Professional Documents

Culture Documents

SCM Module1 Questions and Answers 1

SCM Module1 Questions and Answers 1

Uploaded by

Samba Shiva Reddy.g ShivaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCM Module1 Questions and Answers 1

SCM Module1 Questions and Answers 1

Uploaded by

Samba Shiva Reddy.g ShivaCopyright:

Available Formats

||Jai Sri Gurudev||

SJC Institute of Technology

Supply Chain Management

Module 1 Questions and answers

1 Define Supply Chain 3 OR 4 M

Or

What do you mean by supply chain network?

The Supply chain encompasses all activities involved in the transformation of goods from the raw material

stage to the final stage, when the goods and services reach the end customer. Supply chain management

involves planning, Design and control of flow of material, information and finance along the supply chain to

deliver superior value to the end customer in an effective and efficient manner. a typical supply chain is

represented in figure as below

Product

Distributer Retailer Customer

Supplier Manufac

turer

Information

2 What is supply chain? Consider purchase of a detergent in Wal-Mart stores and with respect to

this explain different stages in supply chain with neat diagram.

The Supply chain encompasses all activities involved in the transformation of goods from

the raw material stage to the final stage, when the goods and services reach the end customer. Supply chain

management involves planning, Design and control of flow of material, information and finance along the

supply chain to deliver superior value to the end customer in an effective and efficient manner.

Note: Replace Big Bazaar super market with Wal-Mart Stores in the diagram

SJC Institute of Technology Page 1

3 Explain Briefly the Objectives of supply chain management 3 OR 4 M

Objectives of supply chain management:

Enhance the supply chain value: Supply chain value is the difference between final worth of the

product to the customer minus supply chain costs incurs in full filling the customer requests.

Increases the supply chain profitability: Supply chin profitability is the difference between the

revenue generated from the customer and the overall cost across the value chain

Maximize the customer satisfaction

Have the product replenishment at right time

4 Explain the importance of supply chain management. 3 OR 4 M

Or

Explain the role of supply chain management.

Importance of supply chain management:

In the past, customers were not very demanding and competition was not really intensive. As a result

Firms could afford to ignore issues pertaining to the supply chain. Today, firms that do not manage their supply

chain will incur huge inventory costs and eventually end up losing a lot of customers because the right products

are not available at right place and time. The following are the 5 major trends that have emerged to make supply

chain management is critical success factor in most industry.

a. Proliferation in product lines.

b. Short product life cycles.

c. High level of out outsourcing.

d. Shift in power structure in the chain.

e. Globalization of manufacturing.

SJC Institute of Technology Page 2

5 Describe the Cycle and Push/Pull view of a supply chain management. 5 or 6 M

or

Describe cycle view of a supply chain management.

Or

Describe Push/Pull view of a supply chain management.

Cycle View: Process in a supply chain are divided into series of cycles, each performed at the interface

between two successive stages of supply chain. All supply chain process can be broken down into the

following four process cycles as shown in figure.

Customer order cycle

Replenishment cycle

Manufacture cycle

Procurement cycle

Push/Pull view: Process in a supply chain are divided into two categories depending on whether they

are executed in response to a customer or in anticipation of customer orders. Pull process are initiated by

a customer order. Push process are initiated and performed in anticipation of customer orders. Push

process may also be referred to as reactive process because they react to customer demand. Push process

may also be referred to as speculative processes because they respond to speculate rather than actual

demand. Push/Pull boundary separates push process from pull process

SJC Institute of Technology Page 3

6 Explain the Decision Phases in supply chain

Successful supply chain management requires many decisions relating to the flow of

information, product and founds. Each decision should be made to raise the supply chain surplus. These

decisions fall into 3 phases, depending on the frequency of each decision and the time frame during

which a decision phase has an impact. As a result, each category of decisions must consider uncertainty

over the decision horizon.

1 Supply chain strategy or Design: During this phase, a company decides how to structure the supply

chain over the next several years. It decides what the chain’s configuration will be, how resources will

be allocated, and what process each stage will perform. Strategic decisions made by companies include

whether to outsource or perform a supply chain function in-house, the location and capacity of

production and warehouse facilities, the product to be manufactured or stored at various location, the

modes of transportation to be made available along different shipping legs, and the type of information

system to be utilized. A firm must ensure that the supply chain configuration supports its strategic

objectives and increases the supply chain surplus during this phase. Supply chain deign decisions are

typically made for the long term and are expensive to alter on short notice. Consequently, when

companies make these decisions, they must take in to account uncertainty in anticipated market

conditions over the next few years.

