Professional Documents

Culture Documents

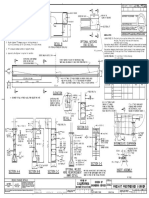

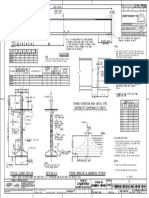

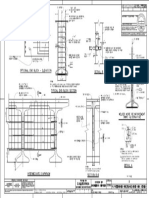

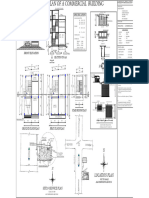

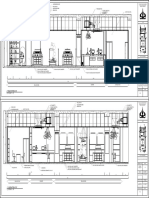

A A A A: Elliptical Casing Detail Type F and P/F Column

A A A A: Elliptical Casing Detail Type F and P/F Column

Uploaded by

Professor PuppiesCopyright:

Available Formats

You might also like

- 5 Steps To CPA Profits PDFDocument40 pages5 Steps To CPA Profits PDFimtool0% (1)

- Reinforced Concrete Crib WallDocument1 pageReinforced Concrete Crib WallrenishkavukattNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofProfessor PuppiesNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofsilvereyes18No ratings yet

- Backfill Excavation: NG CO NUDocument1 pageBackfill Excavation: NG CO NUProfessor PuppiesNo ratings yet

- Apoyos Elastoméricos-02Document1 pageApoyos Elastoméricos-02Andres MontoyaNo ratings yet

- 460-V Line Load Schedule: Panel Mcc2Document1 page460-V Line Load Schedule: Panel Mcc2Jan GarciaNo ratings yet

- Ea 2Document1 pageEa 2cloydNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Model Box Culvert StandardDocument1 pageModel Box Culvert StandardNur HazwaniNo ratings yet

- Esr - Section - R0 - 24.04.23Document1 pageEsr - Section - R0 - 24.04.23Kalika RigsarNo ratings yet

- P01 BH PlotDocument2 pagesP01 BH PlotDileep K NambiarNo ratings yet

- 531 321 20ji Ce 816Document1 page531 321 20ji Ce 816usmanimrannaveedNo ratings yet

- xs1 122 1 A11y PDFDocument1 pagexs1 122 1 A11y PDFProfessor PuppiesNo ratings yet

- General Notes:: Vicinity Map P1Document1 pageGeneral Notes:: Vicinity Map P1Alsean Soriano DetubioNo ratings yet

- Hotel FIRE Model2Document1 pageHotel FIRE Model2Anonymous zrPBiglNo ratings yet

- Restrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideDocument1 pageRestrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideProfessor PuppiesNo ratings yet

- Detail A End Block Elevation Insert Assembly: CaliforniaDocument1 pageDetail A End Block Elevation Insert Assembly: CaliforniaProfessor PuppiesNo ratings yet

- Magaswe A1Document1 pageMagaswe A1Joane ColipanoNo ratings yet

- Diagrama Caterpillar DP150Document1 pageDiagrama Caterpillar DP150Gabino Ubilio MurilloNo ratings yet

- Heat Load Calculations As-Built Ventillation Layout: D P W HDocument1 pageHeat Load Calculations As-Built Ventillation Layout: D P W HAlfred T. Infante IIINo ratings yet

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONo ratings yet

- Genset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCDocument4 pagesGenset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCMark Genesis VelonzaNo ratings yet

- f002. Control Personal EventosDocument4 pagesf002. Control Personal Eventoshenryromero12321No ratings yet

- External Deck Plate Internal: Section P-PDocument1 pageExternal Deck Plate Internal: Section P-PProfessor PuppiesNo ratings yet

- SumilDocument1 pageSumilHerbal Medicine TamilNo ratings yet

- Section A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesDocument1 pageSection A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesProfessor PuppiesNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- M-02 - Ac - Vent Layout PDFDocument1 pageM-02 - Ac - Vent Layout PDFArjay 123No ratings yet

- HRS11 Boo Ar Dga 000 000001Document3 pagesHRS11 Boo Ar Dga 000 000001Vikas PaiNo ratings yet

- HRS11 Boo Ar Dga 000 000002Document3 pagesHRS11 Boo Ar Dga 000 000002Vikas PaiNo ratings yet

- BD RailingsDocument4 pagesBD RailingsAshutoshAparajNo ratings yet

- Detail B Optional End Block - Elevation: CaliforniaDocument1 pageDetail B Optional End Block - Elevation: CaliforniaProfessor PuppiesNo ratings yet

