Professional Documents

Culture Documents

Saudi Arabian Oil Company: Calculation Sheet

Saudi Arabian Oil Company: Calculation Sheet

Uploaded by

John BuntalesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company: Calculation Sheet

Saudi Arabian Oil Company: Calculation Sheet

Uploaded by

John BuntalesCopyright:

Available Formats

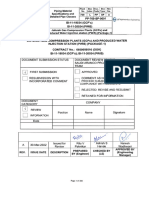

Saudi Aramco 2616-ENG (11/2010)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

Calculation Sheet

Calculation Formulas

Entry # 12 - Wall Thickness Calculation

REVISION DESCRIPTION

2000 X 2.375 P X D

tm= + 0.236 tm= +C ASME B31.8

2 X 35000 X 0.72 X 1 X 1 2 X S X FXE X T

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

where

AS-BUILT

tm= 0.330 inch

P = design pressure, psig = 2000 PSI

D = nominal outside diameter of pipe, in. = 2.375 inch

Tn= 0.436 inch

Entry 12 S = specified minimum yield strength, psi = 35000 PSI

where F = design factor = 0.72

06/16/21

DATE

10-01433-7675

Tn = the selected nominalwall thickness E = longitudinal joint factor = 1

Base of selection: available pipe with t greater thantm T = temperature derating factor = 1

JOB ORDER/EWO NO.

C = Corrosion allowance = = 0.236

Entry # 25, 34 & 35 - Maximum Allowable Operating Pressure

REV. NO.

01

2 X 35000 X 0.2 X 0.72 X 1 X 1 2 XSX t XF X EXT

MAOP for pipe = MAOP for pipe = ASME B31.8

2.375 D

MAOP for pipe = 4244 PSI MAOP for flange as per ASME B16.5 Table II-2 = 2014 PSI

BY/DATE

OTHER

MAOP = 1806 PSI MAOP for valve as per ASME B16.34TableVII-2 = 1806 PSI

Limited By VALVE MAOP MAOP = lesser value of the following:

(MAOP of pipe, MAOP of flange & MAOP of valve)

Pipeline MAOP = Minimum of ( 2014,2014,1806)

OPERATIONS/DATE

Pipeline MAOP = 1806 Entry 25 Pipeline MAOP = Minimum of the MAOP's for each line size

06/16/21

MDA

System MAOP = Minimum of ( 1806 , 2000 ) System MAOP = Minimum of the following:

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

System MAOP = 1806 Entry 34 (Pipeline MAOP and Design pressure)

* t = Tn - C = 0.436 - 0.236 = 0.2

Entry # 28 & 30 - Initial Test Pressure

CONST. AGENCY/DATE

Minimum code test pres. = 2258 PSI ASME B31.8 Minimum code test pres. = 1.25 X Pipeline MAOP

Flange test pressure = 1.5 X 2220 = 3330 PSI Flange test pressure = 1.5 X Flange MAOP @ ambient temp.

06/16/21

MAJ

Valve test pressure = 1.5 X 2160 = 3240 PSI Valve test pressure = 1.5 X Valve MAOP @ ambient temp.

2 X 0.9 X S X Tn

Pipe wall test Pressure = 11565 PSI Pipe wall test Pressure = SAES-L-150

D

✘ Line test pressure = 3250 * PSI Line test pressure = The greater value of the following :

1. Minimum test pressure of (pipe wall, flange, valve)

CERTIFIED/DATE

Limited By Valve test pressure 2. Minimum test pressure as per ASME B31.8

06/16/21

Pipeline test pressure = Minimum of Pipeline Initial Test Pressure = Minimum of

AMA

DESIGN CERTIFICATION

( 3350 , 3350 , 3250 ) The test pressure for each line size

(DESIGN AGENCY)

Pipeline test pressure = 3250 Entry 28

* rounded off to the next higher 1 bar (25 psi) increment.

Entry # 36 - Safety Valve Set Pressure

ENGG./DATE

Safety Valve Set Pressure = 3413 Entry 36 Safety Valve Set Pressure for Strength Test =

06/16/21

JRB

(1.05 X Test Pressure)

Entry # 38 & 39 - Minimum Wall Thickness @ System MAOP

1806 X 2.375 MAOP X D

Tm= + 0.236 Tm= +C ASME B31.8

2 X 35000 X 0.72 X 1 X 1 2 X S X F XEX T

Tm= 0.321 inch Entry 38

Tca = Available Corrosion Allowance = Tn - Tm

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

Tca = 0.115 inch Entry 39

REVISION VALIDATION

10-01433-7675-006

DRAWING COMPLETION CERTIFICATE NO.

01

THIS REVISION NO.