2 Supply chain Planning: for the decisions made during this phase, the time frame considered is a

quarter to a year. The supply chain’s configuration determined in the strategic phase is fixed. Companies

start the planning phase with a forecast for the coming year of demand and other factors such as costs

and prices in different markets. Planning includes making decisions regarding which market will be

supplied from which locations, the subcontracting of manufacturing, the inventory polices to be

fallowed and the timing and size of marketing and price promotions. Planning establishes parameters

within which a supply chain will function over a specified period of time. In the planning phase,

SJC Institute of Technology Page 4

companies must include uncertainty in demand, exchange rates, and completion over this time horizon

in their decisions.

3 Supply chain operation: the time horizon here is weekly or daily. During this phase companies make

decisions regarding individual orders. At the operational level, supply chain configuration is considered

to be fixed. And planning policies are already. The goal of supply chain operation is to handle incoming

orders in the best possible manner. During this phase, firm allocate inventory or production to individual

orders, set a date that an order is to be filled. Generate a pick lists at a warehouse, allocate an order to a

particular shipment mode and shipment, set delivery schedules of trucks, and place replenishment

orders. Because operational decisions are being made in the short term(minutes, hours or days),

therefore less uncertainty about demand information. The goal during the operation phase is to exploit

the reduction of uncertainty and optimize performance.

7 Explain the Evolution of supply chain 8 OR 10 M

The First Revolution (Beginning of 20th Century)

The Ford supply chain management

Tightly integrated Supply chain management

Ford Supply chain would offer any color as long as it was Black and any model as long as it was ‘T’

model

Highly efficient, but inflexible Supply chain that could not handle a wide product variety and was

not sustainable

It could manage the journey from Iron ore mine to finished automobile in 82 Hrs

The Second Revolution (Around 1960)

The Toyota Supply Chain

Toyota motors company came up with ideas that allowed the final assembly and manufacturing of key

components to be done in-house

The bulk of the components was sourced from a large number of suppliers who are part of the Keirestu

system

Keirestu refers to a set of companies with interlocking business relationships and shareholding

The Principals fallowed by Toyota are more popularly known as lean production systems

The Third Revolution (Around 1995)

The Dell Supply Chain:

SJC Institute of Technology Page 5

Dell computers allowed customers to customize their computers

Because of advances in IT Dell could integrate the suppliers electronically

Dell did not believe in long term relationships with suppliers

Dell believed in working with world-class suppliers who would maintained their technology and cost

leadership in their respective fields

At Dell the trigger for supplier orders was the actual orders by the customer, and not forecasts

Advances in IT have fuelled the third revolution

8 Explain with Example, the three basic steps required to achieve the strategic fit 10 M

or

Explain with a figure, the different scopes of strategic fit across a supply chain

OR

Explain why achieving strategic fit is critical to a company’s overall success

What does a company need to do to achieve that all-important strategic fit between the supply chain and

competitive strategy? A competitive strategy will specify, either explicitly or implicitly, one or more customer

segments that company hopes to satisfy? To achieve strategic fit, a company must ensure that its supply chain

capabilities support its ability to satisfy the needs of the targeted customer segments.

There are 3 basic steps to achieve this strategic fit.

• Step1: understanding customer and supply chain uncertainties

• Step 2: understanding the supply chain

• Step 3: Achieving strategic fit

• Step1: understanding customer and supply chain uncertainties: A company must understand the

customer needs for each targeted segment and the uncertainty these needs impose on the supply chain.

these needs help the company define the desired cost and service requirements. The supply chain

uncertainty helps the company identify the extent of the unpredictability of demand, disruption, and

delay that the supply chain must be prepared for

In general customer demand from different segments varies along several attributes as fallows.

SJC Institute of Technology Page 6

Implied demand uncertainty:

• Step 2: understanding the supply chain : each of the many types of supply chains is designed to

perform different tasks well. A company must understand what its supply chain is designed to do well.

