPDocument11 pagesSadia Mam... PPsazzad alaminNo ratings yet

- Student NOTESDocument53 pagesStudent NOTESRohan YadavNo ratings yet

- Apparel Design and Production IDocument18 pagesApparel Design and Production IStacey MinNo ratings yet

- Embrdry Tutorials EbookDocument15 pagesEmbrdry Tutorials EbookMarittaKarmaNo ratings yet

- Fabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchDocument229 pagesFabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & Researchfuad ahmed100% (1)

- Will Be Covered:: Labels Requirement What Are The Safety Rules For Children'S Nightwear?Document5 pagesWill Be Covered:: Labels Requirement What Are The Safety Rules For Children'S Nightwear?SılaNo ratings yet

- Q2 PPT-1 (FABRIC FAULTS)Document28 pagesQ2 PPT-1 (FABRIC FAULTS)abhigupta9809No ratings yet

- S7220D CatalogDocument4 pagesS7220D Catalogluciano casteNo ratings yet

- WarpingDocument10 pagesWarpingNedian87No ratings yet

- Garment Defect AnalysisDocument21 pagesGarment Defect AnalysisIndranil Saha100% (10)

- Print & Emboidery SOPDocument1 pagePrint & Emboidery SOPAbdul AzizNo ratings yet

- Chapter 2 1Document22 pagesChapter 2 1Leslie AnasNo ratings yet

- Denim Seam Quality DefectsDocument6 pagesDenim Seam Quality Defectsapi-26494555No ratings yet

- Identifying Casting Defects - AFSDocument3 pagesIdentifying Casting Defects - AFSnddkNo ratings yet

- Internship JuryDocument24 pagesInternship JurySarthak JainNo ratings yet

- Stitch Types Contd... - Lec 3Document14 pagesStitch Types Contd... - Lec 3dewmikushani1994No ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- 101 Bladesmithing Mistakes: Knife Making Mistakes That Ruin Your Knives and How to Avoid ThemFrom Everand101 Bladesmithing Mistakes: Knife Making Mistakes That Ruin Your Knives and How to Avoid ThemRating: 5 out of 5 stars5/5 (1)

- KRYKARD CORPORATE CLIENTS LIST - StabiliserDocument4 pagesKRYKARD CORPORATE CLIENTS LIST - StabiliserGOWTHAM CHANDRUNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument4 pagesProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- KRYKARD 3phase Stabiliser BrochureDocument2 pagesKRYKARD 3phase Stabiliser BrochureGOWTHAM CHANDRUNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument1 pageProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- Quality Control:: Quality Control Garment Industry Quality Control Colour FastnessDocument2 pagesQuality Control:: Quality Control Garment Industry Quality Control Colour FastnessGOWTHAM CHANDRUNo ratings yet

- Tiruppur DatabaseDocument5 pagesTiruppur DatabaseGOWTHAM CHANDRUNo ratings yet

- Categories An Overview of Quality and Quality Control in Textile IndustryDocument14 pagesCategories An Overview of Quality and Quality Control in Textile IndustryGOWTHAM CHANDRUNo ratings yet

- Krykard Corporate Clients List - StabiliserDocument2 pagesKrykard Corporate Clients List - StabiliserGOWTHAM CHANDRUNo ratings yet

- 18 Types of FABRIC WEAVES (An Overview) - Sew GuideDocument36 pages18 Types of FABRIC WEAVES (An Overview) - Sew GuideGOWTHAM CHANDRUNo ratings yet

- Warping - Objects of Warping - Importance of Warping in Weaving - Textile LearneDocument4 pagesWarping - Objects of Warping - Importance of Warping in Weaving - Textile LearneGOWTHAM CHANDRUNo ratings yet

- Warping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1Document4 pagesWarping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1GOWTHAM CHANDRUNo ratings yet

- Weaving Machinery - Toyota Industries CorporationDocument2 pagesWeaving Machinery - Toyota Industries CorporationGOWTHAM CHANDRUNo ratings yet