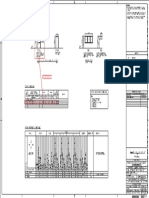

SIS FOR 2"-P-0108/0121-90SD0P DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

HWYH GAS WELL-1118 WELL SITE SIS

HWYH RH-G H92 A TE-269458 004 01

HAWAIYAH SAUDI ARABIA

EKRD/2616-1110.XLS

You might also like

- AIA Contract Documents-Contract Relationship Diagrams (2017.04)Document11 pagesAIA Contract Documents-Contract Relationship Diagrams (2017.04)ed booker100% (2)

- Adams 2013 Training 740 WorkbookDocument458 pagesAdams 2013 Training 740 WorkbookAnonymous ZC1ld1CLm100% (1)

- Saudi Aramco Inspectable ItemsDocument9,400 pagesSaudi Aramco Inspectable ItemsAzeem Chaudhry50% (2)

- Tendernotice 5 PDFDocument148 pagesTendernotice 5 PDFAbhijit BhandarkarNo ratings yet

- Daily Progress Report-Kenz Co.30001592Document1 pageDaily Progress Report-Kenz Co.30001592daranivelNo ratings yet

- Arabian Fal Training Matrix - Non Base Crew UpdateDocument15 pagesArabian Fal Training Matrix - Non Base Crew UpdateastutesureshNo ratings yet

- Crci M98 32 M210 DaDocument6 pagesCrci M98 32 M210 Darajindo1No ratings yet

- Schedule B - Attachment III SCOPE OF WORKDocument6 pagesSchedule B - Attachment III SCOPE OF WORKxue jun xiangNo ratings yet

- Rite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Document8 pagesRite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Cristian PisitelloNo ratings yet

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- Fpi 2022 002841 Vetm Cde PRD Ksa 22 056 R0Document7 pagesFpi 2022 002841 Vetm Cde PRD Ksa 22 056 R0AhmedNo ratings yet

- 24in NDL Completed1Document5 pages24in NDL Completed1Vimin PrakashNo ratings yet

- Chemical Injection Skid Calc1Document1 pageChemical Injection Skid Calc1amiyachemNo ratings yet

- Arabian Fal Holding: TUR DepartmentDocument34 pagesArabian Fal Holding: TUR DepartmentShams TabrezNo ratings yet

- JGCP Pms PP 769 SP 0001Document398 pagesJGCP Pms PP 769 SP 0001Ahmed BoraeyNo ratings yet

- 04-SAMSS-005 2018 Check Valves - Flanged, Lug, and Butt-WeldingDocument10 pages04-SAMSS-005 2018 Check Valves - Flanged, Lug, and Butt-WeldingWHWENNo ratings yet

- Piping Engineering E PI 221Document5 pagesPiping Engineering E PI 221vikramNo ratings yet

- Piping Material Classes REV .4ADocument20 pagesPiping Material Classes REV .4AMohamed RaafatNo ratings yet

- Monolithic Isolating Joint DatasheetDocument3 pagesMonolithic Isolating Joint DatasheetEpwe100% (1)

- Section 32170 - Fusion-Bonded Epoxy CoatingDocument15 pagesSection 32170 - Fusion-Bonded Epoxy CoatinghelalsolimanNo ratings yet

- Quartzoid Bulb DetectorDocument6 pagesQuartzoid Bulb DetectorKirankumar BoddalaNo ratings yet

- MSDS 001139212Document7 pagesMSDS 001139212danny_sosa_3No ratings yet

- Job Safety Analysis - RIG DOWN OF GDS, CASCADE & SAFETY EQUIPMENTDocument3 pagesJob Safety Analysis - RIG DOWN OF GDS, CASCADE & SAFETY EQUIPMENTJun DandoNo ratings yet

- DOC-NA-ME-500 - Piping Class PDFDocument12 pagesDOC-NA-ME-500 - Piping Class PDFedscesc10No ratings yet

- Diaphragm ValveDocument1 pageDiaphragm ValveS AMNo ratings yet

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFDocument19 pages50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFChemkhiNo ratings yet

- FM-DIV00-QAC-0020 Welder Qualification Test (WQT) LogDocument23 pagesFM-DIV00-QAC-0020 Welder Qualification Test (WQT) LogvinothkumarNo ratings yet

- Functional Tasks by Development StagesDocument1 pageFunctional Tasks by Development StagesAl Arafat RummanNo ratings yet

- 03CA2SAE: Specification Piping Material ClassDocument7 pages03CA2SAE: Specification Piping Material Classabhishek186186No ratings yet

- Summary, During Inspection of Chemical Injection Nozzle Installation Inspection at Utility, On 27 August 2014Document1 pageSummary, During Inspection of Chemical Injection Nozzle Installation Inspection at Utility, On 27 August 2014sameer313No ratings yet