Supply chain responsiveness includes a supply chain’s ability to do the following

• respond to wide range of quantities demanded

• meet short lead time

• Handle a large Varity of products

• build highly innovative products

• meet a very high level of service

The responsive spectrum

SJC Institute of Technology Page 7

• Step 3: Achieving strategic fit: Ensure that the degree of supply chain responsiveness is consistent with

the implied uncertainty. The goal is to target high responsiveness for a supply chain facing high implied

uncertainty, and efficiency for a supply chain facing low implied demand.

9 Explain Supply chain Strategy? 4M

10 Discuss the major Drivers of supply chain management 10 M

Or

SJC Institute of Technology Page 8

Explain with Example, the impact of different drivers on the performance of supply chain

OR

How does Wal-Mart structure it drivers so that its competitive strategy and supply chain strategy are in harmony

Drivers interact to determine the supply chain performance in terms of responsiveness and

efficiency. The goal is to structure the drivers to achieve the desired level of responsiveness at the lowest

possible cost, thus improving supply chain surplus and the firm’s financial performance

1 Facility: are a key driver of supply chain performance in terms of responsiveness and efficiency. Companies

can gain economies of scale when a product is manufactured or stored in only one location. This centralization

increases efficiency. The cost reduction, however, comes at the expense of responsiveness. The opposite is also

true. Locating facilities close to customer increases the number of facilities needed and consequently reduces

efficiency.

Role: firm must decide whether production facilities will be flexible, dedicated or a combination of the

two. Flexible capacity can be used for many types of products but is often less efficient. Whereas dedicated

capacity can be used for only limited number of products but is more efficient.

Location: companies must also consider a host of issues related to the various characteristics of the local

area in which the facility is situated. These include macroeconomic factors; quality of workers, cost of workers,

cost of facility, availability of infrastructure, proximity to customers, the location of that firm’s other facilities

and other strategic factors.

Capacity: A large amount of excess capacity allows the facility to respond to wide swings in the demand

placed on it. Excess capacity, however costs money and therefore can decreases efficiency.

2 Inventory: inventory exists in supply chain because of mismatch between supply and demand. Inventory

impacts the assets held, the costs incurred, and responsiveness provided in the supply chain. High level of

inventory in supply chain improves responsiveness but also leave the supply chain vulnerable to the need for

market downs, lowering profit margins. Low level of inventory improves inventory turns but may result in lost

sales if customers are unable to find products they are ready to buy. The goal of good supply chain design to

find right form of inventory that provides the right levels of responsiveness at the lowest possible costs.

3 Transportation: Transportation Moves product between different stages in a supply chain and impacts both

responsive and efficiency. Faster transportation allows a supply chain to be more responsive but reduce its

efficiency. Transportation allows a firm to adjust the location of its facilities and inventory to find right balance

between responsiveness and efficiency. A firm selling high-value items may use rapid transportation to be

responsive while centralizing its facilities and inventory to lower costs. A firm selling low value high-demand

items like light bulbs may carry a fair amount of inventory close to the customer but then use low-cost

transportation like sea, rail and trucks.

SJC Institute of Technology Page 9

4 Information: good information can help improve the utilization of supply chain assets and the

coordination of supply chain flows to increase responsive and reduce costs. The right information can

help a supply chain meet customer needs at lower cost. The appropriate investment in information

technology improves visibility of transactions and coordinate decisions across the supply chain.

Coordination is essential if all stages of the supply chain are to work together towards a common goal

Airlines routinely use information to offer the right number of seats at discount price, leaving

sufficient seats for business customers making reservation at the last minute and willing to pay a higher

price.

5 Sourcing: Sourcing is the set of business process required to purchase goods and services. Managers

must first decide whether each task will be performed by a responsive or efficient source and then

whether source will be internal to the company or a third party. Sourcing decisions are crucial because

they affect the level of efficiency and responsiveness the supply chain can achieve. Firms outsource to

responsive third parties if it is expensive for them to develop this responsiveness on their own. Firms

also outsource for efficiency if the third party can achieve significant economies of scale.

6 Price: pricing is the process by which a firm decides how much to charge customers for its goods and

services. Pricing affects the customer segments that choose to buy the product, as well as the customer’s

expectations. This directly affects the supply chain in terms of the level of responsiveness required as

well as the demand profile that the supply chain attempts to serve. Pricing is also a lever that can be used

to match supply chain demand especially when the supply chain is not very flexible. Pricing is a

significant attribute through which a firm executes its competitive strategy. Firms are targeting a broader

set of customers, some of whom need responsiveness while others need efficiency. It becomes important

for these firms to structure a supply chain that can meet the two divergent needs.