- Almana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Document4 pagesAlmana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Jet ArcaNo ratings yet

- Pavments Drawings SampleDocument181 pagesPavments Drawings Samplefrancisco zepedaNo ratings yet

- Navas Nilamel-ModelDocument1 pageNavas Nilamel-Modelsajukrishna78No ratings yet

- Alternative 3 Bolted Connection: CaliforniaDocument1 pageAlternative 3 Bolted Connection: CaliforniaProfessor PuppiesNo ratings yet

- Note:: Design, Fabrication & Installation of LPG and Solvent System With Distribution Pipe NetworDocument1 pageNote:: Design, Fabrication & Installation of LPG and Solvent System With Distribution Pipe NetworMuhammad Moeed AlamNo ratings yet

- xs1 122 2 A11yDocument1 pagexs1 122 2 A11yProfessor PuppiesNo ratings yet

- Revised PERT Matalam Final3Document1 pageRevised PERT Matalam Final3Jenbert DidelesNo ratings yet

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoNo ratings yet

- B Basden Steel Corp: Bill of MaterialDocument1 pageB Basden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- Hold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"Document1 pageHold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"ai ambaraNo ratings yet

- 69Kv Control Pob FDR SST BreakerDocument1 page69Kv Control Pob FDR SST BreakerJEFFREY BAUTISTANo ratings yet

- Elevation D'-D': SCALE 1: 20Document1 pageElevation D'-D': SCALE 1: 20Silvia PratiwiNo ratings yet

- Tpl-Yiapl-Ph1&2-An-16 R1Document1 pageTpl-Yiapl-Ph1&2-An-16 R1Ramesh BabuNo ratings yet

- Section at Culvert, D-5Document1 pageSection at Culvert, D-5Sanjan SameerNo ratings yet

- Architectural Drawings: Dhamilikuwa StadiumDocument7 pagesArchitectural Drawings: Dhamilikuwa StadiumBinod Raj GiriNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- BR ProscreenDocument1 pageBR ProscreenPRANAV PATILNo ratings yet

- Pile DetailDocument1 pagePile DetailYuefei WuNo ratings yet

- Lay Out ProduksiDocument1 pageLay Out ProduksiMuhammad FaizalNo ratings yet

- Start of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWDocument2 pagesStart of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWs.s engineering and knowledge developed worksNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- Date DrawnDocument1 pageDate DrawnMohamad SannanNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- Lanai: Existing Residential BLDG Existing Residential BLDGDocument1 pageLanai: Existing Residential BLDG Existing Residential BLDGQueenie Marie IlangosNo ratings yet

- X 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyDocument4 pagesX 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyStreloc MarcadoNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Section VIII Drawings OPDDocument10 pagesSection VIII Drawings OPDAlvin Dela CruzNo ratings yet

- ENCHILADASDocument2 pagesENCHILADASProfessor PuppiesNo ratings yet

- SIGN-340-B - 17in - 3Document1 pageSIGN-340-B - 17in - 3Professor PuppiesNo ratings yet

- SIGN-340-B - 17in - 2Document1 pageSIGN-340-B - 17in - 2Professor PuppiesNo ratings yet

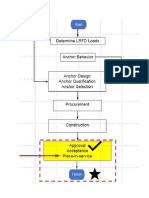

- CRD 5 (2-8) - General Flow Diagram Approval, Acceptance, TestingDocument1 pageCRD 5 (2-8) - General Flow Diagram Approval, Acceptance, TestingProfessor PuppiesNo ratings yet

- CRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualDocument12 pagesCRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualProfessor Puppies100% (1)

- CRD 5 (2-4) - Plan CheckListDocument11 pagesCRD 5 (2-4) - Plan CheckListProfessor PuppiesNo ratings yet

- Webinar No. 5 - Concrete Anchor Implementation 7-21-20 Participant HandoutDocument40 pagesWebinar No. 5 - Concrete Anchor Implementation 7-21-20 Participant HandoutProfessor PuppiesNo ratings yet

- Girder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthDocument1 pageGirder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthProfessor PuppiesNo ratings yet

- Webinar No. 5 - Concrete Anchor Implementation 7-21-20 PDF of PowerPoint PresentationDocument121 pagesWebinar No. 5 - Concrete Anchor Implementation 7-21-20 PDF of PowerPoint PresentationProfessor PuppiesNo ratings yet

- Section A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesDocument1 pageSection A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesProfessor PuppiesNo ratings yet