- 020-GN-BK-101AB, Rev.1 PDFDocument1 page020-GN-BK-101AB, Rev.1 PDFVeena S VNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- Carpenter & Paterson Hardware Price Book CP-0213Document54 pagesCarpenter & Paterson Hardware Price Book CP-0213Sargunam SankaravadivelNo ratings yet

- SL No. Materials Unit Three Month Forecast Amount (3 Months)Document77 pagesSL No. Materials Unit Three Month Forecast Amount (3 Months)Shams TabrezNo ratings yet

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Rosemount 1495 Orifice PlateDocument6 pagesRosemount 1495 Orifice PlateRubénNo ratings yet

- General Technical Requirement For Mechanical - Piping (D 13Document18 pagesGeneral Technical Requirement For Mechanical - Piping (D 13Elias EliasNo ratings yet

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerAnonymous 0OizFXUONo ratings yet

- 07 July 2021 Break DownDocument35 pages07 July 2021 Break DownvinothkumarNo ratings yet

- AA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionDocument26 pagesAA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionThinh NguyenNo ratings yet

- MaterialsDocument2 pagesMaterialsAkshay PoddarNo ratings yet

- Data Sheet, GAD and QAP of Y StrainerDocument13 pagesData Sheet, GAD and QAP of Y StrainerSHABAHATNo ratings yet

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- Al Fara 380 BSP, Abha-December 2019 Spi.Document188 pagesAl Fara 380 BSP, Abha-December 2019 Spi.Sn AhsanNo ratings yet

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- 175-Ir022501, (850146), 07.12.2017Document2 pages175-Ir022501, (850146), 07.12.2017Rami ELLOUMINo ratings yet

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Ansi Valve Leakage Standards Gemco ValveDocument1 pageAnsi Valve Leakage Standards Gemco ValvenithyaNo ratings yet

- FU01-S01-02-005-01 Pipe Spec CS22Document8 pagesFU01-S01-02-005-01 Pipe Spec CS22Javed NasirNo ratings yet

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Document2 pagesDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrNo ratings yet

- Aogc 036 Pi Ess 001 (B1)Document19 pagesAogc 036 Pi Ess 001 (B1)amini_mohiNo ratings yet

- C2 - RevADocument16 pagesC2 - RevAChirag ShahNo ratings yet

- Butterfly ValveDocument6 pagesButterfly ValveRomisamomNo ratings yet

- Material İdentificiation MethodDocument16 pagesMaterial İdentificiation MethodYusufNo ratings yet

- General Notice For AG Piping Layout - TSA - RADocument35 pagesGeneral Notice For AG Piping Layout - TSA - RAkienhg96No ratings yet

- Pt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiDocument8 pagesPt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiAdhya RazanNo ratings yet

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- Yanbu: Export Refinery ProjectDocument7 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Pip Adg003 Specification For Editing Practices: Work ProcessesDocument34 pagesPip Adg003 Specification For Editing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Pip Adg004-2014Document15 pagesPip Adg004-2014John BuntalesNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Da179165 001Document1 pageDa179165 001John BuntalesNo ratings yet

- Q&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeDocument1 pageQ&A第62条,无glazing, with panic hardware: Door & Frame Types Window TypeJohn BuntalesNo ratings yet

- PIP CTSE1000-2018 DatasheetsDocument2 pagesPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- Door & Frame Types Louver TypesDocument1 pageDoor & Frame Types Louver TypesJohn BuntalesNo ratings yet

- Appendix-6 Stress Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-6 Stress Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Pip Adg005 Specification For Developing Data Forms For PracticesDocument20 pagesPip Adg005 Specification For Developing Data Forms For PracticesJohn BuntalesNo ratings yet

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Appendix-7 Stress Summary: Saudi Arabian Oil CompanyDocument1 pageAppendix-7 Stress Summary: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyDocument1 pageAppendix-8 Flange Leakage Calculation: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyDocument1 pageAppendix-1 Piping Isometric With Node Numbers: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Structural Calculation - Excavation ShoringDocument9 pagesStructural Calculation - Excavation ShoringJohn BuntalesNo ratings yet

- Appendix-5 Displacement Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-5 Displacement Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-4 Restraint Report: Saudi Arabian Oil CompanyDocument1 pageAppendix-4 Restraint Report: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Appendix-2 Pipe Data Input: Saudi Arabian Oil CompanyDocument1 pageAppendix-2 Pipe Data Input: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Franklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byDocument1 pageFranklin O. Marinas Felemuel D. Bullos JR.: Design Engineer: Certified byJohn BuntalesNo ratings yet

- Design of Structural Member Soldier Pile: Design Engineer Certified byDocument3 pagesDesign of Structural Member Soldier Pile: Design Engineer Certified byJohn BuntalesNo ratings yet