SJC Institute of Technology Page 10

11 Discuss supply chain performance measures

Supply chain performance measures fall under the fallowing categories

Cost Assets Reliability Flexibility

Cost and Assets termed as internal facing Dr

Reliability and Flexibility termed as External facing

Delivery Performance

Order fulfilment Performance

Fill rate

Order fulfilment lead time

Perfect order fulfilment

Supply chain response time

Total logistical management cost

Value-added productivity

Warranty cost

Cash-to-cash- cycle time

Inventory days of supply

Asset Turns

12 Bring out the comparison between efficient and responsive supply chains.

SJC Institute of Technology Page 11

You might also like

- O&M Lesson PlanDocument4 pagesO&M Lesson PlanGlorivet ZayasNo ratings yet

- PMAN635 Course OverviewDocument10 pagesPMAN635 Course OverviewDerrick Antonio GardnerNo ratings yet

- Technology Plan EvaluationDocument12 pagesTechnology Plan EvaluationKristin SappNo ratings yet

- Test Bank Principles of Web Design 4th Edition Joel SklarDocument10 pagesTest Bank Principles of Web Design 4th Edition Joel SklarMarii WataNo ratings yet

- Operational Excellence RoadmapDocument1 pageOperational Excellence RoadmapWilson Perumal & Company67% (3)

- Chapter 6 Mobilities and Information Technology STUDY GUIDEDocument15 pagesChapter 6 Mobilities and Information Technology STUDY GUIDEAdonna Mari D. MATUTINONo ratings yet

- IE 457 Slides01-SupplyChain-Dr. Ammar Y. AlqahtaniDocument29 pagesIE 457 Slides01-SupplyChain-Dr. Ammar Y. AlqahtaniassaNo ratings yet

- DIBAM BIDI0003 Written Assignment Brief 2020 21Document4 pagesDIBAM BIDI0003 Written Assignment Brief 2020 21cương trươngNo ratings yet

- WBS Case Study 2Document7 pagesWBS Case Study 2Vipanjeet Kaur Ghuman N/ANo ratings yet

- Project Management DeliveryDocument5 pagesProject Management DeliveryFiveer Freelancer0% (1)

- Masters Project ProposalDocument12 pagesMasters Project Proposalapi-217213523No ratings yet

- Chapter01newspring 2015 2016Document53 pagesChapter01newspring 2015 2016Manasa M R100% (1)

- Workshop 4Document3 pagesWorkshop 4Hoa100% (1)

- 08 Konys Inc 3Document18 pages08 Konys Inc 3RohanMohapatraNo ratings yet

- CV PDFDocument6 pagesCV PDFAlemayehu SisayNo ratings yet

- IE 457 Slides07-SupplyChain-Dr. Ammar Y. AlqahtaniDocument22 pagesIE 457 Slides07-SupplyChain-Dr. Ammar Y. AlqahtaniassaNo ratings yet

- Chap#8 PlanningDocument30 pagesChap#8 PlanningMuhram HussainNo ratings yet

- The Development and Policies of ICT Supporting Educational Technology in Singapore, Thailand, Indonesia, and MyanmarDocument8 pagesThe Development and Policies of ICT Supporting Educational Technology in Singapore, Thailand, Indonesia, and MyanmarInternational Journal of Evaluation and Research in Education (IJERE)No ratings yet

- Learning Management System Using PHP and Mysql: Adrian M. de Castro Bernadeth B. Rico Kenneth D. PinedaDocument26 pagesLearning Management System Using PHP and Mysql: Adrian M. de Castro Bernadeth B. Rico Kenneth D. PinedaNesty SarsateNo ratings yet

- PM 10Document59 pagesPM 10Nurdan SarıkayaNo ratings yet

- InterculturalDocument59 pagesInterculturalChirell RevillaNo ratings yet

- Katushabe Hellen - E - Learning Platforms in UgandaDocument20 pagesKatushabe Hellen - E - Learning Platforms in UgandaHellen KatushabeNo ratings yet

- GenAI IN HIGHER EDUCATION FALL 2023 UPDATE TIME FO 240205 203837Document17 pagesGenAI IN HIGHER EDUCATION FALL 2023 UPDATE TIME FO 240205 203837Lydia AnaxagoraNo ratings yet