- ETR's Top 300 For Full-PPR: TE19 TE6Document1 pageETR's Top 300 For Full-PPR: TE19 TE6Professor PuppiesNo ratings yet

- TE6 TE21: RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos AdpDocument1 pageTE6 TE21: RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos AdpProfessor PuppiesNo ratings yet

- Quarterback Running Back Wide Receiver Tight End: Cheat Sheet Updated: 8/27/2021 9:57 AM CentralDocument2 pagesQuarterback Running Back Wide Receiver Tight End: Cheat Sheet Updated: 8/27/2021 9:57 AM CentralProfessor PuppiesNo ratings yet

- Alternative 3 Bolted Connection: CaliforniaDocument1 pageAlternative 3 Bolted Connection: CaliforniaProfessor PuppiesNo ratings yet

- Backfill Excavation: NG CO NUDocument1 pageBackfill Excavation: NG CO NUProfessor PuppiesNo ratings yet

- xs1 180 1 A11yDocument1 pagexs1 180 1 A11yProfessor PuppiesNo ratings yet

- Detail B Optional End Block - Elevation: CaliforniaDocument1 pageDetail B Optional End Block - Elevation: CaliforniaProfessor PuppiesNo ratings yet

- xs1 180 2 A11yDocument1 pagexs1 180 2 A11yProfessor PuppiesNo ratings yet

- xs1 122 2 A11yDocument1 pagexs1 122 2 A11yProfessor PuppiesNo ratings yet

- 750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54Document1 page750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54Carlos_MKTRNo ratings yet

- Set 1 Checked: E. Pathological ConditionDocument60 pagesSet 1 Checked: E. Pathological ConditionKunal BhamareNo ratings yet

- The CockroachDocument4 pagesThe Cockroachnatalie100% (1)

- History of VaccinesDocument1 pageHistory of VaccinesjordanNo ratings yet

- ASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)Document1 pageASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)AHMED YOUSEFNo ratings yet

- Present Perfect Continuous Lesson PlanDocument2 pagesPresent Perfect Continuous Lesson PlanMouradFilaliNo ratings yet

- Contra Max Black: An Examination of Critiques of General SemanticsDocument21 pagesContra Max Black: An Examination of Critiques of General SemanticsBruce I. KodishNo ratings yet

- Contoh Transmital FormDocument20 pagesContoh Transmital FormMawan AghnaNo ratings yet

- Memory Module - WikipediaDocument6 pagesMemory Module - WikipediaJosh VNo ratings yet

- Coll3rd English PaperDocument6 pagesColl3rd English Paperapi-302401594No ratings yet

- Mechanical Design Engineer IIIDocument5 pagesMechanical Design Engineer IIIcrismg1No ratings yet

- Tubos de CalorDocument7 pagesTubos de CalorChristo AcostaNo ratings yet

- 1Q03 Lab1 Time CapsuleDocument2 pages1Q03 Lab1 Time Capsule2487601343No ratings yet

- Artificial Intelligence & Machine Learning: Career GuideDocument18 pagesArtificial Intelligence & Machine Learning: Career Guidekallol100% (1)

- Infinite Series - Cauchy's Root TestDocument7 pagesInfinite Series - Cauchy's Root TestSanjay GuptaNo ratings yet

- Ratio - Analysis - Green - Park Project Report1Document99 pagesRatio - Analysis - Green - Park Project Report1Raju AmmuNo ratings yet

- Oxford Discover Recommended ReadersDocument6 pagesOxford Discover Recommended ReadersHuan ShenNo ratings yet

- @30digital Marketing On Hotel Busines PerformaceDocument80 pages@30digital Marketing On Hotel Busines Performaceassefamenelik1No ratings yet

- Report Templates: The Following Templates Can Be UsedDocument10 pagesReport Templates: The Following Templates Can Be UsedAung Phyoe ThetNo ratings yet

- Hubungan Indeks Massa Tubuh Dengan Siklus Menstruasi Pada Siswi SMP Wahid Hasyim Kota MalangDocument13 pagesHubungan Indeks Massa Tubuh Dengan Siklus Menstruasi Pada Siswi SMP Wahid Hasyim Kota MalangRoslince Umbu patiNo ratings yet

- Lab Report Fine Aggregate A13 PDFDocument10 pagesLab Report Fine Aggregate A13 PDFNur NabilahNo ratings yet

