Professional Documents

Culture Documents

Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 Edition

Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 Edition

Uploaded by

Haryanto ROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 Edition

Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 Edition

Uploaded by

Haryanto RCopyright:

Available Formats

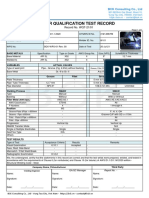

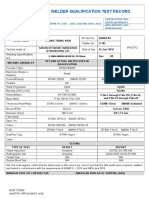

PT. VISTA BANGUN UTAMA Cert No.

VBU-ASME-GTAW+SMAW+007

Office : Ruko Tunas Regency, Blok C No. 05

Workshop : Sarana Industrial Point Blok A, No. 10 Date 15 - Dec - 2019

Telpn/Fax : 0778 4090 073

Website : www.vbutama.com, email : info@vbutama.com By RHS

Rev : (0)

WELDER PERFORMANCE QUALIFICATIONS

In Accordance with Section IX, ASME Boiler and Pressure Vessel Code 2013 Edition

Welder Name IRWAN SYAHYENI DAMANIK NRCIC No. - Stamp No. W-06

Test Description

Identification of WPS followed VBU-WPS-ASME-001 X Test coupon Production weld

Specification of base metal(s) SA-108 Grade B. Thickness 11.07mm

Testing Variables and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding process (es) SMAW SMAW

Type (i, e, manual, semi-auto) used MANUAL MANUAL

backing (metal, weld metal, double-welded etc) WITHOUT or WITHOUT WITHOUT or WITHOUT

Plate Pipe P NPS 2" S/XXS (enter diameter if pipe or tube) NPS. 2" 1" (25MM) OD-UNLIMITED

Base metal P-Number to P-Number P No. 1 to P No. 1 P No. 1-15F, P No.34 & P No.41-49

Filler metal or electrode spesification(s)(SFA)(info only) 5.1 5.1

Filler metal or electrode clarification(s) (info only) E-7018 E-7018

Filler metal F-number(s) F No.4 F No. 1,2,3,4 (with Backing)

& F No. 4 (without Backing)

Consumable Insert for (GTAW or PAW) NONE NONE

Fillet Metal Product Form (solid/metal of cored/powder) (GTAW or PAW) NONE NONE

Deposit thickness for each process

Process 1: SMAW 3 Layer minimum P Yes No 11.77 MM 22.14 MM

Process 2: 3 Layers minimum Yes No

Position qulified (2G, 6G, 3F, etc) 6G ALL

Vertical progression (uphill or downhill) UPHILL UPHILL

Type of fuel gas (OFW) N/A N/A

Insert gas backing (GTAW, PAW, GMAW) NONE NONE

Tranfer mode (Spray/globural or pulse to short circuit-GMAW) N/A N/A

GTAW current type/polarity (AC, DCEP, DCEN)

**Note:

RESULTS

Visual Examination of completed Weld (QW-302.4 ACCEPTED

Transverse root and face [QW-462.3 (a) Longitudinal root and face [QW-462.3 (b)

Side bend (QW-462.2); Pipe bend specimens, corrosion-resistant oeverlay [QW-462.5(c)];

Plate bend specimens, corrotion-resistant overlay [QW-462.5(d)];

Pipe specimen, macro test for fusion [QW-462.5(b)]

Plate specimen, macro test for fusion [QW-462.5(e)]

TYPE RESULT TYPE RESULT TYPE RESULT

- - - - - -

- - - - - -

Alternative radiograhic examination result (QW-191) ACCEPTED RT P UT Report No HANS/WQT/12

Fillet Weld - Fracture test (QW-181.2) N/A Length and percent of defects N/A

Fillet wels in plate (QW-462.4(b)] Fillet welds in pipe [QW-462.4(c)]

Macro examination (QW-184) N/A Fillet size (in) N/A x N/A Concavity/convexity (in) N/A

Film or specimenens evaluated by DODI SETIAWAN Company PT. HANS QKAS INSPECTINDO

Mechanical test conducted by NONE Laboratory test no. NONE

Welding supervised by PT. VISTA BANGUN UTAMA

We certify that the statement in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Manufacturer : PT. VISTA BANGUN UTAMA

Cert By : Verified by :

Name : RHS Name :

Date : 15-Dec-2019 Date :

You might also like

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Test Report of Induction MotorDocument11 pagesTest Report of Induction MotorHaryanto R100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS & Materials Applicable MatrixDocument5 pagesWPS & Materials Applicable Matrixundeath123100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- PQR Form (Welding)Document2 pagesPQR Form (Welding)jasmineammaNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- 174 Smaw Zug Asme (Asep Wahyudi 3g) WPQDocument4 pages174 Smaw Zug Asme (Asep Wahyudi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Cylinder Head GPDocument2 pagesCylinder Head GPHaryanto RNo ratings yet