- BFM Project FinalDocument76 pagesBFM Project FinalChirag LakhotiaNo ratings yet

- Supply Chain Assgmnt Ind - Mej AkramDocument10 pagesSupply Chain Assgmnt Ind - Mej AkramWan Mohd Akram Bin Hj SaidonNo ratings yet

- Guri Dam: Case StudyDocument2 pagesGuri Dam: Case Studykoma komaNo ratings yet

- Internatioanl Marketing EnvironmentDocument24 pagesInternatioanl Marketing Environmentriteshbansal23No ratings yet

- Course Manual - IsDocument3 pagesCourse Manual - IsAreeba SharifNo ratings yet

- Chapter 5 Project Scope Management 1281Document27 pagesChapter 5 Project Scope Management 1281sixfeetandsexyNo ratings yet

- SAMPLE Project Analysis IntroductionDocument8 pagesSAMPLE Project Analysis IntroductionFirehun Alemu100% (1)

- Maluti TVET College Draft Strategic PlanDocument59 pagesMaluti TVET College Draft Strategic PlanAmbi ElizabethNo ratings yet

- Term PaperDocument16 pagesTerm PaperAnu MoudgilNo ratings yet

- MAD SyllabusDocument3 pagesMAD SyllabusBrahmesh MandyaNo ratings yet

- Difference Between PERT and CPMDocument4 pagesDifference Between PERT and CPMIsd BambNo ratings yet

- MGMT20130 Operations Management - Assignment 3Document4 pagesMGMT20130 Operations Management - Assignment 3Richa Deolia100% (1)

- Valenzuela City Polytechnic CollegeDocument4 pagesValenzuela City Polytechnic CollegeJhoerey D Villegas100% (1)

- Motiwalla Esm2e Im 08Document6 pagesMotiwalla Esm2e Im 08rhiyanokeNo ratings yet

- Course Outlines BBA Project ManagementDocument3 pagesCourse Outlines BBA Project ManagementsheikhrazaNo ratings yet

- Reflections On Professional EthicsDocument4 pagesReflections On Professional EthicsLaurence MontenegroNo ratings yet

- Supplier Development StrategiesDocument31 pagesSupplier Development StrategiesJayNo ratings yet

- Web-Based Procurement SystemDocument29 pagesWeb-Based Procurement SystemMish Lei Franxh100% (1)

- Mics Chapter 3 Desining Management Control SystemDocument11 pagesMics Chapter 3 Desining Management Control SystemPUTTU GURU PRASAD SENGUNTHA MUDALIAR100% (1)

- Chapter Four System Design and Implementation 4.1 System DesignDocument10 pagesChapter Four System Design and Implementation 4.1 System DesignNuhu Ibrahim MaigariNo ratings yet

- All ChapterDocument30 pagesAll ChapterIstiaq Ahmed PrinceNo ratings yet

- Ajmal, Et Al., 2019Document22 pagesAjmal, Et Al., 2019states mphinyaneNo ratings yet

- Unit Ii - Project Life Cycle and Effort Estimation 2.1 Software Process and Process ModelsDocument19 pagesUnit Ii - Project Life Cycle and Effort Estimation 2.1 Software Process and Process Models123No ratings yet

- AP - StudyDocument24 pagesAP - StudyTrishaRodriguezBalucas100% (1)

- Comprehensive ExamDocument12 pagesComprehensive ExamMoustafa El ShindidyNo ratings yet

- Project Management AssignmentDocument3 pagesProject Management AssignmentONI OLUSEGUN ADEBAYONo ratings yet

- Beyond ChatGPT A Conceptual Framework and Systematic Review of Speech-Recognition Chatbots For Language LearningDocument43 pagesBeyond ChatGPT A Conceptual Framework and Systematic Review of Speech-Recognition Chatbots For Language LearningGrace ZHANGNo ratings yet

- E-Learning System PDFDocument40 pagesE-Learning System PDFdnlkabaNo ratings yet

- MIS - Project Title ProposalDocument14 pagesMIS - Project Title Proposaljepeeae100% (1)

- Knowledge Skills For Higher EducationDocument65 pagesKnowledge Skills For Higher EducationSumesh JohnNo ratings yet

- M1 - Intro To Technology For Teaching and Learning 1Document15 pagesM1 - Intro To Technology For Teaching and Learning 1Renz E. FerreraNo ratings yet