- Which Psychotropic Medications Induce He PDFDocument9 pagesWhich Psychotropic Medications Induce He PDFnisastNo ratings yet

- Pediatric Hospital PresentationDocument61 pagesPediatric Hospital PresentationLindsay Khryss Cendy MadahanNo ratings yet

- English - X - Set - 2 - QPDocument10 pagesEnglish - X - Set - 2 - QPpassion and commitmentNo ratings yet

- BWISEgrc ConsultantimtDocument4 pagesBWISEgrc ConsultantimtazzuNo ratings yet

- Marco Island Veterans' Community Park Construction Document Proposal - 7-2-19Document14 pagesMarco Island Veterans' Community Park Construction Document Proposal - 7-2-19Omar Rodriguez OrtizNo ratings yet

- Meg Barnett Resume 2012Document1 pageMeg Barnett Resume 2012barnett_meghaneNo ratings yet

- Something.: Responda Las Preguntas 1 A 5 de Acuerdo Con El Siguiente EjemploDocument5 pagesSomething.: Responda Las Preguntas 1 A 5 de Acuerdo Con El Siguiente EjemploJuanita Vargas BeltranNo ratings yet

- SIP ProjectDocument34 pagesSIP ProjectVaishnavi BaviskarNo ratings yet

A A A A: Elliptical Casing Detail Type F and P/F Column

A A A A: Elliptical Casing Detail Type F and P/F Column

Uploaded by

Professor PuppiesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A A A A: Elliptical Casing Detail Type F and P/F Column

A A A A: Elliptical Casing Detail Type F and P/F Column

Uploaded by

Professor PuppiesCopyright:

Available Formats

POST MILES SHEET TOTAL

POINT OF DIST COUNTY ROUTE

TOTAL PROJECT No. SHEETS

COMPOUND CURVE

R1

CENTER OF

CURVE

GAP: 2" Min, GAP: 2" Min,

FESSIO

4" Max 4" Max RO

PCC COLUMN STEEL CASING R2 REGISTERED CIVIL ENGINEER DATE P

N

A

L

CENTER OF D

E

R

E

TEMPORARY LIFTING EARS CURVE

N

E

G

R E G IS T

(OPTIONAL) TO BE REMOVED

A A

IN E E R

A AND GROUND SMOOTH AFTER

A INSTALLATION, Typ PLANS APPROVAL DATE

No.

Exp.

The State of California or its officers or agents

ELLIPTICAL CASING DETAIL CIVIL

S

T

shall not be responsible for the accuracy or A

TE IA

WELDED FIELD completeness of scanned copies of this plan sheet. OF FOR

N

STEEL CASING CALI

LIMITS OF POLYETHYLENE

SEE CONTRACT PLANS

SPLICE (OPTIONAL) TYPE F AND P/F COLUMN

2" SEE "DETAIL C" The Registered Civil Engineer for the project is responsible for the selection

WELDED FIELD and proper application of the component design and any modifications shown.

RADII R1 AND R2 TO BE DETERMINED BY THE CONTRACTOR

FG SPLICE (OPTIONAL) FG B B

SEE "DETAIL C" SUBJECT TO THE APPROVAL OF THE ENGINEER

LIMITS OF

WATERPROOFING SEAL FOR GROUTING. VERTICAL WELDED JOINT

SEAL FOR GROUTING.

SEE NOTE 7

GROUT AT 2" GAP MAY GROUT AT 2" GAP MAY

EXTEND TO OUTERFACE FRONT PANEL BACK PANEL

2" EXTEND TO OUTER FACE 2"

OF STEEL CASING OF STEEL CASING

STEEL CASING, Typ

TOP PANEL

TYPE F COLUMN TYPE P/F COLUMN

SEE NOTE 6 CJP

POLYETHYLENE MUST BE HORIZONTAL

CONTINUOUS WHEN X IS

STEEL CASING WELDED JOINT

BOTTOM PANEL

PCC COLUMN GREATER THAN OR EQUAL

TO 2" SEE NOTE 6 WELD BACKING BAR TO

GROUTED BACKING PLATE LOWER PANEL ONLY

PCC COLUMN " THICK POLYETHYLENE

GAP

X

2-8 GROUT INTERSECTION OF JOINT,

2-8

2-8 GROUT HOLE

STEEL CASING

STEEL

CASING

WELD FIELD SPLICE (OPTIONAL)

CJP

BACKING PLATE DETAIL C

LEGEND:

SECTION A-A CJP

SECTION B-B

Indicates Existing structure

MINIMUM INSIDE DIAMETER OF STEEL CASING = 1"

MINIMUM INSIDE DIAMETER OF STEEL CASING = 2"

GREATER THAN NOMINAL COLUMN DIAMETER FOR TYPE F Indicates new structure

GREATER THAN NOMINAL COLUMN DIAMETER FOR TYPE P/F

AND 2" FOR TYPE P/F

NOTES:

ROUND COLUMN 1. For varying thickness, steel casing inside surface

to remain flush. Minimum clearance from PCC

column to casing shall be maintained.