- Types of Looms and WeavesDocument13 pagesTypes of Looms and WeavesGOWTHAM CHANDRUNo ratings yet

- Explaining TextilesDocument109 pagesExplaining TextilesGOWTHAM CHANDRUNo ratings yet

- Nozzle EfficiencyDocument32 pagesNozzle EfficiencyGOWTHAM CHANDRUNo ratings yet

- Chemical TableDocument16 pagesChemical TableGokul VenugopalNo ratings yet

- Statiflo Brochure - EN-GBDocument12 pagesStatiflo Brochure - EN-GBalfreddieick1No ratings yet

- PDS 100RTS864-469 BlancoDocument3 pagesPDS 100RTS864-469 Blancoandreisanchez32No ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Resin Coated Sand TechnologyDocument5 pagesResin Coated Sand TechnologyTarasree TechnocastNo ratings yet

- Presentation 1Document19 pagesPresentation 1Ika ChasaNo ratings yet

- Br09 Tds Bladerep Lep 9Document2 pagesBr09 Tds Bladerep Lep 9Swarf DwarfNo ratings yet

- Test Report GroutDocument2 pagesTest Report GroutKuldeep Chakerwarti100% (1)

- Elements Compounds and Mixtures WorksheetDocument2 pagesElements Compounds and Mixtures WorksheetLiam PriceNo ratings yet

- 0 Basics Facts About ClinkerDocument1 page0 Basics Facts About ClinkerAhmed Younis100% (1)

- Automatic Fire Extinguishing SystemDocument33 pagesAutomatic Fire Extinguishing Systemlmt76No ratings yet

- The Structure of Crystalline and Amorphous SolidsDocument3 pagesThe Structure of Crystalline and Amorphous SolidsFranzhean Balais CuachonNo ratings yet

- 2019 - CBM - 계면부착 실험간 비교 참고Document11 pages2019 - CBM - 계면부착 실험간 비교 참고이호진No ratings yet

- Comparison of Deformation Behavior of 316L Stainless Steel and Ti6Al4V Alloy Applied in TraumatologyDocument5 pagesComparison of Deformation Behavior of 316L Stainless Steel and Ti6Al4V Alloy Applied in TraumatologyAhmedNo ratings yet

- Pt. Puji Lestari Purnama: Iso Classification HFA HFB HFC HFD-R Hfd-U HLPDocument1 pagePt. Puji Lestari Purnama: Iso Classification HFA HFB HFC HFD-R Hfd-U HLPTommy KurniaNo ratings yet

- Welding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Document14 pagesWelding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Prisma RianNo ratings yet

- Thông Tin Sợi Thủy Tinh Bản t.anhDocument70 pagesThông Tin Sợi Thủy Tinh Bản t.anhhue558110No ratings yet

- ME6302-SCAD-MSM-by WWW - LearnEngineering.inDocument130 pagesME6302-SCAD-MSM-by WWW - LearnEngineering.inKKNo ratings yet

- Sl. No Description of Items Qty Unit Rate Amount 1 2 3 4 5 6 BOQ Quarter & Barrack Abstract of The EstimateDocument8 pagesSl. No Description of Items Qty Unit Rate Amount 1 2 3 4 5 6 BOQ Quarter & Barrack Abstract of The EstimateChandan DeyNo ratings yet

- LMDQDocument601 pagesLMDQMohd Azamuddin Mohd SaifullizanNo ratings yet

- BSR 2016-Renovation PDFDocument141 pagesBSR 2016-Renovation PDFthareendaNo ratings yet

- 6403 en Speedi-SleevesDocument44 pages6403 en Speedi-Sleevesdestro3000No ratings yet

- 3m (Data Sheet) - Scotchkote Fbe-6233Document3 pages3m (Data Sheet) - Scotchkote Fbe-6233PubcrawlNo ratings yet

- JSS 2 Basic TechnologyDocument3 pagesJSS 2 Basic TechnologyTriplejayartNo ratings yet

- CP26 PDFDocument47 pagesCP26 PDFrafik1995No ratings yet