- SyllabusDocument2 pagesSyllabusporseenaNo ratings yet

- Use of MIS in Marketing (Report)Document28 pagesUse of MIS in Marketing (Report)luckyguy_6470% (2)

- Assig5 2010Document4 pagesAssig5 2010WK LamNo ratings yet

- Improve Business Practice FinalDocument26 pagesImprove Business Practice FinalnigusNo ratings yet

- Summative Assessment Brief - Global Strategy and SustainabilityDocument7 pagesSummative Assessment Brief - Global Strategy and SustainabilityFarhan AliNo ratings yet

- School Infrastructure in Paraguay: Needs, Investments, and CostsFrom EverandSchool Infrastructure in Paraguay: Needs, Investments, and CostsNo ratings yet

- Supply Chain Management - NoteDocument16 pagesSupply Chain Management - NoteelsonpaulNo ratings yet

- Decision Phases SCMDocument4 pagesDecision Phases SCMsubhashm.dasariNo ratings yet

- Module-2: Introduction, Lexical Analysis: SyllabusDocument28 pagesModule-2: Introduction, Lexical Analysis: SyllabusSamba Shiva Reddy.g ShivaNo ratings yet

- AI & ML Module-1Document103 pagesAI & ML Module-1Samba Shiva Reddy.g Shiva100% (1)

- Machine Learning Module-3Document23 pagesMachine Learning Module-3Samba Shiva Reddy.g ShivaNo ratings yet

- AI & ML Module-2Document81 pagesAI & ML Module-2Samba Shiva Reddy.g ShivaNo ratings yet

- Machine Learning (15Cs73) : Text Book Tom M. Mitchell, Machine Learning, India Edition 2013, Mcgraw HillDocument78 pagesMachine Learning (15Cs73) : Text Book Tom M. Mitchell, Machine Learning, India Edition 2013, Mcgraw HillSamba Shiva Reddy.g ShivaNo ratings yet

- Android Views and LayoutDocument40 pagesAndroid Views and LayoutSamba Shiva Reddy.g ShivaNo ratings yet

- SCM Module2 Questions and AnswersDocument12 pagesSCM Module2 Questions and AnswersSamba Shiva Reddy.g Shiva100% (1)

- Web Tut 2 SolnDocument12 pagesWeb Tut 2 SolnSamba Shiva Reddy.g ShivaNo ratings yet

- SCM Module 4 New Questions and AnswersDocument8 pagesSCM Module 4 New Questions and AnswersSamba Shiva Reddy.g ShivaNo ratings yet

- Selective Repeat ARQ ProtocolDocument16 pagesSelective Repeat ARQ ProtocolSamba Shiva Reddy.g ShivaNo ratings yet

- Web-Module IIIDocument41 pagesWeb-Module IIISamba Shiva Reddy.g ShivaNo ratings yet

- Web-Question BankDocument7 pagesWeb-Question BankSamba Shiva Reddy.g ShivaNo ratings yet

- Web-Module IVDocument38 pagesWeb-Module IVSamba Shiva Reddy.g ShivaNo ratings yet

- 1 Introduction To LEX: Input - File.lDocument19 pages1 Introduction To LEX: Input - File.lSamba Shiva Reddy.g ShivaNo ratings yet

- Web-Module II - Chapter 2Document23 pagesWeb-Module II - Chapter 2Samba Shiva Reddy.g ShivaNo ratings yet

- Web-Module IDocument35 pagesWeb-Module ISamba Shiva Reddy.g ShivaNo ratings yet

- Web-Module II - Chapter1Document16 pagesWeb-Module II - Chapter1Samba Shiva Reddy.g ShivaNo ratings yet

- Module IiiDocument5 pagesModule IiiSamba Shiva Reddy.g ShivaNo ratings yet

- Module IvDocument3 pagesModule IvSamba Shiva Reddy.g Shiva0% (1)

- Module VDocument6 pagesModule VSamba Shiva Reddy.g ShivaNo ratings yet

- AST LTCC ComputationDocument9 pagesAST LTCC ComputationeiraNo ratings yet

- ABDUL SAMAD (Union Fabrics) (Naz)Document3 pagesABDUL SAMAD (Union Fabrics) (Naz)AtherNo ratings yet