OPENING REINFORCEMENT MUST

SEE "DETAIL A" 2. Appropriate injection nozzles to be provided on

" THICK POLYETHYLENE BE THE SAME THICKNESS AS THE

STEEL CASING UP TO MAXIMUM " casing, but removed and ground flush following

SEE "DETAIL B"

PCC COLUMN PCC COLUMN THICK completion of grouting operation.

3. All voids between steel casing and polyethylene

SEE NOTE 9

CJP, Typ CJP, Typ (TYPE P/F), and steel casing and PCC column

X INNER FACE OF (TYPE F) to be filled with grout.

STEEL CASING

4. Location and number of vertical and horizontal

BACKING PLATE welds to be determined by the Contractor and

BACKING PLATE

2-8 2-8 subject to the approval of the Engineer. The

D

location of casing welds are for illustration.

GROUT ELLIPTICAL CASING GROUT ELLIPTICAL CASING No skip welds allowed.

"

5. Circular steel casing to be " thick minimum for

3D

DRAIN OR UTILITY

D

D+

casings with a 4’-4" diameter or less; all other

SECTION A-A SECTION B-B OPENING, SEE NOTE 8

steel casings to be " thick unless noted

differently on contract plans. Backing plates to

OUTER FACE 3" be the same thickness as casing up to maximum

1" Max

OF STEEL CASING

Min " thick.

RECTANGULAR COLUMN

6. Contractor must remove 12" polyethylene

PIPE strip behind backing plate if backing plate is

EXTENSION

closer than 2" from face of column.

D = PIPE EXTENSION X WATER TIGHT ALL-AROUND

OUTSIDE DIAMETER

7. Waterproof limits for steel casings. Typical for

1" Min @ CHAMFERED

1" Min @ CHAMFERED ELEVATION SECTION X-X TYPE "F" and TYPE "P/F".

CORNER AND @

CORNER

POLYETHYLENE 8. For pipe extensions, opening must be no more than

DETAIL A DETAIL B CASING OPENING " greater than the pipe extension diameter. For

other openings, the opening diameter to be

NOTE:

determined by the Engineer.

THE CONTRACTOR SHALL VERIFY ALL NOTE: OPENING REINFORCEMENT REQUIRED FOR DRAIN

CONTROLLING FIELD DIMENSIONS OR UTILITY OPENINGS LARGER THAN 4"

9. Minimum size of fillet weld must not be less than

BEFORE ORDERING OR FABRICATING thickness of opening reinforcement.

ANY MATERIAL. NO SCALE

BRIDGE NO.

BRIDGE STANDARD DETAILS STATE OF

The components of the Bridge Standard DIVISION OF

xs7-010 October 2015 Details have been prepared under the

responsible charge of the Technical Owner,

CALIFORNIA POST MILE

ENGINEERING SERVICES

FILE NO. APPROVAL DATE

a registered civil engineer in the State

of California DEPARTMENT OF TRANSPORTATION COLUMN CASING - STEEL

REVISION DATES SHEET OF

Refer to: http://www.dot.ca.gov/hq/esc/techpubs/manual/bridgemanuals/bridge-standard-detail- FILE => xs7-010.dgn ORIGINAL SCALE IN INCHES UNIT: DISREGARD PRINTS BEARING

sheets/index.html FOR REDUCED PLANS EARLIER REVISION DATES

USERNAME => s136236 TIME PLOTTED => 07:27 DATE PLOTTED => 12-JUL-2016 0 1 2 3 PROJECT NUMBER & PHASE: CONTRACT NO.: 7-8-16 11-4-14 1-14-15 8-31-15

You might also like

- 5 Steps To CPA Profits PDFDocument40 pages5 Steps To CPA Profits PDFimtool0% (1)

- Reinforced Concrete Crib WallDocument1 pageReinforced Concrete Crib WallrenishkavukattNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofProfessor PuppiesNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofsilvereyes18No ratings yet