- Design Engineer: Certified byDocument4 pagesDesign Engineer: Certified byJohn BuntalesNo ratings yet

- NMR 601 For GATE VALVE Rev.00Document13 pagesNMR 601 For GATE VALVE Rev.00John BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument2 pagesProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Project: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomDocument1 pageProject: Zamil Warehouse, Kaa Port Road, Dammam Bill of Quantity - TelecomJohn BuntalesNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Zamil Warehouse: Original Date Prepared by Checked by Approved byDocument2 pagesZamil Warehouse: Original Date Prepared by Checked by Approved byJohn BuntalesNo ratings yet

- III Year-V Semester: B.Tech. Computer Science and Engineering 5CS4-02: Compiler Design UNIT-1Document11 pagesIII Year-V Semester: B.Tech. Computer Science and Engineering 5CS4-02: Compiler Design UNIT-1shelo berman100% (1)

- TM 750 116Document78 pagesTM 750 1161Y875No ratings yet

- Based On The 1979 Standards of Professional Practice/ SPPDocument10 pagesBased On The 1979 Standards of Professional Practice/ SPPOwns DialaNo ratings yet

- EGCP-2 Engine Generator Control PackageDocument226 pagesEGCP-2 Engine Generator Control PackageJorge EspinozaNo ratings yet

- 10 Tricky PSLE Math QuestionsDocument6 pages10 Tricky PSLE Math QuestionsClarisa CynthiaNo ratings yet

- Manila Prince Hotel vs. GSISDocument5 pagesManila Prince Hotel vs. GSISFenina ReyesNo ratings yet

- Application Form For The Position of Company SecretaryDocument3 pagesApplication Form For The Position of Company SecretarySyed Hasnain YaseenNo ratings yet

- Computer Vision-Based Military Tank Recognition Using Object Detection Technique An Application of The YOLO FrameworkDocument7 pagesComputer Vision-Based Military Tank Recognition Using Object Detection Technique An Application of The YOLO Frameworkanony17cb08No ratings yet

- Curriculum Vitae: Personal DetailsDocument7 pagesCurriculum Vitae: Personal Detailszikrillah1No ratings yet

- Illinois Baptist State Association Case HistoryDocument7 pagesIllinois Baptist State Association Case HistoryGrant GebetsbergerNo ratings yet

- Good Documentation PracticeDocument23 pagesGood Documentation PracticeNiranjan KulkarniNo ratings yet

- CartelizationDocument5 pagesCartelizationGarima BatraNo ratings yet

- Infrastructure Planning and Delivery:: Best Practice Case StudiesDocument88 pagesInfrastructure Planning and Delivery:: Best Practice Case StudiesAnurag KalvaNo ratings yet

- Thru-Tubing Retriveable PackerDocument9 pagesThru-Tubing Retriveable PackerilkerkozturkNo ratings yet

- 65 Francisco v. TollDocument6 pages65 Francisco v. TollVanityHugh100% (1)

- Growing ApricotDocument9 pagesGrowing ApricotRajNo ratings yet

- Plastic Deformation of Al and AA5754 Between 4.2K and 295KDocument15 pagesPlastic Deformation of Al and AA5754 Between 4.2K and 295Kenver328No ratings yet

- Solution Manual For Introduction To Electrodynamics 4 e 4thDocument17 pagesSolution Manual For Introduction To Electrodynamics 4 e 4thglaivefang2a8v67100% (22)

- Icao Flight Plan FilingDocument2 pagesIcao Flight Plan FilingAnwar MuhammadNo ratings yet

- KX Tga272lxsDocument74 pagesKX Tga272lxsAnonymous Lfgk6vygNo ratings yet

- Name: Goutam Mandal Roll No: 1916034 PGPEM-2019 Assignment-IIDocument11 pagesName: Goutam Mandal Roll No: 1916034 PGPEM-2019 Assignment-IIGoutam MandalNo ratings yet

- NutruentsDocument7 pagesNutruentsPEDRO INFANTE AGUILARNo ratings yet

- NHS Lothian A& EDocument2 pagesNHS Lothian A& EKezia Dugdale MSPNo ratings yet

- Commercial LeaseDocument33 pagesCommercial LeaseEmil Mitev100% (2)

- Marketing Plan of Tesco PLCDocument18 pagesMarketing Plan of Tesco PLCAjay Manchanda100% (1)

- CC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Document11 pagesCC 110 Syllabus in Financial Management For Agri-Based Enterprises (F)Cesar Della33% (3)

- Pre-Image-Kit Release Notes R22Document7 pagesPre-Image-Kit Release Notes R22Abdelmadjid BouamamaNo ratings yet

- High Voltage Components PresentationsDocument28 pagesHigh Voltage Components Presentationschristian fruto100% (1)