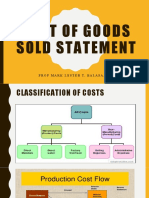

- Cost of Goods Sold StatementDocument18 pagesCost of Goods Sold StatementCherrylane EdicaNo ratings yet

- Job Safety Analysis Worksheet: JSA JSA Participants PPE Required Tools And/or EquipmentDocument5 pagesJob Safety Analysis Worksheet: JSA JSA Participants PPE Required Tools And/or EquipmentVigieNo ratings yet

- Handout 3 Cost ManagementDocument10 pagesHandout 3 Cost ManagementNikki San GabrielNo ratings yet

- Guidelines For The Deploymentdelivery of It Packages Under DCP Fy 2020Document5 pagesGuidelines For The Deploymentdelivery of It Packages Under DCP Fy 2020Boyet CabutihanNo ratings yet

- 5S Housekeeping: A Discipline For ProductivityDocument25 pages5S Housekeeping: A Discipline For ProductivityCarlos HernandezNo ratings yet

- Project Plan: Group Case Study 4 OctoberDocument15 pagesProject Plan: Group Case Study 4 OctobernileshvpNo ratings yet

- Solution: EOQDocument4 pagesSolution: EOQLovely VillasNo ratings yet

- TE World Class Engineering Strategy: December 2013Document28 pagesTE World Class Engineering Strategy: December 2013Surendran AbhinavNo ratings yet

- Modular Construction: Assessing The Challenges Faced With The Adoption of An Innovative Approach To Improve U.S. Residential ConstructionDocument10 pagesModular Construction: Assessing The Challenges Faced With The Adoption of An Innovative Approach To Improve U.S. Residential ConstructiongambakuNo ratings yet

- CSR PDFDocument8 pagesCSR PDFBhumitNo ratings yet

- Lectura 4 - Cultivating A Customer CultureDocument2 pagesLectura 4 - Cultivating A Customer Culturerafael espinosa semperNo ratings yet

- The Study of Service Innovation Affect Satisfaction and Loyalty The Case of Mongolian E BankDocument3 pagesThe Study of Service Innovation Affect Satisfaction and Loyalty The Case of Mongolian E BankEditor IJTSRDNo ratings yet

- 3 Summaries of Harvard Business Review Articles On Project ManagementDocument9 pages3 Summaries of Harvard Business Review Articles On Project Managementshiphatun noorNo ratings yet

- 01 CTD Intercompany72Document33 pages01 CTD Intercompany72Sumanth AmbatiNo ratings yet

- Certificat: S Ent of Ivth M T R A Y S Fte O Ogy B NG Ore. H Und R On G N U Organ A Ion Durin The E A C 2 8Document71 pagesCertificat: S Ent of Ivth M T R A Y S Fte O Ogy B NG Ore. H Und R On G N U Organ A Ion Durin The E A C 2 8Chetana YadawadNo ratings yet

- Project SIKAPDocument3 pagesProject SIKAPMailyn G. ElacreNo ratings yet

- Customer RetentionDocument18 pagesCustomer RetentionHasnainNo ratings yet

- Process Safety Leadership TipsDocument10 pagesProcess Safety Leadership TipsRidha FalehNo ratings yet

- UntitledDocument93 pagesUntitleddipakNo ratings yet

- Tutorial Relevant Costs For StudentsDocument3 pagesTutorial Relevant Costs For StudentsJihan RafiqaNo ratings yet

- Reply: A. Gap-Filling A. Exercise 1 - Reply To Request For Goods On ApprovalDocument11 pagesReply: A. Gap-Filling A. Exercise 1 - Reply To Request For Goods On ApprovalFTU.CS2 Nghiêm Mai Yến NhiNo ratings yet

- The Field of AccountingDocument3 pagesThe Field of AccountingAyu NingsihNo ratings yet

- SCO SCO4H0210031290102022024 UREA CIF Reaam GT LLCDocument6 pagesSCO SCO4H0210031290102022024 UREA CIF Reaam GT LLCmarspublicidadymarketing360No ratings yet

- A-Levels Accounting 2023 AnswersDocument14 pagesA-Levels Accounting 2023 AnswerschauromweaNo ratings yet

- Work Breakdown StructureDocument6 pagesWork Breakdown Structurerashipare656No ratings yet

- Merchant Van Der StedeDocument48 pagesMerchant Van Der StedeAnia Banaszczyk100% (1)