- Backfill Excavation: NG CO NUDocument1 pageBackfill Excavation: NG CO NUProfessor PuppiesNo ratings yet

- Apoyos Elastoméricos-02Document1 pageApoyos Elastoméricos-02Andres MontoyaNo ratings yet

- 460-V Line Load Schedule: Panel Mcc2Document1 page460-V Line Load Schedule: Panel Mcc2Jan GarciaNo ratings yet

- Ea 2Document1 pageEa 2cloydNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- Model Box Culvert StandardDocument1 pageModel Box Culvert StandardNur HazwaniNo ratings yet

- Esr - Section - R0 - 24.04.23Document1 pageEsr - Section - R0 - 24.04.23Kalika RigsarNo ratings yet

- P01 BH PlotDocument2 pagesP01 BH PlotDileep K NambiarNo ratings yet

- 531 321 20ji Ce 816Document1 page531 321 20ji Ce 816usmanimrannaveedNo ratings yet

- xs1 122 1 A11y PDFDocument1 pagexs1 122 1 A11y PDFProfessor PuppiesNo ratings yet

- General Notes:: Vicinity Map P1Document1 pageGeneral Notes:: Vicinity Map P1Alsean Soriano DetubioNo ratings yet

- Hotel FIRE Model2Document1 pageHotel FIRE Model2Anonymous zrPBiglNo ratings yet

- Restrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideDocument1 pageRestrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideProfessor PuppiesNo ratings yet

- Detail A End Block Elevation Insert Assembly: CaliforniaDocument1 pageDetail A End Block Elevation Insert Assembly: CaliforniaProfessor PuppiesNo ratings yet

- Magaswe A1Document1 pageMagaswe A1Joane ColipanoNo ratings yet

- Diagrama Caterpillar DP150Document1 pageDiagrama Caterpillar DP150Gabino Ubilio MurilloNo ratings yet

- Heat Load Calculations As-Built Ventillation Layout: D P W HDocument1 pageHeat Load Calculations As-Built Ventillation Layout: D P W HAlfred T. Infante IIINo ratings yet

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONo ratings yet

- Genset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCDocument4 pagesGenset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCMark Genesis VelonzaNo ratings yet

- f002. Control Personal EventosDocument4 pagesf002. Control Personal Eventoshenryromero12321No ratings yet

- External Deck Plate Internal: Section P-PDocument1 pageExternal Deck Plate Internal: Section P-PProfessor PuppiesNo ratings yet

- SumilDocument1 pageSumilHerbal Medicine TamilNo ratings yet

- Section A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesDocument1 pageSection A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesProfessor PuppiesNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- M-02 - Ac - Vent Layout PDFDocument1 pageM-02 - Ac - Vent Layout PDFArjay 123No ratings yet

- HRS11 Boo Ar Dga 000 000001Document3 pagesHRS11 Boo Ar Dga 000 000001Vikas PaiNo ratings yet

- HRS11 Boo Ar Dga 000 000002Document3 pagesHRS11 Boo Ar Dga 000 000002Vikas PaiNo ratings yet

- BD RailingsDocument4 pagesBD RailingsAshutoshAparajNo ratings yet

- Detail B Optional End Block - Elevation: CaliforniaDocument1 pageDetail B Optional End Block - Elevation: CaliforniaProfessor PuppiesNo ratings yet

- Almana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Document4 pagesAlmana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Jet ArcaNo ratings yet

- Pavments Drawings SampleDocument181 pagesPavments Drawings Samplefrancisco zepedaNo ratings yet

- Navas Nilamel-ModelDocument1 pageNavas Nilamel-Modelsajukrishna78No ratings yet

- Alternative 3 Bolted Connection: CaliforniaDocument1 pageAlternative 3 Bolted Connection: CaliforniaProfessor PuppiesNo ratings yet

- Note:: Design, Fabrication & Installation of LPG and Solvent System With Distribution Pipe NetworDocument1 pageNote:: Design, Fabrication & Installation of LPG and Solvent System With Distribution Pipe NetworMuhammad Moeed AlamNo ratings yet

- xs1 122 2 A11yDocument1 pagexs1 122 2 A11yProfessor PuppiesNo ratings yet

- Revised PERT Matalam Final3Document1 pageRevised PERT Matalam Final3Jenbert DidelesNo ratings yet

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoNo ratings yet

- B Basden Steel Corp: Bill of MaterialDocument1 pageB Basden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- Hold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"Document1 pageHold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"ai ambaraNo ratings yet