- MSDS Jotun Pilot QDDocument13 pagesMSDS Jotun Pilot QDHaryanto RNo ratings yet

- Forklift DaewooDocument1 pageForklift DaewooHaryanto RNo ratings yet

- DaewooDocument1 pageDaewooHaryanto RNo ratings yet

- Inspection and Test Plan: PT. People MecDocument3 pagesInspection and Test Plan: PT. People MecHaryanto RNo ratings yet

- Hempel - S Zinc Primer 16490Document2 pagesHempel - S Zinc Primer 16490Haryanto RNo ratings yet

- SE 508-607 + 1307 K + HS 307: SE and SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard SealsDocument4 pagesSE 508-607 + 1307 K + HS 307: SE and SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard SealsHaryanto RNo ratings yet

- (4.16) Painting Report PDFDocument6 pages(4.16) Painting Report PDFHaryanto RNo ratings yet

- This Area Is Under Construction: Date: PIC: Contact: DetailsDocument1 pageThis Area Is Under Construction: Date: PIC: Contact: DetailsHaryanto RNo ratings yet

- Call 800-DIESELS (343-7357) : Cummins Inc. - Box 3005 - Columbus, Indiana 47202-3005 USADocument1 pageCall 800-DIESELS (343-7357) : Cummins Inc. - Box 3005 - Columbus, Indiana 47202-3005 USAreycoeleNo ratings yet

- Mangalam Cement Limited: - Test CertificateDocument2 pagesMangalam Cement Limited: - Test CertificatePiyush SoniNo ratings yet

- Master List WelderDocument2 pagesMaster List WelderMoch_adiganjarNo ratings yet

- Gas Metal Arc Welding Used On Mainline 80 Ksi Pipeline in CanadaDocument19 pagesGas Metal Arc Welding Used On Mainline 80 Ksi Pipeline in CanadaAlex CunoNo ratings yet

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocument33 pages(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Socket Set Screws, Stainless Steel: Maryland MetricsDocument3 pagesSocket Set Screws, Stainless Steel: Maryland MetricsFabio ParceroNo ratings yet

- New Price List Per 1 Sept 2018Document2 pagesNew Price List Per 1 Sept 2018RizkiMohamadRezaNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- New Microsoft Office Excel WorksheetDocument2 pagesNew Microsoft Office Excel Worksheetg_sanchetiNo ratings yet

- Topic 1 - Cement and Concrete Basics - GrayDocument86 pagesTopic 1 - Cement and Concrete Basics - GraysazedaNo ratings yet

- M 544 ContentDocument11 pagesM 544 ContentRicardoNo ratings yet

- S04 BoomDocument60 pagesS04 BoomJorsh GonzalesNo ratings yet

- List of en Standards: SR No Code/Standard DescriptionDocument4 pagesList of en Standards: SR No Code/Standard DescriptionAnilNo ratings yet

- Question Papers of Advance Welding Technology For BDocument3 pagesQuestion Papers of Advance Welding Technology For BAtul GaurNo ratings yet

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocument5 pagesFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNo ratings yet

- McCormick XTX Tier 3 (2007-2013) - XTX3 - 185 Tractor Service Repair Manual PDFDocument20 pagesMcCormick XTX Tier 3 (2007-2013) - XTX3 - 185 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- Type of Cements As Per IS CodesDocument3 pagesType of Cements As Per IS Codesk_981966368No ratings yet

- Diagrama Cabos PLCDocument17 pagesDiagrama Cabos PLCnferreiNo ratings yet

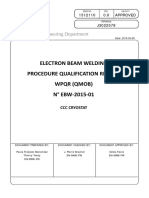

- Electron Beam Welding Procedure Qualification Record WPQR (Qmob) #EBW 2015 01Document18 pagesElectron Beam Welding Procedure Qualification Record WPQR (Qmob) #EBW 2015 01aNKUR100% (1)

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPS-Shell To Shell Joint (CS-CS) .Document1 pageWPS-Shell To Shell Joint (CS-CS) .suria qaqcNo ratings yet

- Internship Report...Document23 pagesInternship Report...Gorle Sai giridharNo ratings yet

- ME-218 Machine Design 1 - Lecture 9 Welded JointsDocument41 pagesME-218 Machine Design 1 - Lecture 9 Welded JointsJaveria KhanNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Universal Wps Mig Mag WeldingDocument3 pagesUniversal Wps Mig Mag WeldingFlorea AdrianNo ratings yet

- Metric BoltsDocument52 pagesMetric BoltsDGW100% (1)

- Pedido AktDocument5 pagesPedido Aktandres parragaNo ratings yet