- 69Kv Control Pob FDR SST BreakerDocument1 page69Kv Control Pob FDR SST BreakerJEFFREY BAUTISTANo ratings yet

- Elevation D'-D': SCALE 1: 20Document1 pageElevation D'-D': SCALE 1: 20Silvia PratiwiNo ratings yet

- Tpl-Yiapl-Ph1&2-An-16 R1Document1 pageTpl-Yiapl-Ph1&2-An-16 R1Ramesh BabuNo ratings yet

- Section at Culvert, D-5Document1 pageSection at Culvert, D-5Sanjan SameerNo ratings yet

- Architectural Drawings: Dhamilikuwa StadiumDocument7 pagesArchitectural Drawings: Dhamilikuwa StadiumBinod Raj GiriNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- BR ProscreenDocument1 pageBR ProscreenPRANAV PATILNo ratings yet

- Pile DetailDocument1 pagePile DetailYuefei WuNo ratings yet

- Lay Out ProduksiDocument1 pageLay Out ProduksiMuhammad FaizalNo ratings yet

- Start of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWDocument2 pagesStart of Taper End of Taper km.74+980: ROW ROW ROW ROW ROW ROW ROWs.s engineering and knowledge developed worksNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- Date DrawnDocument1 pageDate DrawnMohamad SannanNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- Lanai: Existing Residential BLDG Existing Residential BLDGDocument1 pageLanai: Existing Residential BLDG Existing Residential BLDGQueenie Marie IlangosNo ratings yet

- X 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyDocument4 pagesX 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyStreloc MarcadoNo ratings yet

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Section VIII Drawings OPDDocument10 pagesSection VIII Drawings OPDAlvin Dela CruzNo ratings yet

- ENCHILADASDocument2 pagesENCHILADASProfessor PuppiesNo ratings yet

- SIGN-340-B - 17in - 3Document1 pageSIGN-340-B - 17in - 3Professor PuppiesNo ratings yet

- SIGN-340-B - 17in - 2Document1 pageSIGN-340-B - 17in - 2Professor PuppiesNo ratings yet

- CRD 5 (2-8) - General Flow Diagram Approval, Acceptance, TestingDocument1 pageCRD 5 (2-8) - General Flow Diagram Approval, Acceptance, TestingProfessor PuppiesNo ratings yet

- CRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualDocument12 pagesCRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualProfessor Puppies100% (1)

- CRD 5 (2-4) - Plan CheckListDocument11 pagesCRD 5 (2-4) - Plan CheckListProfessor PuppiesNo ratings yet

- Webinar No. 5 - Concrete Anchor Implementation 7-21-20 Participant HandoutDocument40 pagesWebinar No. 5 - Concrete Anchor Implementation 7-21-20 Participant HandoutProfessor PuppiesNo ratings yet

- Girder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthDocument1 pageGirder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthProfessor PuppiesNo ratings yet

- Webinar No. 5 - Concrete Anchor Implementation 7-21-20 PDF of PowerPoint PresentationDocument121 pagesWebinar No. 5 - Concrete Anchor Implementation 7-21-20 PDF of PowerPoint PresentationProfessor PuppiesNo ratings yet

- Section A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesDocument1 pageSection A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesProfessor PuppiesNo ratings yet

- ETR's Top 300 For Full-PPR: TE19 TE6Document1 pageETR's Top 300 For Full-PPR: TE19 TE6Professor PuppiesNo ratings yet

- TE6 TE21: RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos AdpDocument1 pageTE6 TE21: RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos Adp RK Player TM Pos AdpProfessor PuppiesNo ratings yet

- Quarterback Running Back Wide Receiver Tight End: Cheat Sheet Updated: 8/27/2021 9:57 AM CentralDocument2 pagesQuarterback Running Back Wide Receiver Tight End: Cheat Sheet Updated: 8/27/2021 9:57 AM CentralProfessor PuppiesNo ratings yet

- Alternative 3 Bolted Connection: CaliforniaDocument1 pageAlternative 3 Bolted Connection: CaliforniaProfessor PuppiesNo ratings yet

- Backfill Excavation: NG CO NUDocument1 pageBackfill Excavation: NG CO NUProfessor PuppiesNo ratings yet

- xs1 180 1 A11yDocument1 pagexs1 180 1 A11yProfessor PuppiesNo ratings yet

- Detail B Optional End Block - Elevation: CaliforniaDocument1 pageDetail B Optional End Block - Elevation: CaliforniaProfessor PuppiesNo ratings yet

- xs1 180 2 A11yDocument1 pagexs1 180 2 A11yProfessor PuppiesNo ratings yet

- xs1 122 2 A11yDocument1 pagexs1 122 2 A11yProfessor PuppiesNo ratings yet

- 750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54Document1 page750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54Carlos_MKTRNo ratings yet

- Set 1 Checked: E. Pathological ConditionDocument60 pagesSet 1 Checked: E. Pathological ConditionKunal BhamareNo ratings yet

- The CockroachDocument4 pagesThe Cockroachnatalie100% (1)

- History of VaccinesDocument1 pageHistory of VaccinesjordanNo ratings yet

- ASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)Document1 pageASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)AHMED YOUSEFNo ratings yet

- Present Perfect Continuous Lesson PlanDocument2 pagesPresent Perfect Continuous Lesson PlanMouradFilaliNo ratings yet

- Contra Max Black: An Examination of Critiques of General SemanticsDocument21 pagesContra Max Black: An Examination of Critiques of General SemanticsBruce I. KodishNo ratings yet

- Contoh Transmital FormDocument20 pagesContoh Transmital FormMawan AghnaNo ratings yet

- Memory Module - WikipediaDocument6 pagesMemory Module - WikipediaJosh VNo ratings yet

- Coll3rd English PaperDocument6 pagesColl3rd English Paperapi-302401594No ratings yet

- Mechanical Design Engineer IIIDocument5 pagesMechanical Design Engineer IIIcrismg1No ratings yet

- Tubos de CalorDocument7 pagesTubos de CalorChristo AcostaNo ratings yet

- 1Q03 Lab1 Time CapsuleDocument2 pages1Q03 Lab1 Time Capsule2487601343No ratings yet

- Artificial Intelligence & Machine Learning: Career GuideDocument18 pagesArtificial Intelligence & Machine Learning: Career Guidekallol100% (1)

- Infinite Series - Cauchy's Root TestDocument7 pagesInfinite Series - Cauchy's Root TestSanjay GuptaNo ratings yet

- Ratio - Analysis - Green - Park Project Report1Document99 pagesRatio - Analysis - Green - Park Project Report1Raju AmmuNo ratings yet

- Oxford Discover Recommended ReadersDocument6 pagesOxford Discover Recommended ReadersHuan ShenNo ratings yet

- @30digital Marketing On Hotel Busines PerformaceDocument80 pages@30digital Marketing On Hotel Busines Performaceassefamenelik1No ratings yet

- Report Templates: The Following Templates Can Be UsedDocument10 pagesReport Templates: The Following Templates Can Be UsedAung Phyoe ThetNo ratings yet

- Hubungan Indeks Massa Tubuh Dengan Siklus Menstruasi Pada Siswi SMP Wahid Hasyim Kota MalangDocument13 pagesHubungan Indeks Massa Tubuh Dengan Siklus Menstruasi Pada Siswi SMP Wahid Hasyim Kota MalangRoslince Umbu patiNo ratings yet

- Lab Report Fine Aggregate A13 PDFDocument10 pagesLab Report Fine Aggregate A13 PDFNur NabilahNo ratings yet

- Which Psychotropic Medications Induce He PDFDocument9 pagesWhich Psychotropic Medications Induce He PDFnisastNo ratings yet

- Pediatric Hospital PresentationDocument61 pagesPediatric Hospital PresentationLindsay Khryss Cendy MadahanNo ratings yet

- English - X - Set - 2 - QPDocument10 pagesEnglish - X - Set - 2 - QPpassion and commitmentNo ratings yet

- BWISEgrc ConsultantimtDocument4 pagesBWISEgrc ConsultantimtazzuNo ratings yet

- Marco Island Veterans' Community Park Construction Document Proposal - 7-2-19Document14 pagesMarco Island Veterans' Community Park Construction Document Proposal - 7-2-19Omar Rodriguez OrtizNo ratings yet

- Meg Barnett Resume 2012Document1 pageMeg Barnett Resume 2012barnett_meghaneNo ratings yet

- Something.: Responda Las Preguntas 1 A 5 de Acuerdo Con El Siguiente EjemploDocument5 pagesSomething.: Responda Las Preguntas 1 A 5 de Acuerdo Con El Siguiente EjemploJuanita Vargas BeltranNo ratings yet

- SIP ProjectDocument34 pagesSIP ProjectVaishnavi BaviskarNo ratings yet